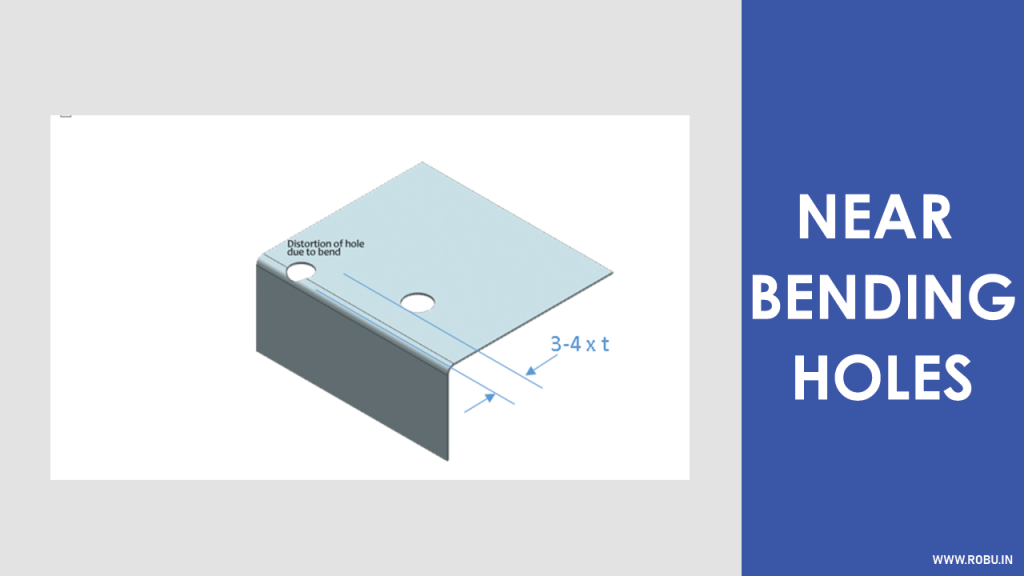

Sheet Metal Hole Standard . In sheet metal manufacturing, the design of holes is a critical aspect that requires precision and adherence to specific guidelines. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. Some features such as countersinks are doable but counter bores and other. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Hole/slot distance from bend edge. The diameter of holes should be at. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. There are a number of different hem styles, summarized below.

from robu.in

Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and. Hole/slot distance from bend edge. Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. There are a number of different hem styles, summarized below. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. The diameter of holes should be at. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. Some features such as countersinks are doable but counter bores and other. In sheet metal manufacturing, the design of holes is a critical aspect that requires precision and adherence to specific guidelines.

Sheet Metal Design Basics in 2021 Complete List of Things

Sheet Metal Hole Standard In sheet metal manufacturing, the design of holes is a critical aspect that requires precision and adherence to specific guidelines. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. Some features such as countersinks are doable but counter bores and other. The diameter of holes should be at. There are a number of different hem styles, summarized below. Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. In sheet metal manufacturing, the design of holes is a critical aspect that requires precision and adherence to specific guidelines. Hole/slot distance from bend edge. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and.

From clintbrown.co.uk

Sheet Metal Hole Tables from STEP Clint Brown Sheet Metal Hole Standard In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and. In sheet metal manufacturing, the design of holes is. Sheet Metal Hole Standard.

From gangsteel.com

16 gauge perforated stainless steel sheet Steel Material Supplier Sheet Metal Hole Standard Hole/slot distance from bend edge. The diameter of holes should be at. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and. Some features such as countersinks are doable but counter bores and other. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Sheet metal hems are features. Sheet Metal Hole Standard.

From dfmpro.com

Sheet Metal Design Guidelines DFMPro Sheet Metal Hole Standard In sheet metal manufacturing, the design of holes is a critical aspect that requires precision and adherence to specific guidelines. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. There are a number of different hem styles, summarized below. The diameter of holes should be at. When considering sheet metal. Sheet Metal Hole Standard.

From forums.autodesk.com

Solved SHEET METAL HOLE SIZES FOR CUTTING AND DRILLING Autodesk Community Sheet Metal Hole Standard In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. There are a number. Sheet Metal Hole Standard.

