May 19, 2024

New 3d Printing Technique For Producing Ultrasmall Metallic Things

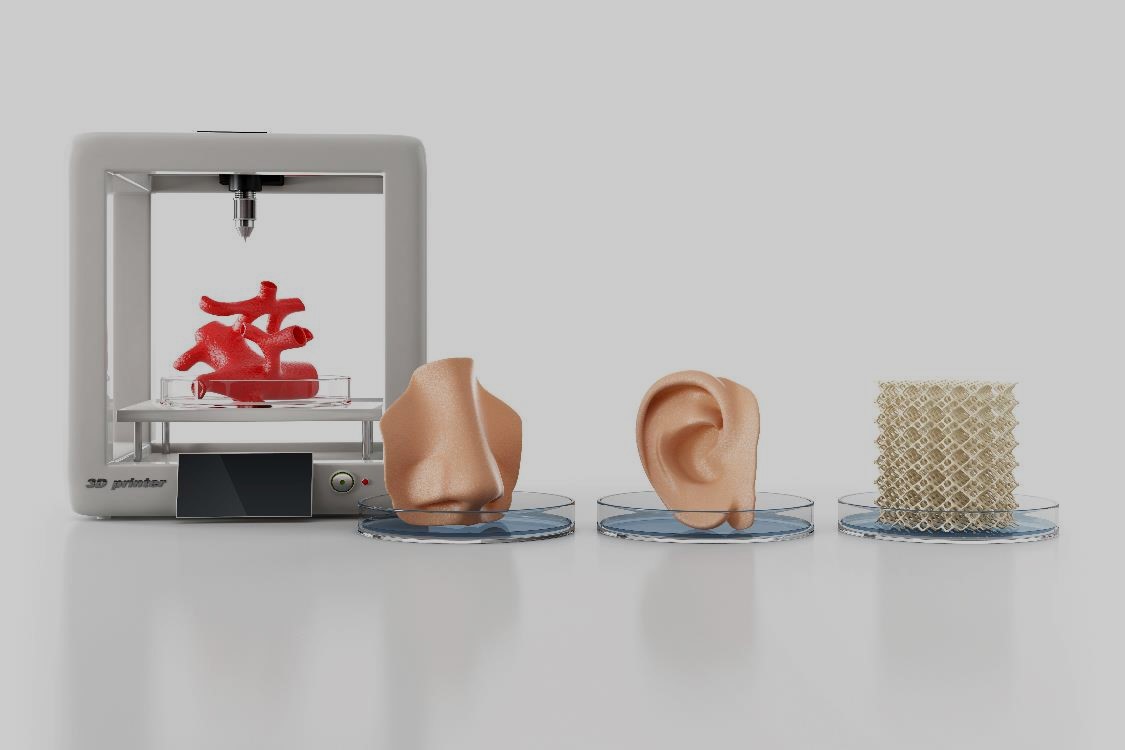

3d Printing Techniques: Different Kinds Of 3d Printing In this overview, we will certainly discover the various 3D printing post-processing methods utilized with different 3D printing modern technologies, from common techniques like fining sand and painting to innovative strategies like hydrographics as well as cold welding. We will also review safety factors to consider and finest methods for post-processing, guaranteeing that you can confidently and also safely improve the quality of your 3D printed components. 3D printing or additive manufacturing enables you to create geometrically complex objects, forms as well as structures. It often utilizes much less product than standard manufacturing methods as well as enables the manufacturing of items that were just not possible to generate financially with conventional manufacturing. For path and information generation, a variety of approaches are executed for the generation of robot building paths.- The kinetics can be regulated by the power of the source of light, the scanning rate as well as the chemistry and also quantity of the monomer as well as photointiators.

- In binder jetting, the input is the crucial product in powder form which the printer deposits with a slim layer of a binding representative.

- In D Concrete Printing started at Loughborough College, UK, headed by Richard Buswell and associates to prolong the teams prior research as well as look to commercial applications relocating from a gantry based technology to an industrial robotic.

- A model of Kyiv's Saint Sophia Cathedral in heaven and also yellow of the Ukrainian flag, used the iCLIP technique for 3D printing, which enables the use of multiple types-- or colors-- of material in a solitary item.

- Choose a 3D printer with a straightforward user interface, a receptive assistance division, and a large community of individuals.

- Wherever conventional processes reach their financial limits as a result of cost-intensive mold construction or transition times, additive 3D printing deal important financial benefits.

Guide To Publishing Food-safe Plastic Items

To discover all about 3D printing and also more concerning optimizing your 3D published items, speak to a Xometry agent or make use of Xometry's powerful estimating device. No. 3D printing has come to be extremely obtainable with simple software and hardware. In addition to this, there are several sources online that discuss every step of the process carefully. You can likewise find many 3D printer jobs for newbies online that can help learn more about the procedure. There are numerous layout and manufacturability restraints fundamental to tooling, which is why 3D printing is such a game changer. 3D printing constructs components from the bottom up as well as doesn't require any type of tooling to execute difficult designs.Cyber Threat Intelligence Market Share Size 2023 : Top Players ... - Digital Journal

Cyber Threat Intelligence Market Share Size 2023 : Top Players ....

Posted: Fri, 09 Jun 2023 10:45:23 GMT [source]

Tips To Boost Your 3d Printing Skills

The knowledge of these techniques is necessary for anyone collaborating with 3D published parts, as it makes certain the effective integration of 3D printing technology in various sectors and also fosters proceeded development in the field. Assistance frameworks are essential for overhangs, bridges, as well as various other intricate geometries that can not be published on their own because of gravitational forces. Nonetheless, assistance frameworks must be gotten rid of after printing to attain the desired final appearance and also functionality of the part. There are several techniques for assistance elimination, each with its benefits and also challenges. For SLS printed steel parts, heat therapy is a vital post-processing action to enhance their mechanical buildings and eliminate internal anxieties.What is the strongest 3D printing approach?

Polycarbonate. According to multiple producers and reviewers, polycarbonate (PC) is thought about the strongest consumer filament available. PC can produce extremely high-strength parts when published correctly with an all-metal hot end and a room.

Social Links