Molding Core Material . Two fundamental components of the mold in injection molding are the mold core and the mold cavity. The mold core is a solid or movable component within the mold that forms the internal features or voids of the final molded part. Aluminum cores are preferred for their lightweight properties and excellent thermal conductivity. This article delves into the specific roles and differences between these crucial elements. The core, also known as the male part of the mold, extends into the mold cavity, which is the female part of the mold surrounding the core. It represents the shape and geometry of the desired internal features of the part. Conversely, the mold core mainly forms the product’s external shape and structure, completing the overall molding of the product. Understanding the essentials of injection molding cores is vital for optimizing both product design and quality. The injection mold core and cavity are the two main components of an injection mold, determining the shape and size of the molded parts. A new way to make composite parts. The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. Determining how the part will be placed in the mold is critical in injection molding.

from dxodokxnx.blob.core.windows.net

Two fundamental components of the mold in injection molding are the mold core and the mold cavity. The core, also known as the male part of the mold, extends into the mold cavity, which is the female part of the mold surrounding the core. Determining how the part will be placed in the mold is critical in injection molding. This article delves into the specific roles and differences between these crucial elements. It represents the shape and geometry of the desired internal features of the part. The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. Aluminum cores are preferred for their lightweight properties and excellent thermal conductivity. Understanding the essentials of injection molding cores is vital for optimizing both product design and quality. A new way to make composite parts. Conversely, the mold core mainly forms the product’s external shape and structure, completing the overall molding of the product.

