Velocity Ratio Of Worm Gear Formula . There are fifteen standard lead angles: The worm acts as a single toothed gear so the ratio is; The pitch line velocity is ideally up to 30. Number of teeth on wormwheel. A worm and worm gear set is used as a speed reducer to drive a winch lift. The velocity ratio (i) of the worm gear is given by i = z2 / z1. 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. M g = ratio of gearing = n / n l = lead of a worm which is the distance any one thread advances in a single revolution. P outout = rated output power (kw), p input = rated input power (kw), n = rotational speed of the worm (rpm), w t = tangential load on the worm gear (n), d m = mean diameter of the gear (mm), m g. Strain gages are commonly used to measure dynamic loads. The gear ratio of a worm gear is worked out through the following formula:

from www.youtube.com

M g = ratio of gearing = n / n l = lead of a worm which is the distance any one thread advances in a single revolution. Strain gages are commonly used to measure dynamic loads. 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. A worm and worm gear set is used as a speed reducer to drive a winch lift. There are fifteen standard lead angles: The gear ratio of a worm gear is worked out through the following formula: Number of teeth on wormwheel. P outout = rated output power (kw), p input = rated input power (kw), n = rotational speed of the worm (rpm), w t = tangential load on the worm gear (n), d m = mean diameter of the gear (mm), m g. The velocity ratio (i) of the worm gear is given by i = z2 / z1. The worm acts as a single toothed gear so the ratio is;

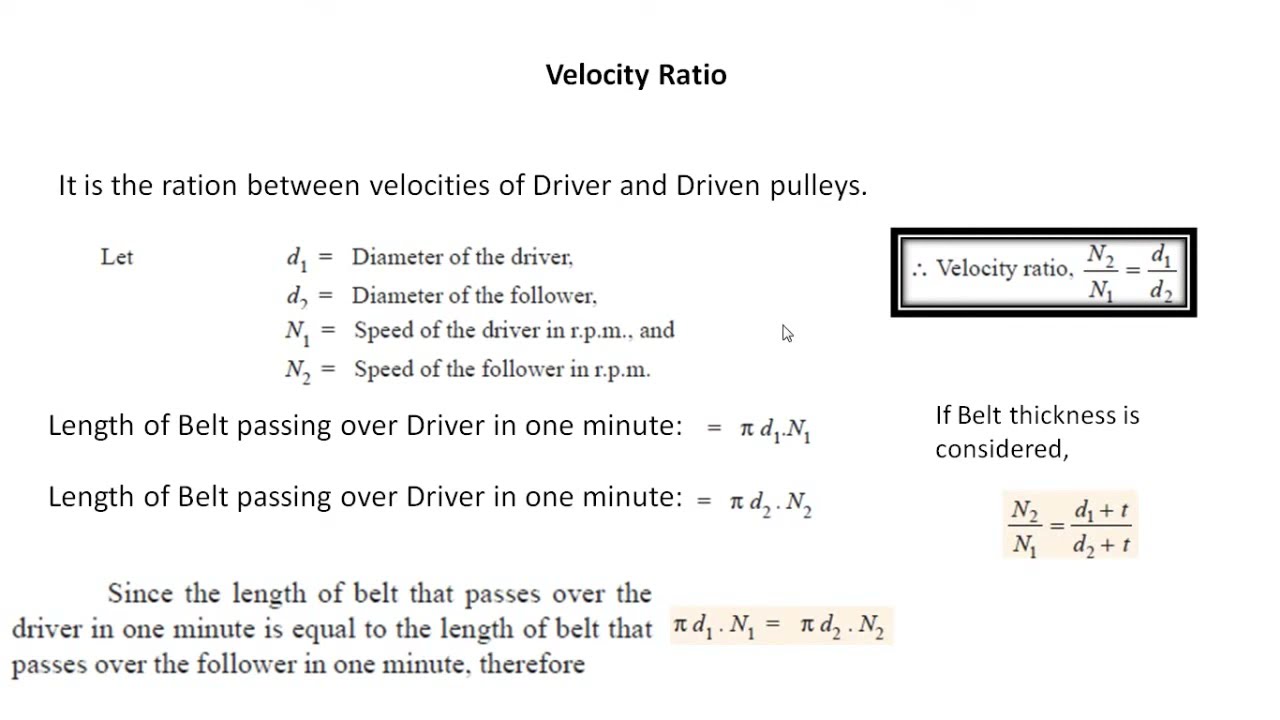

Velocity Ratio YouTube

Velocity Ratio Of Worm Gear Formula The worm acts as a single toothed gear so the ratio is; The gear ratio of a worm gear is worked out through the following formula: The velocity ratio (i) of the worm gear is given by i = z2 / z1. The pitch line velocity is ideally up to 30. Strain gages are commonly used to measure dynamic loads. There are fifteen standard lead angles: M g = ratio of gearing = n / n l = lead of a worm which is the distance any one thread advances in a single revolution. The worm acts as a single toothed gear so the ratio is; A worm and worm gear set is used as a speed reducer to drive a winch lift. Number of teeth on wormwheel. 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. P outout = rated output power (kw), p input = rated input power (kw), n = rotational speed of the worm (rpm), w t = tangential load on the worm gear (n), d m = mean diameter of the gear (mm), m g.

