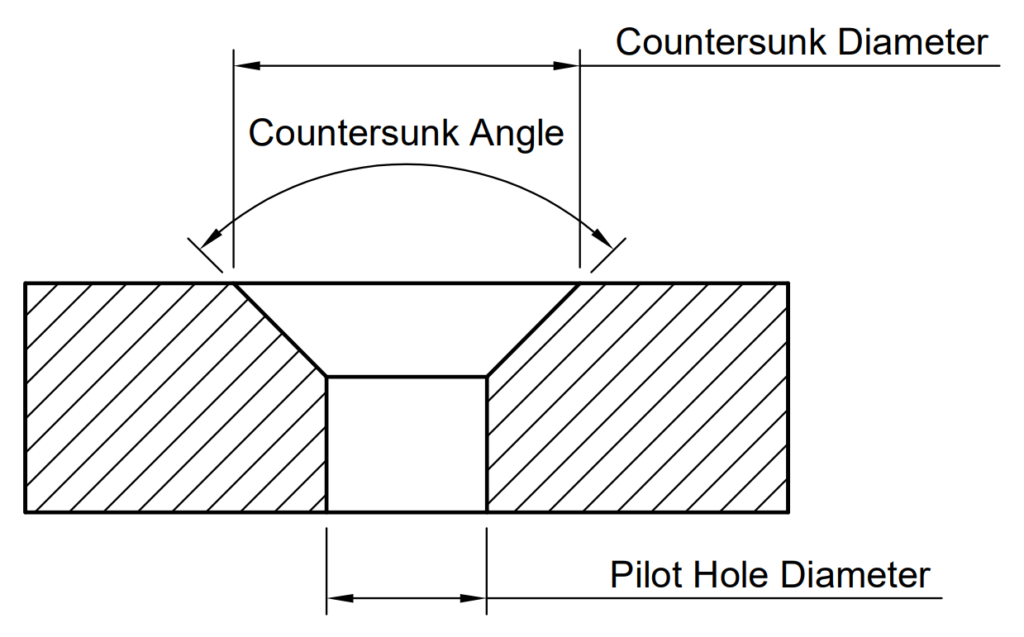

Countersunk Hole Edge Distance . The ratio of the distance between the edge of a countersink hole and a bend to the sheet. it is quite difficult to measure the countersunk hole's edge to determine its diameter, so a gage depth below surface. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Ideally, the hardware has at least 50% contact with. countersink hole to bend distance. the angle of the countersink is dependent upon the hardware being used. if a hole is too close to a part edge or bend, the edge might become distorted. use the countersink min hole center to material edge value to measure the distance between the center of a. If a hole is too close to a part edge or bend, the edge might become distorted. a countersink hole is one in which the outer edge of the hole has been opened up to a conical entry. For ansi/imperial fasteners, it is commonly.

from engineersbible.com

If a hole is too close to a part edge or bend, the edge might become distorted. the angle of the countersink is dependent upon the hardware being used. The ratio of the distance between the edge of a countersink hole and a bend to the sheet. it is quite difficult to measure the countersunk hole's edge to determine its diameter, so a gage depth below surface. countersink hole to bend distance. For ansi/imperial fasteners, it is commonly. use the countersink min hole center to material edge value to measure the distance between the center of a. a countersink hole is one in which the outer edge of the hole has been opened up to a conical entry. Ideally, the hardware has at least 50% contact with. if a hole is too close to a part edge or bend, the edge might become distorted.

Countersunk Hole Size for Flat Head Screws (ISO) The Engineer's Bible

Countersunk Hole Edge Distance If a hole is too close to a part edge or bend, the edge might become distorted. the angle of the countersink is dependent upon the hardware being used. Ideally, the hardware has at least 50% contact with. if a hole is too close to a part edge or bend, the edge might become distorted. a countersink hole is one in which the outer edge of the hole has been opened up to a conical entry. it is quite difficult to measure the countersunk hole's edge to determine its diameter, so a gage depth below surface. The ratio of the distance between the edge of a countersink hole and a bend to the sheet. If a hole is too close to a part edge or bend, the edge might become distorted. For ansi/imperial fasteners, it is commonly. countersink hole to bend distance. use the countersink min hole center to material edge value to measure the distance between the center of a. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending.

From fyomuymai.blob.core.windows.net

Countersink Joints at Larry Bufford blog Countersunk Hole Edge Distance it is quite difficult to measure the countersunk hole's edge to determine its diameter, so a gage depth below surface. if a hole is too close to a part edge or bend, the edge might become distorted. the angle of the countersink is dependent upon the hardware being used. a countersink hole is one in which. Countersunk Hole Edge Distance.

