Component Backflush . Backflush is an inventory management technique used primarily in manufacturing to simplify the process of tracking materials and components. Backflushing is an inventory management method used in manufacturing processes, and its key components involve a systematic approach to material tracking and deduction. If a component is set as backflush, then this component will be posted within the confirmation. Here are the key components of backflushing: Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the production. Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished.

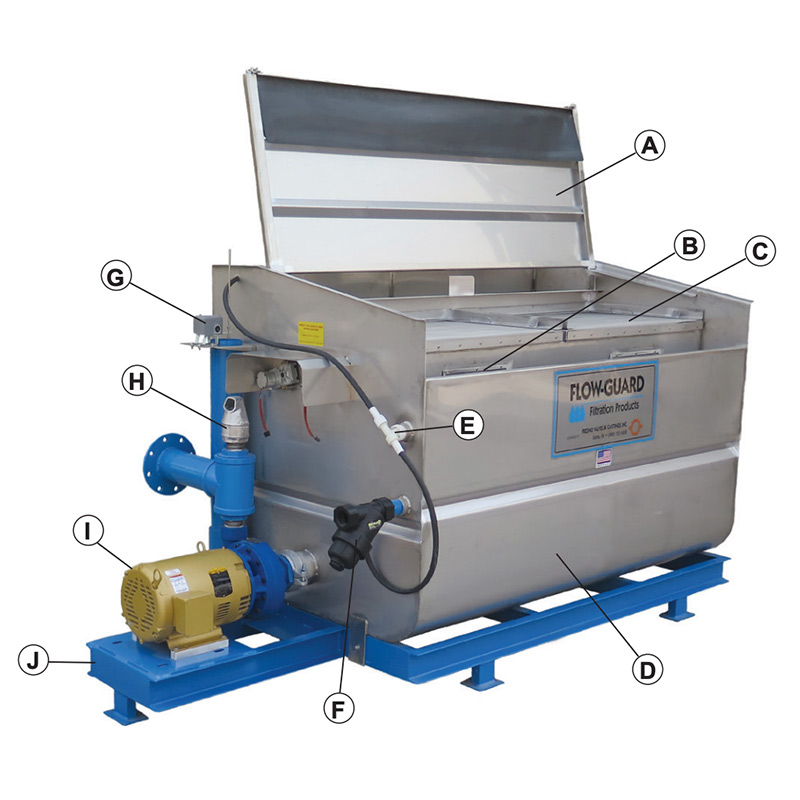

from calwestrain.com

From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the production. Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished. If a component is set as backflush, then this component will be posted within the confirmation. Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. Backflush is an inventory management technique used primarily in manufacturing to simplify the process of tracking materials and components. Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. Backflushing is an inventory management method used in manufacturing processes, and its key components involve a systematic approach to material tracking and deduction. Here are the key components of backflushing:

Backflush Recycle System Filters CalWest Rain Inc

Component Backflush From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the production. From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the production. Backflushing is an inventory management method used in manufacturing processes, and its key components involve a systematic approach to material tracking and deduction. Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. Backflush is an inventory management technique used primarily in manufacturing to simplify the process of tracking materials and components. If a component is set as backflush, then this component will be posted within the confirmation. Here are the key components of backflushing: Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished.

From www.rklesolutions.com

How to Make Backflush Material Issue Process Simpler in Sage X3 Component Backflush Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. Here are the key components of backflushing: Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. If a component is set as backflush, then this component will be posted. Component Backflush.

From www.myalcon.com

Grieshaber Advanced Backflush Soft Tip DSP THIS IS FLUIDITY Alcon Component Backflush From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the production. Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished. Here are the key components of backflushing: Backflushing is a manufacturing process in which finished products are. Component Backflush.

From vincentcorp.com

Backflush System Operating Hints Vincent Corp Component Backflush If a component is set as backflush, then this component will be posted within the confirmation. Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. Backflushing is a term used to describe a process that takes an item after it has been produced but before it is. Component Backflush.

From vincentcorp.com

Backflush System Operating Hints Vincent Corp Component Backflush Backflush is an inventory management technique used primarily in manufacturing to simplify the process of tracking materials and components. Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. If. Component Backflush.

