Gearbox Lubrication System Design . In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. There are three gear lubrication methods in general use: (2) splash lubrication (oil bath method). The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to.

from www.mdpi.com

Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. There are three gear lubrication methods in general use: (2) splash lubrication (oil bath method).

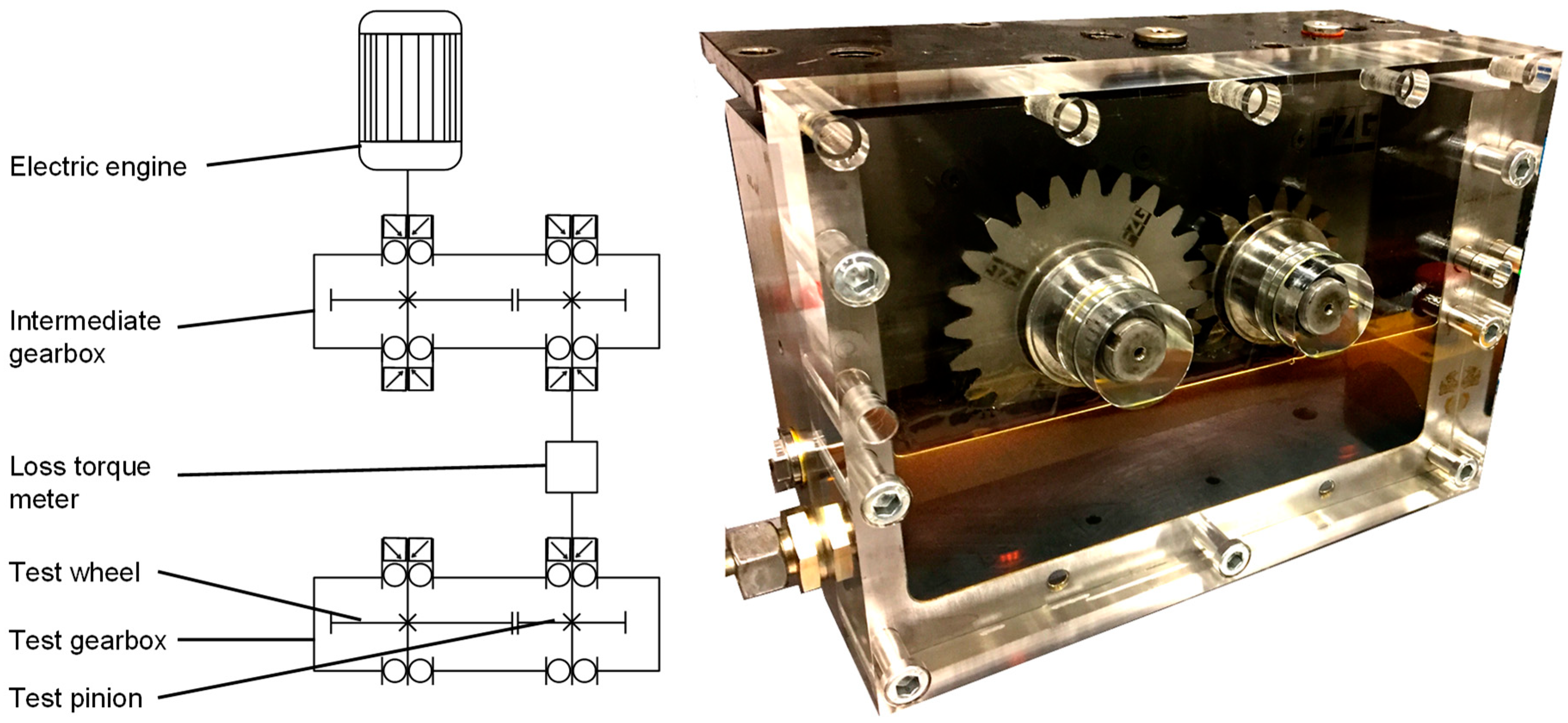

Lubricants Free FullText Detailed Investigations on the Oil Flow

Gearbox Lubrication System Design The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. (2) splash lubrication (oil bath method). There are three gear lubrication methods in general use:

From gearboxelectro.com

Memahami Cara Kerja Gearbox Helikopter untuk Keselamatan Terbang Gear Gearbox Lubrication System Design The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. (2) splash lubrication (oil bath method).. Gearbox Lubrication System Design.

