The Scientific Research Behind Cold-Formed Steel and Its Durability

In the ever-evolving globe of building and architecture, the quest for products that provide strength, longevity, and simplicity of usage is perpetual. What is the Revolutionary Building Remedy That Integrates Toughness and Rate? Discover Cold-Formed Steel Structure Kits! . Amongst the myriad of choices readily available today, cold-formed steel (CFS) becomes an advanced structure remedy, perfectly integrating strength with efficiency. This essay explores the scientific research behind CFS and its amazing strength, shedding light on why CFS structure kits are changing the construction market.

Cold-formed steel refers to architectural products that have actually been formed at area temperature, making use of high-strength steel sheets that are rolled or marked to form a selection of shapes. Unlike hot-rolled steel, which is formed at high temperatures, CFS keeps its structural honesty without the internal tensions that can arise from cooling down hot steel. This process enhances CFS with impressive strength-to-weight ratios, making it an ideal material for contemporary construction.

One of the essential clinical principles underpinning the strength of CFS is the home of stress hardening. As the steel is created at reduced temperatures, the material goes through job hardening, which boosts its return toughness. This process repositions the crystalline framework of the steel, making it harder and more powerful than its hot-rolled equivalent. As a result, buildings created with CFS can stand up to significant tons and anxieties, from heavy snow to high winds, without jeopardizing their architectural soundness.

An additional significant element adding to the toughness of CFS is its galvanized finishing, which protects the steel from deterioration. This zinc layer functions as a sacrificial layer, rusting gradually to protect the steel underneath. The outcome is a material that preserves its honesty and look over a long life expectancy, even in severe weather.

Cold-formed steel's versatility is yet an additional innovative facet. It can be manufactured right into a wide range of shapes and sizes, using unmatched adaptability in layout. From the framing of walls and roofs to the development of elaborate architectural attributes, CFS can fit the most ingenious and tough designs.

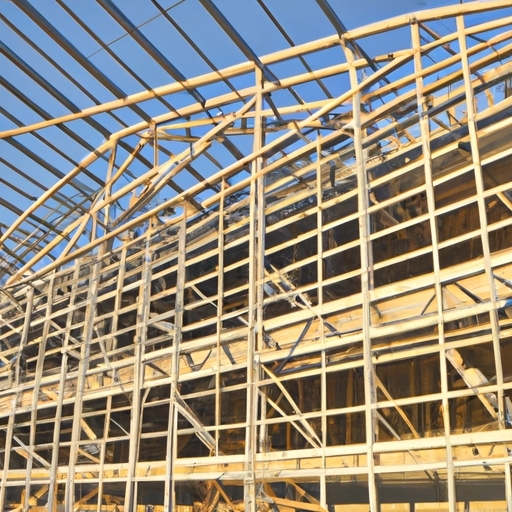

The rate at which CFS structures can be set up is a testimony to its effectiveness. CFS structure kits come precut, punched, and ready to construct, substantially reducing on-site labor and construction time. The lightweight nature of the steel allows for much easier handling and quicker installment without the demand for hefty training tools. These packages also provide a degree of precision that is challenging to attain with conventional structure materials, lowering waste and mistakes on the construction site.

Cold-formed steel is not just tough and efficient yet also sustainable. Steel is one of the

Advantages of Cold-Formed Steel in Building Speed and Performance

In the dynamic globe of construction, the pursuit for products that provide both durability and effectiveness is continuous. Get in cold-formed steel (CFS), an advanced building solution that has been obtaining grip as a result of its extraordinary mix of sturdiness and rate of assembly. Cold-formed steel structure sets illustrate contemporary building and construction methods, where precision-engineered components are created for fast and very easy erection on-site, substantially boosting the general building procedure.

One of one of the most substantial advantages of cold-formed steel is its strength-to-weight proportion. Regardless of being lighter than conventional structure products like hot-rolled steel or concrete, CFS supplies exceptional strength and strength, making it an ideal selection for a selection of frameworks. This intrinsic strength enables higher periods and taller wall surfaces, all while preserving structural honesty, which is especially helpful in areas prone to seismic activity or high winds.

