Tablet Coater Example . Explore the types, materials and examples of conventional, delayed and sustained release coatings. While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Learn what film coatings are, why they are used and how they are applied to solid dosage forms.

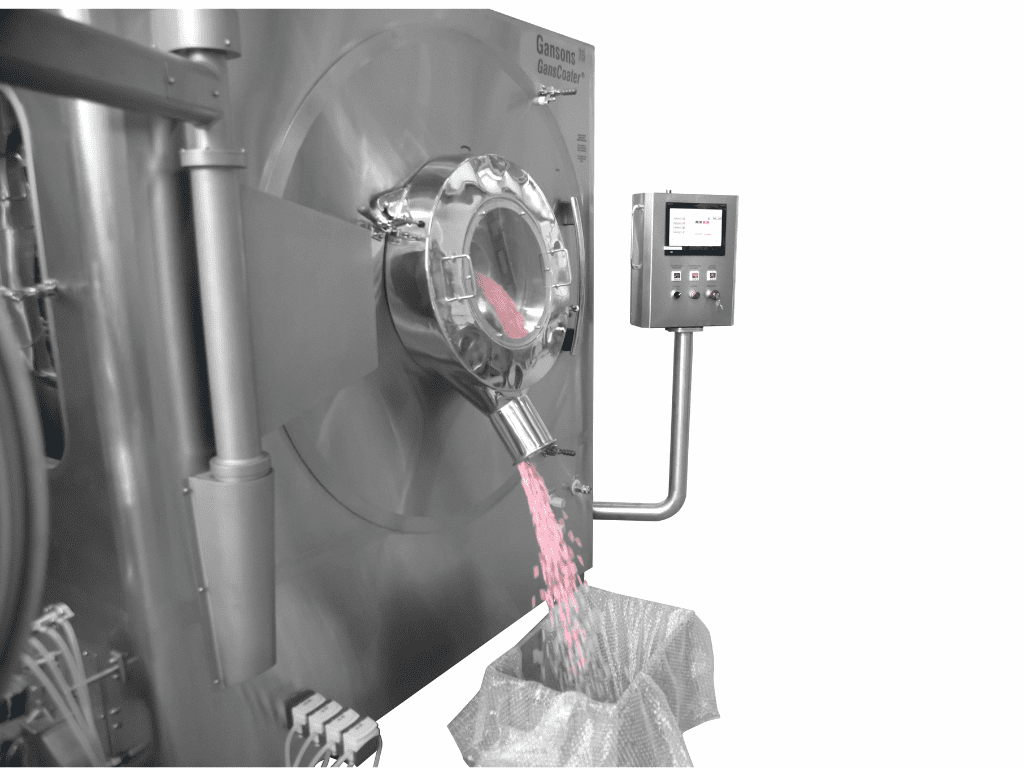

from gansons.com

Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. Explore the types, materials and examples of conventional, delayed and sustained release coatings. Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. Learn what film coatings are, why they are used and how they are applied to solid dosage forms.

The GansCoater® The advanced Tablet Coater in the World

Tablet Coater Example Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. Explore the types, materials and examples of conventional, delayed and sustained release coatings. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. Learn what film coatings are, why they are used and how they are applied to solid dosage forms. Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets.

From www.youtube.com

tablet coating machine pills pharmaceutical coater chestnut type Tablet Coater Example Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. Learn what film coatings are, why they are used and how they are applied to solid dosage. Tablet Coater Example.

From www.adinath.co.in

Types of Tablet Coating in Pharmaceutical Applications Tablet Coater Example Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. Explore the types, materials and examples of conventional, delayed and sustained release coatings. Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Learn what film coatings are,. Tablet Coater Example.

From www.cphi-online.com

Tablet Coater Optima Perforated coating pan for tablets and pellets Tablet Coater Example Learn what film coatings are, why they are used and how they are applied to solid dosage forms. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets.. Tablet Coater Example.

From www.ipharmachine.com

Types of Tablet Coating Machines A Complete Guide IPharmachine Tablet Coater Example Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Learn what film coatings are, why they are used and how they are applied to solid dosage forms. Tablet. Tablet Coater Example.

From thomasprocessing.com

Thomas Flex 500 Tablet Coater the ultimate in tablet coating Tablet Coater Example Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Tablet coating is the process of applying a coating material to the. Tablet Coater Example.

From www.ipharmachine.com

Types of Tablet Coating Machines A Complete Guide IPharmachine Tablet Coater Example Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. Explore the types, materials and examples of conventional, delayed and sustained release coatings. While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Tablet coating is the process of applying a. Tablet Coater Example.

From www.slideserve.com

PPT Tablets coating PowerPoint Presentation, free download ID2195360 Tablet Coater Example Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Explore. Tablet Coater Example.

From www.youtube.com

Tablet Coating YouTube Tablet Coater Example Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf. Tablet Coater Example.

From www.sbpanchal.com

Tablet Coater Tablet Coater Example Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Find out the types of tablet coating such as sugar coating, film. Tablet Coater Example.

From www.ipharmachine.com

5 Important Facts About Tablet Coating Machines IPharmachine Tablet Coater Example Learn what film coatings are, why they are used and how they are applied to solid dosage forms. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. Explore the types, materials and examples of conventional, delayed and sustained release coatings. While tablet. Tablet Coater Example.

From gansons.com

The GansCoater® The advanced Tablet Coater in the World Tablet Coater Example Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Learn. Tablet Coater Example.