From www.mdpi.com

Lubricants Free FullText Detailed Investigations on the Oil Flow Gearbox Lubrication System Design (2) splash lubrication (oil bath method). In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication. Gearbox Lubrication System Design.

From www.vecteezy.com

Lubricate motor oil and Gears. Oil wave splashing in Car engine with Gearbox Lubrication System Design The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. (2) splash lubrication (oil bath method). In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how. Gearbox Lubrication System Design.

From eureka.patsnap.com

Gearbox lubrication system Eureka Patsnap develop intelligence library Gearbox Lubrication System Design Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. (2) splash lubrication (oil bath method). There are three gear lubrication methods in general use: The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load. Gearbox Lubrication System Design.

From www.hydac.com.au

Lubrication Systems HYDAC Gearbox Lubrication System Design (2) splash lubrication (oil bath method). The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. There are three gear lubrication methods in general use: In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. Predictions and. Gearbox Lubrication System Design.

From www.iqsdirectory.com

Lubricating System Types, Uses, Features and Benefits Gearbox Lubrication System Design The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. (2) splash lubrication (oil bath method). The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. Predictions and measurements. Gearbox Lubrication System Design.

From www.iqsdirectory.com

Lubricating System Types, Uses, Features and Benefits Gearbox Lubrication System Design The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in.. Gearbox Lubrication System Design.

From www.indiamart.com

Gearbox Oil at Rs 140/litre Ambattur Chennai ID 9654935562 Gearbox Lubrication System Design (2) splash lubrication (oil bath method). Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. There are three gear lubrication methods in general use: The most common gearbox lubrication. Gearbox Lubrication System Design.

From www.lubeaboom.com

Proper Lubrication for Industrial Crane and Heavy Equipment Maintenance Gearbox Lubrication System Design Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. (2) splash lubrication (oil bath method). The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. There are three gear lubrication methods. Gearbox Lubrication System Design.

From www.youtube.com

Splash Lubrication of Bevel Gears YouTube Gearbox Lubrication System Design There are three gear lubrication methods in general use: The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and.. Gearbox Lubrication System Design.

From www.apexdyna.nl

Apex Dynamics markets a fully automatic lubrication system for automation Gearbox Lubrication System Design The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. (2) splash lubrication (oil bath method). In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in.. Gearbox Lubrication System Design.

From www.filtermagindustrial.com

Gearboxes FilterMag Industrial Products Division Gearbox Lubrication System Design There are three gear lubrication methods in general use: Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. The modern design of mechanical parts, such as gears, goes through. Gearbox Lubrication System Design.

From detoxicrecenze.com

Lubrication System Diagram My Wiring DIagram Gearbox Lubrication System Design The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. There are three gear lubrication methods in general use: In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. (2) splash lubrication (oil bath method). Predictions and. Gearbox Lubrication System Design.

From www.machinerylubrication.com

Add Oil Circulation to Gear and Bearing Sumps for Greater Reliability Gearbox Lubrication System Design In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. (2) splash lubrication (oil bath method). The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication. Gearbox Lubrication System Design.

From autovogdenie.ru

Какая рабочая температура дизельного и бензинового двигателя Gearbox Lubrication System Design (2) splash lubrication (oil bath method). There are three gear lubrication methods in general use: The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. In this article lubrication engineers shares the results of its r&d efforts and their. Gearbox Lubrication System Design.

From rjmellor.co.uk

Open Gear Spray Lubrication Gearbox Lubrication System Design There are three gear lubrication methods in general use: The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and.. Gearbox Lubrication System Design.

From fyoldfrgu.blob.core.windows.net

Lubricant Lubrication System at Richard Brantley blog Gearbox Lubrication System Design (2) splash lubrication (oil bath method). The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in.. Gearbox Lubrication System Design.

From www.avl.com

How to Cut Gearbox Lubrication Development from Days to Hours How to Gearbox Lubrication System Design There are three gear lubrication methods in general use: (2) splash lubrication (oil bath method). In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. The most common gearbox lubrication. Gearbox Lubrication System Design.