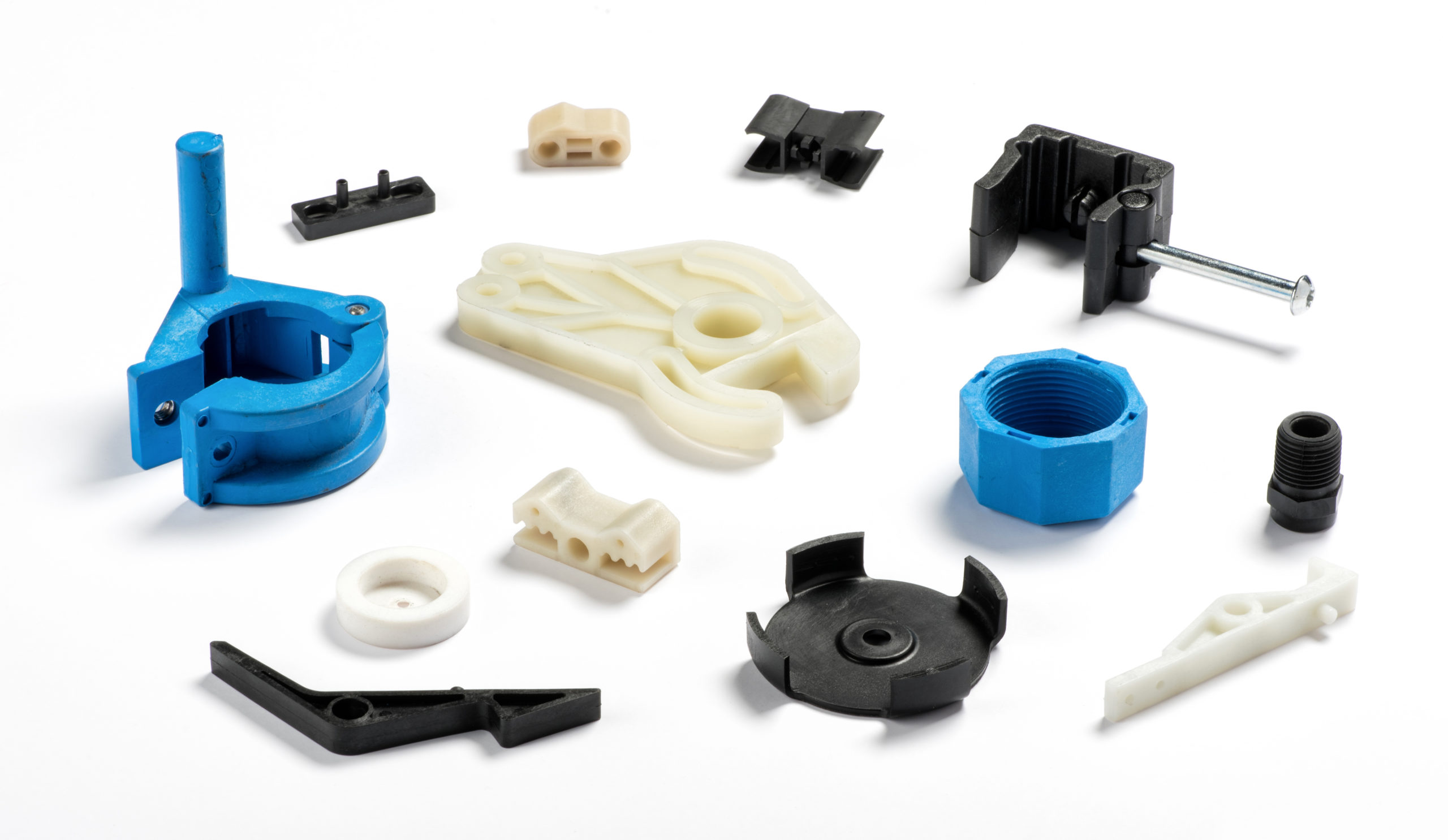

Different Types Of Plastic Injection Molding at Julian Easterling blog

Molding Core Material It represents the shape and geometry of the desired internal features of the part. Conversely, the mold core mainly forms the product’s external shape and structure, completing the overall molding of the product. The mold core is a solid or movable component within the mold that forms the internal features or voids of the final molded part. The injection mold core and cavity are the two main components of an injection mold, determining the shape and size of the molded parts. Understanding the essentials of injection molding cores is vital for optimizing both product design and quality. A new way to make composite parts. Determining how the part will be placed in the mold is critical in injection molding. This article delves into the specific roles and differences between these crucial elements. Aluminum cores are preferred for their lightweight properties and excellent thermal conductivity. Two fundamental components of the mold in injection molding are the mold core and the mold cavity. The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. The core, also known as the male part of the mold, extends into the mold cavity, which is the female part of the mold surrounding the core. It represents the shape and geometry of the desired internal features of the part.

From www.smlease.com

Types Of Injection Molds SMLease Design Molding Core Material The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. Two fundamental components of the mold in injection molding are the mold core and the mold cavity. The injection mold core and cavity are the two main components of an injection mold, determining the shape and size of the molded parts.. Molding Core Material.

From www.youtube.com

Core & Cavity Design Parting Surface & Line of Injection Molding Molding Core Material Two fundamental components of the mold in injection molding are the mold core and the mold cavity. The core, also known as the male part of the mold, extends into the mold cavity, which is the female part of the mold surrounding the core. Determining how the part will be placed in the mold is critical in injection molding. A. Molding Core Material.

From www.youtube.com

elements of mould / component of mould / important part of mould YouTube Molding Core Material This article delves into the specific roles and differences between these crucial elements. The core, also known as the male part of the mold, extends into the mold cavity, which is the female part of the mold surrounding the core. The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. Determining. Molding Core Material.

From upmold.com

Collapsible core mold design internal undercut injection molding Upmold Molding Core Material Understanding the essentials of injection molding cores is vital for optimizing both product design and quality. The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. It represents the shape and geometry of the desired internal features of the part. Conversely, the mold core mainly forms the product’s external shape and. Molding Core Material.

From www.cadrex.com

Starter Guide To Injection Molding Cadrex Molding Core Material Aluminum cores are preferred for their lightweight properties and excellent thermal conductivity. Two fundamental components of the mold in injection molding are the mold core and the mold cavity. The mold core is a solid or movable component within the mold that forms the internal features or voids of the final molded part. It represents the shape and geometry of. Molding Core Material.

From teampti.com

Anatomy of a Mold PTI Plastic Injection Molding Molding Core Material Determining how the part will be placed in the mold is critical in injection molding. The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. This article delves into the specific roles and differences between these crucial elements. Understanding the essentials of injection molding cores is vital for optimizing both product. Molding Core Material.

From www.alpinemold.com

Understanding Core Pulling in Injection Molding Alpine Mold Molding Core Material The injection mold core and cavity are the two main components of an injection mold, determining the shape and size of the molded parts. Determining how the part will be placed in the mold is critical in injection molding. Aluminum cores are preferred for their lightweight properties and excellent thermal conductivity. It represents the shape and geometry of the desired. Molding Core Material.

From www.youtube.com

Sand Casting Molding Processes Binders Patterns Core Making Molding Core Material The injection mold core and cavity are the two main components of an injection mold, determining the shape and size of the molded parts. It represents the shape and geometry of the desired internal features of the part. Determining how the part will be placed in the mold is critical in injection molding. This article delves into the specific roles. Molding Core Material.

From www.youtube.com

Injection Moulding Collapsible Cores YouTube Molding Core Material It represents the shape and geometry of the desired internal features of the part. Conversely, the mold core mainly forms the product’s external shape and structure, completing the overall molding of the product. The mold core is a solid or movable component within the mold that forms the internal features or voids of the final molded part. The core, also. Molding Core Material.

