Identifying And Checking Safety Equipment And Tools . hazard identification and risk assessments form the basis of proactive project safety and prevention. these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. The two safety jobs combine to mitigate and prevent the chances that. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. Refer to safety rules and. learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. The most widely accepted way to identify hazards in the workplace is to conduct safety and health.

from www.tal.sg

learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. The two safety jobs combine to mitigate and prevent the chances that. hazard identification and risk assessments form the basis of proactive project safety and prevention. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. Refer to safety rules and. The most widely accepted way to identify hazards in the workplace is to conduct safety and health.

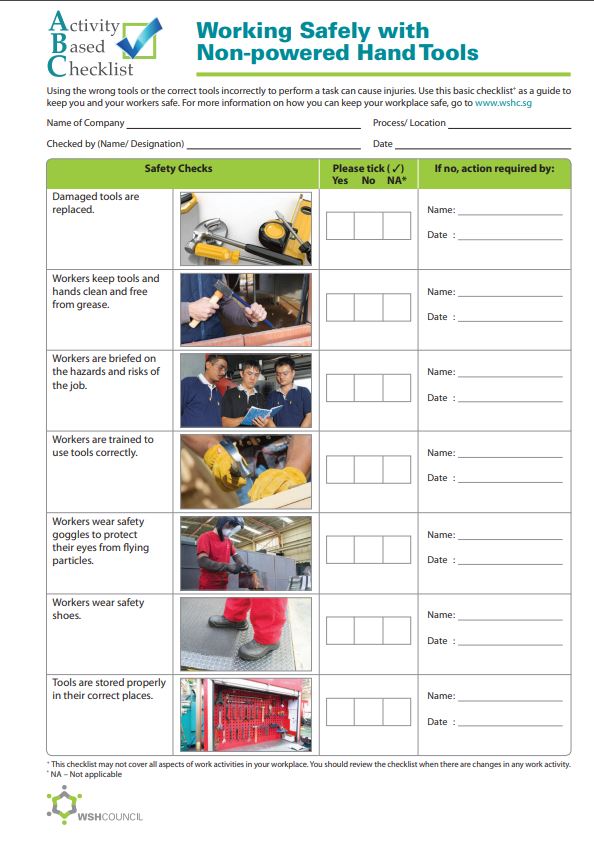

Working Safely with Nonpowered Hand Tools Checklist

Identifying And Checking Safety Equipment And Tools The two safety jobs combine to mitigate and prevent the chances that. hazard identification and risk assessments form the basis of proactive project safety and prevention. these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. Refer to safety rules and. learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. The two safety jobs combine to mitigate and prevent the chances that. The most widely accepted way to identify hazards in the workplace is to conduct safety and health. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best.

From www.scribd.com

Heavy Equipment Inspection Checklist Identifying And Checking Safety Equipment And Tools learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. The most widely accepted way to identify hazards in the workplace is to conduct safety and health. hazard identification and risk assessments form the basis of proactive project safety and prevention. Refer to safety rules and. to create an effective equipment inspection. Identifying And Checking Safety Equipment And Tools.

From safetyskills.com

Safety Data Sheets SafetySkills Identifying And Checking Safety Equipment And Tools learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. The two safety jobs combine to mitigate and prevent the chances that. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. these processes offer a systematic, objective tool for identifying potential hazards, unsafe work. Identifying And Checking Safety Equipment And Tools.

From www.pinterest.com.au

Mechanical Electrical Equipment Safety Check list Download this Identifying And Checking Safety Equipment And Tools Refer to safety rules and. hazard identification and risk assessments form the basis of proactive project safety and prevention. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. The most widely. Identifying And Checking Safety Equipment And Tools.

From www.flightsafetyaustralia.com

One thing at a time a brief history of the checklist Flight Safety Identifying And Checking Safety Equipment And Tools Refer to safety rules and. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. hazard identification and risk assessments form the basis of proactive project safety and prevention. these processes. Identifying And Checking Safety Equipment And Tools.

From studylib.net

JobHazardAnalysisChecklist Identifying And Checking Safety Equipment And Tools learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. Refer to safety rules and. The two safety jobs combine to mitigate and prevent the chances that. these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. to create an effective. Identifying And Checking Safety Equipment And Tools.

From lohimspero.com

Supply of Safety Tools and Equipment Identifying And Checking Safety Equipment And Tools The two safety jobs combine to mitigate and prevent the chances that. learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. Refer to safety rules and. these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. to create an effective. Identifying And Checking Safety Equipment And Tools.

From www.ishn.com

6 reasons why facility safety inspections are important for your Identifying And Checking Safety Equipment And Tools to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. hazard identification and risk assessments form the basis of proactive project safety and prevention. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. learn how to inspect tools, equipment, and. Identifying And Checking Safety Equipment And Tools.

