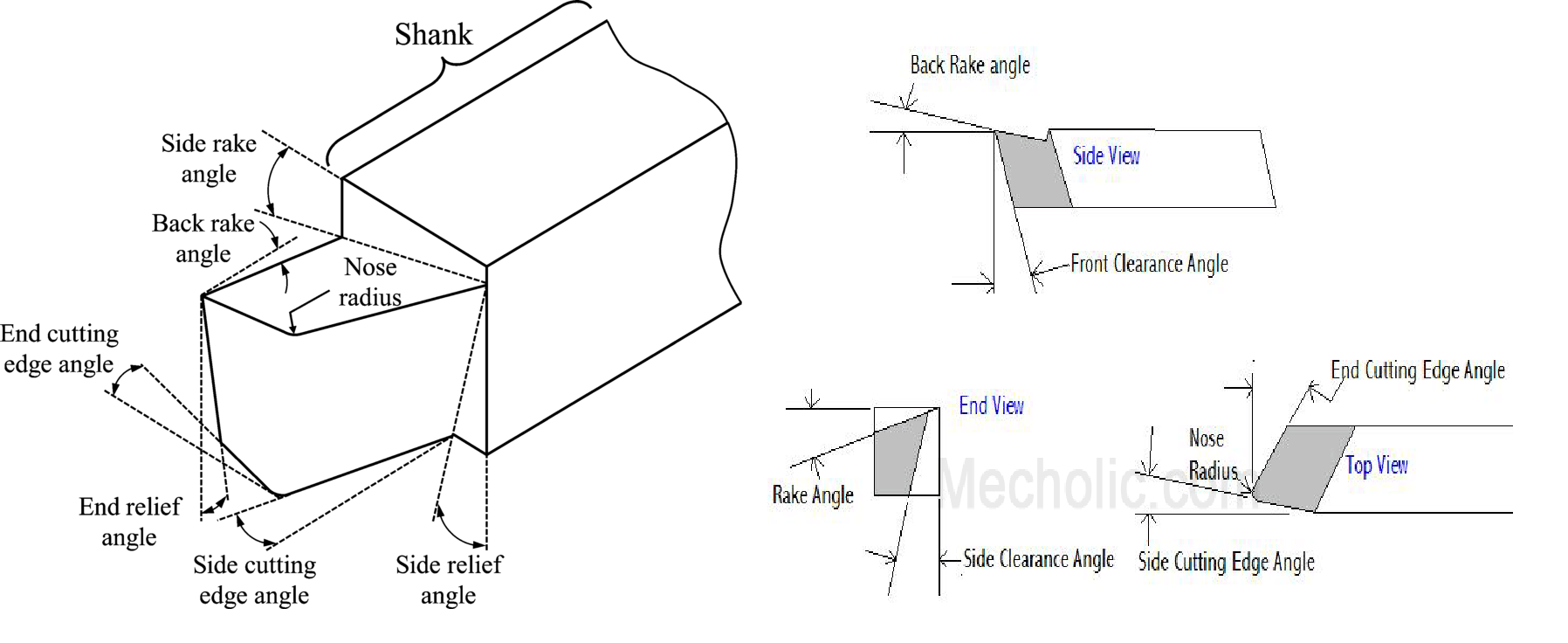

Turning Tool Clearance Angle . the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. Entering kapr (lead psir) angle the. a negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle). An insert with a zero clearance angle (symbol “n“) is. clearance angle is the angle of orientation of tool’s principal flank surface from the cutting velocity vector and measured on some. the clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. principle of selection of clearance angle (α0 ) consider first the processing properties. When finishing, the clearance angle takes a large value,. from the geometry of cutting tool the various cutting tool angles are: considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut, a p.

from www.green-mechanic.com

considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut, a p. An insert with a zero clearance angle (symbol “n“) is. from the geometry of cutting tool the various cutting tool angles are: the clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. clearance angle is the angle of orientation of tool’s principal flank surface from the cutting velocity vector and measured on some. the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. Entering kapr (lead psir) angle the. When finishing, the clearance angle takes a large value,. principle of selection of clearance angle (α0 ) consider first the processing properties. a negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle).

