Salt Bath Quenching Heat Treatment

Salt bath hardening is a popular process for components having a complex shape and varying widely in cross-section and weight. This may include, for instance, shafts, gear wheels, or tools. For such components partial hardening can be used to harden different areas to various levels of hardness. This can be accomplished through heat treatment in a salt melt. What is more, the slow quenching.

Heat Treat with Salt Baths Salt bath heat treatment is a heat treatment process comprising an immersion of the treated part into a molten salt or salts mixture.2 There are numerous benefits of heat treatment in salt baths; the most prevalent is that they provide faster heating.

Heat Treat Today's Technical Tuesday feature provides an overview of the heat treatment process and the benefits wrought from heat treating in salt baths. The article also illuminates details to understand part composition and the austempering and quenching process as a whole.

The Benefits of Salt Quenching for Alloy Steel Many of the same benefits derived by heat-treating HSS in molten salts apply to processing tool steel and alloy steel products in salts. For example, increased toughness can be obtained by quenching into salt, rather than oil.

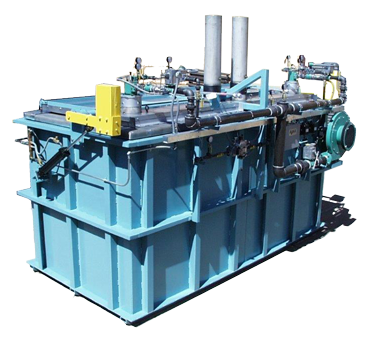

Salt-Bath Furnaces For Heat Treatment Of Steel Or Light Metals | Nabertherm

Heat Treat Today's Technical Tuesday feature provides an overview of the heat treatment process and the benefits wrought from heat treating in salt baths. The article also illuminates details to understand part composition and the austempering and quenching process as a whole.

A work part immersed into a molten salt is heated by heat transferred by conduction (combined with convection) through the liquid media (salt bath). The heat transfer rate in a liquid media is much greater than that in other heating mechanisms: radiation, convection through a gas (e.g., air). Controlled cooling conditions during quenching.

Heat Treat with Salt Baths Salt bath heat treatment is a heat treatment process comprising an immersion of the treated part into a molten salt or salts mixture.2 There are numerous benefits of heat treatment in salt baths; the most prevalent is that they provide faster heating.

Salt Bath Heat Treatment: Process, Applications and Advantages Salt bath heat treatment is a specialized thermal processing technique widely used in the metallurgical industry for improving the mechanical and physical properties of metals. Unlike conventional air or gas furnaces, salt baths offer uniform heating, rapid thermal transfer, and reduced oxidation, making them particularly suitable.

Heat Treating An Anvil Sleeve Molten Salt Quenching Bath - YouTube

In the realm of heat treatment processes, the salt bath heat treatment method has emerged as a reliable and efficient technique. This article aims to shed light on the working principle, types, advantages, disadvantages, and applications of salt bath heat treatment. Let's dive into the world of this fascinating process.

The Benefits of Salt Quenching for Alloy Steel Many of the same benefits derived by heat-treating HSS in molten salts apply to processing tool steel and alloy steel products in salts. For example, increased toughness can be obtained by quenching into salt, rather than oil.

A work part immersed into a molten salt is heated by heat transferred by conduction (combined with convection) through the liquid media (salt bath). The heat transfer rate in a liquid media is much greater than that in other heating mechanisms: radiation, convection through a gas (e.g., air). Controlled cooling conditions during quenching.

Salt Bath Heat Treatment: Process, Applications and Advantages Salt bath heat treatment is a specialized thermal processing technique widely used in the metallurgical industry for improving the mechanical and physical properties of metals. Unlike conventional air or gas furnaces, salt baths offer uniform heating, rapid thermal transfer, and reduced oxidation, making them particularly suitable.

Salt Bath Heat Treatment Explained In Depth - Heat Treatment Masters

Salt Bath Heat Treatment: Process, Applications and Advantages Salt bath heat treatment is a specialized thermal processing technique widely used in the metallurgical industry for improving the mechanical and physical properties of metals. Unlike conventional air or gas furnaces, salt baths offer uniform heating, rapid thermal transfer, and reduced oxidation, making them particularly suitable.