Rate and effectiveness go to the forefront of cold-formed steel's benefits. Since the components are manufactured off-site to specific specs, there's an extreme decrease in on-site labor and the moment required for setting up. This prefabrication procedure means that the individual aspects of a structure package can be rapidly pieced together like a large jigsaw problem, minimizing construction times by weeks or perhaps months. This is not just affordable but likewise lessens the disturbance frequently related to construction jobs, a boon for both professionals and clients.

Moreover, the accuracy of cold-formed steel components makes sure a high degree of precision, leading to fewer errors during the building and construction stage. This accuracy adds to much better installation of components and an extra impermeable structure, which enhances power efficiency and brings about long-lasting cost savings for building proprietors.

One more benefit of cold-formed steel is its versatility. The material can be quickly changed on-site if necessary, which is a crucial factor to consider in the hectic construction atmosphere where modifications and adjustments are frequently required. The lightness of CFS likewise suggests that much less heavy machinery is needed on-site, further minimizing costs and logistical intricacies.

Sustainability is a progressively vital consider building and construction, and CFS scores high hereof too. It is made from recycled materials and is itself fully recyclable at the end of its life, decreasing the environmental impact of building and construction jobs. This aligns completely with the expanding demand for eco-friendly building practices and assists jobs attain greater ratings in sustainability analyses.

To sum up, cold-formed steel structure sets are indeed an advanced solution in the construction market. By integrating sturdiness with speed and efficiency, they provide a sophisticated strategy to building that fulfills the needs of modern-day building

Comparing Cold-Formed Steel to Traditional Building Materials

When considering the future of building and construction and the mission for innovative solutions, one of the standout choices is the use of cold-formed steel (CFS) in developing kits. As we discover this revolutionary structure solution, it emerges that CFS integrates sturdiness with efficiency, offering an one-upmanship over conventional building materials.

Cold-formed steel, an item of modern-day engineering, is produced at room temperature, which protects the steel's strength and ductility. This process contrasts markedly with hot-rolled steel, which is developed at heats and can lose some strength in the cooling process. CFS constructing sets are meticulously made with precision, ensuring each part fits perfectly, thus reducing the moment and expense associated with typical building.

One of the most considerable benefits of CFS is its amazing strength-to-weight proportion. Despite being lightweight, CFS offers premium structural stability, making buildings much more immune to environmental stressors such as quakes, hurricanes, and heavy snow loads. This toughness is not nearly standing up to the elements; it likewise includes fire resistance and pest resistance, adding to the longevity of the structure.

Additionally, cold-formed steel is an eco-friendly choice. It is 100% recyclable, which lowers the carbon footprint of building and construction jobs. The manufacturing procedure additionally produces minimal waste, as CFS structure packages are pre-engineered to specific requirements, making sure ideal material usage. This precision decreases on-site waste and contributes to a cleaner construction site.

One more factor that can not be neglected is the rate at which CFS buildings can be erected. The prefabricated nature of CFS components suggests that building and construction timelines can be substantially shortened. This rapid setting up is not simply a matter of ease; it equates into minimized labor expenses and enables quicker tenancy, which can be specifically beneficial in commercial tasks where time is cash.

When contrasted to typical structure materials like wood and concrete, CFS sticks out for its resistance to common concerns like rot, mold, and termites. Wood, while a renewable resource, is prone to these troubles, which can jeopardize the building's integrity and sustain extra maintenance prices. Concrete, on the other hand, is understood for its stamina yet does not have the versatility and agility of CFS, making it less appropriate for some modern style needs.

Finally, cold-formed steel structure kits go to the forefront of building advancement. They offer a mix of sturdiness and rate, offering an option that fulfills the needs of contemporary structure tasks. With the advantages of being lasting, affordable, and resistant, CFS is not simply a 17

Flexibility and Applications of Cold-Formed Steel Building Kits

The building market continuously advances, seeking ingenious remedies that stabilize stamina, effectiveness, and convenience. In the middle of this quest, cold-formed steel (CFS) building packages have actually become an advanced building option, incorporating the toughness of typical steel with a price of building that appeals to the contemporary building contractor's demand for rate and accuracy.

Cold-formed steel refers to the procedure of shaping steel into architectural members at space temperature level. This procedure changes the steel's properties, making it lighter, yet maintaining its high strength-to-weight proportion. Unlike hot-rolled steel, which is formed at high temperatures, CFS can be formed right into intricate sizes and shapes, using unmatched flexibility in layout.