Green Mechanic Explain single point cutting tool geometry, angles and

Turning Tool Clearance Angle considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut, a p. Entering kapr (lead psir) angle the. principle of selection of clearance angle (α0 ) consider first the processing properties. clearance angle is the angle of orientation of tool’s principal flank surface from the cutting velocity vector and measured on some. a negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle). considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut, a p. the clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. When finishing, the clearance angle takes a large value,. the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. from the geometry of cutting tool the various cutting tool angles are: An insert with a zero clearance angle (symbol “n“) is.

From www.youtube.com

Differences between Rake Angle and Clearance Angle. YouTube Turning Tool Clearance Angle the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut, a p. from the geometry of cutting tool the various cutting tool angles are: principle of selection of clearance. Turning Tool Clearance Angle.

From huanatools.com

Positive Angle Inserts VS Negative Angle Inserts Huana Tools Turning Tool Clearance Angle the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. principle of selection of clearance angle (α0 ) consider first the processing properties. Entering kapr (lead psir) angle the. a negative insert has an angle of 90° (0° clearance angle), while a positive insert has an. Turning Tool Clearance Angle.

From www.ukocarbide.com

How Important to Know Each Part of the CNC Lath Tool? Turning Tool Clearance Angle When finishing, the clearance angle takes a large value,. the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. An insert with a zero clearance angle (symbol “n“) is. clearance angle is the angle of orientation of tool’s principal flank surface from the cutting velocity vector and. Turning Tool Clearance Angle.

From learnmechanical.com

Single Point Cutting Tool Definition, Types, Geometry, Nomenclature Turning Tool Clearance Angle a negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle). the clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. An insert with a zero clearance angle (symbol “n“) is. . Turning Tool Clearance Angle.

From www.mechanicalbooster.com

Single Point Cutting Tool Geometry, Angles, Nomenclature and Signature Turning Tool Clearance Angle principle of selection of clearance angle (α0 ) consider first the processing properties. Entering kapr (lead psir) angle the. considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut, a p. from the geometry of cutting tool the various cutting tool angles are: a negative insert has an angle of. Turning Tool Clearance Angle.

From www.minaprem.com

Name of the angle between face and flank of single point cutting tool Turning Tool Clearance Angle the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. An insert with a zero clearance angle (symbol “n“) is. clearance angle is the angle of orientation of tool’s principal flank surface from the cutting velocity vector and measured on some. Entering kapr (lead psir) angle the.. Turning Tool Clearance Angle.

From www.achtecktool.com

ISO Turning Insert with 11° (P) clearance angle Turning Tool Clearance Angle When finishing, the clearance angle takes a large value,. clearance angle is the angle of orientation of tool’s principal flank surface from the cutting velocity vector and measured on some. Entering kapr (lead psir) angle the. the clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. An insert. Turning Tool Clearance Angle.

From sharpeninghandbook.info

Sharpening Handbook Turning Tool Clearance Angle When finishing, the clearance angle takes a large value,. the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. principle of selection of clearance angle (α0 ) consider first the processing properties. considering the entering kapr (lead psir) angle of the tool holder, and the depth. Turning Tool Clearance Angle.

From davehylands.com

Charts Turning Tool Clearance Angle a negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle). When finishing, the clearance angle takes a large value,. the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. . Turning Tool Clearance Angle.

From www.mech4study.com

Single Point Cutting Tool Nomenclature, Angle,Geometry and Signature Turning Tool Clearance Angle An insert with a zero clearance angle (symbol “n“) is. the clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. Entering kapr (lead psir) angle the. When finishing, the clearance angle takes a large value,. the cutting edge angle, also known as the included angle, is the angle. Turning Tool Clearance Angle.