In the realm of heat treatment processes, the salt bath heat treatment method has emerged as a reliable and efficient technique. This article aims to shed light on the working principle, types, advantages, disadvantages, and applications of salt bath heat treatment. Let's dive into the world of this fascinating process.

A work part immersed into a molten salt is heated by heat transferred by conduction (combined with convection) through the liquid media (salt bath). The heat transfer rate in a liquid media is much greater than that in other heating mechanisms: radiation, convection through a gas (e.g., air). Controlled cooling conditions during quenching.

The Benefits of Salt Quenching for Alloy Steel Many of the same benefits derived by heat-treating HSS in molten salts apply to processing tool steel and alloy steel products in salts. For example, increased toughness can be obtained by quenching into salt, rather than oil.

Benefits Of Salt Heat Treatment - Akron Steel Treating

Salt bath hardening is a popular process for components having a complex shape and varying widely in cross-section and weight. This may include, for instance, shafts, gear wheels, or tools. For such components partial hardening can be used to harden different areas to various levels of hardness. This can be accomplished through heat treatment in a salt melt. What is more, the slow quenching.

In the realm of heat treatment processes, the salt bath heat treatment method has emerged as a reliable and efficient technique. This article aims to shed light on the working principle, types, advantages, disadvantages, and applications of salt bath heat treatment. Let's dive into the world of this fascinating process.

This article provides information on the salt baths used for a variety of heat treatments, including heating, quenching, interrupted quenching (austempering and martempering), case hardening, and tempering. It describes two general types of salt bath systems for steel hardening: the first type uses atmosphere austenitizing followed by salt quench and the second type employs austenitizing salt.

At the turn of the 20th century, the use of molten salt as a heating and quenching medium for steels was developed in England. It rapidly came into use in Europe as a low-cost method of heat treating. Equipment was inexpensive, and molten salt provided a reproducible method of heat treatment. In this short article I will review the types of salts used for heat treating and some hazards.

Tempering Salt Bath Heat Treatment Formulation - At - 1 Chemical ...

The uniformity of salt bath heating and quenching results in more predictable post-hardening size changes than other heating and quench cooling procedures. According to D. Scott MacKenzie, Ph.D., FASM, a research scientist of metallurgy at Houghton International, "Since metals have high thermal conductivity, the core of the part lags the.

Heat Treat with Salt Baths Salt bath heat treatment is a heat treatment process comprising an immersion of the treated part into a molten salt or salts mixture.2 There are numerous benefits of heat treatment in salt baths; the most prevalent is that they provide faster heating.

In the realm of heat treatment processes, the salt bath heat treatment method has emerged as a reliable and efficient technique. This article aims to shed light on the working principle, types, advantages, disadvantages, and applications of salt bath heat treatment. Let's dive into the world of this fascinating process.

Salt Bath Heat Treatment: Process, Applications and Advantages Salt bath heat treatment is a specialized thermal processing technique widely used in the metallurgical industry for improving the mechanical and physical properties of metals. Unlike conventional air or gas furnaces, salt baths offer uniform heating, rapid thermal transfer, and reduced oxidation, making them particularly suitable.

Salt Bath Heat Treatment Services For D2, D3, D6 A2 And H Grade Steel ...

Salt Bath Heat Treatment: Process, Applications and Advantages Salt bath heat treatment is a specialized thermal processing technique widely used in the metallurgical industry for improving the mechanical and physical properties of metals. Unlike conventional air or gas furnaces, salt baths offer uniform heating, rapid thermal transfer, and reduced oxidation, making them particularly suitable.

Salt bath hardening is a popular process for components having a complex shape and varying widely in cross-section and weight. This may include, for instance, shafts, gear wheels, or tools. For such components partial hardening can be used to harden different areas to various levels of hardness. This can be accomplished through heat treatment in a salt melt. What is more, the slow quenching.

The Benefits of Salt Quenching for Alloy Steel Many of the same benefits derived by heat-treating HSS in molten salts apply to processing tool steel and alloy steel products in salts. For example, increased toughness can be obtained by quenching into salt, rather than oil.

A work part immersed into a molten salt is heated by heat transferred by conduction (combined with convection) through the liquid media (salt bath). The heat transfer rate in a liquid media is much greater than that in other heating mechanisms: radiation, convection through a gas (e.g., air). Controlled cooling conditions during quenching.

