Cutting Angles On Round Pipe . Find out the formulas, steps, and outputs for angle of cut, pipe thickness, radius, and pressure drop. First, figure out your angle. Easy trick to cut 90° degree angle round pipe. The welder never told before #diy #tricksvisit my welding projects. What if you want to cut exactly the same angle on the other end to,. Now you have at least one. Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. Secure the tube horizontally in a custom built jig, cut a 22.5 degree angle on one side down to the back. Kevin has a piece of pipe with a 45 degree angle cut on one end. You can take a straight edge, line it up on the pipe you’re going to weld to. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od (like using a height gage on a micro.

from www.pipingengineer.org

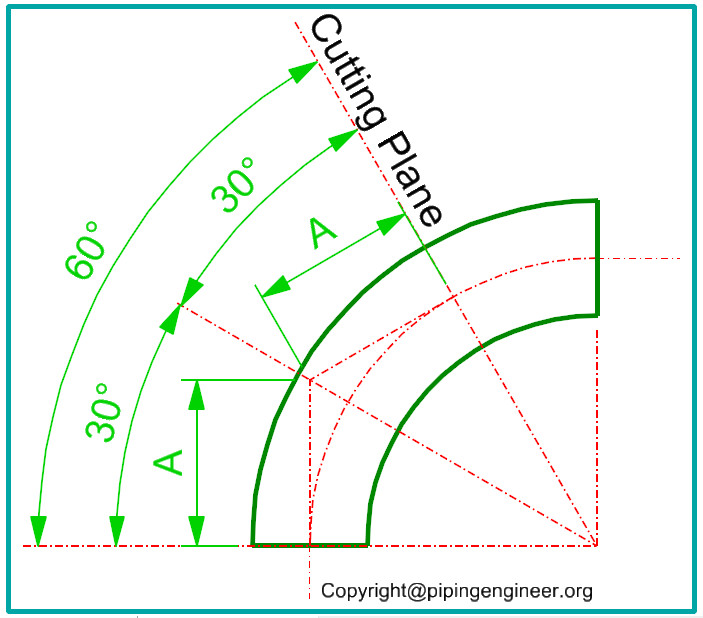

Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od (like using a height gage on a micro. You can take a straight edge, line it up on the pipe you’re going to weld to. Kevin has a piece of pipe with a 45 degree angle cut on one end. Now you have at least one. First, figure out your angle. Easy trick to cut 90° degree angle round pipe. Secure the tube horizontally in a custom built jig, cut a 22.5 degree angle on one side down to the back. What if you want to cut exactly the same angle on the other end to,. The welder never told before #diy #tricksvisit my welding projects.

Pipe Elbow Center Calculation The Piping Engineering World

Cutting Angles On Round Pipe First, figure out your angle. What if you want to cut exactly the same angle on the other end to,. You can take a straight edge, line it up on the pipe you’re going to weld to. Now you have at least one. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od (like using a height gage on a micro. Find out the formulas, steps, and outputs for angle of cut, pipe thickness, radius, and pressure drop. First, figure out your angle. The welder never told before #diy #tricksvisit my welding projects. Secure the tube horizontally in a custom built jig, cut a 22.5 degree angle on one side down to the back. Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. Easy trick to cut 90° degree angle round pipe. Kevin has a piece of pipe with a 45 degree angle cut on one end.

From www.youtube.com

easy way to cut 45 degree angle round pipe without a seated grinder YouTube Cutting Angles On Round Pipe Secure the tube horizontally in a custom built jig, cut a 22.5 degree angle on one side down to the back. The welder never told before #diy #tricksvisit my welding projects. Kevin has a piece of pipe with a 45 degree angle cut on one end. What if you want to cut exactly the same angle on the other end. Cutting Angles On Round Pipe.

From www.appliedalloys.com.au

Standard Pipe Bends Dimensions Applied Alloys International Cutting Angles On Round Pipe The welder never told before #diy #tricksvisit my welding projects. You can take a straight edge, line it up on the pipe you’re going to weld to. What if you want to cut exactly the same angle on the other end to,. Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. I would. Cutting Angles On Round Pipe.