From www.theengineeringknowledge.com

What are Countersink Holes in Engineering? The Engineering Knowledge Countersunk Hole Edge Distance countersink hole to bend distance. if a hole is too close to a part edge or bend, the edge might become distorted. use the countersink min hole center to material edge value to measure the distance between the center of a. the angle of the countersink is dependent upon the hardware being used. Ideally, the hardware. Countersunk Hole Edge Distance.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The Countersunk Hole Edge Distance it is quite difficult to measure the countersunk hole's edge to determine its diameter, so a gage depth below surface. Ideally, the hardware has at least 50% contact with. the angle of the countersink is dependent upon the hardware being used. use the countersink min hole center to material edge value to measure the distance between the. Countersunk Hole Edge Distance.

From engineersbible.com

Countersunk Hole Size for Flat Head Screws (ISO) The Engineer's Bible Countersunk Hole Edge Distance the angle of the countersink is dependent upon the hardware being used. The ratio of the distance between the edge of a countersink hole and a bend to the sheet. it is quite difficult to measure the countersunk hole's edge to determine its diameter, so a gage depth below surface. use the countersink min hole center to. Countersunk Hole Edge Distance.

From www.youtube.com

🔩 How To Make Countersink And Counterbore Holes FreeCAD Hole Tutorial Countersunk Hole Edge Distance it is quite difficult to measure the countersunk hole's edge to determine its diameter, so a gage depth below surface. a countersink hole is one in which the outer edge of the hole has been opened up to a conical entry. use the countersink min hole center to material edge value to measure the distance between the. Countersunk Hole Edge Distance.

From exyrutmlt.blob.core.windows.net

M8 Countersunk Hole Dimensions at Albert Brown blog Countersunk Hole Edge Distance Ideally, the hardware has at least 50% contact with. countersink hole to bend distance. use the countersink min hole center to material edge value to measure the distance between the center of a. For ansi/imperial fasteners, it is commonly. the angle of the countersink is dependent upon the hardware being used. If a hole is too close. Countersunk Hole Edge Distance.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The Countersunk Hole Edge Distance the angle of the countersink is dependent upon the hardware being used. if a hole is too close to a part edge or bend, the edge might become distorted. use the countersink min hole center to material edge value to measure the distance between the center of a. Ideally, the hardware has at least 50% contact with.. Countersunk Hole Edge Distance.

From mechheart.com

What is a Counterbore? MECHHEART Countersunk Hole Edge Distance If a hole is too close to a part edge or bend, the edge might become distorted. the angle of the countersink is dependent upon the hardware being used. For ansi/imperial fasteners, it is commonly. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. it is quite difficult. Countersunk Hole Edge Distance.

From www.theengineeringknowledge.com

What are Countersink Holes in Engineering? The Engineering Knowledge Countersunk Hole Edge Distance it is quite difficult to measure the countersunk hole's edge to determine its diameter, so a gage depth below surface. Ideally, the hardware has at least 50% contact with. For ansi/imperial fasteners, it is commonly. if a hole is too close to a part edge or bend, the edge might become distorted. a countersink hole is one. Countersunk Hole Edge Distance.

From ar.inspiredpencil.com

Standard Countersink Hole Countersunk Hole Edge Distance it is quite difficult to measure the countersunk hole's edge to determine its diameter, so a gage depth below surface. If a hole is too close to a part edge or bend, the edge might become distorted. countersink hole to bend distance. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting,. Countersunk Hole Edge Distance.

From www.researchgate.net

Configuration of the double countersunk hole. Download Scientific Diagram Countersunk Hole Edge Distance For ansi/imperial fasteners, it is commonly. If a hole is too close to a part edge or bend, the edge might become distorted. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Ideally, the hardware has at least 50% contact with. a countersink hole is one in which the. Countersunk Hole Edge Distance.

From eurocodeapplied.com

Table of design properties for metric steel bolts M5 to M39 Eurocode 3 Countersunk Hole Edge Distance countersink hole to bend distance. Ideally, the hardware has at least 50% contact with. the angle of the countersink is dependent upon the hardware being used. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. use the countersink min hole center to material edge value to measure. Countersunk Hole Edge Distance.

