Refrigerant lines

Maintenance

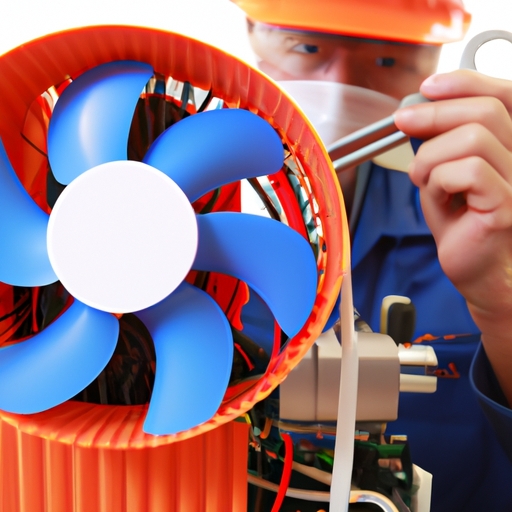

Maintenance of refrigerant lines is very important. Without proper maintenance, your refrigerator will not (function) optimally and it can be dangerous! Neglecting to regularly maintain the lines runs the risk of leaks or complete failure. This could lead to costly repairs as well as potential harm (to) people in close proximity. Let's take a look at how you can ensure that your refrigerant lines are kept up to date.

Firstly, check for any visible signs of damage or wear and tear. If anything looks out of place, replace it immediately! Additionally, make sure you inspect the system on a regular basis for any signs of corrosion or blockages in the pipes. This is especially true if your refrigerator has been exposed to extreme temperatures over a prolonged period of time.

Furthermore, it's important to have routine maintenance done by an experienced technician every couple years depending on usage and climate conditions. The technician will be able to detect any small issues before they become big problems! Furthermore, they will also lubricate all the moving parts which will keep them functioning properly and prevent future breakdowns from happening due to insufficient lubrication.

Finally, always read through manufacturer instructions carefully so you know exactly what needs to be done when performing maintenance checks and repairs yourself! And never attempt something without double-checking first - safety should always come first! In conclusion, taking good care of your refrigerant lines is essential for keeping them running smoothly and safely for years down the road. With proper maintenance you can rest assured that your refrigerator will continue working flawlessly no matter what environment it's placed in!

Firstly, check for any visible signs of damage or wear and tear. If anything looks out of place, replace it immediately! Additionally, make sure you inspect the system on a regular basis for any signs of corrosion or blockages in the pipes. This is especially true if your refrigerator has been exposed to extreme temperatures over a prolonged period of time.

Furthermore, it's important to have routine maintenance done by an experienced technician every couple years depending on usage and climate conditions. The technician will be able to detect any small issues before they become big problems! Furthermore, they will also lubricate all the moving parts which will keep them functioning properly and prevent future breakdowns from happening due to insufficient lubrication.

Finally, always read through manufacturer instructions carefully so you know exactly what needs to be done when performing maintenance checks and repairs yourself! And never attempt something without double-checking first - safety should always come first! In conclusion, taking good care of your refrigerant lines is essential for keeping them running smoothly and safely for years down the road. With proper maintenance you can rest assured that your refrigerator will continue working flawlessly no matter what environment it's placed in!