From www.plasticmoulds.net

What Is Plastic Mold And How To Make Reliable Plastic Mold? Molding Core Material The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. A new way to make composite parts. Aluminum cores are preferred for their lightweight properties and excellent thermal conductivity. It represents the shape and geometry of the desired internal features of the part. The injection mold core and cavity are the. Molding Core Material.

From www.plastopialtd.com

Mold Core for Injection Molding Plastopia Molding Core Material The injection mold core and cavity are the two main components of an injection mold, determining the shape and size of the molded parts. It represents the shape and geometry of the desired internal features of the part. The mold core is a solid or movable component within the mold that forms the internal features or voids of the final. Molding Core Material.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Molding Core Material The injection mold core and cavity are the two main components of an injection mold, determining the shape and size of the molded parts. This article delves into the specific roles and differences between these crucial elements. The core, also known as the male part of the mold, extends into the mold cavity, which is the female part of the. Molding Core Material.

From www.plastopialtd.com

Mold Core for Injection Molding Plastopia Molding Core Material It represents the shape and geometry of the desired internal features of the part. A new way to make composite parts. Conversely, the mold core mainly forms the product’s external shape and structure, completing the overall molding of the product. Two fundamental components of the mold in injection molding are the mold core and the mold cavity. The core, also. Molding Core Material.

From www.ada-precision.com

Precision Plastic Injection Molding Cores ADA Precision Molding Core Material It represents the shape and geometry of the desired internal features of the part. Aluminum cores are preferred for their lightweight properties and excellent thermal conductivity. Determining how the part will be placed in the mold is critical in injection molding. The mold core is a solid or movable component within the mold that forms the internal features or voids. Molding Core Material.

From www.iqsdirectory.com

Polyurethane Molding What Is It? How Does It Work? Uses, Types Of Molding Core Material This article delves into the specific roles and differences between these crucial elements. Conversely, the mold core mainly forms the product’s external shape and structure, completing the overall molding of the product. The mold core is a solid or movable component within the mold that forms the internal features or voids of the final molded part. The mold cavity is. Molding Core Material.

From www.youtube.com

Core and Cavity in Siemens NX Plastic Injection Mold Design YouTube Molding Core Material The core, also known as the male part of the mold, extends into the mold cavity, which is the female part of the mold surrounding the core. It represents the shape and geometry of the desired internal features of the part. Aluminum cores are preferred for their lightweight properties and excellent thermal conductivity. The injection mold core and cavity are. Molding Core Material.

From www.youtube.com

What is core & cavity in plastic mould / Core & cavity Inserts YouTube Molding Core Material Understanding the essentials of injection molding cores is vital for optimizing both product design and quality. Aluminum cores are preferred for their lightweight properties and excellent thermal conductivity. The core, also known as the male part of the mold, extends into the mold cavity, which is the female part of the mold surrounding the core. The injection mold core and. Molding Core Material.

From upmold.com

Collapsible Core Injection Molding collapsible core mechanism Upmold Molding Core Material The mold core is a solid or movable component within the mold that forms the internal features or voids of the final molded part. Determining how the part will be placed in the mold is critical in injection molding. The injection mold core and cavity are the two main components of an injection mold, determining the shape and size of. Molding Core Material.

From www.youtube.com

Collapsible core injection molding mold making YouTube Molding Core Material Conversely, the mold core mainly forms the product’s external shape and structure, completing the overall molding of the product. Understanding the essentials of injection molding cores is vital for optimizing both product design and quality. Two fundamental components of the mold in injection molding are the mold core and the mold cavity. The core, also known as the male part. Molding Core Material.

From www.spark-mould.com

Two shot molding 54 expert advice About mold and product design Molding Core Material The mold core is a solid or movable component within the mold that forms the internal features or voids of the final molded part. It represents the shape and geometry of the desired internal features of the part. Aluminum cores are preferred for their lightweight properties and excellent thermal conductivity. Understanding the essentials of injection molding cores is vital for. Molding Core Material.

From sculptcad.com

Soluble Core Molding Molding Core Material A new way to make composite parts. Understanding the essentials of injection molding cores is vital for optimizing both product design and quality. The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. The core, also known as the male part of the mold, extends into the mold cavity, which is. Molding Core Material.

From www.reliance-foundry.com

Coremaking Life of a Casting Reliance Foundry Molding Core Material The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. It represents the shape and geometry of the desired internal features of the part. The injection mold core and cavity are the two main components of an injection mold, determining the shape and size of the molded parts. The mold core. Molding Core Material.

