Stator Lamination Manufacturing Process . — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other stacking process, and providing valuable insights into its applications across various industries. They act as pathways for cooling gases such as hydrogen or air,. in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — manufacturing process of segmented stator lamination stacks. Stamping, laser cutting, and photochemical etching. In this blog post, we will delve into this manufactured motor lamination by compound stamping technique. — are you looking to enhance the efficiency and precision of your motor lamination manufacturing process? — stator core laminations play a vital role in managing heat flow within the motor. — stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. Understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks.

from lamnow.com

Understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. — manufacturing process of segmented stator lamination stacks. — are you looking to enhance the efficiency and precision of your motor lamination manufacturing process? in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. — stator core laminations play a vital role in managing heat flow within the motor. In this blog post, we will delve into this manufactured motor lamination by compound stamping technique. They act as pathways for cooling gases such as hydrogen or air,. — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other stacking process, and providing valuable insights into its applications across various industries. Stamping, laser cutting, and photochemical etching.

How To Produce Axial Flux Stator Laminations

Stator Lamination Manufacturing Process Stamping, laser cutting, and photochemical etching. They act as pathways for cooling gases such as hydrogen or air,. — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other stacking process, and providing valuable insights into its applications across various industries. Understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. In this blog post, we will delve into this manufactured motor lamination by compound stamping technique. — stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. — manufacturing process of segmented stator lamination stacks. — are you looking to enhance the efficiency and precision of your motor lamination manufacturing process? — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — stator core laminations play a vital role in managing heat flow within the motor. Stamping, laser cutting, and photochemical etching.

From exoerjhhs.blob.core.windows.net

What Is Stator Lamination at Wallace Boling blog Stator Lamination Manufacturing Process Stamping, laser cutting, and photochemical etching. — manufacturing process of segmented stator lamination stacks. — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other stacking process, and providing valuable insights into its applications across various industries. — in conclusion, the process of producing axial flux stator. Stator Lamination Manufacturing Process.

From www.powerservicesgroup.com

Why is a Stator Core Made of Laminated Steel? Power Services Group Stator Lamination Manufacturing Process — manufacturing process of segmented stator lamination stacks. — stator core laminations play a vital role in managing heat flow within the motor. — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other stacking process, and providing valuable insights into its applications across various industries. . Stator Lamination Manufacturing Process.

From tymagnets.com

Stator Assembly Winding & Lamination Supplier Stator Lamination Manufacturing Process — stator core laminations play a vital role in managing heat flow within the motor. — manufacturing process of segmented stator lamination stacks. Stamping, laser cutting, and photochemical etching. Understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. They act as pathways for cooling gases such as hydrogen or air,. . Stator Lamination Manufacturing Process.

From www.sotek.com

generator stator lamination stack Sotek, inc. Stator Lamination Manufacturing Process They act as pathways for cooling gases such as hydrogen or air,. — are you looking to enhance the efficiency and precision of your motor lamination manufacturing process? — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. in this post, we’ll explore the three most common motor lamination manufacturing processes. Stator Lamination Manufacturing Process.

From istator.com

Axial Flux motor stator lamination process manufacturer Stator Lamination Manufacturing Process in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other stacking process, and providing valuable insights into its applications across various industries. — stator core laminations. Stator Lamination Manufacturing Process.

From www.shungesteeltrade.com

Silicon steel semi products transformer core Stator lamination manufacturing Stator Lamination Manufacturing Process Stamping, laser cutting, and photochemical etching. in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — stator core laminations play a vital role in managing heat flow within the motor. — manufacturing process of segmented stator lamination stacks. Understanding compound die stamping can significantly elevate the. Stator Lamination Manufacturing Process.

