Aluminum Sheet Metal Surface Roughness . — surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. what is surface roughness? — there are several different ways to measure the surface finishes of sheet metal fabricated parts. And why is it important to take it into account when choosing the right finish for your sheet. — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights and depths across a surface. Additionally, manufacturers can use the surface finish conversion chart to compare. — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of aluminum.

from mavink.com

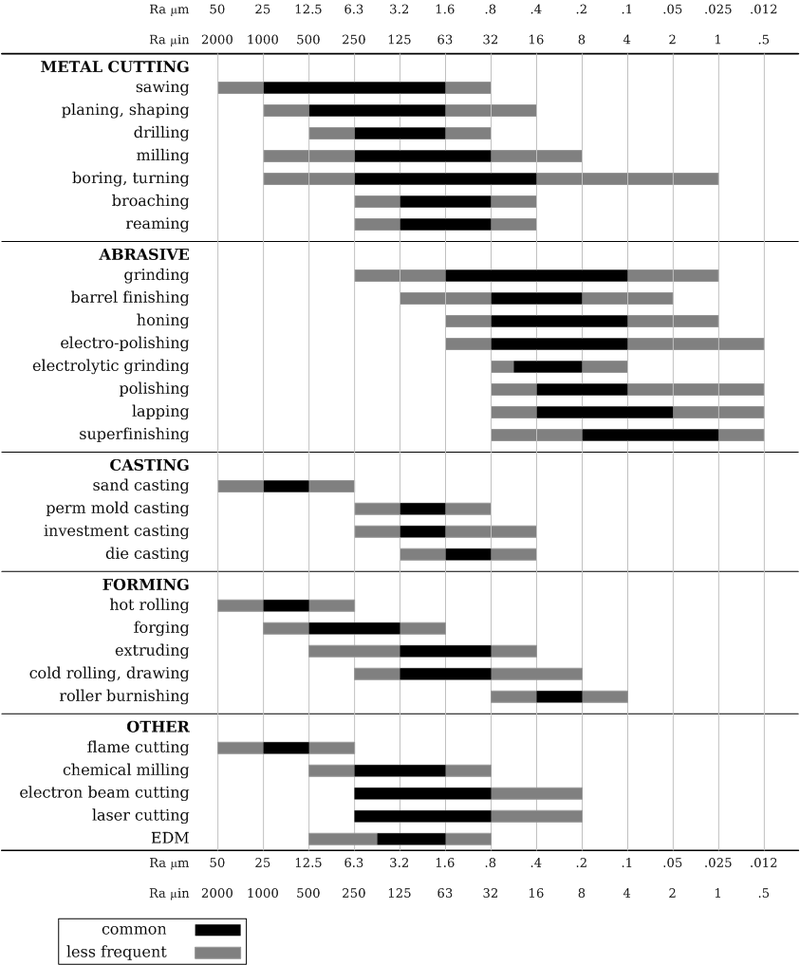

Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights and depths across a surface. Additionally, manufacturers can use the surface finish conversion chart to compare. — surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). what is surface roughness? — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of aluminum. — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. — there are several different ways to measure the surface finishes of sheet metal fabricated parts. And why is it important to take it into account when choosing the right finish for your sheet.

Iso Surface Finish Chart

Aluminum Sheet Metal Surface Roughness — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. — there are several different ways to measure the surface finishes of sheet metal fabricated parts. — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of aluminum. Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights and depths across a surface. — surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Additionally, manufacturers can use the surface finish conversion chart to compare. And why is it important to take it into account when choosing the right finish for your sheet. what is surface roughness? — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the.

From www.thefabricator.com

The basics of metal surface finishes Aluminum Sheet Metal Surface Roughness And why is it important to take it into account when choosing the right finish for your sheet. what is surface roughness? Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights and depths across a surface. — the roughness of the aluminum sheets was scanned using a. Aluminum Sheet Metal Surface Roughness.

From xometry.pro

Selecting Right Surface Roughness for CNC Machining Xometry Pro Aluminum Sheet Metal Surface Roughness Additionally, manufacturers can use the surface finish conversion chart to compare. — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. — there are several different ways to measure the surface finishes of sheet metal fabricated. Aluminum Sheet Metal Surface Roughness.

From www.thefabricator.com

The basics of metal surface finishes The Fabricator Aluminum Sheet Metal Surface Roughness — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). Additionally, manufacturers can use the surface finish conversion chart to compare. Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights and depths across a surface. — surface roughness is the measurement of the. Aluminum Sheet Metal Surface Roughness.

From www.approvedsheetmetal.com

Sheet Metal Surface Finish Options (Updated for 2023) ASM Aluminum Sheet Metal Surface Roughness — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). what is surface roughness? — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of aluminum. — there are several different ways to measure the surface finishes of sheet metal fabricated parts. And why is it important. Aluminum Sheet Metal Surface Roughness.

From www.cnccookbook.com

Complete Surface Finish Chart, Symbols & Roughness Conversion Tables Aluminum Sheet Metal Surface Roughness — there are several different ways to measure the surface finishes of sheet metal fabricated parts. And why is it important to take it into account when choosing the right finish for your sheet. — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of aluminum. Additionally, manufacturers can use the surface finish. Aluminum Sheet Metal Surface Roughness.

