Candy Cane Making Process

For generations, candy canes, with their distinctive red and white stripes and enjoyable peppermint taste, have added a touch of sweetness to the holiday season. But have you ever wondered how these sweet treats are made? In this article, I will take you through the fascinating process of candy cane production, from the ingredients used to the final packaging and distribution. To create these.

Discover the sweet journey of how candy canes are made! From mixing sugar and peppermint to shaping the iconic red-and-white stripes, watch the fascinating process that brings this holiday classic.

In conclusion, the process of making candy canes is a fascinating blend of tradition, technology, and taste. From the initial mixture of ingredients to the final hook-shaped delight, every stage of candy cane production requires precision, quality control, and a focus on sustainability.

Evolution of Candy Cane Production Over the centuries, candy cane production has evolved significantly, from a labor-intensive, handmade process to a highly mechanized and efficient industry. The introduction of new technologies, such as the starch molding machine, has enabled mass production of candy canes, making them more accessible and affordable for consumers. Today, candy canes are.

Candy Cane Making At Home ( Recipe Included ) - YouTube

Every year, there's nothing that signals the approach of the Christmas season quite like the appearance of candy canes. For many folks these candies are a quaint reminder of how simple candy used to be. Nowadays, upscale food and drinks like white chocolate bark and vanilla lattes get flavored with candy canes, but how many people these days actually eat them?

Evolution of Candy Cane Production Over the centuries, candy cane production has evolved significantly, from a labor-intensive, handmade process to a highly mechanized and efficient industry. The introduction of new technologies, such as the starch molding machine, has enabled mass production of candy canes, making them more accessible and affordable for consumers. Today, candy canes are.

Discover the sweet journey of how candy canes are made! From mixing sugar and peppermint to shaping the iconic red-and-white stripes, watch the fascinating process that brings this holiday classic.

Candy canes are a beloved holiday treat, but the process behind making them is both intricate and fascinating. The journey starts with heating sugar and corn syrup to create a thick, sticky candy.

Making Candy By Hand. Production Process Of Candy Canes! #shorts # ...

Every year, there's nothing that signals the approach of the Christmas season quite like the appearance of candy canes. For many folks these candies are a quaint reminder of how simple candy used to be. Nowadays, upscale food and drinks like white chocolate bark and vanilla lattes get flavored with candy canes, but how many people these days actually eat them?

In conclusion, the process of making candy canes is a fascinating blend of tradition, technology, and taste. From the initial mixture of ingredients to the final hook-shaped delight, every stage of candy cane production requires precision, quality control, and a focus on sustainability.

The process of shaping candy canes involves pulling, stretching, curving, and twisting the sugar mixture to create the desired shape and pattern. Adding color and flavors to candy canes can be done by melting candy melts and incorporating high-quality extracts, ensuring even distribution for visual appeal and taste.

Evolution of Candy Cane Production Over the centuries, candy cane production has evolved significantly, from a labor-intensive, handmade process to a highly mechanized and efficient industry. The introduction of new technologies, such as the starch molding machine, has enabled mass production of candy canes, making them more accessible and affordable for consumers. Today, candy canes are.

Logan's Candies: Candy Cane Making Demonstrations In Time For Christmas ...

Candy makers start the candy cane-making process by cooking up a batch of sugar, water, and corn syrup. The batch is then stretched and rolled into canes.The.

In conclusion, the process of making candy canes is a fascinating blend of tradition, technology, and taste. From the initial mixture of ingredients to the final hook-shaped delight, every stage of candy cane production requires precision, quality control, and a focus on sustainability.

Every year, there's nothing that signals the approach of the Christmas season quite like the appearance of candy canes. For many folks these candies are a quaint reminder of how simple candy used to be. Nowadays, upscale food and drinks like white chocolate bark and vanilla lattes get flavored with candy canes, but how many people these days actually eat them?