Quenching Process | Heat Treatment Process | Steel & Iron | Salt Bath ...

In the realm of heat treatment processes, the salt bath heat treatment method has emerged as a reliable and efficient technique. This article aims to shed light on the working principle, types, advantages, disadvantages, and applications of salt bath heat treatment. Let's dive into the world of this fascinating process.

This article provides information on the salt baths used for a variety of heat treatments, including heating, quenching, interrupted quenching (austempering and martempering), case hardening, and tempering. It describes two general types of salt bath systems for steel hardening: the first type uses atmosphere austenitizing followed by salt quench and the second type employs austenitizing salt.

The Benefits of Salt Quenching for Alloy Steel Many of the same benefits derived by heat-treating HSS in molten salts apply to processing tool steel and alloy steel products in salts. For example, increased toughness can be obtained by quenching into salt, rather than oil.

At the turn of the 20th century, the use of molten salt as a heating and quenching medium for steels was developed in England. It rapidly came into use in Europe as a low-cost method of heat treating. Equipment was inexpensive, and molten salt provided a reproducible method of heat treatment. In this short article I will review the types of salts used for heat treating and some hazards.

Salt Bath Heat Treatment Services For D2, D3, D6 A2 And H Grade Steel ...

The uniformity of salt bath heating and quenching results in more predictable post-hardening size changes than other heating and quench cooling procedures. According to D. Scott MacKenzie, Ph.D., FASM, a research scientist of metallurgy at Houghton International, "Since metals have high thermal conductivity, the core of the part lags the.

At the turn of the 20th century, the use of molten salt as a heating and quenching medium for steels was developed in England. It rapidly came into use in Europe as a low-cost method of heat treating. Equipment was inexpensive, and molten salt provided a reproducible method of heat treatment. In this short article I will review the types of salts used for heat treating and some hazards.

Heat Treat Today's Technical Tuesday feature provides an overview of the heat treatment process and the benefits wrought from heat treating in salt baths. The article also illuminates details to understand part composition and the austempering and quenching process as a whole.

In the realm of heat treatment processes, the salt bath heat treatment method has emerged as a reliable and efficient technique. This article aims to shed light on the working principle, types, advantages, disadvantages, and applications of salt bath heat treatment. Let's dive into the world of this fascinating process.

Heat Treating Processes | Salt Bath Heat Treatment | Ajax

In the realm of heat treatment processes, the salt bath heat treatment method has emerged as a reliable and efficient technique. This article aims to shed light on the working principle, types, advantages, disadvantages, and applications of salt bath heat treatment. Let's dive into the world of this fascinating process.

The Benefits of Salt Quenching for Alloy Steel Many of the same benefits derived by heat-treating HSS in molten salts apply to processing tool steel and alloy steel products in salts. For example, increased toughness can be obtained by quenching into salt, rather than oil.

Heat Treat Today's Technical Tuesday feature provides an overview of the heat treatment process and the benefits wrought from heat treating in salt baths. The article also illuminates details to understand part composition and the austempering and quenching process as a whole.

The uniformity of salt bath heating and quenching results in more predictable post-hardening size changes than other heating and quench cooling procedures. According to D. Scott MacKenzie, Ph.D., FASM, a research scientist of metallurgy at Houghton International, "Since metals have high thermal conductivity, the core of the part lags the.

At the turn of the 20th century, the use of molten salt as a heating and quenching medium for steels was developed in England. It rapidly came into use in Europe as a low-cost method of heat treating. Equipment was inexpensive, and molten salt provided a reproducible method of heat treatment. In this short article I will review the types of salts used for heat treating and some hazards.

In the realm of heat treatment processes, the salt bath heat treatment method has emerged as a reliable and efficient technique. This article aims to shed light on the working principle, types, advantages, disadvantages, and applications of salt bath heat treatment. Let's dive into the world of this fascinating process.

The Benefits of Salt Quenching for Alloy Steel Many of the same benefits derived by heat-treating HSS in molten salts apply to processing tool steel and alloy steel products in salts. For example, increased toughness can be obtained by quenching into salt, rather than oil.

Heat Treat Today's Technical Tuesday feature provides an overview of the heat treatment process and the benefits wrought from heat treating in salt baths. The article also illuminates details to understand part composition and the austempering and quenching process as a whole.

