Colour Coding Cleaning Equipment . to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. here are seven benefits: By assigning specific colours to different cleaning tools colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and perhaps one for drains.

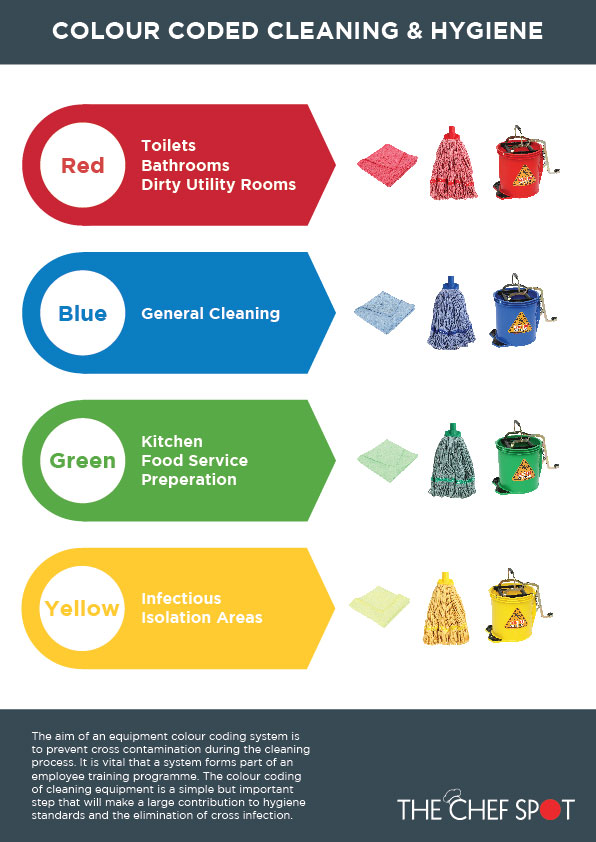

from www.chefspot.com.au

to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and perhaps one for drains. here are seven benefits: The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. By assigning specific colours to different cleaning tools

Cleaning & Hygiene Colour Coded System Chef Spot Australia

Colour Coding Cleaning Equipment The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and perhaps one for drains. here are seven benefits: By assigning specific colours to different cleaning tools colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that.

From blog.bunzlchs.com

Colour code your cleaning to prevent cross contamination BUNZL Colour Coding Cleaning Equipment here are seven benefits: At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and perhaps one for drains. to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. colour coding systems. Colour Coding Cleaning Equipment.

From www.applesupply.ca

Use the Colour Code System to avoid crosscontamination in your Colour Coding Cleaning Equipment at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. By assigning specific colours to different cleaning tools The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. to colour code your cleaning equipment is a simple,. Colour Coding Cleaning Equipment.

From www.hanleys.com.au

Commercial Colour Coding Practices Hanleys Colour Coding Cleaning Equipment at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and perhaps one for. Colour Coding Cleaning Equipment.

From www.catersigns.co.uk

Colour Coded Staff Guidance Cleaning Equipment Notice Colour Coding Cleaning Equipment here are seven benefits: to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. At a basic level, a facility might have a. Colour Coding Cleaning Equipment.

From www.clenasupplies.co.uk

A guide to colour coding for cleaning equipment Clena Supplies Colour Coding Cleaning Equipment to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and perhaps one for drains. here are seven benefits: By assigning specific colours. Colour Coding Cleaning Equipment.

From www.bradfieldproperty.com

National Colour Coding Bradfield Property Management Ltd Colour Coding Cleaning Equipment The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. By assigning specific colours to different cleaning tools at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. At a basic level, a facility might have a set. Colour Coding Cleaning Equipment.

From www.stainlesscleans.co.uk

Essential Cleaning Material ColourCode Signage A3 Stainlesscleans Colour Coding Cleaning Equipment The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and perhaps one for drains. here are seven benefits: colour coding systems in cleaning are designed. Colour Coding Cleaning Equipment.

