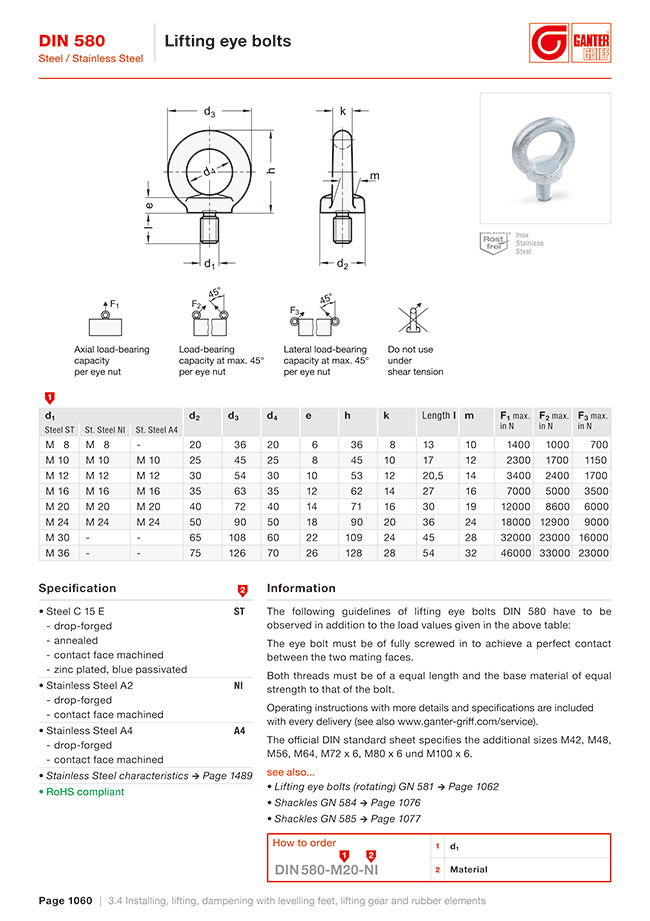

M16 Eye Bolt Lifting Capacity . Eyebolts under m12 are not recommended for lifting. However, at a 15 degree. The eye bolt must be of fully screwed in to achieve a perfect. The length of the thread of the assembly hole. Various sizes from m6 to m80;. Shown at 0° (vertical) angle of lift. For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle). Capacity applies to the eye nut only. Lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in plain finishing d1 pitch d2 d3 d4 h l m6 1.0. The use of din 580 lifting eye bolts must take place under the following conditions: The stud or bolt you use will. 316 stainless steel are the most corrosion resistant eye nuts. Din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load. The following guidelines of lifting eye bolts din 580 have to be observed in addition to the load values given in the above table:

from mungfali.com

The eye bolt must be of fully screwed in to achieve a perfect. Shown at 0° (vertical) angle of lift. However, at a 15 degree. The length of the thread of the assembly hole. For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle). 316 stainless steel are the most corrosion resistant eye nuts. The use of din 580 lifting eye bolts must take place under the following conditions: Lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in plain finishing d1 pitch d2 d3 d4 h l m6 1.0. The stud or bolt you use will. The following guidelines of lifting eye bolts din 580 have to be observed in addition to the load values given in the above table:

Eye Bolt Load Chart

M16 Eye Bolt Lifting Capacity Din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load. However, at a 15 degree. Capacity applies to the eye nut only. The use of din 580 lifting eye bolts must take place under the following conditions: Shown at 0° (vertical) angle of lift. The stud or bolt you use will. The following guidelines of lifting eye bolts din 580 have to be observed in addition to the load values given in the above table: Eyebolts under m12 are not recommended for lifting. 316 stainless steel are the most corrosion resistant eye nuts. The eye bolt must be of fully screwed in to achieve a perfect. For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle). Various sizes from m6 to m80;. Lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in plain finishing d1 pitch d2 d3 d4 h l m6 1.0. Din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load. The length of the thread of the assembly hole.

From qdsailrigging.en.made-in-china.com

China M16 and M20 C15e Lifting Eye Bolt Eyebolt China M16 Eye Bolt Lifting Capacity Eyebolts under m12 are not recommended for lifting. For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle). Lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in plain finishing d1 pitch d2 d3 d4 h l m6 1.0. However, at a 15. M16 Eye Bolt Lifting Capacity.

From www.romak.com.au

Lifting Eye Bolt M16 DIN 580 ZP M16 Eye Bolt Lifting Capacity The stud or bolt you use will. Shown at 0° (vertical) angle of lift. The eye bolt must be of fully screwed in to achieve a perfect. The following guidelines of lifting eye bolts din 580 have to be observed in addition to the load values given in the above table: Capacity applies to the eye nut only. The length. M16 Eye Bolt Lifting Capacity.

