Linear Actuator Motor Torque Calculation . it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. drag torque can be significant (td) depending on the viscosity of the lubricant. to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. The approach outlined here is a. The speed should be around 0.3 m/s. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. The rms torque requirement predicts whether the motor will work. calculate velocity, reflected inertia, and reflected load at the linear actuator's input. For a first approximation analysis, this can.

from www.firgelliauto.com

calculate velocity, reflected inertia, and reflected load at the linear actuator's input. i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. The rms torque requirement predicts whether the motor will work. The speed should be around 0.3 m/s. The approach outlined here is a. it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. For a first approximation analysis, this can. drag torque can be significant (td) depending on the viscosity of the lubricant.

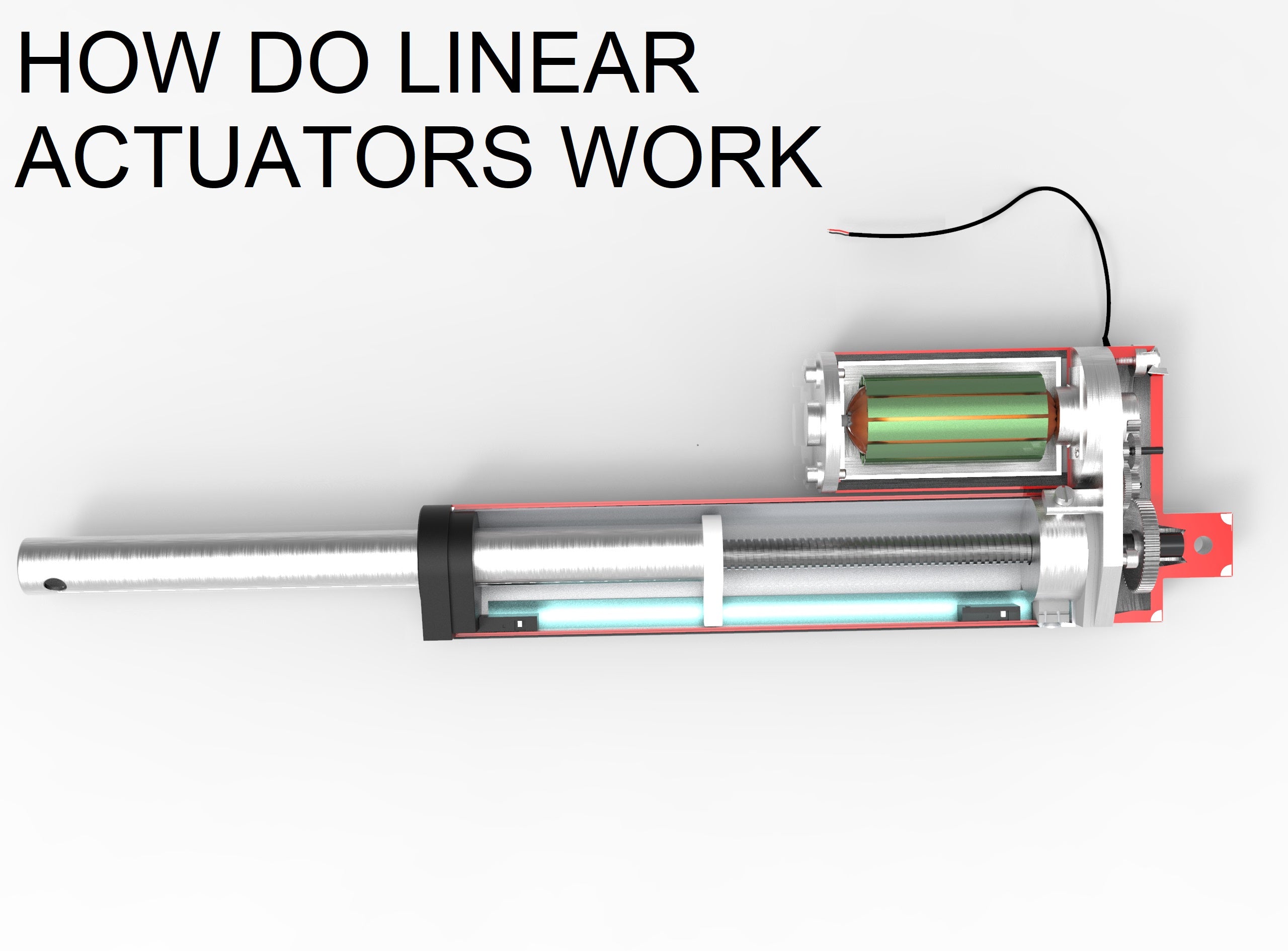

How Does a Linear Actuator Work? FIRGELLI

Linear Actuator Motor Torque Calculation it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. The speed should be around 0.3 m/s. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. The rms torque requirement predicts whether the motor will work. it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. calculate velocity, reflected inertia, and reflected load at the linear actuator's input. For a first approximation analysis, this can. The approach outlined here is a. i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. drag torque can be significant (td) depending on the viscosity of the lubricant. to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration.

From exymazlrx.blob.core.windows.net

Electric Motor Torque Calculator at Trudi Montoya blog Linear Actuator Motor Torque Calculation The speed should be around 0.3 m/s. For a first approximation analysis, this can. to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. The rms torque requirement predicts whether the motor will work. it is useful to determine the output torque needed from a motor. Linear Actuator Motor Torque Calculation.

From www.youtube.com

Optimize Your Linear Actuator Selection with Our Calculator A HowTo Linear Actuator Motor Torque Calculation drag torque can be significant (td) depending on the viscosity of the lubricant. calculate velocity, reflected inertia, and reflected load at the linear actuator's input. For a first approximation analysis, this can. The rms torque requirement predicts whether the motor will work. to determine the required motor drive torque for a belt and pulley system, calculate the. Linear Actuator Motor Torque Calculation.

From blog.orientalmotor.com