The versatility of CFS structure kits is one of their most engaging attributes. These kits can be made use of for a wide variety of applications, from household real estate to business structures, and from simple storage space devices to complex skyscraper frameworks. Engineers and designers value the ability to develop personalized designs that fulfill specific aesthetic and functional demands without being constrained by product limitations.

Furthermore, the accuracy of CFS parts, which are normally made in a controlled factory setting, makes certain that each piece is consistent in quality and dimensions. This precision promotes a smooth setting up process on-site, decreasing the likelihood of building and construction delays and cost overruns. The premade nature of CFS packages suggests that parts can be quickly set up, often with simple bolt-together construction, increasing the total structure timeline.

The toughness of cold-formed steel is equally remarkable. It provides exceptional resistance to fire, termites, and moisture-- common issues that pester typical structure products like wood. The toughness of CFS indicates that frameworks can withstand harsh ecological conditions, making them suitable for usage in areas prone to quakes, storms, or hefty snowfalls. This strength equates to reduce maintenance expenses and a longer life-span for the structure, supplying long-term worth to owners and passengers.

Sustainability is one more advantage of CFS structure kits. Steel is just one of one of the most recycled products on earth, and CFS components can be made from reused steel, minimizing the ecological impact of building. Furthermore, the light-weight nature of cold-formed steel makes it simpler and much more cost-efficient to transport, further reducing the carbon footprint associated with structure projects.

In regards to expense, CFS structure packages provide a competitive price when considering the life-span and minimized upkeep needs of the framework. While the in advance price might be greater in comparison to some standard products, the long-lasting financial savings, effectiveness, and flexibility present an engaging instance for their use

Ecological Benefits and Sustainability of Cold-Formed Steel

When we start the trip of building a new building, whether it's a household home, an industrial room, or an industrial facility, we unavoidably face a myriad of decisions regarding products, price, resilience, and ecological impact. Amidst the substantial sea of selections, one innovative remedy sticks out for its special combination of toughness and efficiency: cold-formed steel (CFS) structure sets.

Cold-formed steel has become an innovative structure product, offering a blend of stamina, versatility, and sustainability that is difficult to match. The procedure includes rolling or pressing steel right into semi-finished or ended up products at area temperature, which contrasts with hot-formed steel that is crafted at high temperatures. This approach not only saves power however also permits accurate shaping, leading to components that are incredibly strong and lightweight.

Among the most engaging environmental advantages of cold-formed steel is its sustainability. Steel is the most recycled material on the planet, and CFS components can be made from recycled steel, reducing the demand for brand-new basic materials and the environmental footprint connected with their removal and processing. In addition, at the end of a building's life cycle, the steel can be reused yet once again, developing a closed-loop system that significantly diminishes waste.

In regards to power performance, structures created with CFS are champs. The material allows for tight and precise settings up and, when combined with correct insulation, results in frameworks that are highly energy-efficient, reducing heating & cooling costs. This is not just advantageous for the environment by reducing power usage and greenhouse gas exhausts yet also for the structure owner's budget.

Additionally, CFS structure packages are made for quick setting up, lowering building and construction time and on-site waste. The components are pre-engineered to fit together effortlessly, which reduces the requirement for additional sources and on-site alterations that can result in excess scrap product. This streamlined building and construction process not only accelerates project timelines yet additionally minimizes the environmental effect related to traditional construction methods.

Cold-formed steel additionally has exceptional sturdiness, able to endure severe climate condition, fire, and pests. This durability translates into a much longer life expectancy for buildings and minimizes the demand for frequent fixings or replacements, further preserving sources and reducing the waste related to building maintenance.

In conclusion, as we grapple with the pressing need for sustainable development, cold-formed steel building sets provide a beacon of hope. With their outstanding stamina, accuracy, and ecological advantages, these materials give a smart option for those looking for to produce durable, energy-efficient frameworks without jeopardizing on environmental obligation

Price Evaluation: Lasting Cost Savings with Cold-Formed Steel Structures

In the ever-evolving world of building and construction and design, the mission for products that offer longevity, cost-effectiveness, and speed of assembly is nonstop. One revolutionary building solution that examines all these boxes is using cold-formed steel (CFS) frameworks, specifically in the kind of structure kits. These sets have transformed the sector by supplying a combination of toughness and effectiveness that is hard to match.