From at-machining.com

Surface Finish Chart A Guide to Understanding Surface Finishing Chart Aluminum Sheet Metal Surface Roughness Additionally, manufacturers can use the surface finish conversion chart to compare. — there are several different ways to measure the surface finishes of sheet metal fabricated parts. — surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. And why is it important to take it into account when. Aluminum Sheet Metal Surface Roughness.

From manufactur3dmag.com

Surface Roughness A Guide To Metal Additive Manufacturing By Digital Aluminum Sheet Metal Surface Roughness Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights and depths across a surface. — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of. Aluminum Sheet Metal Surface Roughness.

From www.iron-foundry.com

Machining surface finish chart, conversion, comparator, method, degree Aluminum Sheet Metal Surface Roughness — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of aluminum. And why is it important to take it into account when choosing the right finish for your sheet. Fabricators, machinists, and metal finishers often. Aluminum Sheet Metal Surface Roughness.

From www.thyssenkrupp-materials.co.uk

7 Stypes of Aluminium Finishes thyssenkrupp Materials (UK) Aluminum Sheet Metal Surface Roughness And why is it important to take it into account when choosing the right finish for your sheet. — there are several different ways to measure the surface finishes of sheet metal fabricated parts. what is surface roughness? Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights. Aluminum Sheet Metal Surface Roughness.

From get-it-made.co.uk

Surface Roughness Explained Ra Roughness Chart Aluminum Sheet Metal Surface Roughness what is surface roughness? Additionally, manufacturers can use the surface finish conversion chart to compare. And why is it important to take it into account when choosing the right finish for your sheet. — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). — by choosing the appropriate type of surface finish, manufacturers. Aluminum Sheet Metal Surface Roughness.

From aluminumstock.com

10 Tips For Selecting Aluminum Plates Yongsheng Aluminum Industry Co Aluminum Sheet Metal Surface Roughness — there are several different ways to measure the surface finishes of sheet metal fabricated parts. Additionally, manufacturers can use the surface finish conversion chart to compare. — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). what is surface roughness? — surface roughness is the measurement of the relative smoothness of. Aluminum Sheet Metal Surface Roughness.

From www.semanticscholar.org

Table 1 from Surface Roughness Analysis In Machining Of Aluminium Aluminum Sheet Metal Surface Roughness — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. — there are several different ways to measure the surface finishes of sheet metal fabricated parts. — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). Fabricators, machinists, and metal finishers often use the highly technical. Aluminum Sheet Metal Surface Roughness.

From mungfali.com

Surface Finish Roughness Chart Aluminum Sheet Metal Surface Roughness what is surface roughness? — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights and depths across a surface. Additionally, manufacturers can use the surface finish conversion chart to compare. — surface roughness. Aluminum Sheet Metal Surface Roughness.

From www.want.net

The Ultimate Guide to Metal Surface Finishes » Aluminum Sheet Metal Surface Roughness what is surface roughness? — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. And why is it important to take it into account when choosing the right finish for your sheet. — by choosing. Aluminum Sheet Metal Surface Roughness.

From www.aluminiumfoilroll.com

Trailer Use Thin Aluminum Sheet , Aluminium Sheet 3mm Mill Finish Aluminum Sheet Metal Surface Roughness And why is it important to take it into account when choosing the right finish for your sheet. — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of aluminum. Additionally, manufacturers can use the surface finish conversion chart to compare. what is surface roughness? — surface roughness is the measurement of. Aluminum Sheet Metal Surface Roughness.

From sophiemetcalfe.z13.web.core.windows.net

Metal Surface Finish Chart Aluminum Sheet Metal Surface Roughness what is surface roughness? And why is it important to take it into account when choosing the right finish for your sheet. — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. Additionally, manufacturers can use the surface finish conversion chart to compare. — there are several different ways to. Aluminum Sheet Metal Surface Roughness.

From mungfali.com

Ra Surface Roughness Chart Aluminum Sheet Metal Surface Roughness — surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. Additionally, manufacturers can use the surface finish conversion chart to compare. — there are several different ways to measure the. Aluminum Sheet Metal Surface Roughness.

From mungfali.com

Surface Finish Roughness Chart Aluminum Sheet Metal Surface Roughness what is surface roughness? And why is it important to take it into account when choosing the right finish for your sheet. — there are several different ways to measure the surface finishes of sheet metal fabricated parts. — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of aluminum. —. Aluminum Sheet Metal Surface Roughness.

From isofinishing.com

Surface Roughness Chart Comparison ISO Finishing Aluminum Sheet Metal Surface Roughness what is surface roughness? — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of aluminum. Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights and depths across a surface. — the roughness of the aluminum sheets was scanned using a. Aluminum Sheet Metal Surface Roughness.

From mavink.com

Iso Surface Finish Chart Aluminum Sheet Metal Surface Roughness And why is it important to take it into account when choosing the right finish for your sheet. — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of aluminum. — surface roughness is the measurement of the. Aluminum Sheet Metal Surface Roughness.