Motor Sizing Basics Part 3 How to Calculate Speed, Acceleration Torque Linear Actuator Motor Torque Calculation For a first approximation analysis, this can. The speed should be around 0.3 m/s. it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. The rms torque requirement. Linear Actuator Motor Torque Calculation.

From fyobxuldc.blob.core.windows.net

How To Calculate Torque Of Pneumatic Actuator at Victor Ming blog Linear Actuator Motor Torque Calculation to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. The speed should be around 0.3 m/s. it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. The approach outlined here is a. calculate velocity, reflected inertia,. Linear Actuator Motor Torque Calculation.

From www.chegg.com

Solved For long cost linear actuator application, we are Linear Actuator Motor Torque Calculation to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. calculate velocity, reflected inertia, and reflected load at the linear actuator's input. For a first approximation analysis, this can. The approach outlined here is a. it is useful to determine the output torque needed from. Linear Actuator Motor Torque Calculation.

From www.youtube.com

Torque Equation 3phase Induction Motor Lec33 YouTube Linear Actuator Motor Torque Calculation drag torque can be significant (td) depending on the viscosity of the lubricant. The rms torque requirement predicts whether the motor will work. The approach outlined here is a. calculate velocity, reflected inertia, and reflected load at the linear actuator's input. The speed should be around 0.3 m/s. For a first approximation analysis, this can. i need. Linear Actuator Motor Torque Calculation.

From www.youtube.com

Comparing Linear Servos & Linear Actuators with Kyle and Jason YouTube Linear Actuator Motor Torque Calculation i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. For a first approximation analysis, this can. drag torque can be significant (td) depending on the viscosity of the lubricant. The rms torque requirement predicts whether the motor will work. to determine the required motor drive torque for a. Linear Actuator Motor Torque Calculation.

From www.progressiveautomations.ca

How To Calculate Torque Needed For Linear Actuator Progressive Linear Actuator Motor Torque Calculation For a first approximation analysis, this can. i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. The speed should be around 0.3 m/s. it is useful to determine the output torque. Linear Actuator Motor Torque Calculation.

From www.chegg.com

Solved Find the torque required to accelerate a 200 lb. Linear Actuator Motor Torque Calculation i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. The approach outlined here is a. calculate velocity, reflected inertia, and reflected load at the linear actuator's input. For a first approximation analysis, this can. electrical linear actuator calculations, allowing you to determine the size of the motor from. Linear Actuator Motor Torque Calculation.

