The types of carpet pile explained

by Admin

Posted on 16-06-2023 05:56 PM

Although axminster and wilton still use the traditional woven method, the vast majority of carpets produced today are tufted. Modern manufacturing techniques mean that it takes just an hour to produce a roll of tufted carpet, whereas it takes around eight hours to create a roll of woven. Tufted carpets can produce a variety of different types of carpet pile too, depending whether their looped yarn is cut into tufts or left as loops.

In addition to pile height, the type of fiber used in your carpeting will impact its appearance and feel. These are the four most common types of carpet fibers:.

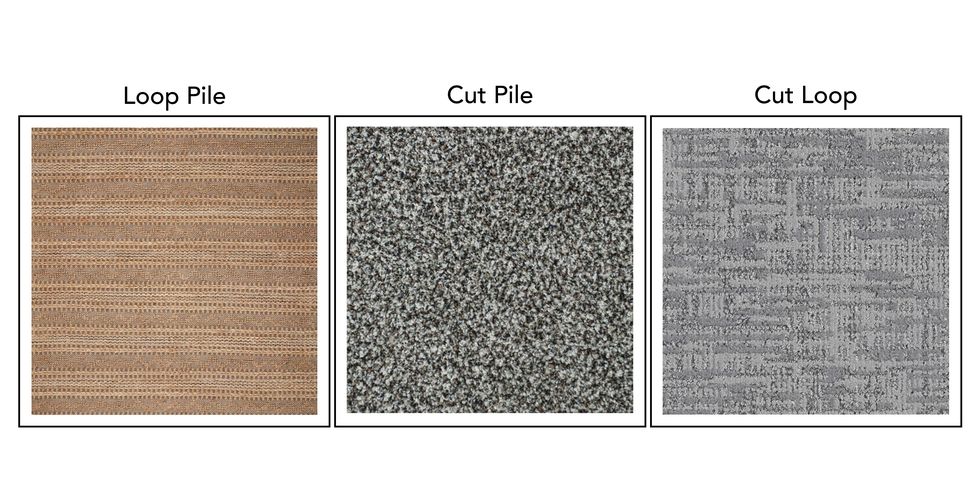

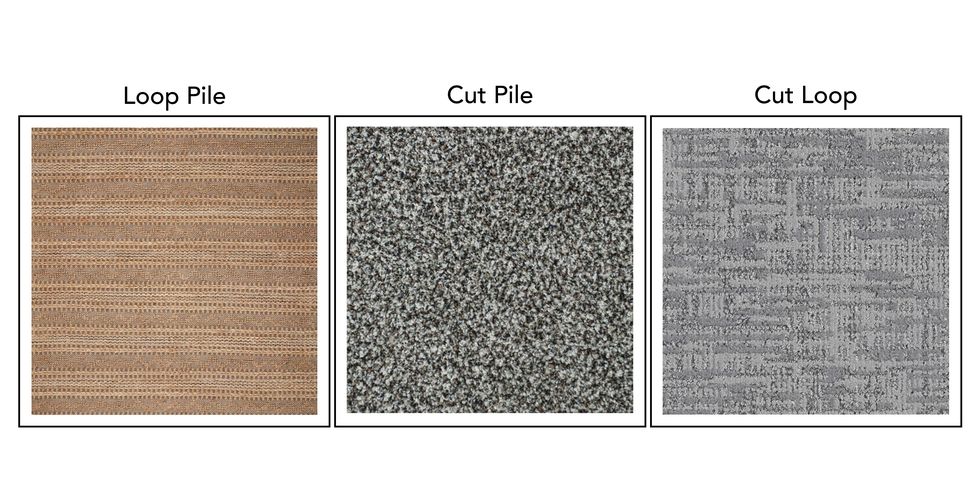

Carpet is created by looping yarn-style material through backing and then creating a particular pile on the other side (i. E. The upside). There’s a loop pile (i. E. Berber) and cut pile (i. E. Saxony). The type of pile will determine the carpet texture, but it should also be noted that the carpet fiber will also have an effect. Below we set out the various carpet options for both main types of pile.

