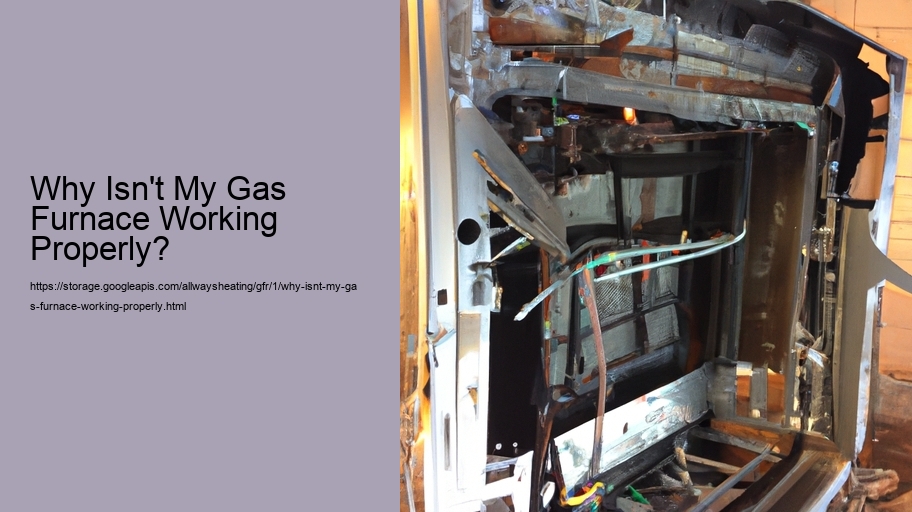

Thermostat issues and troubleshooting

When your gas furnace stops working properly, it can be due to various reasons, but one common culprit is often the thermostat. Contact All-Ways Heating & A/C for gas furnace repair services . The thermostat acts as the command center for your heating system, dictating when and how much heat should be produced by the furnace. If there are issues with this critical component, it can result in your home being too cold or too warm, or even cause your furnace to cease functioning entirely.

Thermostat-related problems can generally be categorized into a few areas: power issues, miscommunication with the furnace, incorrect settings, or mechanical failure.

Firstly, if the thermostat has no display or seems unresponsive, it may simply be a power issue. This could stem from dead batteries if your model is battery-operated. Replacing them may quickly solve the problem. For wired models, ensure that the circuit breaker hasn't tripped and that there is no blown fuse affecting its operation.

Secondly, improper communication between your thermostat and furnace can lead to heating woes. This might occur due to loose wiring or terminal screws inside the thermostat housing. zone control system installation Checking these connections (after turning off power for safety) and ensuring they are secure can resolve such issues. Additionally, modern thermostats require proper programming to communicate effectively with smart furnaces; therefore reprogramming or resetting might be needed.

Incorrect settings on the thermostat could also prevent proper function of your gas furnace. Ensure that it's set to "heat" mode and that the desired temperature setting is above room temperature – otherwise, it won't signal the furnace to start heating. Programmable thermostats need careful setup so their schedules align with your needs; an oversight here could mean heat isn’t being delivered when you expect it.

Lastly comes mechanical failure – over time thermostats can wear out and malfunction which may lead to inconsistent temperatures or lack of response altogether. Signs of a failing unit include frequent temperature swings without reason or hearing clicking sounds without any resulting action from the furnace.

When troubleshooting doesn't yield results or you're uncomfortable handling electrical components yourself (a very reasonable concern), calling an HVAC professional is always advised. They will not only safely diagnose and repair any thermostat issue but also check your entire heating system for other potential problems.

In summary, while a non-functioning gas furnace could indicate various issues within your home’s heating system itself, starting with checking and troubleshooting potential thermostat troubles is often a wise first step towards regaining warmth and comfort in your living space.

Pilot light and ignition system failures

When discussing the intricacies of a gas furnace's functionality, one might encounter several issues that could hinder its proper operation. Among them, pilot light and ignition system failures stand out as common culprits for a malfunctioning gas furnace.

The pilot light in a gas furnace is a small, continuous flame that ignites the main burner when your thermostat calls for heat. It serves as an essential component in older furnaces where it acts as the primary source of ignition for the heating cycle. However, if you find that your home remains cold despite setting your thermostat appropriately, it may be due to the pilot light being extinguished. This could be caused by drafts or air currents within the utility room or simply because of a dirty pilot tube. A thermocouple—a safety device which shuts off gas flow if it does not sense the heat from a lit pilot—may also malfunction and erroneously cut off fuel supply even when everything else is working fine.

As technology has advanced, many modern furnaces have moved away from using a standing pilot light to electronic ignition systems. These systems are more complex but offer higher efficiency and reliability. The two prevalent types of electronic ignition systems are intermittent pilot and hot surface igniters.

Intermittent pilots use a high-voltage electrical spark to ignite the gas only when needed, thus saving energy compared to maintaining a constant flame like older pilots. Meanwhile, hot surface igniters utilize resistance heating elements similar to those found in toaster ovens; they glow red-hot to ignite the gas burner.