From amptec.ca

Building Inspection and Fire Safety Checklist, Check out our Guide! Identifying And Checking Safety Equipment And Tools hazard identification and risk assessments form the basis of proactive project safety and prevention. these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. The most widely accepted. Identifying And Checking Safety Equipment And Tools.

From pt.scribd.com

ES Safety & Maintenance ChecklistExcavators V0810.1 PDF Identifying And Checking Safety Equipment And Tools this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. The most widely accepted way to identify hazards in the workplace is to conduct safety and health. these processes offer a systematic,. Identifying And Checking Safety Equipment And Tools.

From sitemate.com

Electrical Tool Inspection Checklist (Free to use and customisable) Identifying And Checking Safety Equipment And Tools this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. . Identifying And Checking Safety Equipment And Tools.

From templates.rjuuc.edu.np

Osha Safety Inspection Checklist Template Identifying And Checking Safety Equipment And Tools The two safety jobs combine to mitigate and prevent the chances that. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. these processes offer a systematic, objective tool for identifying potential. Identifying And Checking Safety Equipment And Tools.

From cholonautas.edu.pe

Printable Equipment Inspection Checklist Template Printable Templates Identifying And Checking Safety Equipment And Tools learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. Refer to safety rules and. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. The most widely accepted way to identify hazards in the workplace is to conduct safety and health. to create an. Identifying And Checking Safety Equipment And Tools.

From www.equipmentworld.com

Free printable equipment inspection checklist Identifying And Checking Safety Equipment And Tools these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. hazard identification and risk assessments form the basis of proactive project safety and prevention. The two safety jobs combine to mitigate and prevent the chances that. Refer to safety rules and. learn how to inspect tools,. Identifying And Checking Safety Equipment And Tools.

From med-texservices.com

What Safety Equipment Should Be In The Workplace? MedTex Services Identifying And Checking Safety Equipment And Tools Refer to safety rules and. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. The most widely accepted way to identify hazards in the workplace is to conduct safety and health. The two safety jobs combine to mitigate and prevent the chances that. hazard identification and risk assessments form the. Identifying And Checking Safety Equipment And Tools.

From dxogrjhhy.blob.core.windows.net

What Is Tools And Equipment Safety at Jeff Happel blog Identifying And Checking Safety Equipment And Tools these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. . Identifying And Checking Safety Equipment And Tools.

From sitemate.com

Heavy Equipment Inspection Checklist Template Download as PDF Identifying And Checking Safety Equipment And Tools these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. The two safety jobs combine to mitigate and prevent the chances that. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. The most widely accepted way to identify. Identifying And Checking Safety Equipment And Tools.

From scssafetyandhealth.com

Safety & Emergency Equipment Supplies SCS Safety Health & Security Identifying And Checking Safety Equipment And Tools The two safety jobs combine to mitigate and prevent the chances that. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. hazard identification and risk assessments form the basis of proactive project safety and prevention. these processes offer a systematic, objective tool for identifying potential hazards, unsafe work. Identifying And Checking Safety Equipment And Tools.

From tineopprinnelse.tine.no

Printable Harness Inspection Sheet Identifying And Checking Safety Equipment And Tools hazard identification and risk assessments form the basis of proactive project safety and prevention. The two safety jobs combine to mitigate and prevent the chances that. The most widely accepted way to identify hazards in the workplace is to conduct safety and health. these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and. Identifying And Checking Safety Equipment And Tools.

From www.youtube.com

SAFETY PROTECTIVE EQUIPMENT CHECK YouTube Identifying And Checking Safety Equipment And Tools The two safety jobs combine to mitigate and prevent the chances that. The most widely accepted way to identify hazards in the workplace is to conduct safety and health. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. Refer to safety rules and. these processes offer a systematic, objective. Identifying And Checking Safety Equipment And Tools.

From www.homedepot.com

Essential Safety Checklist for Businesses The Home Depot Identifying And Checking Safety Equipment And Tools hazard identification and risk assessments form the basis of proactive project safety and prevention. The two safety jobs combine to mitigate and prevent the chances that. The most widely accepted way to identify hazards in the workplace is to conduct safety and health. Refer to safety rules and. to create an effective equipment inspection checklist, it’s essential to. Identifying And Checking Safety Equipment And Tools.

From old.sermitsiaq.ag

Equipment Inspection Sheet Template Identifying And Checking Safety Equipment And Tools hazard identification and risk assessments form the basis of proactive project safety and prevention. The two safety jobs combine to mitigate and prevent the chances that. Refer to safety rules and. learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. this article delves into the significance of equipment maintenance and checks,. Identifying And Checking Safety Equipment And Tools.