Tufted vs woven carpet pile

Bonded carpets are created by applying adhesives to the yarns themselves, rather than having the yarns sewn into a backing like tufted or loop pile carpets, bonded carpets simply glue the yarns to a backing.

The most popular form of this carpet is commercial carpet tiles.

The most popular form of this carpet is commercial carpet tiles.

Woven: woven carpet is made using a labor-intensive method whereby colors and decoration are woven in rather than printed onto the surface. A high-end product, it is usually made from 80 to 100 per cent wool, and it comes in two forms: axminster, often patterned with a velvet finish, and wilton, which can be plain or textured. Tufted: tufted carpet is the most popular type, with a more varied choice of styles. It is made by punching the pile yarn into a backing fabric using needles, which produces cut and loop pile designs. Cut-pile: there are lots of variations of cut-pile carpets.

This is the third chapter of the architects guide to choosing the right carpet. Download the full guide here. Among the many decisions to be made when selecting carpet, colour and design are actually the final aspects. First come important decisions as to the type or types of carpet most suitable for your project, and your choices will impact aspects such as delivery time, cost, quality, durability and, finally, design options. Should you choose wall to wall or carpet tiles ? tufted, woven or needle-punched construction? a knowledge of carpet construction can assist you as you make important decisions in the specification phase, buying phase and, not least, the fitting phase of your flooring project.

Berber loop pile carpet

Polypropylene is another popular carpet fiber, used in commercial applications and in growing numbers of residential settings, and is almost as soft as nylon. Also known as olefin , polypropylene fibers are similar to natural wool and are often used as a synthetic wool substitute. This fiber is highly stain-resistant but is prone to soiling and holding onto oils which in turn, collect dirt. It is, however, relatively easy to clean—bleach can even be used in some cases. Polypropylene is not as resilient as nylon, so is therefore commonly used for loop-style carpets, such as berbers. The cost of polypropylene is slightly less than most nylon carpets, but more than polyester and acrylic.

Loop pile carpet is made from loops of yarn that create a hard-wearing carpet ideal for higher traffic areas. These types of carpet don’t feel as luxurious on bare feet as most types of cut pile carpet, but it has a much warmer and softer feel than hardwood, so is a good compromise between the two.

Start learning about different carpet options by becoming familiar with key vocabulary. Fiber: the principal material of a carpet that is seen and felt on the visible surface. Pile: the surface of the carpet, made up of looped carpet fibers. Weight: the number of fibers in a carpet. The more fibers, the heavier the weight, and the better the carpet quality. Density: the number of fibers in a pile. The more fibers, the denser the pile, and the higher the carpet quality. Height: the length of the wear layer of the carpet, measured from the top of the pile to the top of the backing.

As we mentioned below, different types of carpet fibers can be attached to the carpet backing in many different ways—creating different types of carpet piles! the different cuts, heights, and textures you can achieve with different types of carpet piles all suit various needs. For example, rooms with high traffic levels will need a different pile than rooms designed for comfort that see little traffic. Here’s a crash course in different types of carpet piles.

Whether designing your dream home or giving new life to an existing space, the softness and warmth of wall-to-wall carpeting might be right for you. As you consider the different types of carpet, you’ll see certain fiber names again and again—polyester, nylon, wool, polypropylene, and triexta among them. This guide breaks down these types as well as piles and pile heights. We go over the strengths and drawbacks of each so you can make the most informed decision for your space.

Carpet is manufactured by sewing strands of yarn into a backing material, creating thousands of yarn loops known as “piles. ” there are three types of carpet determined by pile: cut pile - yarn loops are cut. This is one of the most popular carpet types. Texture helps to hide footprints and vacuum cleaner marks. Shag - cut-pile with a taller height of yarn. Saxony - cut-pile with lower, smoother finishes. Frieze - cut-pile with twisty, medium height that creates a less formal but perfect foundation for a variety of spaces. Loop pile - yarn loops remain uncut. This type of carpet has more texture or pattern and is known for excellent appearance retention.