From www.slideserve.com

PPT Simple Machines Gears, Velocity Ratios and Mechanical Advantage Velocity Ratio Of Worm Gear Formula A worm and worm gear set is used as a speed reducer to drive a winch lift. There are fifteen standard lead angles: The worm acts as a single toothed gear so the ratio is; Number of teeth on wormwheel. M g = ratio of gearing = n / n l = lead of a worm which is the distance. Velocity Ratio Of Worm Gear Formula.

From briarsamuil.blogspot.com

15+ Worm Gear Calculation BriarSamuil Velocity Ratio Of Worm Gear Formula P outout = rated output power (kw), p input = rated input power (kw), n = rotational speed of the worm (rpm), w t = tangential load on the worm gear (n), d m = mean diameter of the gear (mm), m g. M g = ratio of gearing = n / n l = lead of a worm which. Velocity Ratio Of Worm Gear Formula.

From www.chegg.com

Solved Design a gear train for an EXACT velocity ratio of Velocity Ratio Of Worm Gear Formula P outout = rated output power (kw), p input = rated input power (kw), n = rotational speed of the worm (rpm), w t = tangential load on the worm gear (n), d m = mean diameter of the gear (mm), m g. The pitch line velocity is ideally up to 30. 204 rows this document specifies formulae for calculating. Velocity Ratio Of Worm Gear Formula.

From www.artofit.org

Understanding gear ratios Artofit Velocity Ratio Of Worm Gear Formula The velocity ratio (i) of the worm gear is given by i = z2 / z1. P outout = rated output power (kw), p input = rated input power (kw), n = rotational speed of the worm (rpm), w t = tangential load on the worm gear (n), d m = mean diameter of the gear (mm), m g. Number. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

Video 5 Calculation on Velocity ratio for epicyclic gear train using Velocity Ratio Of Worm Gear Formula The velocity ratio (i) of the worm gear is given by i = z2 / z1. Strain gages are commonly used to measure dynamic loads. The gear ratio of a worm gear is worked out through the following formula: A worm and worm gear set is used as a speed reducer to drive a winch lift. 204 rows this document. Velocity Ratio Of Worm Gear Formula.

From www.pinterest.co.uk

Robotic Mechanisms WORM GEARS 51038 Eğitim Velocity Ratio Of Worm Gear Formula Number of teeth on wormwheel. A worm and worm gear set is used as a speed reducer to drive a winch lift. The velocity ratio (i) of the worm gear is given by i = z2 / z1. 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. The. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

Worm Gear Worm Gear Calculation Different Calculations of Worm Gear Velocity Ratio Of Worm Gear Formula The gear ratio of a worm gear is worked out through the following formula: Number of teeth on wormwheel. The velocity ratio (i) of the worm gear is given by i = z2 / z1. 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. M g = ratio. Velocity Ratio Of Worm Gear Formula.

From www.slideshare.net

Worm gears Velocity Ratio Of Worm Gear Formula M g = ratio of gearing = n / n l = lead of a worm which is the distance any one thread advances in a single revolution. A worm and worm gear set is used as a speed reducer to drive a winch lift. Strain gages are commonly used to measure dynamic loads. 204 rows this document specifies formulae. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

Velocity Ratio of Gear Drive YouTube Velocity Ratio Of Worm Gear Formula Number of teeth on wormwheel. The gear ratio of a worm gear is worked out through the following formula: The worm acts as a single toothed gear so the ratio is; M g = ratio of gearing = n / n l = lead of a worm which is the distance any one thread advances in a single revolution. The. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

Reverted gear train / Velocity ratio of Reverted gear train / How to Velocity Ratio Of Worm Gear Formula The worm acts as a single toothed gear so the ratio is; The gear ratio of a worm gear is worked out through the following formula: M g = ratio of gearing = n / n l = lead of a worm which is the distance any one thread advances in a single revolution. The velocity ratio (i) of the. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

Velocity Ratio of Gears II Gear Ratio II Understanding Gear Velocity Velocity Ratio Of Worm Gear Formula There are fifteen standard lead angles: 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. P outout = rated output power (kw), p input = rated input power (kw), n = rotational speed of the worm (rpm), w t = tangential load on the worm gear (n), d. Velocity Ratio Of Worm Gear Formula.