From www.minaprem.com

What is Clearance Angle in Cutting Tool? Machining Principles Turning Tool Clearance Angle Entering kapr (lead psir) angle the. An insert with a zero clearance angle (symbol “n“) is. principle of selection of clearance angle (α0 ) consider first the processing properties. from the geometry of cutting tool the various cutting tool angles are: the clearance angle (α / an) refers to the angle between the “sides” of the insert. Turning Tool Clearance Angle.

From www.machinemfg.com

Lathe Cutting Tool Angles Selection Principle MachineMFG Turning Tool Clearance Angle the clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut,. Turning Tool Clearance Angle.

From www.minaprem.com

What is Clearance Angle in Cutting Tool? Machining Principles Turning Tool Clearance Angle the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. An insert with a zero clearance angle (symbol “n“) is. a negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle).. Turning Tool Clearance Angle.

From www.youtube.com

LATHE CUTTING EDGE POSITIONING, HOW TO SET UP LATHE TOOLS FOR TURNING Turning Tool Clearance Angle from the geometry of cutting tool the various cutting tool angles are: the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut, a p. principle of selection of clearance. Turning Tool Clearance Angle.

From answer2questn.blogspot.com

Questions Answers About the Lathe Introduction of Centre Lathe Turning Tool Clearance Angle from the geometry of cutting tool the various cutting tool angles are: the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut, a p. the clearance angle (α /. Turning Tool Clearance Angle.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Turning Tool Clearance Angle considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut, a p. When finishing, the clearance angle takes a large value,. the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. the clearance angle (α / an) refers to the. Turning Tool Clearance Angle.

From www.slideserve.com

PPT QE 107 Technology Section 4 Metal Cutting PowerPoint Turning Tool Clearance Angle An insert with a zero clearance angle (symbol “n“) is. the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. Entering kapr (lead psir) angle the. from the geometry of cutting tool the various cutting tool angles are: the clearance angle (α / an) refers to. Turning Tool Clearance Angle.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Turning Tool Clearance Angle from the geometry of cutting tool the various cutting tool angles are: clearance angle is the angle of orientation of tool’s principal flank surface from the cutting velocity vector and measured on some. the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. An insert with. Turning Tool Clearance Angle.

From www.manufacturingguide.com

Turning tool angles Find suppliers, processes & material Turning Tool Clearance Angle principle of selection of clearance angle (α0 ) consider first the processing properties. considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut, a p. Entering kapr (lead psir) angle the. the clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis.. Turning Tool Clearance Angle.

From www.difference.minaprem.com

Difference Between Rake Angle and Clearance Angle Turning Tool Clearance Angle considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut, a p. When finishing, the clearance angle takes a large value,. principle of selection of clearance angle (α0 ) consider first the processing properties. Entering kapr (lead psir) angle the. the cutting edge angle, also known as the included angle, is. Turning Tool Clearance Angle.

From www.minaprem.com

Minimum Clearance Angle of Cutting Tool Its Advantages in Tool Grinding Turning Tool Clearance Angle the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut, a p. clearance angle is the angle of orientation of tool’s principal flank surface from the cutting velocity vector and. Turning Tool Clearance Angle.

From www.pinterest.fr

Lathe Turning tool, Grind angles Machining Metal Projects, Lathe Turning Tool Clearance Angle from the geometry of cutting tool the various cutting tool angles are: the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. the clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. principle of selection. Turning Tool Clearance Angle.

From www.youtube.com

Single Point Cutting Tool Nomenclature, Tool Signature, Side Rake Turning Tool Clearance Angle Entering kapr (lead psir) angle the. clearance angle is the angle of orientation of tool’s principal flank surface from the cutting velocity vector and measured on some. the clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. a negative insert has an angle of 90° (0° clearance. Turning Tool Clearance Angle.