From www.mdpi.com

Pharmaceutics Free FullText Pharmaceutical Application of Tablet Tablet Coater Example Explore the types, materials and examples of conventional, delayed and sustained release coatings. Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that. Tablet Coater Example.

From www.youtube.com

Tablet Coating Machine BYC300 YouTube Tablet Coater Example While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Explore the types, materials and examples of conventional, delayed and sustained release coatings. Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Learn about the objectives, techniques, equipment and quality control of. Tablet Coater Example.

From lbbohle.com

Tabletcoating Coating Systems For The Pharmaceutical Industry L.B Tablet Coater Example Explore the types, materials and examples of conventional, delayed and sustained release coatings. Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are. Tablet Coater Example.

From www.slideshare.net

Tablet Coating Machine Tablet Coater Example Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. Learn what film coatings are, why they. Tablet Coater Example.

From www.youtube.com

Film coating tablet coating sugar coating purposes types of coating Tablet Coater Example Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste,. Tablet Coater Example.

From www.icapsulepack.com

Standard Guideline Before Buying Tablet Coating Machine in 2021 AIPAK Tablet Coater Example Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry. Tablet Coater Example.

From nupharmamachinery.4bz.ae

Automatic Tablet Coater Nu Pharma Engineers & Consultant Tablet Coater Example Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Learn about the objectives, techniques, equipment. Tablet Coater Example.

From pharma-industry-review.com

Pharmaceutical Tablet Coating Machines Tablet Coater Example Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. Explore the types, materials and examples of conventional, delayed and sustained release coatings. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such. Tablet Coater Example.

From www.pharmapproach.com

Tablet Coating Process Film Coating Tablet Coater Example Explore the types, materials and examples of conventional, delayed and sustained release coatings. Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. Learn what film coatings are, why they are used and how they are applied to solid dosage forms. Tablet coating is. Tablet Coater Example.

From gansons.com

The GansCoater® The advanced Tablet Coater in the World Tablet Coater Example Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection,. Tablet Coater Example.

From www.youtube.com

Coating Pan, Tablet Coating Machine YouTube Tablet Coater Example Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. While. Tablet Coater Example.

From making.com

Tablet coater for laboratory scale Tablet Coater Example Explore the types, materials and examples of conventional, delayed and sustained release coatings. While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage. Tablet Coater Example.

From www.plantautomation-technology.com

Tablet Coater Gcc Powerdriven Hand Tools Glatt Group Plant Tablet Coater Example Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Learn what film coatings are, why they are used and how they are applied to solid dosage forms. Tablet coating is. Tablet Coater Example.

From www.youtube.com

Types of Tablet Coating Machines, why coating is important YouTube Tablet Coater Example Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Learn what film coatings are, why they are used and how they are applied to solid dosage forms. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of.. Tablet Coater Example.

From www.slideserve.com

PPT Tablet Coating PowerPoint Presentation, free download ID473582 Tablet Coater Example While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. Explore the types, materials and examples of conventional, delayed and sustained. Tablet Coater Example.

From www.pharmapproach.com

Tablet Coating Process Concepts and Advancements Pharmapproach... Tablet Coater Example Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. Learn. Tablet Coater Example.

From www.scientistlive.com

New tablet coater Scientist Live Tablet Coater Example Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. Learn what film coatings are, why they are used and how they are applied to solid dosage forms. Explore the types, materials and examples of conventional, delayed and sustained release coatings. Tablet coating is the process of applying a coating material to the. Tablet Coater Example.

From www.ipharmachine.com

The 9 Most Important Parts of a Tablet Coating Machine IPharmachine Tablet Coater Example Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. Learn what film coatings are, why they are used and how they are applied to solid dosage forms. Explore the types, materials and examples of conventional, delayed and sustained release coatings. Find out the. Tablet Coater Example.

From www.trustar-pharma.com

Classification & Types of Tablet Coating Machine (Learn How to Choose Tablet Coater Example While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. Explore the types, materials and examples of conventional, delayed and sustained release. Tablet Coater Example.

From gansons.com

The GansCoater® The advanced Tablet Coater in the World Tablet Coater Example Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating material to a dosage form. Tablet coating is the process of applying a coating material to the surface of a tablet to. Tablet Coater Example.

From www.youtube.com

TABLET COATING STEPS AND POLYMER USE YouTube Tablet Coater Example Explore the types, materials and examples of conventional, delayed and sustained release coatings. Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. While tablet coatings. Tablet Coater Example.

From www.youtube.com

Film Coating of tablets, Mechanism of film formation, Raw materials use Tablet Coater Example While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. Tablet coating is a multifaceted process that enhances the functionality, stability, and appearance of tablets. Learn about the objectives, techniques, equipment. Tablet Coater Example.

From thomasprocessing.com

What Coating Makes Sense for Your Tablets? Thomas Processing Tablet Coater Example Find out the types of tablet coating such as sugar coating, film coating, compression coating and microencapsulation. While tablet coatings have the same general functions, such as masking the odor taste and ensuring shelf life protection, there are several. Learn about the objectives, techniques, equipment and quality control of tablet coating, a process that applies a dry layer of coating. Tablet Coater Example.

From repassa.com

Tablet Coater REPASSA Tablet Coater Example Learn what film coatings are, why they are used and how they are applied to solid dosage forms. Tablet coating is the process of applying a coating material to the surface of a tablet to enhance its properties, such as taste, stability, and ease of. Find out the types of tablet coating such as sugar coating, film coating, compression coating. Tablet Coater Example.