From www.slideserve.com

PPT Gears and Gear Ratios PowerPoint Presentation, free download ID Velocity Ratio Of Worm Gear Formula A worm and worm gear set is used as a speed reducer to drive a winch lift. M g = ratio of gearing = n / n l = lead of a worm which is the distance any one thread advances in a single revolution. Strain gages are commonly used to measure dynamic loads. The gear ratio of a worm. Velocity Ratio Of Worm Gear Formula.

From www.slideserve.com

PPT Chapter 8 Kinematics of Gears PowerPoint Presentation, free Velocity Ratio Of Worm Gear Formula Strain gages are commonly used to measure dynamic loads. Number of teeth on wormwheel. The velocity ratio (i) of the worm gear is given by i = z2 / z1. P outout = rated output power (kw), p input = rated input power (kw), n = rotational speed of the worm (rpm), w t = tangential load on the worm. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

Compound gear train / Velocity ratio of Compound gear train / How to Velocity Ratio Of Worm Gear Formula 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. The gear ratio of a worm gear is worked out through the following formula: Strain gages are commonly used to measure dynamic loads. A worm and worm gear set is used as a speed reducer to drive a winch. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

Gear velocity ratio for Simple and Compound Gear train. Reduction or Velocity Ratio Of Worm Gear Formula A worm and worm gear set is used as a speed reducer to drive a winch lift. The gear ratio of a worm gear is worked out through the following formula: 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. The worm acts as a single toothed gear. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

Simple gear train / Velocity ratio of simple gear train / How to Velocity Ratio Of Worm Gear Formula M g = ratio of gearing = n / n l = lead of a worm which is the distance any one thread advances in a single revolution. The pitch line velocity is ideally up to 30. There are fifteen standard lead angles: A worm and worm gear set is used as a speed reducer to drive a winch lift.. Velocity Ratio Of Worm Gear Formula.

From www.slideserve.com

PPT Rotary Motion PowerPoint Presentation, free download ID1886800 Velocity Ratio Of Worm Gear Formula The worm acts as a single toothed gear so the ratio is; A worm and worm gear set is used as a speed reducer to drive a winch lift. The gear ratio of a worm gear is worked out through the following formula: Strain gages are commonly used to measure dynamic loads. P outout = rated output power (kw), p. Velocity Ratio Of Worm Gear Formula.

From gasesaver.weebly.com

Worm gear design calculation pdf editor gasesaver Velocity Ratio Of Worm Gear Formula Strain gages are commonly used to measure dynamic loads. A worm and worm gear set is used as a speed reducer to drive a winch lift. 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. The gear ratio of a worm gear is worked out through the following. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

Worm & Worm Wheel (Hindi) YouTube Velocity Ratio Of Worm Gear Formula There are fifteen standard lead angles: 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. Strain gages are commonly used to measure dynamic loads. P outout = rated output power (kw), p input = rated input power (kw), n = rotational speed of the worm (rpm), w t. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

WORM AND WORM WHEEL THEORY Worm and Worm Wheel Gear Working of Velocity Ratio Of Worm Gear Formula The velocity ratio (i) of the worm gear is given by i = z2 / z1. 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. A worm and worm gear set is used as a speed reducer to drive a winch lift. There are fifteen standard lead angles:. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

Gear Basics and Relations Velocity Ratio Example 2 YouTube Velocity Ratio Of Worm Gear Formula The worm acts as a single toothed gear so the ratio is; The pitch line velocity is ideally up to 30. The velocity ratio (i) of the worm gear is given by i = z2 / z1. M g = ratio of gearing = n / n l = lead of a worm which is the distance any one thread. Velocity Ratio Of Worm Gear Formula.

From www.engineerknow.com

How to calculate gear ratio of Worm gear Velocity Ratio Of Worm Gear Formula Strain gages are commonly used to measure dynamic loads. There are fifteen standard lead angles: Number of teeth on wormwheel. P outout = rated output power (kw), p input = rated input power (kw), n = rotational speed of the worm (rpm), w t = tangential load on the worm gear (n), d m = mean diameter of the gear. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

Worm Gear Calculation Reverse Engineering YouTube Velocity Ratio Of Worm Gear Formula There are fifteen standard lead angles: The pitch line velocity is ideally up to 30. M g = ratio of gearing = n / n l = lead of a worm which is the distance any one thread advances in a single revolution. The gear ratio of a worm gear is worked out through the following formula: 204 rows this. Velocity Ratio Of Worm Gear Formula.

