What Are DTF Transfers and Why Are They Revolutionizing the Custom Apparel Industry?

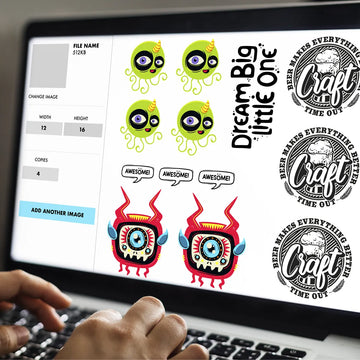

Direct-to-Film transfers (DTF) have emerged as a game-changing technology in the custom apparel industry. This innovative printing method offers unprecedented versatility, allowing businesses and individual creators to print vibrant, detailed designs on virtually any material with remarkable durability. In this comprehensive guide, we'll explore everything you need to know about DTF transfers, from the technology behind them to their diverse applications, and why EazyDTF stands as the industry leader in this revolutionary printing solution.

Understanding DTF Technology

DTF transfers represent the perfect blend of innovation and practicality in the custom printing world. Unlike traditional methods like screen printing, sublimation, or heat transfer vinyl (HTV), DTF printing employs a specialized process where designs are first printed onto a film carrier using specially formulated inks. A powdered adhesive is then applied before the transfer is heat-pressed onto the target material, creating vibrant, durable designs with incredible detail.

What truly sets DTF transfers apart is their unmatched versatility. While other printing methods have significant limitations in terms of compatible materials or color options, DTF transfers work beautifully on virtually any fabric, including cotton, polyester, blends, nylon, leather, and even non-fabric surfaces. This universal compatibility has made DTF the preferred choice for businesses seeking a single printing solution for diverse applications.

The Growth of DTF Transfers in the Custom Apparel Market

The custom apparel and merchandise market has witnessed explosive growth in recent years, driven by increasing demand for personalized products and the rise of e-commerce platforms. DTF transfers have emerged as a pivotal technology in this expanding market, offering businesses a cost-effective way to produce high-quality custom products without compromising on design complexity or durability.

Small businesses, in particular, have embraced DTF transfers as they provide a low barrier to entry compared to expensive direct-to-garment (DTG) printers or complex screen printing setups. With minimal equipment required—primarily a heat press—entrepreneurs can now offer professional-quality custom apparel services without massive upfront investments.

Why Choose DTF Transfers? 8 Compelling Benefits

DTF transfers aren't just another printing method—they represent a fundamental shift in how businesses approach custom apparel production. Below are eight compelling reasons why DTF transfers have become the preferred choice for both established print shops and entrepreneurial startups.

- Unlimited Color Options Without Added Cost: Unlike screen printing, where each color requires a separate screen and increases production costs, DTF transfers allow for unlimited colors and gradients in a single print with no additional costs.

- Exceptional Detail and Vibrancy: DTF transfers can reproduce incredibly fine details, photorealistic images, and vibrant colors with remarkable precision, offering superior image quality compared to many alternative methods.

- Universal Material Compatibility: Whether you're decorating cotton t-shirts, polyester athletic wear, leather jackets, or even hard surfaces like wood or metal, DTF transfers adhere beautifully to virtually any surface.

- Superior Durability and Wash Resistance: Properly applied DTF transfers can withstand 100+ wash cycles while maintaining their color vibrancy and integrity, far outlasting many competing technologies.

- Excellent Stretchability: The flexible nature of DTF transfers makes them ideal for stretchy fabrics and materials that undergo regular movement, as they move with the fabric without cracking or peeling.

- Cost-Effective Production: With no minimum order requirements and minimal equipment needs, DTF transfers provide an economical solution for both large production runs and one-off custom pieces.

- Quick Turnaround Times: The streamlined DTF process allows for rapid production, with transfers typically ready for application within 24-48 hours of ordering from quality providers like EazyDTF.

- Environmentally Friendly Option: Modern DTF technology uses water-based inks and efficient production methods, making it a more environmentally responsible choice compared to some traditional printing methods.

The DTF Transfer Process: From Design to Finished Product

Understanding the DTF transfer process helps businesses appreciate the technology's advantages and ensures optimal results when incorporating these transfers into their products. Here's a detailed breakdown of how DTF transfers are created and applied:

1. Design Preparation and Upload

The journey begins with preparing your design in a compatible format, typically PNG files with transparent backgrounds work best. Whether you're working with simple text, intricate artwork, or photorealistic images, DTF transfers can accommodate designs of any complexity. Once prepared, designs are uploaded to your DTF transfer provider's platform, such as EazyDTF, where you can specify size, quantity, and other customization options.