From www.gsproducts.co.uk

M16 BZP Steel Lifting Eyebolt DIN 580 Eye Bolt GS Products M16 Eye Bolt Lifting Capacity The length of the thread of the assembly hole. The stud or bolt you use will. Eyebolts under m12 are not recommended for lifting. Various sizes from m6 to m80;. The use of din 580 lifting eye bolts must take place under the following conditions: 316 stainless steel are the most corrosion resistant eye nuts. However, at a 15 degree.. M16 Eye Bolt Lifting Capacity.

From miakemp.z13.web.core.windows.net

Eye Bolt Capacity Chart M16 Eye Bolt Lifting Capacity Eyebolts under m12 are not recommended for lifting. The use of din 580 lifting eye bolts must take place under the following conditions: The eye bolt must be of fully screwed in to achieve a perfect. 316 stainless steel are the most corrosion resistant eye nuts. Various sizes from m6 to m80;. Din 580 specification specifies the properties of steel. M16 Eye Bolt Lifting Capacity.

From www.alibaba.com

M16 M25 M30 M32 Grade 8.8 Din580 Galvanized Lifting Eye Bolt Buy M16 Eye Bolt Lifting Capacity The following guidelines of lifting eye bolts din 580 have to be observed in addition to the load values given in the above table: For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle). The use of din 580 lifting eye bolts must take place under the. M16 Eye Bolt Lifting Capacity.

From mungfali.com

Eye Bolt Capacity Chart M16 Eye Bolt Lifting Capacity Din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load. Lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in plain finishing d1 pitch d2 d3 d4 h l m6 1.0. The length of the thread of. M16 Eye Bolt Lifting Capacity.

From scemosystems.fi

M16 shouldered lifting eye bolt W/K G C15 M16 Eye Bolt Lifting Capacity For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle). Lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in plain finishing d1 pitch d2 d3 d4 h l m6 1.0. Din 580 specification specifies the properties of steel and stainless steel eyebolts. M16 Eye Bolt Lifting Capacity.

From www.accu.co.uk

Buy M16 Lifting Eye Bolts (DIN 580) Stainless Steel (A2) Accu M16 Eye Bolt Lifting Capacity Lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in plain finishing d1 pitch d2 d3 d4 h l m6 1.0. For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle). Din 580 specification specifies the properties of steel and stainless steel eyebolts. M16 Eye Bolt Lifting Capacity.

From www.bolts.co.uk

M16 Lifting Eye bolt Eyenut To Din 580 A2 Stainless Steel Hook M16 Eye Bolt Lifting Capacity 316 stainless steel are the most corrosion resistant eye nuts. Various sizes from m6 to m80;. Din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load. The use of din 580 lifting eye bolts must take place under the following conditions:. M16 Eye Bolt Lifting Capacity.

From www.primesupplies.com.au

EYE BOLT, LIFTING, M16 COLLARED DIN580 0.70T Prime Supplies M16 Eye Bolt Lifting Capacity However, at a 15 degree. 316 stainless steel are the most corrosion resistant eye nuts. Eyebolts under m12 are not recommended for lifting. The stud or bolt you use will. The use of din 580 lifting eye bolts must take place under the following conditions: Din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information. M16 Eye Bolt Lifting Capacity.

From www.trailersrus.com.au

Lifting Eye Bolt M16 Thread 740kg Load Capacity Zinc TRU M16 Eye Bolt Lifting Capacity However, at a 15 degree. For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle). 316 stainless steel are the most corrosion resistant eye nuts. Various sizes from m6 to m80;. The length of the thread of the assembly hole. Lifting eye bolt (din580) material steel, stainless. M16 Eye Bolt Lifting Capacity.

From dxooepcsq.blob.core.windows.net

M16 Lifting Eye Capacity at Robert Chase blog M16 Eye Bolt Lifting Capacity Various sizes from m6 to m80;. Shown at 0° (vertical) angle of lift. The use of din 580 lifting eye bolts must take place under the following conditions: Din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load. Lifting eye bolt. M16 Eye Bolt Lifting Capacity.

From www.tecni.uk

M16 A4AISI 316L Stainless Steel Certified Lifting Eyebolt DIN 580 WLL M16 Eye Bolt Lifting Capacity The length of the thread of the assembly hole. Shown at 0° (vertical) angle of lift. The use of din 580 lifting eye bolts must take place under the following conditions: For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle). Capacity applies to the eye nut. M16 Eye Bolt Lifting Capacity.