From us.meviy.misumi-ec.com

Specifications for External Thread, Internal Thread, Keyways, Holes and Countersunk Hole Edge Distance Ideally, the hardware has at least 50% contact with. The ratio of the distance between the edge of a countersink hole and a bend to the sheet. the angle of the countersink is dependent upon the hardware being used. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. . Countersunk Hole Edge Distance.

From www.eng-tips.com

Hole to hole distance & inspection, ASME 14.5 Drafting Standards, GD Countersunk Hole Edge Distance it is quite difficult to measure the countersunk hole's edge to determine its diameter, so a gage depth below surface. countersink hole to bend distance. the angle of the countersink is dependent upon the hardware being used. use the countersink min hole center to material edge value to measure the distance between the center of a.. Countersunk Hole Edge Distance.

From giodxozdv.blob.core.windows.net

What Size Countersink Do I Need at Johnny Hensley blog Countersunk Hole Edge Distance Ideally, the hardware has at least 50% contact with. countersink hole to bend distance. if a hole is too close to a part edge or bend, the edge might become distorted. use the countersink min hole center to material edge value to measure the distance between the center of a. a countersink hole is one in. Countersunk Hole Edge Distance.

From ar.inspiredpencil.com

Standard Countersink Hole Countersunk Hole Edge Distance if a hole is too close to a part edge or bend, the edge might become distorted. If a hole is too close to a part edge or bend, the edge might become distorted. Ideally, the hardware has at least 50% contact with. the angle of the countersink is dependent upon the hardware being used. a countersink. Countersunk Hole Edge Distance.

From dobemy.com

Countersunk Holes vs. Counterbore Holes What's the Difference?DOBEMY Countersunk Hole Edge Distance For ansi/imperial fasteners, it is commonly. countersink hole to bend distance. it is quite difficult to measure the countersunk hole's edge to determine its diameter, so a gage depth below surface. the angle of the countersink is dependent upon the hardware being used. The ratio of the distance between the edge of a countersink hole and a. Countersunk Hole Edge Distance.

From sawsonskates.com

pilotholevscountersinkhole1 Saws on Skates Countersunk Hole Edge Distance If a hole is too close to a part edge or bend, the edge might become distorted. if a hole is too close to a part edge or bend, the edge might become distorted. Ideally, the hardware has at least 50% contact with. For ansi/imperial fasteners, it is commonly. The ratio of the distance between the edge of a. Countersunk Hole Edge Distance.

From mechheart.com

What is a Countersunk Screw? MECHHEART Countersunk Hole Edge Distance Ideally, the hardware has at least 50% contact with. For ansi/imperial fasteners, it is commonly. the angle of the countersink is dependent upon the hardware being used. countersink hole to bend distance. The ratio of the distance between the edge of a countersink hole and a bend to the sheet. if a hole is too close to. Countersunk Hole Edge Distance.

From www.semanticscholar.org

Table 2 from Avoiding knifeedge countersinks in GLARE through dimpling Countersunk Hole Edge Distance Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. If a hole is too close to a part edge or bend, the edge might become distorted. the angle of the countersink is dependent upon the hardware being used. use the countersink min hole center to material edge value. Countersunk Hole Edge Distance.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersunk Hole Edge Distance For ansi/imperial fasteners, it is commonly. if a hole is too close to a part edge or bend, the edge might become distorted. countersink hole to bend distance. it is quite difficult to measure the countersunk hole's edge to determine its diameter, so a gage depth below surface. The ratio of the distance between the edge of. Countersunk Hole Edge Distance.

From www.youtube.com

Sheet metal design guidelines Minimum Distance Between Extruded Holes Countersunk Hole Edge Distance The ratio of the distance between the edge of a countersink hole and a bend to the sheet. the angle of the countersink is dependent upon the hardware being used. if a hole is too close to a part edge or bend, the edge might become distorted. it is quite difficult to measure the countersunk hole's edge. Countersunk Hole Edge Distance.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersunk Hole Edge Distance The ratio of the distance between the edge of a countersink hole and a bend to the sheet. use the countersink min hole center to material edge value to measure the distance between the center of a. it is quite difficult to measure the countersunk hole's edge to determine its diameter, so a gage depth below surface. Sheet. Countersunk Hole Edge Distance.

From mechieedu.blogspot.com

Dimensioning Countersunk Hole Edge Distance The ratio of the distance between the edge of a countersink hole and a bend to the sheet. the angle of the countersink is dependent upon the hardware being used. If a hole is too close to a part edge or bend, the edge might become distorted. countersink hole to bend distance. it is quite difficult to. Countersunk Hole Edge Distance.