From www.researchgate.net

Schematic diagram of main gearbox oilguiding splash lubrication system Gearbox Lubrication System Design The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. There are three gear lubrication methods in general use: The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox.. Gearbox Lubrication System Design.

From www.rjlink.com

Gearbox Lubricant Considersations RJ Link International, Inc. Gearbox Lubrication System Design In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. The modern design of mechanical parts, such as gears, goes through the continuous demand for a high. Gearbox Lubrication System Design.

From www.youtube.com

Gearbox lubrication YouTube Gearbox Lubrication System Design There are three gear lubrication methods in general use: (2) splash lubrication (oil bath method). The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. In this article lubrication engineers shares the results of its r&d efforts and their. Gearbox Lubrication System Design.

From www.youtube.com

Gearbox lubrication system YouTube Gearbox Lubrication System Design The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. (2) splash lubrication (oil bath method). There are three gear lubrication methods. Gearbox Lubrication System Design.

From c-mclellan.com.au

Oil Lubrication System Design CMA Engineering Gearbox Lubrication System Design Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in.. Gearbox Lubrication System Design.

From cullen-has-burgess.blogspot.com

Car Engine Lubrication System CullenhasBurgess Gearbox Lubrication System Design The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. (2) splash lubrication (oil bath method).. Gearbox Lubrication System Design.

From www.machinerylubrication.com

Centralized Grease Lubrication Systems Explained Gearbox Lubrication System Design (2) splash lubrication (oil bath method). In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. The modern design of mechanical parts, such as gears, goes through. Gearbox Lubrication System Design.

From www.engineernewsnetwork.com

Drive system solutions for rack and pinion applications Engineer News Gearbox Lubrication System Design In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. (2) splash lubrication (oil bath method).. Gearbox Lubrication System Design.

From www.mdpi.com

Applied Sciences Free FullText CFDBased Investigation of Gearbox Lubrication System Design In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. There are three gear lubrication methods in general use: Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. (2) splash lubrication (oil bath method). The modern design of mechanical. Gearbox Lubrication System Design.

From evolution.skf.com

Up in the air or deep in the sea, lubrication is key Evolution Online Gearbox Lubrication System Design (2) splash lubrication (oil bath method). Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. The modern design of mechanical parts, such as gears, goes through the continuous demand. Gearbox Lubrication System Design.

From www.linkedin.com

Lubrication Systems Demystified Keeping your machinery in motion Gearbox Lubrication System Design Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. (2) splash lubrication (oil bath method). There are three gear lubrication methods in general use: In this article lubrication engineers shares the results. Gearbox Lubrication System Design.

From www.iqsdirectory.com

Lubricating System Types, Uses, Features and Benefits Gearbox Lubrication System Design (2) splash lubrication (oil bath method). The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in.. Gearbox Lubrication System Design.

From www.skf.com

SKF Oil+Air lubrication systems Gearbox Lubrication System Design The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. There are three gear lubrication methods in general use: (2) splash lubrication (oil bath method). The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as. Gearbox Lubrication System Design.

From www.machinerylubrication.com

Centralized Grease Lubrication Systems Explained Gearbox Lubrication System Design (2) splash lubrication (oil bath method). The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in.. Gearbox Lubrication System Design.

From www.slideserve.com

PPT Gearbox Lubrication System Maufacturers in India PowerPoint Gearbox Lubrication System Design The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. (2) splash lubrication (oil bath method). In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in.. Gearbox Lubrication System Design.

From cmaengineers.com.au

Oil Lubrication System Design CMA Engineering Gearbox Lubrication System Design The modern design of mechanical parts, such as gears, goes through the continuous demand for a high level of efficiency and reliability, as well as an increased load carrying capacity and. Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. The most common gearbox lubrication system is wading lubrication, which currently solves. Gearbox Lubrication System Design.

From www.machinerylubrication.com

Chain Lubrication Best Practices for Drives and Conveyors Gearbox Lubrication System Design The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox. There are three gear lubrication methods in general use: Predictions and measurements of gear transmission efficiency are crucial during gear system design and operation due to. In this article lubrication engineers shares the results of its r&d efforts and their. Gearbox Lubrication System Design.