Heat Treating Using Oil Quenching And Molten Salt Baths I AGCS

At the turn of the 20th century, the use of molten salt as a heating and quenching medium for steels was developed in England. It rapidly came into use in Europe as a low-cost method of heat treating. Equipment was inexpensive, and molten salt provided a reproducible method of heat treatment. In this short article I will review the types of salts used for heat treating and some hazards.

Salt bath hardening is a popular process for components having a complex shape and varying widely in cross-section and weight. This may include, for instance, shafts, gear wheels, or tools. For such components partial hardening can be used to harden different areas to various levels of hardness. This can be accomplished through heat treatment in a salt melt. What is more, the slow quenching.

This article provides information on the salt baths used for a variety of heat treatments, including heating, quenching, interrupted quenching (austempering and martempering), case hardening, and tempering. It describes two general types of salt bath systems for steel hardening: the first type uses atmosphere austenitizing followed by salt quench and the second type employs austenitizing salt.

Salt Bath Heat Treatment: Process, Applications and Advantages Salt bath heat treatment is a specialized thermal processing technique widely used in the metallurgical industry for improving the mechanical and physical properties of metals. Unlike conventional air or gas furnaces, salt baths offer uniform heating, rapid thermal transfer, and reduced oxidation, making them particularly suitable.

Tecma Srl

In the realm of heat treatment processes, the salt bath heat treatment method has emerged as a reliable and efficient technique. This article aims to shed light on the working principle, types, advantages, disadvantages, and applications of salt bath heat treatment. Let's dive into the world of this fascinating process.

The uniformity of salt bath heating and quenching results in more predictable post-hardening size changes than other heating and quench cooling procedures. According to D. Scott MacKenzie, Ph.D., FASM, a research scientist of metallurgy at Houghton International, "Since metals have high thermal conductivity, the core of the part lags the.

A work part immersed into a molten salt is heated by heat transferred by conduction (combined with convection) through the liquid media (salt bath). The heat transfer rate in a liquid media is much greater than that in other heating mechanisms: radiation, convection through a gas (e.g., air). Controlled cooling conditions during quenching.

At the turn of the 20th century, the use of molten salt as a heating and quenching medium for steels was developed in England. It rapidly came into use in Europe as a low-cost method of heat treating. Equipment was inexpensive, and molten salt provided a reproducible method of heat treatment. In this short article I will review the types of salts used for heat treating and some hazards.

Heat Treatment - TAKAHIRO ENGINEERING WORKS LTD.

This article provides information on the salt baths used for a variety of heat treatments, including heating, quenching, interrupted quenching (austempering and martempering), case hardening, and tempering. It describes two general types of salt bath systems for steel hardening: the first type uses atmosphere austenitizing followed by salt quench and the second type employs austenitizing salt.

The uniformity of salt bath heating and quenching results in more predictable post-hardening size changes than other heating and quench cooling procedures. According to D. Scott MacKenzie, Ph.D., FASM, a research scientist of metallurgy at Houghton International, "Since metals have high thermal conductivity, the core of the part lags the.

At the turn of the 20th century, the use of molten salt as a heating and quenching medium for steels was developed in England. It rapidly came into use in Europe as a low-cost method of heat treating. Equipment was inexpensive, and molten salt provided a reproducible method of heat treatment. In this short article I will review the types of salts used for heat treating and some hazards.

Heat Treat Today's Technical Tuesday feature provides an overview of the heat treatment process and the benefits wrought from heat treating in salt baths. The article also illuminates details to understand part composition and the austempering and quenching process as a whole.

Heat-treatment Of Steel Using Molten-salt Baths

In the realm of heat treatment processes, the salt bath heat treatment method has emerged as a reliable and efficient technique. This article aims to shed light on the working principle, types, advantages, disadvantages, and applications of salt bath heat treatment. Let's dive into the world of this fascinating process.

Heat Treat Today's Technical Tuesday feature provides an overview of the heat treatment process and the benefits wrought from heat treating in salt baths. The article also illuminates details to understand part composition and the austempering and quenching process as a whole.

Heat Treat with Salt Baths Salt bath heat treatment is a heat treatment process comprising an immersion of the treated part into a molten salt or salts mixture.2 There are numerous benefits of heat treatment in salt baths; the most prevalent is that they provide faster heating.