From studylib.net

Motor Torque Calculation Linear Actuator Motor Torque Calculation The approach outlined here is a. The speed should be around 0.3 m/s. it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. electrical linear actuator calculations, allowing you to determine. Linear Actuator Motor Torque Calculation.

From giowlldgb.blob.core.windows.net

What Is An Actuator Assembly at Michael Murphy blog Linear Actuator Motor Torque Calculation The approach outlined here is a. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. drag torque can be significant (td) depending on the viscosity of the lubricant. For a first. Linear Actuator Motor Torque Calculation.

From www.firgelliauto.com

How Does a Linear Actuator Work? FIRGELLI Linear Actuator Motor Torque Calculation to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. The approach outlined here is a. drag torque can be significant (td) depending on the viscosity of the lubricant. it is useful to determine the output torque needed from a motor to produce the appropriate. Linear Actuator Motor Torque Calculation.

From bakemotor.org

How To Calculate The Torque Of A Dc Motor Linear Actuator Motor Torque Calculation The approach outlined here is a. i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. electrical linear actuator calculations, allowing you to determine the size of the motor from the. Linear Actuator Motor Torque Calculation.

From www.firgelliauto.com

Components of an Electric Linear Actuator FIRGELLI Linear Actuator Motor Torque Calculation The speed should be around 0.3 m/s. The rms torque requirement predicts whether the motor will work. it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. The approach outlined here is a. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's.. Linear Actuator Motor Torque Calculation.

From hxezcwvgy.blob.core.windows.net

Moto Motion Linear Actuator at Richard Munson blog Linear Actuator Motor Torque Calculation to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. calculate velocity, reflected inertia, and reflected load at the linear actuator's input. i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. For a first approximation analysis,. Linear Actuator Motor Torque Calculation.

From www.youtube.com

How to Use the Linear Actuator Calculator YouTube Linear Actuator Motor Torque Calculation electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. calculate velocity, reflected inertia, and reflected load at the linear actuator's input. drag torque can be significant (td) depending on the viscosity of the lubricant. The approach outlined here is a. to determine the required motor drive torque for. Linear Actuator Motor Torque Calculation.

From www.youtube.com

How to calculate DC motor torque based on supply voltage and speed A Linear Actuator Motor Torque Calculation i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. The approach outlined here is a. it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. The speed should be around 0.3 m/s. drag torque can be significant (td) depending on. Linear Actuator Motor Torque Calculation.

From www.linearmotiontips.com

What’s the use of a force versus linear velocity chart? Linear Actuator Motor Torque Calculation i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. The rms torque requirement predicts whether the motor will work. calculate velocity, reflected inertia, and reflected load at the linear actuator's input.. Linear Actuator Motor Torque Calculation.

From www.pinterest.de

Mechanical Energy, Linear Actuator, Hydraulic, Switches, Valve, Sensor Linear Actuator Motor Torque Calculation to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. The speed should be around 0.3 m/s. The approach outlined here is a. calculate velocity, reflected inertia, and. Linear Actuator Motor Torque Calculation.

From www.progressiveautomations.com

Components Of Electric Linear Actuator Progressive Automations Linear Actuator Motor Torque Calculation to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. The rms torque requirement predicts whether the motor will work. calculate velocity, reflected inertia, and reflected load at the linear actuator's input. it is useful to determine the output torque needed from a motor to. Linear Actuator Motor Torque Calculation.

From www.orientalmotor.com

Method for Calculating Moment Loads on Linear Actuators Linear Actuator Motor Torque Calculation to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. The speed should be around 0.3 m/s. The approach outlined here is a. electrical linear actuator calculations,. Linear Actuator Motor Torque Calculation.

From copyprogramming.com

Motor Armature Torque and Shaft Torque Understanding Torque in DC Motors Linear Actuator Motor Torque Calculation The rms torque requirement predicts whether the motor will work. i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. The approach outlined here is a. calculate velocity, reflected inertia, and reflected load at the linear actuator's input. drag torque can be significant (td) depending on the viscosity of. Linear Actuator Motor Torque Calculation.