From mungfali.com

Eye Bolt Load Chart M16 Eye Bolt Lifting Capacity For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle). The length of the thread of the assembly hole. Eyebolts under m12 are not recommended for lifting. The eye bolt must be of fully screwed in to achieve a perfect. The stud or bolt you use will.. M16 Eye Bolt Lifting Capacity.

From www.alibaba.com

Bs 4278 Drop Lifting Eye Bolts M16 Buy Lifting Eye Bolts M16 M16 Eye Bolt Lifting Capacity However, at a 15 degree. The stud or bolt you use will. Eyebolts under m12 are not recommended for lifting. Shown at 0° (vertical) angle of lift. Din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load. The eye bolt must. M16 Eye Bolt Lifting Capacity.

From mavink.com

Eye Bolt Weight Chart M16 Eye Bolt Lifting Capacity Din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load. The stud or bolt you use will. 316 stainless steel are the most corrosion resistant eye nuts. The eye bolt must be of fully screwed in to achieve a perfect. However,. M16 Eye Bolt Lifting Capacity.

From www.indiamart.com

Silver Round Mild Steel Lifting Eye Bolt Hook, For Hardware Fitting M16 Eye Bolt Lifting Capacity Eyebolts under m12 are not recommended for lifting. Capacity applies to the eye nut only. The following guidelines of lifting eye bolts din 580 have to be observed in addition to the load values given in the above table: 316 stainless steel are the most corrosion resistant eye nuts. The eye bolt must be of fully screwed in to achieve. M16 Eye Bolt Lifting Capacity.

From eloisewilkinson.z21.web.core.windows.net

Standard Eye Bolt Lifting Capacity Chart M16 Eye Bolt Lifting Capacity Lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in plain finishing d1 pitch d2 d3 d4 h l m6 1.0. The use of din 580 lifting eye bolts must take place under the following conditions: The stud or bolt you use will. Capacity applies to the eye nut only. The following guidelines of lifting eye. M16 Eye Bolt Lifting Capacity.

From www.mscdirect.com

Gibraltar Fixed Lifting Eye Bolt With Shoulder, 3,990 lb Capacity M16 Eye Bolt Lifting Capacity For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle). However, at a 15 degree. 316 stainless steel are the most corrosion resistant eye nuts. Lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in plain finishing d1 pitch d2 d3 d4 h. M16 Eye Bolt Lifting Capacity.

From dxooepcsq.blob.core.windows.net

M16 Lifting Eye Capacity at Robert Chase blog M16 Eye Bolt Lifting Capacity The length of the thread of the assembly hole. However, at a 15 degree. Din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load. The following guidelines of lifting eye bolts din 580 have to be observed in addition to the. M16 Eye Bolt Lifting Capacity.

From www.gsproducts.co.uk

Swivel Lifting Eye Bolts M16 x 120mm Grade 80 GS Products M16 Eye Bolt Lifting Capacity Lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in plain finishing d1 pitch d2 d3 d4 h l m6 1.0. The use of din 580 lifting eye bolts must take place under the following conditions: However, at a 15 degree. 316 stainless steel are the most corrosion resistant eye nuts. For example, an eye bolt. M16 Eye Bolt Lifting Capacity.

From samanthapatterson.z19.web.core.windows.net

Standard Eye Bolt Lifting Capacity Chart M16 Eye Bolt Lifting Capacity Capacity applies to the eye nut only. The stud or bolt you use will. The eye bolt must be of fully screwed in to achieve a perfect. Various sizes from m6 to m80;. 316 stainless steel are the most corrosion resistant eye nuts. Eyebolts under m12 are not recommended for lifting. Din 580 specification specifies the properties of steel and. M16 Eye Bolt Lifting Capacity.

From www.tecni.uk

M16 A4AISI 316L Stainless Steel Certified Lifting Eyebolt DIN 580 WLL M16 Eye Bolt Lifting Capacity The use of din 580 lifting eye bolts must take place under the following conditions: The following guidelines of lifting eye bolts din 580 have to be observed in addition to the load values given in the above table: Shown at 0° (vertical) angle of lift. However, at a 15 degree. The stud or bolt you use will. The eye. M16 Eye Bolt Lifting Capacity.

From mavink.com

Lifting Eye Bolt Chart M16 Eye Bolt Lifting Capacity The following guidelines of lifting eye bolts din 580 have to be observed in addition to the load values given in the above table: The eye bolt must be of fully screwed in to achieve a perfect. Din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as. M16 Eye Bolt Lifting Capacity.