A work part immersed into a molten salt is heated by heat transferred by conduction (combined with convection) through the liquid media (salt bath). The heat transfer rate in a liquid media is much greater than that in other heating mechanisms: radiation, convection through a gas (e.g., air). Controlled cooling conditions during quenching.

QUENCHING IN WARM OIL SAMPLE FOR HEAT TREATMENT AFTER CASE HARDNING IN ...

Salt bath hardening is a popular process for components having a complex shape and varying widely in cross-section and weight. This may include, for instance, shafts, gear wheels, or tools. For such components partial hardening can be used to harden different areas to various levels of hardness. This can be accomplished through heat treatment in a salt melt. What is more, the slow quenching.

Salt Bath Heat Treatment: Process, Applications and Advantages Salt bath heat treatment is a specialized thermal processing technique widely used in the metallurgical industry for improving the mechanical and physical properties of metals. Unlike conventional air or gas furnaces, salt baths offer uniform heating, rapid thermal transfer, and reduced oxidation, making them particularly suitable.

This article provides information on the salt baths used for a variety of heat treatments, including heating, quenching, interrupted quenching (austempering and martempering), case hardening, and tempering. It describes two general types of salt bath systems for steel hardening: the first type uses atmosphere austenitizing followed by salt quench and the second type employs austenitizing salt.

At the turn of the 20th century, the use of molten salt as a heating and quenching medium for steels was developed in England. It rapidly came into use in Europe as a low-cost method of heat treating. Equipment was inexpensive, and molten salt provided a reproducible method of heat treatment. In this short article I will review the types of salts used for heat treating and some hazards.

At the turn of the 20th century, the use of molten salt as a heating and quenching medium for steels was developed in England. It rapidly came into use in Europe as a low-cost method of heat treating. Equipment was inexpensive, and molten salt provided a reproducible method of heat treatment. In this short article I will review the types of salts used for heat treating and some hazards.

Heat Treat with Salt Baths Salt bath heat treatment is a heat treatment process comprising an immersion of the treated part into a molten salt or salts mixture.2 There are numerous benefits of heat treatment in salt baths; the most prevalent is that they provide faster heating.

In the realm of heat treatment processes, the salt bath heat treatment method has emerged as a reliable and efficient technique. This article aims to shed light on the working principle, types, advantages, disadvantages, and applications of salt bath heat treatment. Let's dive into the world of this fascinating process.

Heat Treat Today's Technical Tuesday feature provides an overview of the heat treatment process and the benefits wrought from heat treating in salt baths. The article also illuminates details to understand part composition and the austempering and quenching process as a whole.

A work part immersed into a molten salt is heated by heat transferred by conduction (combined with convection) through the liquid media (salt bath). The heat transfer rate in a liquid media is much greater than that in other heating mechanisms: radiation, convection through a gas (e.g., air). Controlled cooling conditions during quenching.

Salt bath hardening is a popular process for components having a complex shape and varying widely in cross-section and weight. This may include, for instance, shafts, gear wheels, or tools. For such components partial hardening can be used to harden different areas to various levels of hardness. This can be accomplished through heat treatment in a salt melt. What is more, the slow quenching.

This article provides information on the salt baths used for a variety of heat treatments, including heating, quenching, interrupted quenching (austempering and martempering), case hardening, and tempering. It describes two general types of salt bath systems for steel hardening: the first type uses atmosphere austenitizing followed by salt quench and the second type employs austenitizing salt.

The Benefits of Salt Quenching for Alloy Steel Many of the same benefits derived by heat-treating HSS in molten salts apply to processing tool steel and alloy steel products in salts. For example, increased toughness can be obtained by quenching into salt, rather than oil.

The uniformity of salt bath heating and quenching results in more predictable post-hardening size changes than other heating and quench cooling procedures. According to D. Scott MacKenzie, Ph.D., FASM, a research scientist of metallurgy at Houghton International, "Since metals have high thermal conductivity, the core of the part lags the.

Salt Bath Heat Treatment: Process, Applications and Advantages Salt bath heat treatment is a specialized thermal processing technique widely used in the metallurgical industry for improving the mechanical and physical properties of metals. Unlike conventional air or gas furnaces, salt baths offer uniform heating, rapid thermal transfer, and reduced oxidation, making them particularly suitable.