From www.slideshare.net

Gear Velocity Ratio Of Worm Gear Formula 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. The velocity ratio (i) of the worm gear is given by i = z2 / z1. P outout = rated output power (kw), p input = rated input power (kw), n = rotational speed of the worm (rpm), w. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

Worm Gear terminology/Nomenclature and velocity ratio YouTube Velocity Ratio Of Worm Gear Formula The velocity ratio (i) of the worm gear is given by i = z2 / z1. Strain gages are commonly used to measure dynamic loads. Number of teeth on wormwheel. P outout = rated output power (kw), p input = rated input power (kw), n = rotational speed of the worm (rpm), w t = tangential load on the worm. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

WORM GEARS Forces and Speed Relations in Just Under 15 Minutes! YouTube Velocity Ratio Of Worm Gear Formula 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. M g = ratio of gearing = n / n l = lead of a worm which is the distance any one thread advances in a single revolution. A worm and worm gear set is used as a speed. Velocity Ratio Of Worm Gear Formula.

From brainsherof.weebly.com

Worm gear design calculation download brainsherofMy Site Velocity Ratio Of Worm Gear Formula The gear ratio of a worm gear is worked out through the following formula: 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. P outout = rated output power (kw), p input = rated input power (kw), n = rotational speed of the worm (rpm), w t =. Velocity Ratio Of Worm Gear Formula.

From www.numerade.com

A triple thread worm gear having a diametral pitch of 5in is used to Velocity Ratio Of Worm Gear Formula 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. M g = ratio of gearing = n / n l = lead of a worm which is the distance any one thread advances in a single revolution. The pitch line velocity is ideally up to 30. The worm. Velocity Ratio Of Worm Gear Formula.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Velocity Ratio Of Worm Gear Formula There are fifteen standard lead angles: The pitch line velocity is ideally up to 30. A worm and worm gear set is used as a speed reducer to drive a winch lift. Number of teeth on wormwheel. The worm acts as a single toothed gear so the ratio is; The gear ratio of a worm gear is worked out through. Velocity Ratio Of Worm Gear Formula.

From exoieqxzh.blob.core.windows.net

Gear Ratio Calculator Input Output at Annie Pepe blog Velocity Ratio Of Worm Gear Formula The pitch line velocity is ideally up to 30. The worm acts as a single toothed gear so the ratio is; There are fifteen standard lead angles: A worm and worm gear set is used as a speed reducer to drive a winch lift. The velocity ratio (i) of the worm gear is given by i = z2 / z1.. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

Worm and Wheel Gearbox Gear ratio Calculation How to calculate worm Velocity Ratio Of Worm Gear Formula The pitch line velocity is ideally up to 30. The gear ratio of a worm gear is worked out through the following formula: The velocity ratio (i) of the worm gear is given by i = z2 / z1. The worm acts as a single toothed gear so the ratio is; There are fifteen standard lead angles: M g =. Velocity Ratio Of Worm Gear Formula.

From webmotor.org

Motor Gear Ratio Formula Velocity Ratio Of Worm Gear Formula The velocity ratio (i) of the worm gear is given by i = z2 / z1. The worm acts as a single toothed gear so the ratio is; Strain gages are commonly used to measure dynamic loads. Number of teeth on wormwheel. The gear ratio of a worm gear is worked out through the following formula: The pitch line velocity. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

VELOCITY RATIO OF GEARS YouTube Velocity Ratio Of Worm Gear Formula The pitch line velocity is ideally up to 30. The worm acts as a single toothed gear so the ratio is; The gear ratio of a worm gear is worked out through the following formula: M g = ratio of gearing = n / n l = lead of a worm which is the distance any one thread advances in. Velocity Ratio Of Worm Gear Formula.

From www.youtube.com

Velocity Ratio YouTube Velocity Ratio Of Worm Gear Formula There are fifteen standard lead angles: 204 rows this document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with. The velocity ratio (i) of the worm gear is given by i = z2 / z1. A worm and worm gear set is used as a speed reducer to drive a winch lift.. Velocity Ratio Of Worm Gear Formula.

From www.researchgate.net

Coordinate system of globoid worm drive. Download Scientific Diagram Velocity Ratio Of Worm Gear Formula There are fifteen standard lead angles: The pitch line velocity is ideally up to 30. The velocity ratio (i) of the worm gear is given by i = z2 / z1. Strain gages are commonly used to measure dynamic loads. M g = ratio of gearing = n / n l = lead of a worm which is the distance. Velocity Ratio Of Worm Gear Formula.