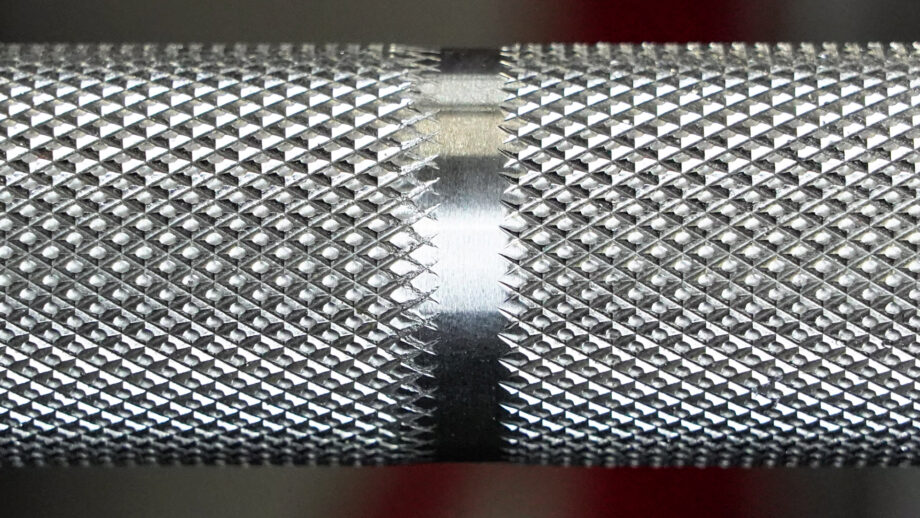

Knurling Examples . Engraving, on the other hand, uses a. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. Knurling is a manufacturing technique usually conducted on a lathe involving intricate patterns on a component’s surface. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. Straight, diagonal (left or right. Knurling, in most cases, is the roller application of forming tools that plastically distort the target surface to form the required pattern. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. The patterns are created by cutting or forming the surface material. These patterns can consist of straight. Three common knurl patterns are: Different patterns require various knurling.

from www.garagegymreviews.com

Engraving, on the other hand, uses a. Straight, diagonal (left or right. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Knurling, in most cases, is the roller application of forming tools that plastically distort the target surface to form the required pattern. These patterns can consist of straight. Different patterns require various knurling. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well.

What is Barbell Knurling and Why It Matters Garage Gym Reviews

Knurling Examples Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. These patterns can consist of straight. Knurling is a manufacturing technique usually conducted on a lathe involving intricate patterns on a component’s surface. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. Knurling, in most cases, is the roller application of forming tools that plastically distort the target surface to form the required pattern. Engraving, on the other hand, uses a. Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. The patterns are created by cutting or forming the surface material. It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. Different patterns require various knurling. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. Three common knurl patterns are: Straight, diagonal (left or right. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts.

From mensquats.com

What is a knurl on a barbell? 3 Types of Knurling. MENSQUATS Knurling Examples We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned. Knurling Examples.

From en.wikipedia.org

Knurling Wikipedia Knurling Examples It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. Knurling is a manufacturing technique usually conducted on a lathe involving intricate patterns on a component’s surface. These patterns can consist of straight. Different patterns require various knurling. Engraving, on the other hand, uses a. Three common knurl patterns are:. Knurling Examples.

From garagegymreviews.com

What is Barbell Knurling and Why It Matters Garage Gym Reviews Knurling Examples Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. Knurling is a manufacturing technique usually conducted on a lathe involving intricate patterns on a component’s surface. The patterns are. Knurling Examples.

From www.gdandtbasics.com

Knurling GD&T Basics Knurling Examples Knurling, in most cases, is the roller application of forming tools that plastically distort the target surface to form the required pattern. Straight, diagonal (left or right. Engraving, on the other hand, uses a. Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. It is mostly performed on round. Knurling Examples.

From hackaday.com

How To Achieve Knurling On A Flat Surface Hackaday Knurling Examples Different patterns require various knurling. Knurling, in most cases, is the roller application of forming tools that plastically distort the target surface to form the required pattern. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Three common knurl patterns are: The patterns are created by cutting or forming. Knurling Examples.