Cold-formed steel stands out in the building and construction landscape for its impressive strength-to-weight proportion. Unlike typical hot-rolled steel, CFS is formed at space temperature, which leads to a lighter yet solid material that can stand up to serious weather conditions and seismic activities. This fundamental strength implies that buildings can be created with less materials while preserving architectural integrity, causing guide cost reductions.

From an expense analysis perspective, the long-term cost savings associated with CFS frameworks are significant. The accuracy of steel parts made in a controlled manufacturing facility environment converts right into much less waste and an extra effective use sources. The predictability of CFS additionally simplifies the planning and budgeting process, as the expenses are recognized upfront, reducing the risk of unforeseen costs throughout building.

In addition to product financial savings, labor prices are additionally decreased with CFS structure packages. The prefabricated nature of these packages indicates that elements are made to mesh effortlessly, which substantially speeds up the building procedure. This is a significant benefit in today's fast-paced construction industry where time is essential. Faster conclusion times not only indicate reduced labor prices however likewise enable quicker occupancy, which is specifically advantageous for commercial tasks where time-to-market is an important factor.

Additionally, the lasting upkeep prices of CFS frameworks are lower compared to conventional building materials. Steel does not succumb to termites, mold and mildew, or rot, and it is non-combustible, which can result in reduced insurance coverage premiums. Over the life expectancy of the building, these aspects can result in substantial financial savings and contribute to a more beneficial roi.

Cold-formed steel building kits also use a degree of design versatility that is both cutting-edge and functional. The flexibility of CFS permits a variety of building styles and can fit future alterations or growths with relative ease. This suggests that a building can adjust to transforming requirements with time without sustaining the large expenses normally connected with renovations.

Environmental considerations are likewise at the center of the advantages of CFS. Steel is just one of the most recycled products in the world, and the sustainable nature of CFS structure sets contributes positively to

Just How to Begin with Cold-Formed Steel Building Kits

As we venture into the world of contemporary building and construction, an innovative structure solution has actually been progressively getting grip, offering both toughness and effectiveness in a bundle that is surprisingly very easy to handle. Go into cold-formed steel structure kits, the ingenious solution to the demands of modern structure projects. Whether you're an experienced specialist or a do it yourself fanatic aiming to embark on a new job, these kits give a streamlined path to constructing durable and durable structures.

Cold-formed steel (CFS) is manufactured at area temperature level, which entails rolling or pushing steel into semi-finished or finished items at relatively reduced temperature levels. This procedure causes a lightweight yet high-strength product that can be conveniently delivered and taken care of on-site. Yet how does one start with these versatile structure packages? Allow's explore the actions to embrace this modern-day building marvel:

1. ** Research and Planning: ** Start by comprehending the extent of your project. What are you aiming to build? A garage, home enhancement, or probably a whole business structure? Study local building codes and guidelines to guarantee conformity. Cold-formed steel is known for its adaptability, making it suitable for different applications.

2. ** Select a Credible Vendor: ** Choose a supplier that uses high quality cold-formed steel building sets. Seek firms with good evaluations, customer testimonials, and a performance history of successful projects. They should provide detailed information on their kits, including layout specifications and design qualifications.

3. ** Customize Your Kit: ** Among the elegances of CFS structure sets is personalization. Vendors commonly offer basic styles that can be modified to meet certain needs. Think about variables like dimension, design, and additional features such as windows, doors, and insulation. Collaborate with the provider to customize the package to your precise needs.

4. ** Acquire the Needed Devices: ** Cold-formed steel construction does not require heavy equipment. Nevertheless, you will certainly require standard devices such as screw guns, drills, clamps, and gauging tapes. Guarantee you have the ideal tools for assembly, which can commonly be performed with common power devices.

5. ** Prepare the Website: ** Before your set shows up, prepare the structure site. This entails leveling the ground, laying a foundation, and ensuring that all energies are suitably routed. A strong structure is important for the stability and durability of any kind of structure, and this is no various for structures constructed with cold-formed steel.

6. ** Construct Your Structure: ** Upon the arrival of your package, you can begin the assembly procedure. CFS constructing sets come with pre-cut, pre