From www.cooksmill.co.uk

Colour Coded Cleaning What You Need To Know Cooksmill Colour Coding Cleaning Equipment By assigning specific colours to different cleaning tools here are seven benefits: At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and perhaps one for drains. to colour code your cleaning equipment is a simple, effective and clear way. Colour Coding Cleaning Equipment.

From www.infectionpreventioncontrol.co.uk

National colour coding scheme for General Practice cleaning materials Colour Coding Cleaning Equipment At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and perhaps one for drains. The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. colour coding systems in cleaning are designed to show the risk of. Colour Coding Cleaning Equipment.

From aukhygiene.com

What is colour coding in cleaning? Why is it so important? Colour Coding Cleaning Equipment The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination.. Colour Coding Cleaning Equipment.

From www.monarchbrands.com

ColorCoded Cleaning Systems in 5 Easy Steps Monarch Brands Colour Coding Cleaning Equipment By assigning specific colours to different cleaning tools The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. here are seven benefits: colour coding systems in. Colour Coding Cleaning Equipment.

From www.ipcworldwide.com

THE IMPORTANCE OF COLOUR CODING IN PROFESSIONAL SCHOOL CLEANING IPC Colour Coding Cleaning Equipment By assigning specific colours to different cleaning tools to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. The distinct colour assignments streamline cleaning. Colour Coding Cleaning Equipment.

From www.buzzcateringsupplies.com

Colour Coded Cleaning Guide Colour Coding Cleaning Equipment colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. to colour code your cleaning equipment is a simple, effective and. Colour Coding Cleaning Equipment.

From www.mmcatering.co.uk

Colour coded cleaning system MM Catering Wholesale Colour Coding Cleaning Equipment The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. At a basic level, a facility might have. Colour Coding Cleaning Equipment.

From www.slideserve.com

PPT DETERGENT PowerPoint Presentation, free download ID3101850 Colour Coding Cleaning Equipment at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. here are seven benefits: The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. colour coding systems in cleaning are designed to show the risk of. Colour Coding Cleaning Equipment.

From www.vanguardsv.com

ColorCoded Cleaning Colour Coding Cleaning Equipment colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. The distinct colour assignments streamline cleaning processes, creating a more organised and. Colour Coding Cleaning Equipment.

From www.vrogue.co

Colour Coding Inhaler Colors Chart Custom Colour Codi vrogue.co Colour Coding Cleaning Equipment At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and perhaps one for drains. here are seven benefits: at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to. Colour Coding Cleaning Equipment.

From www.stainlesscleans.co.uk

Hospitality Cleaning Material ColourCode A3 Stainlesscleans Colour Coding Cleaning Equipment The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. By assigning specific colours to different cleaning tools colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination.. Colour Coding Cleaning Equipment.

From cleaningequipmenttefutote.blogspot.com

Cleaning Equipment Cleaning Equipment Colour Coding Colour Coding Cleaning Equipment The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. By assigning specific colours to different cleaning tools here are seven benefits: colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. At a basic level, a facility might have a set of tools used. Colour Coding Cleaning Equipment.

From www.taren.com.au

Taren Cleaning Supplies Colour Coding Colour Coding Cleaning Equipment By assigning specific colours to different cleaning tools colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. here are seven benefits: to colour code your cleaning equipment is a simple, effective and clear. Colour Coding Cleaning Equipment.

From www.slideshare.net

Colour Coding for Cleaning Equipment, food safety, infection control,… Colour Coding Cleaning Equipment The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. here are seven benefits: At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and perhaps one for drains. By assigning specific colours to different cleaning tools. Colour Coding Cleaning Equipment.

From www.vrogue.co

How To Implement A Colour Coded Cleaning System vrogue.co Colour Coding Cleaning Equipment at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. By assigning specific colours to different cleaning tools here are seven benefits: colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way. Colour Coding Cleaning Equipment.