From www.artofit.org

New trick to cut 90 degree angle round pipe the welder never told before pipecutting Artofit Cutting Angles On Round Pipe The welder never told before #diy #tricksvisit my welding projects. Kevin has a piece of pipe with a 45 degree angle cut on one end. Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. Secure the tube horizontally in a custom built jig, cut a 22.5 degree angle on one side down to. Cutting Angles On Round Pipe.

From waterwelders.com

How to Bevel Pipe for Welding A Pipe Beveling Guide WaterWelders Cutting Angles On Round Pipe Find out the formulas, steps, and outputs for angle of cut, pipe thickness, radius, and pressure drop. Easy trick to cut 90° degree angle round pipe. Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. You can take a straight edge, line it up on the pipe you’re going to weld to. Secure. Cutting Angles On Round Pipe.

From www.youtube.com

Best Way to Cut Stainless Steel Pipe With Angle Grinder YouTube Cutting Angles On Round Pipe Kevin has a piece of pipe with a 45 degree angle cut on one end. Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od (like. Cutting Angles On Round Pipe.

From astand.com.au

Pie Cut Calculator for Exhaust Tube Astand Cutting Angles On Round Pipe I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od (like using a height gage on a micro. The welder never told before #diy #tricksvisit my welding projects. First, figure out your angle. Easy trick to cut 90° degree angle round pipe.. Cutting Angles On Round Pipe.

From www.youtube.com

new trick to cut 90 degree angle round pipe the welder never told before pipecutting YouTube Cutting Angles On Round Pipe You can take a straight edge, line it up on the pipe you’re going to weld to. Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. Now you have at least one. Secure the tube horizontally in a custom built jig, cut a 22.5 degree angle on one side down to the back.. Cutting Angles On Round Pipe.

From mungfali.com

Miter Angles Chart Cutting Angles On Round Pipe First, figure out your angle. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od (like using a height gage on a micro. Easy trick to cut 90° degree angle round pipe. Secure the tube horizontally in a custom built jig, cut. Cutting Angles On Round Pipe.

From www.youtube.com

new trick to cut 90 degree angle round pipe the welder never told before pipecutting YouTube Cutting Angles On Round Pipe Secure the tube horizontally in a custom built jig, cut a 22.5 degree angle on one side down to the back. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od (like using a height gage on a micro. Easy trick to. Cutting Angles On Round Pipe.

From www.youtube.com

how to cut round tube at 45 degrees Cut 45 Degree Angle Pipe homemade tools YouTube Cutting Angles On Round Pipe First, figure out your angle. You can take a straight edge, line it up on the pipe you’re going to weld to. Find out the formulas, steps, and outputs for angle of cut, pipe thickness, radius, and pressure drop. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base,. Cutting Angles On Round Pipe.

From www.youtube.com

Angles on Round Pipe!! TIP YouTube Cutting Angles On Round Pipe First, figure out your angle. Kevin has a piece of pipe with a 45 degree angle cut on one end. What if you want to cut exactly the same angle on the other end to,. Now you have at least one. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a. Cutting Angles On Round Pipe.

From fasrcurrent118.weebly.com

Pipe Angle Cutting Patterns fasrcurrent Cutting Angles On Round Pipe Easy trick to cut 90° degree angle round pipe. Now you have at least one. First, figure out your angle. Secure the tube horizontally in a custom built jig, cut a 22.5 degree angle on one side down to the back. Kevin has a piece of pipe with a 45 degree angle cut on one end. The welder never told. Cutting Angles On Round Pipe.

From www.youtube.com

Round Pipe Cutting idea // 45 Degree Angle Cutting YouTube Cutting Angles On Round Pipe You can take a straight edge, line it up on the pipe you’re going to weld to. Easy trick to cut 90° degree angle round pipe. Find out the formulas, steps, and outputs for angle of cut, pipe thickness, radius, and pressure drop. Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. What. Cutting Angles On Round Pipe.