2. Specialized DTF Printing

After receiving your design, DTF transfer providers print it onto a specialized PET film using proprietary DTF inks. This stage is where the magic happens—the inks used are formulated specifically for optimal adhesion, color vibrancy, and durability. Advanced DTF printers ensure precise color reproduction and exceptional detail, even for the most complex designs.

3. Adhesive Application

Once printed, a specially formulated adhesive powder is applied to the wet ink. This powder is what allows the transfer to bond permanently to various materials during the heat application process. The powder-coated print is then cured, creating a transfer that's ready for application.

4. Heat Press Application

The final step involves applying the transfer to your desired material using a heat press. At EazyDTF, transfers come with specific heat press instructions—typically 320°F (160°C) with medium pressure for 12-15 seconds. After a cooling period of about 15 seconds, the backing film is peeled away, revealing your vibrant design perfectly adhered to the material.

"I ordered a custom sample and when it arrived I was shocked, it looked so well for such a large print and when placed on a T-shirt it was beautiful, I would definitely recommend!" - Kayla L., Verified EazyDTF Customer

DTF Transfers vs. Alternative Printing Methods

To fully appreciate the advantages of DTF transfers, it's helpful to compare them with other popular printing methods in the custom apparel industry. This comparison highlights why many businesses are transitioning to DTF technology for their custom printing needs.

| Feature |

DTF Transfers |

Screen Printing |

Sublimation |

DTG Printing |

Vinyl Heat Transfer |

| Material Compatibility |

Universal (cotton, polyester, blends, leather, etc.) |

Most fabrics, limited on some synthetics |

Polyester and polymer-coated only |

Best on cotton, limited on dark synthetics |

Most fabrics, varied results |

| Color Options |

Unlimited colors in one print |

Each color adds cost/complexity |

Full color capability |

Full color capability |

Limited by vinyl types/layers |

| Detail Quality |

Exceptional fine details |

Limited for fine details |

High detail on compatible fabrics |

Good but can blur on some fabrics |

Limited by cutting precision |

| Durability |

100+ washes with proper care |

Very durable (50+ washes) |

Permanent but can fade |

Moderate (20-30 washes) |

Variable depending on quality |

| Setup Costs |

Minimal (only heat press needed) |

High (screens, equipment, space) |

Moderate (special printer, paper, heat press) |

Very high (specialized DTG printer) |

Moderate (cutter, heat press) |

| Production Speed |

Fast application (12-15 seconds) |

Slow setup, very fast production |

Moderate |

Slow per item |

Time-consuming for complex designs |

| Minimum Orders |

No minimums |

Usually requires minimums |

No minimums |

No minimums |

No minimums |

| Hand Feel |

Soft, lightweight |

Varies with ink thickness |

No feel (part of fabric) |

Minimal feel on light fabrics |

Heavy, plastic-like feel |

As this comparison demonstrates, DTF transfers combine the best elements of competing technologies while eliminating many of their limitations. The exceptional versatility, quality, and ease of use make DTF transfers the superior choice for businesses seeking a comprehensive printing solution.

EazyDTF: Leading the DTF Transfer Revolution

In the rapidly evolving DTF transfer market, EazyDTF has established itself as an industry leader, delivering exceptional quality, reliability, and customer service. Founded on the principle that high-quality DTF transfers should be accessible to businesses of all sizes, EazyDTF has built a reputation for excellence that sets them apart from competitors.

The EazyDTF Difference

What distinguishes EazyDTF from other DTF transfer providers is their unwavering commitment to quality at every stage of the process. Using state-of-the-art printing equipment, premium inks, and proprietary adhesive formulations, EazyDTF consistently delivers transfers that exceed industry standards for vibrancy, detail, and durability.

Beyond product quality, EazyDTF has revolutionized the customer experience with their user-friendly online ordering system, transparent pricing without hidden fees, and lighting-fast production times. With most orders shipping within 24-48 hours, businesses can respond quickly to customer demands without lengthy wait times.

Comprehensive DTF Solutions

EazyDTF offers a full spectrum of DTF transfer options to meet diverse business needs. Their product lineup includes:

- Custom DTF Transfers: Available in various sizes to accommodate any design requirements

- DTF Transfers Gang Sheets: Cost-effective option for printing multiple designs on a single sheet

- Upload Your Own DTF Sheet: For businesses with pre-arranged gang sheet layouts

- Specialty DTF Products: Including UV-reactive transfers and other innovative options

Customer Success Stories with EazyDTF

EazyDTF's impact extends beyond providing quality products—they're helping businesses transform their operations and expand their product offerings. Small apparel shops, custom merchandise businesses, and even individual creators have reported significant growth after incorporating EazyDTF transfers into their production processes.

One standout example is Ashley M., who faced a potential disaster when her transfers for a family reunion were delayed. EazyDTF's customer service team stepped in, overnight shipping new transfers to ensure her event was a success. This level of dedication to customer satisfaction exemplifies the EazyDTF approach to business relationships.