From upmold.com

Collapsible core mold design internal undercut injection molding Upmold Molding Core Material Aluminum cores are preferred for their lightweight properties and excellent thermal conductivity. The core, also known as the male part of the mold, extends into the mold cavity, which is the female part of the mold surrounding the core. Determining how the part will be placed in the mold is critical in injection molding. It represents the shape and geometry. Molding Core Material.

From www.taiwanmoldmaker.com

Article about Core Mold Making and molding Technology service Molding Core Material Understanding the essentials of injection molding cores is vital for optimizing both product design and quality. This article delves into the specific roles and differences between these crucial elements. The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. It represents the shape and geometry of the desired internal features of. Molding Core Material.

From www.thelibraryofmanufacturing.com

Metal Casting Process Molding Core Material The injection mold core and cavity are the two main components of an injection mold, determining the shape and size of the molded parts. Conversely, the mold core mainly forms the product’s external shape and structure, completing the overall molding of the product. A new way to make composite parts. Determining how the part will be placed in the mold. Molding Core Material.

From grace-plastic-injection-mold.blogspot.com

Grace plastic injection mold Basic Mold Components Molding Core Material The injection mold core and cavity are the two main components of an injection mold, determining the shape and size of the molded parts. A new way to make composite parts. Conversely, the mold core mainly forms the product’s external shape and structure, completing the overall molding of the product. This article delves into the specific roles and differences between. Molding Core Material.

From www.simplexitypd.com

Top 10 tips for designing plastic injection molding parts Simplexity Molding Core Material This article delves into the specific roles and differences between these crucial elements. Conversely, the mold core mainly forms the product’s external shape and structure, completing the overall molding of the product. Understanding the essentials of injection molding cores is vital for optimizing both product design and quality. Aluminum cores are preferred for their lightweight properties and excellent thermal conductivity.. Molding Core Material.

From www.tradeindia.com

Architraves Mdf Moulding Core Material Solid Wood at Best Price in Molding Core Material This article delves into the specific roles and differences between these crucial elements. It represents the shape and geometry of the desired internal features of the part. Conversely, the mold core mainly forms the product’s external shape and structure, completing the overall molding of the product. Aluminum cores are preferred for their lightweight properties and excellent thermal conductivity. The injection. Molding Core Material.

From alloymaster.net

Molding / Core Making Alloy Master Molding Core Material Determining how the part will be placed in the mold is critical in injection molding. The core, also known as the male part of the mold, extends into the mold cavity, which is the female part of the mold surrounding the core. The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s. Molding Core Material.

From www.precision-mouldparts.com

Precision Mold Core And Cavity In Injection Molding 4852HRC Hardness Molding Core Material A new way to make composite parts. Two fundamental components of the mold in injection molding are the mold core and the mold cavity. The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. The core, also known as the male part of the mold, extends into the mold cavity, which. Molding Core Material.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Molding Core Material A new way to make composite parts. Conversely, the mold core mainly forms the product’s external shape and structure, completing the overall molding of the product. It represents the shape and geometry of the desired internal features of the part. The injection mold core and cavity are the two main components of an injection mold, determining the shape and size. Molding Core Material.

From www.weetect.com

Polycarbonate Injection Molding The Complete Guide Wee Tect Molding Core Material The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. Determining how the part will be placed in the mold is critical in injection molding. The injection mold core and cavity are the two main components of an injection mold, determining the shape and size of the molded parts. The mold. Molding Core Material.

From mold-and-tool.com

Mold Core and Cavity Making Kehui Mold Co., Limited Molding Core Material It represents the shape and geometry of the desired internal features of the part. The injection mold core and cavity are the two main components of an injection mold, determining the shape and size of the molded parts. Understanding the essentials of injection molding cores is vital for optimizing both product design and quality. This article delves into the specific. Molding Core Material.

From dxodokxnx.blob.core.windows.net

Different Types Of Plastic Injection Molding at Julian Easterling blog Molding Core Material Aluminum cores are preferred for their lightweight properties and excellent thermal conductivity. The injection mold core and cavity are the two main components of an injection mold, determining the shape and size of the molded parts. The core, also known as the male part of the mold, extends into the mold cavity, which is the female part of the mold. Molding Core Material.

From coremt.com

Home CORE Molding Technologies Molding Core Material The mold core is a solid or movable component within the mold that forms the internal features or voids of the final molded part. It represents the shape and geometry of the desired internal features of the part. This article delves into the specific roles and differences between these crucial elements. Conversely, the mold core mainly forms the product’s external. Molding Core Material.