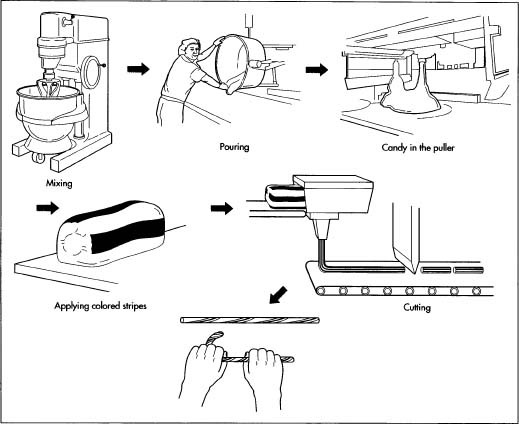

The process of creating candy canes is a fascinating one, involving a combination of traditional techniques and modern machinery. In this article, we'll take a step-by-step look at how candy canes are made. Step 1: Mixing the Ingredients The process of making candy canes begins with mixing the ingredients.

What Is Going Wrong In My Candy Cane Making Process? : R/CandyMakers

For generations, candy canes, with their distinctive red and white stripes and enjoyable peppermint taste, have added a touch of sweetness to the holiday season. But have you ever wondered how these sweet treats are made? In this article, I will take you through the fascinating process of candy cane production, from the ingredients used to the final packaging and distribution. To create these.

Evolution of Candy Cane Production Over the centuries, candy cane production has evolved significantly, from a labor-intensive, handmade process to a highly mechanized and efficient industry. The introduction of new technologies, such as the starch molding machine, has enabled mass production of candy canes, making them more accessible and affordable for consumers. Today, candy canes are.

Candy makers start the candy cane-making process by cooking up a batch of sugar, water, and corn syrup. The batch is then stretched and rolled into canes.The.

Discover the sweet journey of how candy canes are made! From mixing sugar and peppermint to shaping the iconic red-and-white stripes, watch the fascinating process that brings this holiday classic.

America's Best Candy Cane Factory Tours

:max_bytes(150000):strip_icc()/CandyCaneFactoryTour_LoftyPursuits-56b7ea555f9b5829f83cc2b6.jpg)

Candy Cane Background A candy cane is a hard candy usually peppermint flavored and decorated with stripes. The candy is long, thin, and bent at the top to resemble a walking cane. These candies are made using a batch process, which involves mixing and cooking the candy base, forming the stick shapes, and putting it in the appropriate packaging.

Every year, there's nothing that signals the approach of the Christmas season quite like the appearance of candy canes. For many folks these candies are a quaint reminder of how simple candy used to be. Nowadays, upscale food and drinks like white chocolate bark and vanilla lattes get flavored with candy canes, but how many people these days actually eat them?

Candy canes are a beloved holiday treat, but the process behind making them is both intricate and fascinating. The journey starts with heating sugar and corn syrup to create a thick, sticky candy.

The process of shaping candy canes involves pulling, stretching, curving, and twisting the sugar mixture to create the desired shape and pattern. Adding color and flavors to candy canes can be done by melting candy melts and incorporating high-quality extracts, ensuring even distribution for visual appeal and taste.

Prepare To Be Amazed By How Candy Canes Are Made, Christmas Spirit ...

The process of shaping candy canes involves pulling, stretching, curving, and twisting the sugar mixture to create the desired shape and pattern. Adding color and flavors to candy canes can be done by melting candy melts and incorporating high-quality extracts, ensuring even distribution for visual appeal and taste.

In conclusion, the process of making candy canes is a fascinating blend of tradition, technology, and taste. From the initial mixture of ingredients to the final hook-shaped delight, every stage of candy cane production requires precision, quality control, and a focus on sustainability.

Evolution of Candy Cane Production Over the centuries, candy cane production has evolved significantly, from a labor-intensive, handmade process to a highly mechanized and efficient industry. The introduction of new technologies, such as the starch molding machine, has enabled mass production of candy canes, making them more accessible and affordable for consumers. Today, candy canes are.