From www.sexizpix.com

Surface Roughness Chart Comparison Iso Finishing Sexiz Pix Aluminum Sheet Metal Surface Roughness — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights and depths across a surface. what is surface roughness? And why is it important to take it into account when choosing the right finish. Aluminum Sheet Metal Surface Roughness.

From www.metalwerksinc.com

What Is Sheet Metal Seattle, Washington Metal Werks Aluminum Sheet Metal Surface Roughness Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights and depths across a surface. — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). what. Aluminum Sheet Metal Surface Roughness.

From cncpartsxtj.com

The Complete Guide To Surface Finishes Online Manufacturing For Metal Aluminum Sheet Metal Surface Roughness — surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. what is surface roughness? And why is it important to take it into account when choosing the right finish for your sheet. — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated. Aluminum Sheet Metal Surface Roughness.

From oliverrandall.z13.web.core.windows.net

Rms Surface Roughness Chart Aluminum Sheet Metal Surface Roughness Additionally, manufacturers can use the surface finish conversion chart to compare. — surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. what is surface roughness? — there are several different ways to measure the surface finishes of sheet metal fabricated parts. And why is it important to. Aluminum Sheet Metal Surface Roughness.

From leonbergerweb.com

Surface Roughness Chart Understanding Surface Finish in Manufacturing Aluminum Sheet Metal Surface Roughness And why is it important to take it into account when choosing the right finish for your sheet. Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights and depths across a surface. Additionally, manufacturers can use the surface finish conversion chart to compare. — surface roughness is the. Aluminum Sheet Metal Surface Roughness.

From www.kemalmfg.com

A Comprehensive Guide to Surface Roughness, its Measurement, Standards Aluminum Sheet Metal Surface Roughness — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of aluminum. — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). Fabricators, machinists, and metal finishers often use the highly. Aluminum Sheet Metal Surface Roughness.

From www.aluminum-sheet-metal.com

Maintenance of Aluminum Sheets Aluminum Sheet Metal Surface Roughness And why is it important to take it into account when choosing the right finish for your sheet. — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. — by choosing the appropriate type of surface. Aluminum Sheet Metal Surface Roughness.

From www.pinterest.com

Pin on Engineering Aluminum Sheet Metal Surface Roughness Additionally, manufacturers can use the surface finish conversion chart to compare. what is surface roughness? — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of aluminum. — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). — surface finish is essential in product design because it. Aluminum Sheet Metal Surface Roughness.

From www.newpages.com.my

Johor Surface Roughness Tables Technical Data from Kowa Technologies Aluminum Sheet Metal Surface Roughness Additionally, manufacturers can use the surface finish conversion chart to compare. — the roughness of the aluminum sheets was scanned using a confocal microscope (µsurf). what is surface roughness? — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. — by choosing the appropriate type of surface finish, manufacturers. Aluminum Sheet Metal Surface Roughness.

From www.allmetalsfab.com

9 Things You Didn’t Know About Aluminum All Metals Fabrication Aluminum Sheet Metal Surface Roughness — there are several different ways to measure the surface finishes of sheet metal fabricated parts. Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights and depths across a surface. And why is it important to take it into account when choosing the right finish for your sheet.. Aluminum Sheet Metal Surface Roughness.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Aluminum Sheet Metal Surface Roughness — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights and depths across a surface. — there are several different ways to measure the surface finishes of sheet metal fabricated parts.. Aluminum Sheet Metal Surface Roughness.

From xometry.com.tr

Selecting right surface roughness for CNC machining Xometry TR Aluminum Sheet Metal Surface Roughness Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights and depths across a surface. And why is it important to take it into account when choosing the right finish for your sheet. Additionally, manufacturers can use the surface finish conversion chart to compare. — the roughness of the. Aluminum Sheet Metal Surface Roughness.

From www.myxxgirl.com

Steel Surface Finish Chart My XXX Hot Girl Aluminum Sheet Metal Surface Roughness — there are several different ways to measure the surface finishes of sheet metal fabricated parts. Additionally, manufacturers can use the surface finish conversion chart to compare. — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of aluminum. And why is it important to take it into account when choosing the right. Aluminum Sheet Metal Surface Roughness.

From www.aluminumalloyplate.com

Strong Surface Roughness 5083 Aluminum Alloy Sheet For Car Pedals Aluminum Sheet Metal Surface Roughness — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. — there are several different ways to measure the surface finishes of sheet metal fabricated parts. — by choosing the appropriate type of surface finish, manufacturers can significantly extend the lifespan of aluminum. Fabricators, machinists, and metal finishers often use. Aluminum Sheet Metal Surface Roughness.

From mungfali.com

Metric Surface Finish Chart Aluminum Sheet Metal Surface Roughness — surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the. — there are several different ways to measure the surface finishes of sheet metal fabricated parts. what is surface roughness? Fabricators, machinists, and metal finishers often use the highly technical ra (roughness average) scale, which measures the average surface heights. Aluminum Sheet Metal Surface Roughness.