From letsfab.in

Miter Bend Calculator for Flat Pattern Fabrication Layout Cutting Angles On Round Pipe Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. Kevin has a piece of pipe with a 45 degree angle cut on one end. Now you have at least one. What if you want to cut exactly the same angle on the other end to,. Find out the formulas, steps, and outputs for. Cutting Angles On Round Pipe.

From edu.svet.gob.gt

90 Degree Miter Bend Formula With Pipe To Type Fitter Cutting Angles On Round Pipe Find out the formulas, steps, and outputs for angle of cut, pipe thickness, radius, and pressure drop. Now you have at least one. The welder never told before #diy #tricksvisit my welding projects. Kevin has a piece of pipe with a 45 degree angle cut on one end. Easy trick to cut 90° degree angle round pipe. You can take. Cutting Angles On Round Pipe.

From anglegrinderreviews.com

Top 10 Tips For Cutting Piping With An Angle Grinder Cutting Angles On Round Pipe Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. Find out the formulas, steps, and outputs for angle of cut, pipe thickness, radius, and pressure drop. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's. Cutting Angles On Round Pipe.

From knoppoauto.en.made-in-china.com

Round Tube Rhs Angles and Channels Robotic CNC Pipe Profile Plasma Cutting Machine China CNC Cutting Angles On Round Pipe Kevin has a piece of pipe with a 45 degree angle cut on one end. Find out the formulas, steps, and outputs for angle of cut, pipe thickness, radius, and pressure drop. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od. Cutting Angles On Round Pipe.

From www.williamsburgpediatrics.com

Round Pipe Cutting Idea // 45 Degree Angle Cutting, 54 OFF Cutting Angles On Round Pipe First, figure out your angle. The welder never told before #diy #tricksvisit my welding projects. Now you have at least one. You can take a straight edge, line it up on the pipe you’re going to weld to. What if you want to cut exactly the same angle on the other end to,. Secure the tube horizontally in a custom. Cutting Angles On Round Pipe.

From www.youtube.com

How to cut round ductwork YouTube Cutting Angles On Round Pipe I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od (like using a height gage on a micro. Now you have at least one. Find out the formulas, steps, and outputs for angle of cut, pipe thickness, radius, and pressure drop. The. Cutting Angles On Round Pipe.

From www.youtube.com

Amazing Techniques Of Round Tube Angle Cutting YouTube Cutting Angles On Round Pipe Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. First, figure out your angle. The welder never told before #diy #tricksvisit my welding projects. Easy trick to cut 90° degree angle round pipe. Secure the tube horizontally in a custom built jig, cut a 22.5 degree angle on one side down to the. Cutting Angles On Round Pipe.

From old.sermitsiaq.ag

45 Degree Pipe Cutting Template Cutting Angles On Round Pipe Now you have at least one. Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. The welder never told before #diy #tricksvisit my welding projects. Easy trick to cut 90° degree angle round pipe. What if you want to cut exactly the same angle on the other end to,. Secure the tube horizontally. Cutting Angles On Round Pipe.

From edu.svet.gob.gt

90 Degree Miter Bend Formula With Pipe To Type Fitter Cutting Angles On Round Pipe Now you have at least one. Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. What if you want to cut exactly the same angle on the other end to,. Find out the formulas, steps, and outputs for angle of cut, pipe thickness, radius, and pressure drop. First, figure out your angle. Easy. Cutting Angles On Round Pipe.

From www.youtube.com

How to cut 45 degrees (pipe notching) YouTube Cutting Angles On Round Pipe Kevin has a piece of pipe with a 45 degree angle cut on one end. First, figure out your angle. Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. What if you want to cut exactly the same angle on the other end to,. Secure the tube horizontally in a custom built jig,. Cutting Angles On Round Pipe.

From www.youtube.com

CUTTING DIFFERENT ANGLES OF ANGLE BARbhamzkievlog5624 YouTube Cutting Angles On Round Pipe First, figure out your angle. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od (like using a height gage on a micro. Secure the tube horizontally in a custom built jig, cut a 22.5 degree angle on one side down to. Cutting Angles On Round Pipe.