From www.youtube.com

How To Make Knurling Solidworks Tutorial YouTube Knurling Examples Knurling is a manufacturing technique usually conducted on a lathe involving intricate patterns on a component’s surface. Engraving, on the other hand, uses a. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. Knurling is done to increase the friction on a surface, and is typically performed on a. Knurling Examples.

From garagegymreviews.com

What is Barbell Knurling and Why It Matters Garage Gym Reviews Knurling Examples These patterns can consist of straight. The patterns are created by cutting or forming the surface material. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. Straight, diagonal. Knurling Examples.

From www.easiahome.com

A Comprehensive Guide About Knurling Easiahome Knurling Examples Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. Different patterns require various knurling. The patterns are created by cutting or forming the surface material. Knurling is a manufacturing technique usually conducted on a lathe involving intricate patterns on a component’s surface. Knurling, in most cases, is the roller. Knurling Examples.

From www.practicalmachinist.com

Knurling designs Knurling Examples Three common knurl patterns are: It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. These patterns can consist of straight. Engraving, on the other hand, uses a. Different patterns require various knurling. The patterns are created by cutting or forming the surface material. Knurling is a manufacturing process that. Knurling Examples.

From mensquats.com

What is a knurl on a barbell? 3 Types of Knurling. MENSQUATS Knurling Examples Engraving, on the other hand, uses a. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. The patterns are created by cutting or forming the surface material. Three common knurl patterns are: Knurling is a manufacturing technique usually conducted on a lathe involving intricate patterns on a component’s surface.. Knurling Examples.

From www.garagegymreviews.com

What is Barbell Knurling and Why It Matters Garage Gym Reviews Knurling Examples The patterns are created by cutting or forming the surface material. Straight, diagonal (left or right. Engraving, on the other hand, uses a. Different patterns require various knurling. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. Knurling is a finishing process in metalworking where grooves or patterns. Knurling Examples.

From www.cutwel.co.uk

Cut Knurling vs Form Knurling Cutwel Ltd Knurling Examples We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. The patterns are created by cutting or forming the surface material. Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. Knurling is a manufacturing technique usually conducted on. Knurling Examples.

From www.tworepcave.com

The 3 Types of Barbell Knurling and What It Means for Your Grip Knurling Examples Knurling, in most cases, is the roller application of forming tools that plastically distort the target surface to form the required pattern. Three common knurl patterns are: The patterns are created by cutting or forming the surface material. It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. Knurling is. Knurling Examples.

From www.teachmint.com

Knurling, Serrated Shafts, Splined Shafts, Keys, Keyways Mech. Working Drawing Notes Teachmint Knurling Examples Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. The patterns are created by cutting or forming the surface material. Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. We've explored the basic principles of knurling, detailing the. Knurling Examples.

From www.doriantool.com

Knurling Tools « Dorian Tool International Incorporated Knurling Examples We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. Knurling is a manufacturing technique usually conducted on a lathe involving intricate patterns on a component’s surface. Three common knurl patterns are: Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of. Knurling Examples.

From www.youtube.com

Knurling YouTube Knurling Examples The patterns are created by cutting or forming the surface material. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Different patterns require various knurling. These patterns can consist of straight. Three common knurl patterns are: It is mostly performed on round or cylindrical parts, but in some cases,. Knurling Examples.

From at-machining.com

Knurling Tools and Techniques A Comprehensive Guide ATMachining Knurling Examples The patterns are created by cutting or forming the surface material. Different patterns require various knurling. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. It is mostly. Knurling Examples.

From www.theengineerspost.com

Knurling Operation Definition, Process, Types & Uses [PDF] Knurling Examples The patterns are created by cutting or forming the surface material. Three common knurl patterns are: Straight, diagonal (left or right. Knurling is a manufacturing technique usually conducted on a lathe involving intricate patterns on a component’s surface. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. These patterns. Knurling Examples.

From www.gdandtbasics.com

Knurling GD&T Basics Knurling Examples Different patterns require various knurling. Knurling is a manufacturing technique usually conducted on a lathe involving intricate patterns on a component’s surface. The patterns are created by cutting or forming the surface material. Knurling, in most cases, is the roller application of forming tools that plastically distort the target surface to form the required pattern. These patterns can consist of. Knurling Examples.

From at-machining.com

Knurling Tools and Techniques A Comprehensive Guide ATMachining Knurling Examples Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and. Knurling Examples.