From dxooepcsq.blob.core.windows.net

M16 Lifting Eye Capacity at Robert Chase blog M16 Eye Bolt Lifting Capacity The eye bolt must be of fully screwed in to achieve a perfect. The following guidelines of lifting eye bolts din 580 have to be observed in addition to the load values given in the above table: Eyebolts under m12 are not recommended for lifting. Shown at 0° (vertical) angle of lift. The use of din 580 lifting eye bolts. M16 Eye Bolt Lifting Capacity.

From www.gsproducts.co.uk

M16 Zinc Plated Steel Swing Eye Bolt 16mm x 100mm Bolts M16 Eye Bolt Lifting Capacity Shown at 0° (vertical) angle of lift. Eyebolts under m12 are not recommended for lifting. The stud or bolt you use will. The following guidelines of lifting eye bolts din 580 have to be observed in addition to the load values given in the above table: Lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in. M16 Eye Bolt Lifting Capacity.

From mavink.com

Eye Bolt Load Chart M16 Eye Bolt Lifting Capacity Shown at 0° (vertical) angle of lift. The stud or bolt you use will. Capacity applies to the eye nut only. The eye bolt must be of fully screwed in to achieve a perfect. Lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in plain finishing d1 pitch d2 d3 d4 h l m6 1.0. For. M16 Eye Bolt Lifting Capacity.

From charliecarr.z19.web.core.windows.net

Standard Eye Bolt Lifting Capacity Chart M16 Eye Bolt Lifting Capacity 316 stainless steel are the most corrosion resistant eye nuts. For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle). The use of din 580 lifting eye bolts must take place under the following conditions: Various sizes from m6 to m80;. The stud or bolt you use. M16 Eye Bolt Lifting Capacity.

From nathanandrews.z21.web.core.windows.net

Eye Bolt Lifting Capacity Chart M16 Eye Bolt Lifting Capacity Shown at 0° (vertical) angle of lift. The eye bolt must be of fully screwed in to achieve a perfect. The stud or bolt you use will. Various sizes from m6 to m80;. The following guidelines of lifting eye bolts din 580 have to be observed in addition to the load values given in the above table: Din 580 specification. M16 Eye Bolt Lifting Capacity.

From logangarner.z19.web.core.windows.net

Standard Eye Bolt Lifting Capacity Chart M16 Eye Bolt Lifting Capacity Various sizes from m6 to m80;. The eye bolt must be of fully screwed in to achieve a perfect. The length of the thread of the assembly hole. Din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load. 316 stainless steel. M16 Eye Bolt Lifting Capacity.

From www.kljack.com

M1620 x 27mm Shoulder Machinery Lifting Eyebolt K.L. Jack M16 Eye Bolt Lifting Capacity The following guidelines of lifting eye bolts din 580 have to be observed in addition to the load values given in the above table: However, at a 15 degree. Shown at 0° (vertical) angle of lift. 316 stainless steel are the most corrosion resistant eye nuts. The length of the thread of the assembly hole. The stud or bolt you. M16 Eye Bolt Lifting Capacity.

From mavink.com

Metric Eye Bolt Sizes Chart M16 Eye Bolt Lifting Capacity Din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load. 316 stainless steel are the most corrosion resistant eye nuts. For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull. M16 Eye Bolt Lifting Capacity.

From www.indiamart.com

Silver Galvanized Mild Steel Lifting Eye Bolt, Size/Capacity 1 Ton M16 Eye Bolt Lifting Capacity Din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load. For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle). 316 stainless steel are the most corrosion resistant. M16 Eye Bolt Lifting Capacity.

From www.colliermiller.com.au

LIFTING EYE BOLT M16 700KG GOLD ZINC DICHROMATE FINISH Collier Miller M16 Eye Bolt Lifting Capacity The stud or bolt you use will. The eye bolt must be of fully screwed in to achieve a perfect. Lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in plain finishing d1 pitch d2 d3 d4 h l m6 1.0. Eyebolts under m12 are not recommended for lifting. Various sizes from m6 to m80;. The. M16 Eye Bolt Lifting Capacity.

From www.fourfasteners.co.uk

M16 LIFTING EYE BOLT 700Kg Four Fasteners Ltd M16 Eye Bolt Lifting Capacity Eyebolts under m12 are not recommended for lifting. However, at a 15 degree. Various sizes from m6 to m80;. Lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in plain finishing d1 pitch d2 d3 d4 h l m6 1.0. For example, an eye bolt with a 1/4 inch shank can typically hold up to 600. M16 Eye Bolt Lifting Capacity.