From motioncontrol.blog

Linear Actuator Thrust and Speed Calculator Tool Motion Control Linear Actuator Motor Torque Calculation The speed should be around 0.3 m/s. calculate velocity, reflected inertia, and reflected load at the linear actuator's input. For a first approximation analysis, this can. to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. The rms torque requirement predicts whether the motor will work.. Linear Actuator Motor Torque Calculation.

From calculatorcgw.blogspot.com

Rotary Actuator Torque Calculation CALCULATOR CGW Linear Actuator Motor Torque Calculation electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. drag torque can be significant (td) depending on the viscosity of the lubricant. For a first approximation analysis, this can. The rms torque requirement predicts whether the motor will work. i need a motor to move a 500 kg horizontally. Linear Actuator Motor Torque Calculation.

From www.researchgate.net

This linear actuator can be powered by either an AC or DC motor. It Linear Actuator Motor Torque Calculation i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. The speed should be around 0.3 m/s. drag torque can be significant (td) depending on the viscosity of the lubricant. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. For a. Linear Actuator Motor Torque Calculation.

From www.youtube.com

How Linear Actuator Circuits Work YouTube Linear Actuator Motor Torque Calculation i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. The rms torque requirement predicts whether the motor will work. For a first approximation analysis, this can. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. to determine the required motor. Linear Actuator Motor Torque Calculation.

From www.orientalmotor.com

Method for Calculating Moment Loads on Linear Actuators Linear Actuator Motor Torque Calculation The speed should be around 0.3 m/s. drag torque can be significant (td) depending on the viscosity of the lubricant. The rms torque requirement predicts whether the motor will work. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. For a first approximation analysis, this can. The approach outlined here. Linear Actuator Motor Torque Calculation.

From www.electric-linear-actuators.com

The working principle of electric linear actuator Electric Linear Linear Actuator Motor Torque Calculation The rms torque requirement predicts whether the motor will work. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. The approach outlined here is a. calculate velocity, reflected inertia, and reflected. Linear Actuator Motor Torque Calculation.

From www.orientalmotor.com

Method for Calculating Moment Loads on Linear Actuators Linear Actuator Motor Torque Calculation i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. The rms torque requirement predicts whether the motor will work. to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. it is useful to determine the output. Linear Actuator Motor Torque Calculation.

From www.iqsdirectory.com

Linear Actuator What Is It? How Does It Work? Types Of Linear Actuator Motor Torque Calculation The speed should be around 0.3 m/s. For a first approximation analysis, this can. it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. The approach outlined here is a. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. to determine. Linear Actuator Motor Torque Calculation.

From www.slideserve.com

PPT ROBOT DYNAMICS PowerPoint Presentation, free download ID2324839 Linear Actuator Motor Torque Calculation calculate velocity, reflected inertia, and reflected load at the linear actuator's input. For a first approximation analysis, this can. i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. drag torque can be significant (td) depending on the viscosity of the lubricant. to determine the required motor drive. Linear Actuator Motor Torque Calculation.

From bakemotor.org

How To Calculate Stall Torque Of A Dc Motor Linear Actuator Motor Torque Calculation The rms torque requirement predicts whether the motor will work. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's. i need a motor to move a 500 kg horizontally (linear motion), where the friction constant is 0.8. The speed should be around 0.3 m/s. The approach outlined here is a.. Linear Actuator Motor Torque Calculation.

From calculatorshub.net

Linear Actuator Position Calculator Online Linear Actuator Motor Torque Calculation The rms torque requirement predicts whether the motor will work. to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. The speed should be around 0.3 m/s. . Linear Actuator Motor Torque Calculation.

From fyobxuldc.blob.core.windows.net

How To Calculate Torque Of Pneumatic Actuator at Victor Ming blog Linear Actuator Motor Torque Calculation to determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. electrical linear actuator calculations, allowing you to determine the size of the motor from the motor manufacturer's.. Linear Actuator Motor Torque Calculation.

From www.linearmotiontips.com

Applications for hybrid stepper motor linear actuators Linear Actuator Motor Torque Calculation The speed should be around 0.3 m/s. drag torque can be significant (td) depending on the viscosity of the lubricant. it is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. The rms torque requirement predicts whether the motor will work. The approach outlined here is a. For a first approximation. Linear Actuator Motor Torque Calculation.