From www.brightworkresearch.com

How to Best Perform Backflushing in SAP ERP Brightwork Research Component Backflush Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished. Here are the key components of backflushing: From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the production. Key component backflushing information will be transferred from mes to. Component Backflush.

From solidswiki.com

Backflush Filters SolidsWiki Component Backflush Backflush is an inventory management technique used primarily in manufacturing to simplify the process of tracking materials and components. Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. Backflushing. Component Backflush.

From calwestrain.com

Backflush Recycle System Filters CalWest Rain Inc Component Backflush Backflush is an inventory management technique used primarily in manufacturing to simplify the process of tracking materials and components. Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished.. Component Backflush.

From www.slideserve.com

PPT Valveless “LIVE” Column Switching PowerPoint Presentation, free Component Backflush Backflush is an inventory management technique used primarily in manufacturing to simplify the process of tracking materials and components. From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the production. Backflushing is an inventory management method used in manufacturing processes, and its key components involve a systematic approach to material tracking. Component Backflush.

From support.ritesoft.com

riteSCAN 8 Backflush Guide riteSOFT Support Component Backflush Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished. From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the production. Key component backflushing information will be transferred from mes to sap ecc, and the key components are. Component Backflush.

From blog.sepscience.com

Post Column Backflush Component Backflush If a component is set as backflush, then this component will be posted within the confirmation. From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the production. Backflush is an inventory management technique used primarily in manufacturing to simplify the process of tracking materials and components. Backflushing is a term used. Component Backflush.

From mixing.com

Backflush Systems Component Backflush Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished. Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. If a component is set as backflush, then this component will be posted within the. Component Backflush.

From www.watco-group.co

Strategies to Achieve Flow Reversal for Back Flushing Heat Exchangers Component Backflush Backflush is an inventory management technique used primarily in manufacturing to simplify the process of tracking materials and components. If a component is set as backflush, then this component will be posted within the confirmation. Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. Backflushing is an inventory management method used. Component Backflush.

From help.sap.com

SAP Help Portal Component Backflush Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. Backflush is an inventory management technique used primarily in manufacturing to simplify the process of tracking materials and components. If a component is set as backflush, then this component will be posted within the confirmation. Backflushing is a term used to describe. Component Backflush.

From www.youtube.com

Loop sampling with backflush of pre column to vent with a diaphragm Component Backflush Backflushing is an inventory management method used in manufacturing processes, and its key components involve a systematic approach to material tracking and deduction. Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. Backflush is an inventory management technique used primarily in manufacturing to simplify the process of. Component Backflush.

From www.researchgate.net

Backflush algorithm. Şekil 4. Geri yıkama algoritması. Download Component Backflush Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. Backflushing is an inventory management method used in manufacturing processes, and its key components involve a systematic approach to material tracking and deduction. Here are the key components of backflushing: From a functional perspective, backflushing automates the issuing of material to the. Component Backflush.

From www.tdm.it

Backflush TDM Total Dairy Management Component Backflush Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished. Here are the key components of backflushing: From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the production. Backflushing is an inventory management method used in manufacturing processes,. Component Backflush.

From blog.csdn.net

WIP Component Pick Release_backflush transfer_田攀的博客CSDN博客 Component Backflush Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished. If a component is set as backflush, then this component will be posted within the. Component Backflush.

From www.netafimusa.com

Backflush Valves Netafim USA Component Backflush Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished. Here are the key components of backflushing: From a functional perspective, backflushing automates the issuing. Component Backflush.

From blog.sepscience.com

Coated PreColumn Backflush Component Backflush Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. Here are the key components of backflushing: Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. Backflushing is an inventory management method used in manufacturing processes, and its key. Component Backflush.

From www.programmersought.com

Oracle WIP Backflush Programmer Sought Component Backflush Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished. Backflush is an inventory management technique used primarily in manufacturing to simplify the process of. Component Backflush.

From nguyennk.home.blog

Epicor Material Backflush Flow Nguyễn Khôi Nguyên Component Backflush If a component is set as backflush, then this component will be posted within the confirmation. Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. Backflush is an inventory management technique used primarily in manufacturing to simplify the process of tracking materials and components. Backflushing is an. Component Backflush.