Applications and Industries Benefiting from DTF Transfers

The versatility of DTF transfers has made them invaluable across numerous industries and applications. Here's how different sectors are leveraging this technology to enhance their products and services:

Custom Apparel Businesses

From small boutique operations to large-scale production facilities, apparel businesses are using DTF transfers to create premium custom clothing with intricate designs, photorealistic images, and vibrant colors that were previously challenging to achieve. The ability to print on demand without minimum quantities also allows for more agile inventory management and custom order fulfillment.

Sports Teams and Athletic Wear

Sports organizations at all levels utilize DTF transfers for creating team uniforms, spirit wear, and promotional merchandise. The exceptional durability and stretchability of DTF transfers make them ideal for athletic apparel that undergoes rigorous use and frequent washing.

Corporate Branding and Promotional Products

Businesses seeking branded merchandise leverage DTF transfers to create consistent, high-quality promotional items across diverse materials. From corporate polos and t-shirts to tote bags and hats, DTF transfers ensure brand colors and logos are reproduced with precision.

Event Merchandise

Concert promoters, festival organizers, and event planners rely on DTF transfers for creating limited-run merchandise with complex designs. The quick turnaround times and ability to produce small quantities make DTF transfers perfect for time-sensitive event applications.

Fashion and Streetwear Brands

Emerging and established fashion brands use DTF transfers to create distinctive apparel with unique design elements that stand out in the competitive fashion market. The ability to incorporate photorealistic images, gradients, and fine details allows for innovative design approaches.

Custom Gift and Novelty Items

Businesses specializing in personalized gifts leverage DTF transfers to create custom items for special occasions, from family reunion shirts to personalized baby onesies, wedding party gifts, and commemorative items.

Getting Started with DTF Transfers: A Practical Guide

For businesses looking to incorporate DTF transfers into their product offerings, here's a straightforward guide to getting started:

1. Essential Equipment

The beauty of using premade DTF transfers from EazyDTF is that you need minimal equipment to get started. The primary requirement is a quality heat press that can maintain consistent temperature and pressure. Most standard heat presses suitable for t-shirt production will work perfectly with DTF transfers. Some businesses also invest in a heat press pillow or pad for handling seams and uneven surfaces.

2. Design Preparation

Prepare your designs in a high-resolution format, ideally with transparent backgrounds. PNG files typically work best for DTF transfers. While complex designs with gradients and multiple colors work beautifully with DTF, ensure your design has suitable dimensions for your intended application.

3. Ordering Your First Transfers

Start with a small order to test the process. EazyDTF offers individual transfers or custom gang sheets where multiple designs can be printed on a single sheet for cost efficiency. Their user-friendly website makes the ordering process straightforward, with options to:

- Upload individual designs for custom sizing

- Create custom gang sheets with multiple designs

- Upload pre-arranged gang sheets for more complex layouts

4. Application Techniques

When your transfers arrive, follow the included application instructions carefully. EazyDTF recommends pressing at 320°F (160°C) with medium pressure for 12-15 seconds. After allowing the transfer to cool for approximately 15 seconds, peel the backing film and press again briefly for maximum durability. Practice on a few test pieces before moving to production items to perfect your technique.

5. Expanding Your Offerings

As you become comfortable with the process, consider expanding your product line to include diverse materials and items. The versatility of DTF transfers allows you to decorate everything from standard t-shirts to specialty items like leather goods, athletic wear, and even wood or metal surfaces with the same high-quality results.

The Future of Custom Printing: Why DTF Transfers Are Here to Stay

As we look toward the future of the custom printing industry, it's clear that DTF transfers represent not just a temporary trend but a fundamental shift in how businesses approach custom decoration. The unmatched combination of quality, versatility, durability, and cost-effectiveness positions DTF transfers as the premier printing solution for businesses of all sizes.

What makes DTF transfers particularly valuable is their accessibility—businesses no longer need massive investments in equipment or specialized training to offer premium custom products. With partners like EazyDTF providing high-quality transfers with rapid turnaround times, even small operations can compete effectively in the custom merchandise space.

As technology continues to evolve, we can expect DTF transfers to become even more refined, with advancements in inks, adhesives, and application techniques further enhancing their already impressive capabilities. Businesses that embrace this technology now will be well-positioned to lead in the custom apparel and merchandise markets of tomorrow.

Ready to transform your custom printing capabilities with DTF transfers? Partner with EazyDTF, the industry leader in quality, reliability, and customer satisfaction. Whether you're looking to create DTF Transfers for apparel, promotional items, or specialty products, EazyDTF offers the expertise and premium transfers you need to exceed customer expectations.

Start Creating with EazyDTF Today!