Candy canes are a beloved holiday treat, but the process behind making them is both intricate and fascinating. The journey starts with heating sugar and corn syrup to create a thick, sticky candy.

How Candy Canes Are Made | TODAY - YouTube

The process of shaping candy canes involves pulling, stretching, curving, and twisting the sugar mixture to create the desired shape and pattern. Adding color and flavors to candy canes can be done by melting candy melts and incorporating high-quality extracts, ensuring even distribution for visual appeal and taste.

Every year, there's nothing that signals the approach of the Christmas season quite like the appearance of candy canes. For many folks these candies are a quaint reminder of how simple candy used to be. Nowadays, upscale food and drinks like white chocolate bark and vanilla lattes get flavored with candy canes, but how many people these days actually eat them?

Candy canes are a beloved holiday treat, but the process behind making them is both intricate and fascinating. The journey starts with heating sugar and corn syrup to create a thick, sticky candy.

Evolution of Candy Cane Production Over the centuries, candy cane production has evolved significantly, from a labor-intensive, handmade process to a highly mechanized and efficient industry. The introduction of new technologies, such as the starch molding machine, has enabled mass production of candy canes, making them more accessible and affordable for consumers. Today, candy canes are.

Behind The Scenes Making Candy Canes | Candy Cane | It's Actually A ...

The process of creating candy canes is a fascinating one, involving a combination of traditional techniques and modern machinery. In this article, we'll take a step-by-step look at how candy canes are made. Step 1: Mixing the Ingredients The process of making candy canes begins with mixing the ingredients.

Evolution of Candy Cane Production Over the centuries, candy cane production has evolved significantly, from a labor-intensive, handmade process to a highly mechanized and efficient industry. The introduction of new technologies, such as the starch molding machine, has enabled mass production of candy canes, making them more accessible and affordable for consumers. Today, candy canes are.

The process of shaping candy canes involves pulling, stretching, curving, and twisting the sugar mixture to create the desired shape and pattern. Adding color and flavors to candy canes can be done by melting candy melts and incorporating high-quality extracts, ensuring even distribution for visual appeal and taste.

Discover the sweet journey of how candy canes are made! From mixing sugar and peppermint to shaping the iconic red-and-white stripes, watch the fascinating process that brings this holiday classic.

How Candy Cane Is Made - Manufacture, Making, History, Used, Processing ...

In conclusion, the process of making candy canes is a fascinating blend of tradition, technology, and taste. From the initial mixture of ingredients to the final hook-shaped delight, every stage of candy cane production requires precision, quality control, and a focus on sustainability.

Candy makers start the candy cane-making process by cooking up a batch of sugar, water, and corn syrup. The batch is then stretched and rolled into canes.The.

The process of creating candy canes is a fascinating one, involving a combination of traditional techniques and modern machinery. In this article, we'll take a step-by-step look at how candy canes are made. Step 1: Mixing the Ingredients The process of making candy canes begins with mixing the ingredients.

Evolution of Candy Cane Production Over the centuries, candy cane production has evolved significantly, from a labor-intensive, handmade process to a highly mechanized and efficient industry. The introduction of new technologies, such as the starch molding machine, has enabled mass production of candy canes, making them more accessible and affordable for consumers. Today, candy canes are.

RETRO KIMMER'S BLOG: HOW CANDY CANES ARE MADE

Candy Cane Background A candy cane is a hard candy usually peppermint flavored and decorated with stripes. The candy is long, thin, and bent at the top to resemble a walking cane. These candies are made using a batch process, which involves mixing and cooking the candy base, forming the stick shapes, and putting it in the appropriate packaging.

Every year, there's nothing that signals the approach of the Christmas season quite like the appearance of candy canes. For many folks these candies are a quaint reminder of how simple candy used to be. Nowadays, upscale food and drinks like white chocolate bark and vanilla lattes get flavored with candy canes, but how many people these days actually eat them?