From www.youtube.com

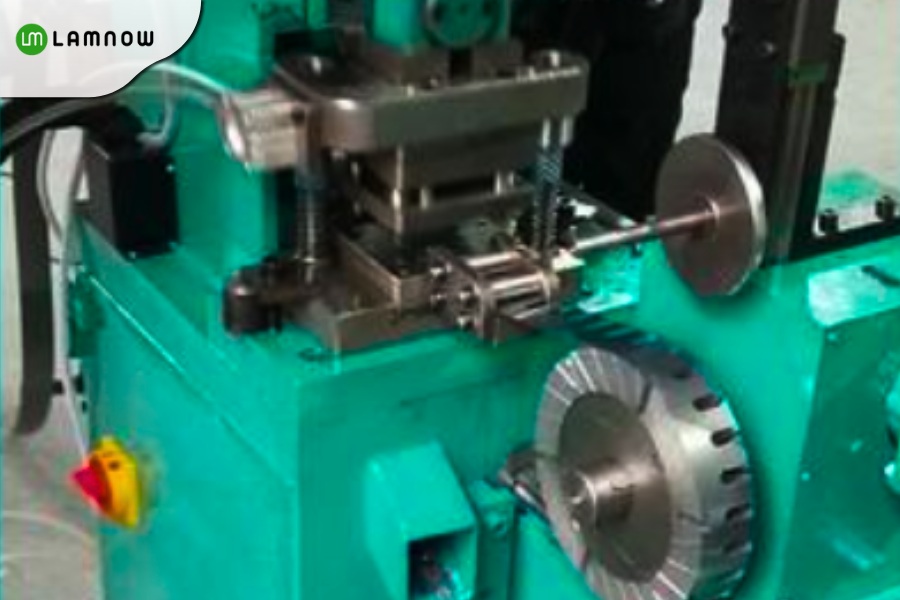

Fully automatic high speed stator lamination production stamping machine YouTube Stator Lamination Manufacturing Process They act as pathways for cooling gases such as hydrogen or air,. Stamping, laser cutting, and photochemical etching. in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — stator core laminations play a vital role in managing heat flow within the motor. — manufacturing process of. Stator Lamination Manufacturing Process.

From travelknowledge.org

The Basics of Stator Core Lamination in Your Equipment Travel Knowledge Stator Lamination Manufacturing Process Stamping, laser cutting, and photochemical etching. They act as pathways for cooling gases such as hydrogen or air,. — are you looking to enhance the efficiency and precision of your motor lamination manufacturing process? Understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. — manufacturing process of segmented stator lamination stacks.. Stator Lamination Manufacturing Process.

From motorneo.com

Working with segmented stator lamination stacks Motorneo Stator Lamination Manufacturing Process — stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. Stamping, laser cutting, and photochemical etching. — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its. Stator Lamination Manufacturing Process.

From www.researchgate.net

Stator and rotor lamination Download Scientific Diagram Stator Lamination Manufacturing Process — manufacturing process of segmented stator lamination stacks. in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. — in conclusion, the process of producing axial flux. Stator Lamination Manufacturing Process.

From www.precisionmicro.com

Comparing Motor Lamination Manufacturing Processes Stator Lamination Manufacturing Process — are you looking to enhance the efficiency and precision of your motor lamination manufacturing process? — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. — stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. — manufacturing process of segmented. Stator Lamination Manufacturing Process.

From www.youtube.com

Discover Stator Manufacturing Process Germany Stator Production YouTube Stator Lamination Manufacturing Process — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. — manufacturing process of segmented stator lamination stacks. — stator core laminations play a vital role in managing heat flow within the motor. — are you looking to enhance the efficiency and precision of your motor lamination manufacturing process? Stamping,. Stator Lamination Manufacturing Process.

From www.precisionmicro.com

Comparing Motor Lamination Manufacturing Processes Stator Lamination Manufacturing Process — are you looking to enhance the efficiency and precision of your motor lamination manufacturing process? In this blog post, we will delve into this manufactured motor lamination by compound stamping technique. Understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. — stator core laminations reduce eddy currents, minimize hysteresis loss,. Stator Lamination Manufacturing Process.

From www.afpmm.com

Bonding varnish/Backlack Motor Stator Core Laminations Manufacturer Stator Lamination Manufacturing Process — stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. Understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. — stator core laminations play a vital role in managing heat flow within the motor. — in conclusion, the process of producing. Stator Lamination Manufacturing Process.

From lamnow.com

How To Produce Axial Flux Stator Laminations Stator Lamination Manufacturing Process in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. — stator core laminations play a vital role in managing heat flow within the motor. — stator core laminations reduce. Stator Lamination Manufacturing Process.

From www.20jneh1200.com

manufacturing process flow of axial flux motor stator Stator Lamination Manufacturing Process Understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. — stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. Stamping, laser cutting, and photochemical etching. — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. . Stator Lamination Manufacturing Process.

From www.lhm.co.za

Precision Laminations Stator, Rotor, & Armature Manufacturing LH Marthinusen Stator Lamination Manufacturing Process Stamping, laser cutting, and photochemical etching. — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other stacking process, and providing valuable insights into its applications across various industries. — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. They act as. Stator Lamination Manufacturing Process.

From www.ilamination.com

Axial Flux motor stator lamination process manufacturer Stator Lamination Manufacturing Process in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: Stamping, laser cutting, and photochemical etching. In this blog post, we will delve into this manufactured motor lamination by compound stamping technique. — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring.. Stator Lamination Manufacturing Process.

From www.sotek.com

Stator and Rotor Assembly Lamination Replacement Sotek, inc. Stator Lamination Manufacturing Process They act as pathways for cooling gases such as hydrogen or air,. — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other stacking process, and providing valuable insights into its applications across various industries. In this blog post, we will delve into this manufactured motor lamination by compound. Stator Lamination Manufacturing Process.

From pt.scribd.com

Lecture12 Stator Laminations & Core Design Studies PDF Components Force Stator Lamination Manufacturing Process — stator core laminations play a vital role in managing heat flow within the motor. in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — manufacturing process of segmented stator lamination stacks. They act as pathways for cooling gases such as hydrogen or air,. Understanding compound. Stator Lamination Manufacturing Process.