From www.cadimensions.com

Knurled Surfaces CADimensions Knurling Examples Knurling, in most cases, is the roller application of forming tools that plastically distort the target surface to form the required pattern. Different patterns require various knurling. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. Straight, diagonal (left or right. Engraving, on the other hand, uses a. Three. Knurling Examples.

From accu-trak.com

General Knurling Information Knurling Examples Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. Straight, diagonal (left or right. Knurling, in most cases, is the roller application of forming tools that plastically distort the target surface to form the required pattern. Three common knurl patterns are: We've explored the basic principles of knurling, detailing. Knurling Examples.

From fractory.com

Knurling Explained What Is it, Methods & Applications Fractory Knurling Examples Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Three common knurl patterns are: Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. Engraving, on the other hand, uses a. It is mostly performed on round or cylindrical. Knurling Examples.

From wiki.cadcam.com.my

CATIA How to create Knurling Cross Pattern IME Wiki Knurling Examples Knurling is a manufacturing technique usually conducted on a lathe involving intricate patterns on a component’s surface. It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. Engraving, on the. Knurling Examples.

From hackaday.com

How To Achieve Knurling On A Flat Surface Hackaday Knurling Examples The patterns are created by cutting or forming the surface material. Engraving, on the other hand, uses a. Three common knurl patterns are: These patterns can consist of straight. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. Different patterns require various knurling. It is mostly performed on. Knurling Examples.

From www.practicalmachinist.com

Knurling how to? Knurling Examples Straight, diagonal (left or right. The patterns are created by cutting or forming the surface material. Different patterns require various knurling. Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. These patterns can consist of straight. It is mostly performed on round or cylindrical parts, but in some cases,. Knurling Examples.

From garagegymlab.com

Barbell Knurling Everything you Need to Know Garage Gym Lab Knurling Examples Engraving, on the other hand, uses a. The patterns are created by cutting or forming the surface material. Three common knurl patterns are: These patterns can consist of straight. Different patterns require various knurling. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. Knurling, in most cases, is the. Knurling Examples.

From www.gdandtbasics.com

Knurling GD&T Basics Knurling Examples Engraving, on the other hand, uses a. Three common knurl patterns are: The patterns are created by cutting or forming the surface material. Straight, diagonal (left or right. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. We've explored the basic principles of knurling, detailing the knurling operation and. Knurling Examples.

From www.youtube.com

How Knurling is done YouTube Knurling Examples Straight, diagonal (left or right. Different patterns require various knurling. It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. The patterns are created by cutting or forming the surface material. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned. Knurling Examples.

From engistudies.blogspot.com

Knurls and Knurling process Engistudies Knurling Examples These patterns can consist of straight. It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. Three common knurl patterns are: Engraving, on the other hand, uses a. Different patterns. Knurling Examples.

From www.youtube.com

Knurling in FreeCAD Two Examples JOKO ENGINEERING YouTube Knurling Examples Knurling, in most cases, is the roller application of forming tools that plastically distort the target surface to form the required pattern. Straight, diagonal (left or right. Knurling is a manufacturing technique usually conducted on a lathe involving intricate patterns on a component’s surface. The patterns are created by cutting or forming the surface material. These patterns can consist of. Knurling Examples.

From www.manufacturingguide.com

Knurling Find suppliers, processes & material Knurling Examples Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. Three common knurl patterns are: It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. Engraving, on the other hand, uses a. Knurling is a manufacturing process that deforms a. Knurling Examples.

From commediadelartebrighella.blogspot.com

How To Call Out Knurling On A Drawing / Mechanical Engineering How To Define Knurl On Drawing Knurling Examples Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Different patterns require various knurling. Knurling, in most cases, is the roller application of forming tools that plastically distort the target surface to form the required pattern. Straight, diagonal (left or right. It is mostly performed on round or cylindrical. Knurling Examples.

From www.youtube.com

knurling operation? Purpose of knurling 5 knurl patterns knurling tool holders Knurling Knurling Examples Three common knurl patterns are: Engraving, on the other hand, uses a. Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. The patterns are created by cutting or. Knurling Examples.

From fractory.com

Knurling Explained What Is it, Methods & Applications Fractory Knurling Examples It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. Knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface.. Knurling Examples.