From www.chemlys.com

The Backflush, what is it for, how does it work ? CHEMLYS Component Backflush Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished. Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. Key component backflushing information will be transferred from mes to sap ecc, and the key. Component Backflush.

From www.pinterest.com

Backflush Bill of materials, Manufacturing, Solutions Component Backflush Backflushing is an inventory management method used in manufacturing processes, and its key components involve a systematic approach to material tracking and deduction. If a component is set as backflush, then this component will be posted within the confirmation. Backflush is an inventory management technique used primarily in manufacturing to simplify the process of tracking materials and components. Backflushing is. Component Backflush.

From ordercircle.com

What is Backflush? Detailed Guide OrderCircle Component Backflush Backflushing is an inventory management method used in manufacturing processes, and its key components involve a systematic approach to material tracking and deduction. Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. Here are the key components of backflushing: Backflush is an inventory management technique used primarily in manufacturing to simplify. Component Backflush.

From www.atlagri.com

Backflush System Component Backflush Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished. Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. Backflushing is an inventory management method used in manufacturing processes, and its key components involve. Component Backflush.

From mixing.com

Backflush Systems Component Backflush From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the production. Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished. Backflushing is a manufacturing process in which finished products are flushed out of a system or machine,. Component Backflush.

From www.itread01.com

SAP REM Backflush 重複製造報工反衝 IT閱讀 Component Backflush From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the production. If a component is set as backflush, then this component will be posted within the confirmation. Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. Backflush is an inventory management technique. Component Backflush.

From www.machineryoffers.com

3Way 2chamber Backflush Control Valve for Backflushing Filtration Component Backflush Here are the key components of backflushing: Backflush is an inventory management technique used primarily in manufacturing to simplify the process of tracking materials and components. Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. Backflushing is an inventory management method used in manufacturing processes, and its key components involve a. Component Backflush.

From mixing.com

Backflush Systems Component Backflush Backflush is an inventory management technique used primarily in manufacturing to simplify the process of tracking materials and components. Backflushing is an inventory management method used in manufacturing processes, and its key components involve a systematic approach to material tracking and deduction. If a component is set as backflush, then this component will be posted within the confirmation. Here are. Component Backflush.

From craftcoffeespot.com

How To Backflush An Espresso Machine Component Backflush Backflushing is a term used to describe a process that takes an item after it has been produced but before it is finished. Backflushing is an inventory management method used in manufacturing processes, and its key components involve a systematic approach to material tracking and deduction. Here are the key components of backflushing: Backflushing is a manufacturing process in which. Component Backflush.

From www.olofsimren.com

Simple Production with Generic Backflush Routing in Microsoft Dynamics Component Backflush Backflushing is an inventory management method used in manufacturing processes, and its key components involve a systematic approach to material tracking and deduction. Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the. Component Backflush.

From www.olofsimren.com

Simple Production with Generic Backflush Routing in Microsoft Dynamics Component Backflush From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the production. Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. Backflushing is an inventory management method used in manufacturing processes, and its key components involve a systematic approach to material tracking and. Component Backflush.

From community.agilent.com

Backflush EPC module Forum Gas Chromatography Agilent Community Component Backflush Backflushing is an inventory management method used in manufacturing processes, and its key components involve a systematic approach to material tracking and deduction. Key component backflushing information will be transferred from mes to sap ecc, and the key components are maintained. If a component is set as backflush, then this component will be posted within the confirmation. Backflushing is a. Component Backflush.

From www.chemlys.com

The Backflush, what is it for, how does it work ? CHEMLYS Component Backflush From a functional perspective, backflushing automates the issuing of material to the manufacturing floor upon the completion of the production. Backflushing is an inventory management method used in manufacturing processes, and its key components involve a systematic approach to material tracking and deduction. Backflushing is a term used to describe a process that takes an item after it has been. Component Backflush.

From www.neoperl.com

Automatic Backflush Component Backflush Here are the key components of backflushing: Backflushing is a manufacturing process in which finished products are flushed out of a system or machine, leaving behind only the waste. If a component is set as backflush, then this component will be posted within the confirmation. Key component backflushing information will be transferred from mes to sap ecc, and the key. Component Backflush.