The process of shaping candy canes involves pulling, stretching, curving, and twisting the sugar mixture to create the desired shape and pattern. Adding color and flavors to candy canes can be done by melting candy melts and incorporating high-quality extracts, ensuring even distribution for visual appeal and taste.

Discover the sweet journey of how candy canes are made! From mixing sugar and peppermint to shaping the iconic red-and-white stripes, watch the fascinating process that brings this holiday classic.

Candy Cane Making Process : R/oddlysatisfying

Discover the sweet journey of how candy canes are made! From mixing sugar and peppermint to shaping the iconic red-and-white stripes, watch the fascinating process that brings this holiday classic.

In conclusion, the process of making candy canes is a fascinating blend of tradition, technology, and taste. From the initial mixture of ingredients to the final hook-shaped delight, every stage of candy cane production requires precision, quality control, and a focus on sustainability.

Candy makers start the candy cane-making process by cooking up a batch of sugar, water, and corn syrup. The batch is then stretched and rolled into canes.The.

Evolution of Candy Cane Production Over the centuries, candy cane production has evolved significantly, from a labor-intensive, handmade process to a highly mechanized and efficient industry. The introduction of new technologies, such as the starch molding machine, has enabled mass production of candy canes, making them more accessible and affordable for consumers. Today, candy canes are.

How To Make Your Own Candy Canes | Recipe | Home Made Candy, Candy Cane ...

For generations, candy canes, with their distinctive red and white stripes and enjoyable peppermint taste, have added a touch of sweetness to the holiday season. But have you ever wondered how these sweet treats are made? In this article, I will take you through the fascinating process of candy cane production, from the ingredients used to the final packaging and distribution. To create these.

Discover the sweet journey of how candy canes are made! From mixing sugar and peppermint to shaping the iconic red-and-white stripes, watch the fascinating process that brings this holiday classic.

Candy makers start the candy cane-making process by cooking up a batch of sugar, water, and corn syrup. The batch is then stretched and rolled into canes.The.

The process of creating candy canes is a fascinating one, involving a combination of traditional techniques and modern machinery. In this article, we'll take a step-by-step look at how candy canes are made. Step 1: Mixing the Ingredients The process of making candy canes begins with mixing the ingredients.

An Interesting Look At The Process Of Making Candy Canes (13 Gifs ...

The process of shaping candy canes involves pulling, stretching, curving, and twisting the sugar mixture to create the desired shape and pattern. Adding color and flavors to candy canes can be done by melting candy melts and incorporating high-quality extracts, ensuring even distribution for visual appeal and taste.

Evolution of Candy Cane Production Over the centuries, candy cane production has evolved significantly, from a labor-intensive, handmade process to a highly mechanized and efficient industry. The introduction of new technologies, such as the starch molding machine, has enabled mass production of candy canes, making them more accessible and affordable for consumers. Today, candy canes are.

Candy Cane Background A candy cane is a hard candy usually peppermint flavored and decorated with stripes. The candy is long, thin, and bent at the top to resemble a walking cane. These candies are made using a batch process, which involves mixing and cooking the candy base, forming the stick shapes, and putting it in the appropriate packaging.

Candy makers start the candy cane-making process by cooking up a batch of sugar, water, and corn syrup. The batch is then stretched and rolled into canes.The.

DIY CANDY CANE BOWS (TIPS & TRICKS) - CARLY

Candy Cane Background A candy cane is a hard candy usually peppermint flavored and decorated with stripes. The candy is long, thin, and bent at the top to resemble a walking cane. These candies are made using a batch process, which involves mixing and cooking the candy base, forming the stick shapes, and putting it in the appropriate packaging.

Candy canes are a beloved holiday treat, but the process behind making them is both intricate and fascinating. The journey starts with heating sugar and corn syrup to create a thick, sticky candy.