Why Isn't My Gas Furnace Working Properly? - condensate drain cleaning

- condensate drain cleaning

- oil to gas conversion

Regardless of whether your furnace uses an old-fashioned pilot light or modern electronic ignitions, troubleshooting often requires professional expertise due to potential risks involved with handling natural gas and high-voltage equipment. Regular maintenance checks by qualified technicians can help prevent unexpected failures during peak usage times by ensuring all components remain clean and functional.

In conclusion, understanding how both traditional pilot lights and contemporary electronic ignition systems work provides valuable insight into why your gas furnace may not be working properly. Whether it’s an extinguished flame or an electrical hiccup disrupting service, recognizing these potential issues allows homeowners to seek timely professional assistance before small problems escalate into expensive repairs—or worse yet—leave you shivering on a cold winter night.

Dirty or clogged filters compromising airflow

When your home feels colder than usual, despite the thermostat being set to your usual cozy temperature, it might be time to take a closer look at your gas furnace. One of the most common culprits for a furnace not working properly is dirty or clogged filters compromising airflow.

The air filter in your furnace plays a pivotal role in maintaining indoor air quality and ensuring efficient operation of your heating system. Its primary function is to trap dust, dirt, pet dander, and other airborne particles before they can enter the furnace. Over time, as these particles accumulate on the filter's surface, they can obstruct the flow of air. exhaust flue checking This seemingly small issue can have significant consequences for both comfort and energy efficiency.

Firstly, when airflow is reduced due to a clogged filter, the furnace has to work harder to circulate warm air through your home. The blower fan strains against the resistance created by the buildup on the filter which can lead to increased wear and tear on its components. In extreme cases, this extra effort can cause overheating or even result in an automatic shutdown of the system as a safety measure.

Furthermore, compromised airflow affects heat exchange within the furnace itself. A well-functioning system relies on a steady stream of air moving across its heat exchanger. When this flow is insufficient due to a dirty filter, heat buildup occurs and reduces heating efficiency. The unit runs longer cycles as it struggles to reach desired temperatures which unnecessarily inflates energy bills and places undue stress on your HVAC system.

It's also important to note that restricted airflow from clogged filters may create uneven heating throughout different areas of your house. You might notice some rooms are warmer than others because not enough warm air reaches them—a phenomenon that disrupts overall comfort.

To avoid these issues caused by dirty or clogged filters compromising airflow:

1. Regularly check and replace or clean (if reusable) your furnace's air filter—typically every 90 days or sooner if you have pets or suffer from allergies.

2. Be mindful of higher-efficiency filters that while trapping more contaminants could restrict airflow more than lower-efficiency ones; always consider manufacturer recommendations.

3. Ensure that nothing blocks return-air vents around your home; furniture or drapes should be clear from those areas.

4. Consider scheduling annual maintenance with an HVAC professional who will inspect not only filters but also other critical components like burners and fans.

In summary, routine maintenance including regular replacement or cleaning of air filters is integral for keeping a gas furnace operating effectively without interruption during cold months. Ignoring such simple tasks could lead down a path toward discomfort and costly repairs—an outcome easily avoidable with just a little attention toward this unsung hero of household warmth: the humble yet essential air filter.

Mechanical wear and tear affecting performance

When your gas furnace begins to falter and fails to provide the warmth and comfort you've come to expect, it's only natural to wonder what could be going wrong. Mechanical wear and tear is a common culprit behind a poorly functioning gas furnace, and understanding how it can affect performance is key in addressing the issue.

As with any mechanical system, your gas furnace comprises an array of components that work in harmony to heat your home. Over time, these parts endure stress from regular use, which can lead to gradual deterioration. For instance, bearings may become worn out, fan belts might lose their tension or snap altogether, and motor components could start to degrade. Each of these instances of wear can manifest as inefficiency in operation or even complete system failure.

The blower motor is a prime example of a component that suffers from regular wear. It's responsible for circulating air throughout your ductwork. As it ages, its efficiency can diminish due to dust accumulation or lubricant breakdown leading to overheating or noisy operation. Similarly, if the heat exchanger – the heart of the furnace where air is heated – starts developing cracks due to metal fatigue from constant heating and cooling cycles, not only does this reduce efficiency but it also poses serious health risks due to potential carbon monoxide leaks.

Ignition systems are not immune either; whether your furnace uses a traditional pilot light or an electronic ignition system, issues like dirt buildup or faulty electrical connections can prevent the burner from lighting properly. The outcome? A cold house and maybe even repeated cycling without producing adequate heat.

Even simple components like filters play a significant role in maintaining performance. If not changed regularly, they become clogged with debris which restricts airflow making the furnace work harder than necessary—this extra strain accelerates wear on other components while also reducing efficacy.

Regular maintenance is crucial in mitigating mechanical wear and tear on your gas furnace. Preventive measures such as replacing filters frequently, scheduling annual inspections by certified technicians who can spot early signs of trouble before they escalate into major problems, keeping internal parts clean and well-lubricated—all contribute toward preserving optimal function for longer periods.