From old.sermitsiaq.ag

Pipe Angle Cutting Template Cutting Angles On Round Pipe I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od (like using a height gage on a micro. Secure the tube horizontally in a custom built jig, cut a 22.5 degree angle on one side down to the back. What if you. Cutting Angles On Round Pipe.

From thetoolscout.com

How To Use An Angle Grinder To Smooth Concrete Cutting Angles On Round Pipe I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od (like using a height gage on a micro. You can take a straight edge, line it up on the pipe you’re going to weld to. Learn how to design miter elbows or. Cutting Angles On Round Pipe.

From www.youtube.com

HOW TO CUT METAL PIPE TO 45° ANGLE ROUND PIPE CUTTING IDEA YouTube Cutting Angles On Round Pipe I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od (like using a height gage on a micro. Find out the formulas, steps, and outputs for angle of cut, pipe thickness, radius, and pressure drop. Easy trick to cut 90° degree angle. Cutting Angles On Round Pipe.

From www.youtube.com

pipe secrets, the easiest trick to cut metal pipes 45 degrees cutting pipe 45 degree YouTube Cutting Angles On Round Pipe Kevin has a piece of pipe with a 45 degree angle cut on one end. Secure the tube horizontally in a custom built jig, cut a 22.5 degree angle on one side down to the back. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle. Cutting Angles On Round Pipe.

From www.youtube.com

How to Cut Pipe Angles Accurately Kevin Caron YouTube Cutting Angles On Round Pipe Easy trick to cut 90° degree angle round pipe. You can take a straight edge, line it up on the pipe you’re going to weld to. The welder never told before #diy #tricksvisit my welding projects. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle. Cutting Angles On Round Pipe.

From www.youtube.com

A smart way to cut a 45° angle round pipe YouTube Cutting Angles On Round Pipe I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od (like using a height gage on a micro. First, figure out your angle. Secure the tube horizontally in a custom built jig, cut a 22.5 degree angle on one side down to. Cutting Angles On Round Pipe.

From www.youtube.com

Simple Cutting idea Of Round Pipe // Cut Round Pipe At 45 Degree Angle YouTube Cutting Angles On Round Pipe First, figure out your angle. Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. The welder never told before #diy #tricksvisit my welding projects. Now you have at least one. You can take a straight edge, line it up on the pipe you’re going to weld to. What if you want to cut. Cutting Angles On Round Pipe.

From fittertraining.com

how to calculate miter cut pipe any degree Fitter training Cutting Angles On Round Pipe Easy trick to cut 90° degree angle round pipe. The welder never told before #diy #tricksvisit my welding projects. Find out the formulas, steps, and outputs for angle of cut, pipe thickness, radius, and pressure drop. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle. Cutting Angles On Round Pipe.

From yvchuanglaser.en.made-in-china.com

Round Tube Rhs Angles and Channels Robotic CNC Pipe Profile Plasma Cutting Machine China Cutting Angles On Round Pipe What if you want to cut exactly the same angle on the other end to,. I would setup a plate at the proper angle, alongside the pipe and, using a long scribe on a flat base, transfer that angle to the pipe's od (like using a height gage on a micro. First, figure out your angle. Learn how to design. Cutting Angles On Round Pipe.

From www.youtube.com

How to Cut Pipe at an Angle Accurately Kevin Caron YouTube Cutting Angles On Round Pipe Kevin has a piece of pipe with a 45 degree angle cut on one end. Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. Now you have at least one. Find out the formulas, steps, and outputs for angle of cut, pipe thickness, radius, and pressure drop. What if you want to cut. Cutting Angles On Round Pipe.

From www.pipingengineer.org

Pipe Elbow Center Calculation The Piping Engineering World Cutting Angles On Round Pipe First, figure out your angle. Learn how to design miter elbows or miter bends for piping systems using asme b31.3 standards. The welder never told before #diy #tricksvisit my welding projects. Easy trick to cut 90° degree angle round pipe. Kevin has a piece of pipe with a 45 degree angle cut on one end. I would setup a plate. Cutting Angles On Round Pipe.