Candy makers start the candy cane-making process by cooking up a batch of sugar, water, and corn syrup. The batch is then stretched and rolled into canes.The.

In conclusion, the process of making candy canes is a fascinating blend of tradition, technology, and taste. From the initial mixture of ingredients to the final hook-shaped delight, every stage of candy cane production requires precision, quality control, and a focus on sustainability.

How Candy Canes Are Made: A Sweet Manufacturing Process - VidBuddy

Every year, there's nothing that signals the approach of the Christmas season quite like the appearance of candy canes. For many folks these candies are a quaint reminder of how simple candy used to be. Nowadays, upscale food and drinks like white chocolate bark and vanilla lattes get flavored with candy canes, but how many people these days actually eat them?

The process of shaping candy canes involves pulling, stretching, curving, and twisting the sugar mixture to create the desired shape and pattern. Adding color and flavors to candy canes can be done by melting candy melts and incorporating high-quality extracts, ensuring even distribution for visual appeal and taste.

Candy Cane Background A candy cane is a hard candy usually peppermint flavored and decorated with stripes. The candy is long, thin, and bent at the top to resemble a walking cane. These candies are made using a batch process, which involves mixing and cooking the candy base, forming the stick shapes, and putting it in the appropriate packaging.

For generations, candy canes, with their distinctive red and white stripes and enjoyable peppermint taste, have added a touch of sweetness to the holiday season. But have you ever wondered how these sweet treats are made? In this article, I will take you through the fascinating process of candy cane production, from the ingredients used to the final packaging and distribution. To create these.

Every year, there's nothing that signals the approach of the Christmas season quite like the appearance of candy canes. For many folks these candies are a quaint reminder of how simple candy used to be. Nowadays, upscale food and drinks like white chocolate bark and vanilla lattes get flavored with candy canes, but how many people these days actually eat them?

In conclusion, the process of making candy canes is a fascinating blend of tradition, technology, and taste. From the initial mixture of ingredients to the final hook-shaped delight, every stage of candy cane production requires precision, quality control, and a focus on sustainability.

Evolution of Candy Cane Production Over the centuries, candy cane production has evolved significantly, from a labor-intensive, handmade process to a highly mechanized and efficient industry. The introduction of new technologies, such as the starch molding machine, has enabled mass production of candy canes, making them more accessible and affordable for consumers. Today, candy canes are.

Candy makers start the candy cane-making process by cooking up a batch of sugar, water, and corn syrup. The batch is then stretched and rolled into canes.The.

Discover the sweet journey of how candy canes are made! From mixing sugar and peppermint to shaping the iconic red-and-white stripes, watch the fascinating process that brings this holiday classic.

For generations, candy canes, with their distinctive red and white stripes and enjoyable peppermint taste, have added a touch of sweetness to the holiday season. But have you ever wondered how these sweet treats are made? In this article, I will take you through the fascinating process of candy cane production, from the ingredients used to the final packaging and distribution. To create these.

Candy Cane Background A candy cane is a hard candy usually peppermint flavored and decorated with stripes. The candy is long, thin, and bent at the top to resemble a walking cane. These candies are made using a batch process, which involves mixing and cooking the candy base, forming the stick shapes, and putting it in the appropriate packaging.

The process of shaping candy canes involves pulling, stretching, curving, and twisting the sugar mixture to create the desired shape and pattern. Adding color and flavors to candy canes can be done by melting candy melts and incorporating high-quality extracts, ensuring even distribution for visual appeal and taste.

The process of creating candy canes is a fascinating one, involving a combination of traditional techniques and modern machinery. In this article, we'll take a step-by-step look at how candy canes are made. Step 1: Mixing the Ingredients The process of making candy canes begins with mixing the ingredients.

Candy canes are a beloved holiday treat, but the process behind making them is both intricate and fascinating. The journey starts with heating sugar and corn syrup to create a thick, sticky candy.