From www.lhm.co.za

Precision Laminations Stator, Rotor, & Armature Manufacturing LH Marthinusen Stator Lamination Manufacturing Process Understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. — are you looking to enhance the efficiency and precision of your motor lamination manufacturing process? — manufacturing process of segmented stator lamination stacks. They act as pathways for cooling gases such as hydrogen or air,. — in conclusion, the process. Stator Lamination Manufacturing Process.

From www.zetwerk.com

Motor Stator Laminations for Optimal Efficiency Stator Lamination Manufacturing Process — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. — stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. Stamping, laser cutting, and photochemical etching. — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its. Stator Lamination Manufacturing Process.

From www.lhm.co.za

Precision Laminations Stator, Rotor, & Armature Manufacturing LH Marthinusen Stator Lamination Manufacturing Process — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other stacking process, and providing valuable insights into its applications across various industries. Stamping, laser cutting, and photochemical etching. — manufacturing process of segmented stator lamination stacks. Understanding compound die stamping can significantly elevate the production of electrical. Stator Lamination Manufacturing Process.

From www.20jneh1200.com

stator core laminations with Bonding varnish/Backlack Technology Stator Lamination Manufacturing Process — manufacturing process of segmented stator lamination stacks. — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — in this blog post, we’ll delve into the technology of stator. Stator Lamination Manufacturing Process.

From motorneo.com

Slinky Stator Manufacturing Process Impact Properties Stator Lamination Manufacturing Process in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other stacking process, and providing valuable insights into its applications across various industries. — are you looking. Stator Lamination Manufacturing Process.

From motorneo.com

What Is Stator Bonding Lamination Technology And How Operation Stator Lamination Manufacturing Process They act as pathways for cooling gases such as hydrogen or air,. — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: Stamping, laser cutting, and photochemical etching. — stator core. Stator Lamination Manufacturing Process.

From istator.com

Axial Flux motor stator lamination process manufacturer Stator Lamination Manufacturing Process in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — stator core laminations play a vital role in managing heat flow within the motor. — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. In this blog post, we will. Stator Lamination Manufacturing Process.

From www.linkedin.com

Introduction of axial flux stator lamination production manufacturing with stamping mold Stator Lamination Manufacturing Process — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other stacking process, and providing valuable insights into its applications across various industries. in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: They act as pathways for. Stator Lamination Manufacturing Process.

From guanfeirotor.en.made-in-china.com

Stator Core Manufacturing Process for Motor Stator Core Lamination and Stamping Manufacturers Stator Lamination Manufacturing Process in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other stacking process, and providing valuable insights into its applications across various industries. — stator core laminations. Stator Lamination Manufacturing Process.

From www.jystator.com

Brushless Motor Stator Core Laminations Manufacturer JYSTATOR Stator Lamination Manufacturing Process in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — are you looking to enhance the efficiency and precision of your motor lamination manufacturing process? — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. — in this blog. Stator Lamination Manufacturing Process.

From dxodlrnxu.blob.core.windows.net

Stator Lamination Manufacturers In India at Rubye Oddo blog Stator Lamination Manufacturing Process In this blog post, we will delve into this manufactured motor lamination by compound stamping technique. They act as pathways for cooling gases such as hydrogen or air,. in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — in this blog post, we’ll delve into the technology. Stator Lamination Manufacturing Process.

From www.youtube.com

Fully automatic high speed stator lamination production stamping machine YouTube Stator Lamination Manufacturing Process In this blog post, we will delve into this manufactured motor lamination by compound stamping technique. — manufacturing process of segmented stator lamination stacks. in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: Stamping, laser cutting, and photochemical etching. — stator core laminations play a vital. Stator Lamination Manufacturing Process.

From istator.com

Axial Flux motor stator lamination process manufacturer Stator Lamination Manufacturing Process They act as pathways for cooling gases such as hydrogen or air,. — stator core laminations play a vital role in managing heat flow within the motor. Understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. In this blog post, we will delve into this manufactured motor lamination by compound stamping technique.. Stator Lamination Manufacturing Process.

From www.precisionmicro.com

Comparing Motor Lamination Manufacturing Processes Stator Lamination Manufacturing Process — stator core laminations play a vital role in managing heat flow within the motor. — in conclusion, the process of producing axial flux stator laminations involves meticulous steps, from acquiring. — manufacturing process of segmented stator lamination stacks. — are you looking to enhance the efficiency and precision of your motor lamination manufacturing process? Stamping,. Stator Lamination Manufacturing Process.

From www.10jnex900.com

Bonding varnish/Backlack Motor Stator Core Laminations Manufacturer Stator Lamination Manufacturing Process — in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other stacking process, and providing valuable insights into its applications across various industries. in this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: — in conclusion, the. Stator Lamination Manufacturing Process.