From dobemy.com

Countersunk Holes vs. Counterbore Holes What's the Difference?DOBEMY Countersunk Hole Edge Distance The ratio of the distance between the edge of a countersink hole and a bend to the sheet. If a hole is too close to a part edge or bend, the edge might become distorted. For ansi/imperial fasteners, it is commonly. Ideally, the hardware has at least 50% contact with. use the countersink min hole center to material edge. Countersunk Hole Edge Distance.

From www.altium.com

Working with Additional Views for Your Draftsman Documentation in Countersunk Hole Edge Distance The ratio of the distance between the edge of a countersink hole and a bend to the sheet. the angle of the countersink is dependent upon the hardware being used. use the countersink min hole center to material edge value to measure the distance between the center of a. if a hole is too close to a. Countersunk Hole Edge Distance.

From exytpqmxq.blob.core.windows.net

Countersink Bit Size Chart at Holly Blair blog Countersunk Hole Edge Distance a countersink hole is one in which the outer edge of the hole has been opened up to a conical entry. For ansi/imperial fasteners, it is commonly. If a hole is too close to a part edge or bend, the edge might become distorted. the angle of the countersink is dependent upon the hardware being used. Ideally, the. Countersunk Hole Edge Distance.

From forums.autodesk.com

Add hole type counterbored+countersunk Autodesk Community Countersunk Hole Edge Distance For ansi/imperial fasteners, it is commonly. a countersink hole is one in which the outer edge of the hole has been opened up to a conical entry. The ratio of the distance between the edge of a countersink hole and a bend to the sheet. Ideally, the hardware has at least 50% contact with. Sheet metal fabrication is the. Countersunk Hole Edge Distance.

From exykdifqn.blob.core.windows.net

How To Callout A Countersunk Hole On A Drawing at Thea Chaney blog Countersunk Hole Edge Distance countersink hole to bend distance. If a hole is too close to a part edge or bend, the edge might become distorted. if a hole is too close to a part edge or bend, the edge might become distorted. Ideally, the hardware has at least 50% contact with. the angle of the countersink is dependent upon the. Countersunk Hole Edge Distance.

From be-cu.com

Countersink Holes An Essential Guide To Precision And Functionality Countersunk Hole Edge Distance if a hole is too close to a part edge or bend, the edge might become distorted. For ansi/imperial fasteners, it is commonly. the angle of the countersink is dependent upon the hardware being used. use the countersink min hole center to material edge value to measure the distance between the center of a. countersink hole. Countersunk Hole Edge Distance.

From blacktile.com.au

Slotted Hole Size Chart (Updated for 2023) Countersunk Hole Edge Distance The ratio of the distance between the edge of a countersink hole and a bend to the sheet. countersink hole to bend distance. a countersink hole is one in which the outer edge of the hole has been opened up to a conical entry. the angle of the countersink is dependent upon the hardware being used. Sheet. Countersunk Hole Edge Distance.

From edu.svet.gob.gt

The Benefits Of Countersinking SendCutSend edu.svet.gob.gt Countersunk Hole Edge Distance The ratio of the distance between the edge of a countersink hole and a bend to the sheet. Ideally, the hardware has at least 50% contact with. countersink hole to bend distance. the angle of the countersink is dependent upon the hardware being used. it is quite difficult to measure the countersunk hole's edge to determine its. Countersunk Hole Edge Distance.

From forums.sketchup.com

Help needed on countersinking holes SketchUp SketchUp Community Countersunk Hole Edge Distance use the countersink min hole center to material edge value to measure the distance between the center of a. countersink hole to bend distance. Ideally, the hardware has at least 50% contact with. For ansi/imperial fasteners, it is commonly. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending.. Countersunk Hole Edge Distance.

From ar.inspiredpencil.com

Standard Countersink Hole Countersunk Hole Edge Distance use the countersink min hole center to material edge value to measure the distance between the center of a. If a hole is too close to a part edge or bend, the edge might become distorted. a countersink hole is one in which the outer edge of the hole has been opened up to a conical entry. For. Countersunk Hole Edge Distance.

From www.villageinframe.com

Bolt Hole Edge Distance A Pictures Of Hole 2018 Countersunk Hole Edge Distance Ideally, the hardware has at least 50% contact with. countersink hole to bend distance. the angle of the countersink is dependent upon the hardware being used. if a hole is too close to a part edge or bend, the edge might become distorted. For ansi/imperial fasteners, it is commonly. If a hole is too close to a. Countersunk Hole Edge Distance.