From www.a1hygiene.net

Infection Control & Colour Coding Information Chart A1 Hygiene Colour Coding Cleaning Equipment colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. By assigning specific colours to different cleaning tools to colour code. Colour Coding Cleaning Equipment.

From pura4d.chespackhygiene.com

What Is Colour Coded Cleaning and Why Is It So Important? Colour Coding Cleaning Equipment colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. By assigning specific colours to different cleaning tools at its core, the science behind colour coding is based on the principle. Colour Coding Cleaning Equipment.

From virtueplus.com.au

Colour Coded Cleaning Virtue Plus Colour Coding Cleaning Equipment At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and perhaps one for drains. By assigning specific colours to different cleaning tools here are seven benefits: to colour code your cleaning equipment is a simple, effective and clear way. Colour Coding Cleaning Equipment.

From www.vrogue.co

A Guide To Colour Coding For Cleaning Equipment Clena vrogue.co Colour Coding Cleaning Equipment By assigning specific colours to different cleaning tools to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. here are seven benefits: colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. The distinct colour assignments streamline cleaning processes, creating a. Colour Coding Cleaning Equipment.

From www.ultimaenvironmental.store

Colour Coding for Cleaning Ultima Store Colour Coding Cleaning Equipment colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. At a basic level, a facility might have a set of tools. Colour Coding Cleaning Equipment.

From www.pinterest.com

109 best Cleaning Tips and Tricks images on Pinterest Cleaning hacks Colour Coding Cleaning Equipment By assigning specific colours to different cleaning tools colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and perhaps one for. Colour Coding Cleaning Equipment.

From powerhygiene.com

7 Benefits of Colour Coding in Cleaning & How You Can Use It Colour Coding Cleaning Equipment here are seven benefits: colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. By assigning specific colours to different cleaning tools The distinct colour assignments streamline cleaning processes, creating a. Colour Coding Cleaning Equipment.

From www.buzzcateringsupplies.com

Colour Coded Cleaning Guide Colour Coding Cleaning Equipment By assigning specific colours to different cleaning tools at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. The distinct colour assignments streamline cleaning. Colour Coding Cleaning Equipment.

From www.vrogue.co

A Guide To Colour Coding For Cleaning Equipment Clena vrogue.co Colour Coding Cleaning Equipment By assigning specific colours to different cleaning tools at its core, the science behind colour coding is based on the principle of differentiation, visually segregating areas and equipment to reduce the risk of pathogens spreading. The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. here are seven benefits: to colour code your. Colour Coding Cleaning Equipment.

From ubicaciondepersonas.cdmx.gob.mx

Colour Coded Cleaning System ubicaciondepersonas.cdmx.gob.mx Colour Coding Cleaning Equipment By assigning specific colours to different cleaning tools here are seven benefits: The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. colour coding systems in cleaning are designed to show the risk of contamination and. Colour Coding Cleaning Equipment.

From www.chefspot.com.au

Cleaning & Hygiene Colour Coded System Chef Spot Australia Colour Coding Cleaning Equipment At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and perhaps one for drains. colour coding systems in cleaning are designed to show the risk of contamination and hazards in a way that. By assigning specific colours to different cleaning. Colour Coding Cleaning Equipment.

From capitalcleaningsupplies.weebly.com

The Importance Of Colour Coding Cleaning Equipment. Capital Cleaning Colour Coding Cleaning Equipment to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. here are seven benefits: By assigning specific colours to different cleaning tools At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls, and. Colour Coding Cleaning Equipment.

From www.catersigns.co.uk

Colour Coded Cleaning in Progress Floor Stands Colour Coding Cleaning Equipment The distinct colour assignments streamline cleaning processes, creating a more organised and efficient system. to colour code your cleaning equipment is a simple, effective and clear way to prevent cross contamination. At a basic level, a facility might have a set of tools used for cleaning product contact surfaces, another for product proximity surfaces, one for floors and walls,. Colour Coding Cleaning Equipment.