In summary, mechanical wear and tear is an inevitable aspect of owning a gas furnace but one that can be managed through vigilance and proper care. Recognizing its impact on performance helps homeowners take proactive steps towards ensuring their unit remains reliable season after season. Addressing small issues promptly avoids larger disruptions down the line—keeping you warm when you need it most.

Inadequate maintenance leading to breakdowns

Inadequate maintenance is often the silent culprit behind a gas furnace that isn't working properly. It’s easy to overlook the importance of regular upkeep, but the consequences of neglect can become apparent when your furnace starts to malfunction, especially during the times you need it most.

A gas furnace is much like any other piece of complex machinery; it requires periodic attention and care to function optimally. Without routine maintenance, various components within the system can degrade. For example, filters can become clogged with dust and debris, impeding airflow and forcing the furnace to work harder than necessary. This not only diminishes efficiency but also puts undue strain on the blower motor and can lead to overheating or premature failure.

The heat exchanger, a critical component responsible for transferring heat from the combustion process to the air circulating through your home's ductwork, is another part that suffers from inadequate maintenance. If not inspected regularly for signs of wear or corrosion, it could develop cracks that may allow harmful gases such as carbon monoxide to seep into your living space.

Ignition systems in modern furnaces are finely tuned mechanisms that can become unreliable if they're dirty or poorly adjusted. Inadequate maintenance might mean failed ignition attempts which result in your home not being heated as expected.

Burners themselves can accumulate dirt over time which affects their ability to provide an efficient burn. This inefficiency means more fuel is used for less heat produced - translating directly into increased costs for homeowners both in terms of energy bills and potential repair fees.

Another aspect easily overlooked is the calibration of thermostats and safety controls. These devices need regular checks to ensure they accurately measure temperature and regulate system operation correctly. A faulty thermostat may cause erratic heating patterns or prevent the furnace from turning on altogether.

What's more concerning is that some issues stemming from inadequate maintenance carry risks beyond discomfort and expense – they pose serious safety hazards too. Gas leaks, electrical shorts, and fire risks increase significantly when a furnace lacks proper care.

In conclusion, overlooking routine maintenance on your gas furnace doesn't just potentially leave you out in the cold; it also sets up a chain reaction of wear-and-tear that can lead to costly breakdowns or even endanger household occupants' health and safety. To keep your gas furnace working properly – efficiently, reliably, safely – make sure you adhere strictly to recommended service schedules as outlined by manufacturers or trusted HVAC professionals. Regular check-ups will prolong its lifespan while assuring peace of mind throughout those chilly months when you depend on it most.

Blocked or leaky ductwork impacting efficiency

When it comes to ensuring that your gas furnace operates effectively and efficiently, the condition of your ductwork is crucial. Ductwork is the network of tubes in walls, floors, and ceilings; it carries the warm air from your furnace to every part of your home and returns cooler air back to the furnace for reheating. However, if you're experiencing issues with your gas furnace not working properly, one potential culprit may be blocked or leaky ductwork.

Blocked ductwork can occur for a variety of reasons. It might be due to a buildup of dust and debris over time which can restrict airflow. This not only strains your furnace as it works harder to push air through the blockage but also results in uneven heating throughout your home. Some rooms may become too hot while others remain cold because they're not receiving their fair share of warm air.

In other cases, furniture or other objects may have been inadvertently placed over vents in certain rooms, impeding airflow. oil to gas conversion Moreover, if renovations were conducted without considering the impact on existing ductwork layout, some sections may have been closed off entirely.

Leaky ductwork presents another set of problems that impact efficiency. If there are gaps or cracks in the ducts – possibly stemming from corrosion over time or poor installation – heated air will escape before reaching its intended destination. This leakage means that energy is being wasted: Your furnace has to work overtime to compensate for lost heat, driving up energy consumption and costs.

Furthermore, leaks can create pressure imbalances that lead to more serious mechanical failures within the system. The loss of heated air into unconditioned spaces such as attics or basements is akin to throwing money away as you pay for heat that never warms your living areas.

To diagnose whether blocked or leaky ductwork is affecting your gas furnace's performance requires a thorough investigation which often involves inspecting accessible parts of the ducts visually for any obvious signs of obstruction or damage. Professional HVAC technicians use specialized tools like smoke pencils or diagnostic cameras and perform pressure tests to determine if there are less visible leaks present within the system.

Once identified, solutions range from cleaning out blockages, repositioning furniture that obstructs vents, repairing any holes or gaps using mastic sealant or metal tape (never standard duct tape), and insulating exposed sections of ductwork as necessary.

Regular maintenance checks by an HVAC professional should include assessments of both the furnace itself and its associated ductwork to ensure everything is functioning optimally. By addressing issues related to blocked or leaky ductwork promptly when they arise - ideally before they cause significant efficiency losses - homeowners save money on energy bills while enjoying consistent comfort levels throughout their homes.