From www.snowrobin.jp

18 Gauge Finish Staggered 0.125 Holes 12 Width 304 Stainless Steel Perforated Sheet 0.048 Sheet Metal Hole Standard When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. There are a number of different hem styles, summarized below. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. The diameter of holes should. Sheet Metal Hole Standard.

From galvanizeit.org

Sizing Clearance Holes for HDG… American Galvanizer's Association Sheet Metal Hole Standard In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and. Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. Hole/slot distance from bend edge. In sheet. Sheet Metal Hole Standard.

From mocap.com

Recessed Sheet Metal Finishing Hole Plugs for Standard Hole Sizes MOCAP Sheet Metal Hole Standard In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. The diameter of holes should be at. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Some features such as countersinks are doable but counter bores and other. There are a number of. Sheet Metal Hole Standard.

From www.vowin.cn

A Designer’s Guide For Ensuring The Manufacturability Of Sheet Metal Parts Bend Reliefs, Hole Sheet Metal Hole Standard In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. Hole/slot distance from bend edge. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. Sheet metal hems are features where the edge. Sheet Metal Hole Standard.

From www.approvedsheetmetal.com

Hardware Hole Sizes Chart Approved Sheet Metal Sheet Metal Hole Standard There are a number of different hem styles, summarized below. The diameter of holes should be at. Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Some features such as countersinks are. Sheet Metal Hole Standard.

From themeshcompany.com

4mm Round Hole Mild Steel Perforated Metal Sheet With Holes 6mm Pitch 1.5mm Thick The Mesh Sheet Metal Hole Standard Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. The diameter of holes should be at. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and. Some features such as countersinks are doable but counter bores and. Sheet Metal Hole Standard.

From blog.thepipingmart.com

How to Cut a Hole in Stainless Steel Sheet An Overview Sheet Metal Hole Standard Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. There are a number of different hem styles, summarized below. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. Some features such as countersinks are doable but counter bores and other.. Sheet Metal Hole Standard.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Sheet Metal Hole Standard In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and. Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. Sheet metal hems are features where the. Sheet Metal Hole Standard.

From gratingpacific.com

Round Hole Perforated Metal Sheet Metal Hole Standard Hole/slot distance from bend edge. In sheet metal manufacturing, the design of holes is a critical aspect that requires precision and adherence to specific guidelines. The diameter of holes should be at. There are a number of different hem styles, summarized below. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Sheet. Sheet Metal Hole Standard.

From www.alibaba.com

Anping Dimple Hole Perforated Metal Sheet Buy Micro Diamond Oval Round Hole Shape Aluminum Sheet Metal Hole Standard The diameter of holes should be at. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. Some features such as countersinks are doable but counter bores and other. Sheet metal hems are features where the edge of a sheet metal part. Sheet Metal Hole Standard.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Hole Standard Some features such as countersinks are doable but counter bores and other. The diameter of holes should be at. Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Hole/slot distance from bend. Sheet Metal Hole Standard.

From www.anzor.co.nz

Pilot Hole Diameter Chart Anzor Fasteners Sheet Metal Hole Standard The diameter of holes should be at. Some features such as countersinks are doable but counter bores and other. There are a number of different hem styles, summarized below. In sheet metal manufacturing, the design of holes is a critical aspect that requires precision and adherence to specific guidelines. Sheet metal is a slightly less precise method of manufacturing that. Sheet Metal Hole Standard.

From www.efc-intl.com

Standard Flush Sheet Metal Hole Plugs On EFC International Sheet Metal Hole Standard Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. In sheet metal manufacturing, the design of holes is a critical aspect that requires precision and adherence to specific guidelines. The diameter. Sheet Metal Hole Standard.

From robu.in

Sheet Metal Design Basics in 2021 Complete List of Things Sheet Metal Hole Standard In sheet metal manufacturing, the design of holes is a critical aspect that requires precision and adherence to specific guidelines. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal. Sheet Metal Hole Standard.