From www.themachinedesign.com

Single Point Cutting Tool Tool Angles , Nomenclature, Geometry Turning Tool Clearance Angle clearance angle is the angle of orientation of tool’s principal flank surface from the cutting velocity vector and measured on some. the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. the clearance angle (α / an) refers to the angle between the “sides” of the. Turning Tool Clearance Angle.

From www.mmc-carbide.com

Rake Angle Technical Info / Cutting Formula MITSUBISHI MATERIALS Turning Tool Clearance Angle a negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle). An insert with a zero clearance angle (symbol “n“) is. Entering kapr (lead psir) angle the. clearance angle is the angle of orientation of tool’s principal flank surface from the cutting. Turning Tool Clearance Angle.

From www.green-mechanic.com

Green Mechanic Explain single point cutting tool geometry, angles and Turning Tool Clearance Angle clearance angle is the angle of orientation of tool’s principal flank surface from the cutting velocity vector and measured on some. from the geometry of cutting tool the various cutting tool angles are: An insert with a zero clearance angle (symbol “n“) is. principle of selection of clearance angle (α0 ) consider first the processing properties. Entering. Turning Tool Clearance Angle.

From www.cutwel.co.uk

Learn The Turning Tool ISO Code System Cutwel Ltd Turning Tool Clearance Angle When finishing, the clearance angle takes a large value,. the clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. a negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle). the. Turning Tool Clearance Angle.

From www.cobanengineering.com

Back Rake, Side Rake, Rake angle, wedge angle and flank angles,the Turning Tool Clearance Angle a negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle). An insert with a zero clearance angle (symbol “n“) is. the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool.. Turning Tool Clearance Angle.

From www.mechanicalbooster.com

Single Point Cutting Tool Geometry, Angles, Nomenclature and Signature Turning Tool Clearance Angle from the geometry of cutting tool the various cutting tool angles are: considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut, a p. the clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. principle of selection of clearance angle. Turning Tool Clearance Angle.

From www.sharpeninghandbook.info

Sharpening Handbook Turning Tool Clearance Angle a negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle). principle of selection of clearance angle (α0 ) consider first the processing properties. Entering kapr (lead psir) angle the. from the geometry of cutting tool the various cutting tool angles. Turning Tool Clearance Angle.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Turning Tool Clearance Angle clearance angle is the angle of orientation of tool’s principal flank surface from the cutting velocity vector and measured on some. from the geometry of cutting tool the various cutting tool angles are: considering the entering kapr (lead psir) angle of the tool holder, and the depth of cut, a p. An insert with a zero clearance. Turning Tool Clearance Angle.

From www.researchgate.net

Geometry of singlepoint cutting tool Download Scientific Diagram Turning Tool Clearance Angle clearance angle is the angle of orientation of tool’s principal flank surface from the cutting velocity vector and measured on some. When finishing, the clearance angle takes a large value,. from the geometry of cutting tool the various cutting tool angles are: considering the entering kapr (lead psir) angle of the tool holder, and the depth of. Turning Tool Clearance Angle.

From www.meetyoucarbide.com

How to choose the turning insert angle Meetyou Carbide Turning Tool Clearance Angle An insert with a zero clearance angle (symbol “n“) is. a negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle). When finishing, the clearance angle takes a large value,. Entering kapr (lead psir) angle the. the clearance angle (α / an). Turning Tool Clearance Angle.

From www.mech4study.com

Single Point Cutting Tool Nomenclature, Angle,Geometry and Signature Turning Tool Clearance Angle a negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle). from the geometry of cutting tool the various cutting tool angles are: An insert with a zero clearance angle (symbol “n“) is. When finishing, the clearance angle takes a large value,.. Turning Tool Clearance Angle.

From www.minaprem.com

Minimum Clearance Angle of Cutting Tool Its Advantages in Tool Grinding Turning Tool Clearance Angle from the geometry of cutting tool the various cutting tool angles are: clearance angle is the angle of orientation of tool’s principal flank surface from the cutting velocity vector and measured on some. the cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. When finishing, the. Turning Tool Clearance Angle.