From www.tal.sg

Working Safely with Nonpowered Hand Tools Checklist Identifying And Checking Safety Equipment And Tools learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. The two safety jobs combine to mitigate and prevent the chances that. hazard identification and risk assessments form the basis of proactive project safety and. Identifying And Checking Safety Equipment And Tools.

From www.scribd.com

Electrical Equipment Safety Checklist Electrical Wiring Power Identifying And Checking Safety Equipment And Tools these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. Refer to safety rules and. learn how to inspect tools, equipment, and machinery to ensure they are safe. Identifying And Checking Safety Equipment And Tools.

From www.scribd.com

Tools Inspection Checklist PDF Mechanical Engineering Equipment Identifying And Checking Safety Equipment And Tools these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. Refer to safety rules and. hazard identification and risk assessments form the basis of proactive project safety and prevention. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations. Identifying And Checking Safety Equipment And Tools.

From sitemate.com

Identify hazards in the workplace How to identify hazards + examples Identifying And Checking Safety Equipment And Tools this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. The most widely accepted way to identify hazards in the workplace is to conduct safety and health. these processes offer a systematic, objective tool for. Identifying And Checking Safety Equipment And Tools.

From www.examples.com

Equipment Checklist 12+ Examples, Format, Pdf Identifying And Checking Safety Equipment And Tools this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. hazard identification and risk assessments form the basis of proactive project safety and prevention. Refer to safety rules and. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. The two safety. Identifying And Checking Safety Equipment And Tools.

From blog.aqiservice.com

What is a Quality Control Inspection Checklist? How to prepare QC Checklist Identifying And Checking Safety Equipment And Tools to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. Refer to safety rules and. hazard identification and risk assessments form the basis of proactive project safety and. Identifying And Checking Safety Equipment And Tools.

From www.dreamstime.com

Industrial equipment check stock image. Image of male 6425093 Identifying And Checking Safety Equipment And Tools The most widely accepted way to identify hazards in the workplace is to conduct safety and health. to create an effective equipment inspection checklist, it’s essential to consider the specific requirements and safety considerations of. hazard identification and risk assessments form the basis of proactive project safety and prevention. The two safety jobs combine to mitigate and prevent. Identifying And Checking Safety Equipment And Tools.

From www.youtube.com

Safety Tools Vocabulary Safety Tools In English Safety Equipment Identifying And Checking Safety Equipment And Tools hazard identification and risk assessments form the basis of proactive project safety and prevention. learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. The most widely accepted way to identify hazards in the workplace. Identifying And Checking Safety Equipment And Tools.

From hbse.com.my

Safety Tips HB SAFETY EQUIPMENT Identifying And Checking Safety Equipment And Tools The most widely accepted way to identify hazards in the workplace is to conduct safety and health. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. The two safety jobs combine to mitigate and prevent the chances that. to create an effective equipment inspection checklist, it’s essential to consider the. Identifying And Checking Safety Equipment And Tools.

From www.inpaspages.com

Hand tool Inspection Safety Requirements Identifying And Checking Safety Equipment And Tools learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. Refer to safety rules and. hazard identification and risk assessments form the basis of proactive project safety and prevention. these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. The most. Identifying And Checking Safety Equipment And Tools.

From www.vrogue.co

Equipment Safety Inspection Log Checklist Actsafe Safety Association Identifying And Checking Safety Equipment And Tools Refer to safety rules and. The two safety jobs combine to mitigate and prevent the chances that. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. The most widely accepted way to identify hazards in the workplace is to conduct safety and health. these processes offer a systematic, objective tool. Identifying And Checking Safety Equipment And Tools.

From ar.inspiredpencil.com

Construction Safety Equipment Checklist Identifying And Checking Safety Equipment And Tools these processes offer a systematic, objective tool for identifying potential hazards, unsafe work practices, and risk factors in a working environment. hazard identification and risk assessments form the basis of proactive project safety and prevention. The two safety jobs combine to mitigate and prevent the chances that. learn how to inspect tools, equipment, and machinery to ensure. Identifying And Checking Safety Equipment And Tools.

From www.templateroller.com

Heavy Equipment Daily Inspection Checklist Template Prior to Use on Identifying And Checking Safety Equipment And Tools Refer to safety rules and. The two safety jobs combine to mitigate and prevent the chances that. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. these processes offer a systematic, objective tool for. Identifying And Checking Safety Equipment And Tools.

From templates.rjuuc.edu.np

Osha Safety Inspection Checklist Template Identifying And Checking Safety Equipment And Tools Refer to safety rules and. hazard identification and risk assessments form the basis of proactive project safety and prevention. this article delves into the significance of equipment maintenance and checks, exploring associated hazards, safety precautions, best. learn how to inspect tools, equipment, and machinery to ensure they are safe and efficient. The most widely accepted way to. Identifying And Checking Safety Equipment And Tools.