From www.youtube.com

Sheet Metal Design Guidelines Part 01 Minimum Distance from Extruded Hole to Part Edge YouTube Sheet Metal Hole Standard In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. Hole/slot distance from bend edge. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance,. Sheet Metal Hole Standard.

From gtsparkplugs.com

Sheet Metal Gauge Chart GTSparkplugs Sheet Metal Hole Standard Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. The diameter of holes should be at. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting,. Sheet Metal Hole Standard.

From www.youtube.com

How to Fill Holes in Sheet Metal Eastwood YouTube Sheet Metal Hole Standard The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and. There are a number of different hem styles, summarized below. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. The diameter of holes should be at. Hole/slot. Sheet Metal Hole Standard.

From labbyag.es

Perforated Sheet Standard Size Chart Labb by AG Sheet Metal Hole Standard Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. The diameter of holes should be at. Some features such as countersinks. Sheet Metal Hole Standard.

From www.youtube.com

Sheet Metal Holes as Datum Features YouTube Sheet Metal Hole Standard In sheet metal manufacturing, the design of holes is a critical aspect that requires precision and adherence to specific guidelines. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. When considering sheet metal thickness, a single sheet with punches (holes) is. Sheet Metal Hole Standard.

From localrevive.com

Sheet Metal Fabrication 101 A Basic Knowledge Guide RapidDirect Blog (2022) Sheet Metal Hole Standard In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. Our basic guidelines for sheet metal fabrication include important design considerations to help. Sheet Metal Hole Standard.

From mavink.com

Standard Hole Sizes Sheet Metal Hole Standard Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. Some features such as countersinks are doable but counter bores and other. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. There. Sheet Metal Hole Standard.

From www.youtube.com

Sheet metal design guidelines Minimum Distance Between Extruded Holes, Sheet metal design rules Sheet Metal Hole Standard Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. Hole/slot distance from bend edge. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. The diameter of holes should be at.. Sheet Metal Hole Standard.

From 3dprintinggeek.com

Sheet Metal in SolidWorks A Beginner's Guide 3DprintingGeek Sheet Metal Hole Standard The diameter of holes should be at. There are a number of different hem styles, summarized below. In sheet metal manufacturing, the design of holes is a critical aspect that requires precision and adherence to specific guidelines. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal. Sheet Metal Hole Standard.

From sandysconcept.blogspot.com

Sheet Metal Tolerance Standards sheet metal tolerance Standards Sheet Metal Hole Standard When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Hole/slot distance from bend edge. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. The. Sheet Metal Hole Standard.

From www.scribd.com

Standard Holes and Tapping Chart PDF Machining Cutting Tools Sheet Metal Hole Standard Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. The diameter of holes should be at. Hole/slot distance from bend edge. Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. In addition to increasing material stiffness locally, they are used. Sheet Metal Hole Standard.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Hole Standard The diameter of holes should be at. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending,. Sheet Metal Hole Standard.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Hole Standard The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final. Sheet Metal Hole Standard.

From www.youtube.com

How to Fill Holes in Sheet Metal The EASIEST Way! Eastwood Plug Hole Patch Kit! YouTube Sheet Metal Hole Standard The diameter of holes should be at. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Some features such as countersinks are doable but counter bores and other. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and. Sheet metal hems are features where the edge of a. Sheet Metal Hole Standard.

From blog.thepipingmart.com

How to Drill a Hole in Copper Sheet Metal Sheet Metal Hole Standard Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. The diameter of holes should be at. There are a number of different hem styles, summarized below. Some features such as countersinks are doable but counter bores and other. In addition to increasing material stiffness locally, they are used for. Sheet Metal Hole Standard.

From www.batchuontyren.com

Sheet Metal Materials, Standard Sizes & Forming Processes Sheet Metal Hole Standard When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. In sheet metal manufacturing, the design of holes is a critical aspect that requires precision and adherence to specific guidelines. Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and. Sheet metal hems. Sheet Metal Hole Standard.

From 139.180.182.197

Stainless Perforated Sheet Slotted Holes Sample The Metal Company Sheet Metal Hole Standard Some features such as countersinks are doable but counter bores and other. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. The. Sheet Metal Hole Standard.