Key Takeaways

- Summary of compressor structures and innovative energy-saving techniques

- Efficient compressors designed for reduced energy usage

- Cutting-edge technologies in compressor development

- Insights into compressor regulation mechanisms

- Strategies for controlling compressor energy use

- Approaches to enhance performance in compressor frameworks

Compressor Systems | Advanced Energy Saving Solutions | Overview of Compressor Systems

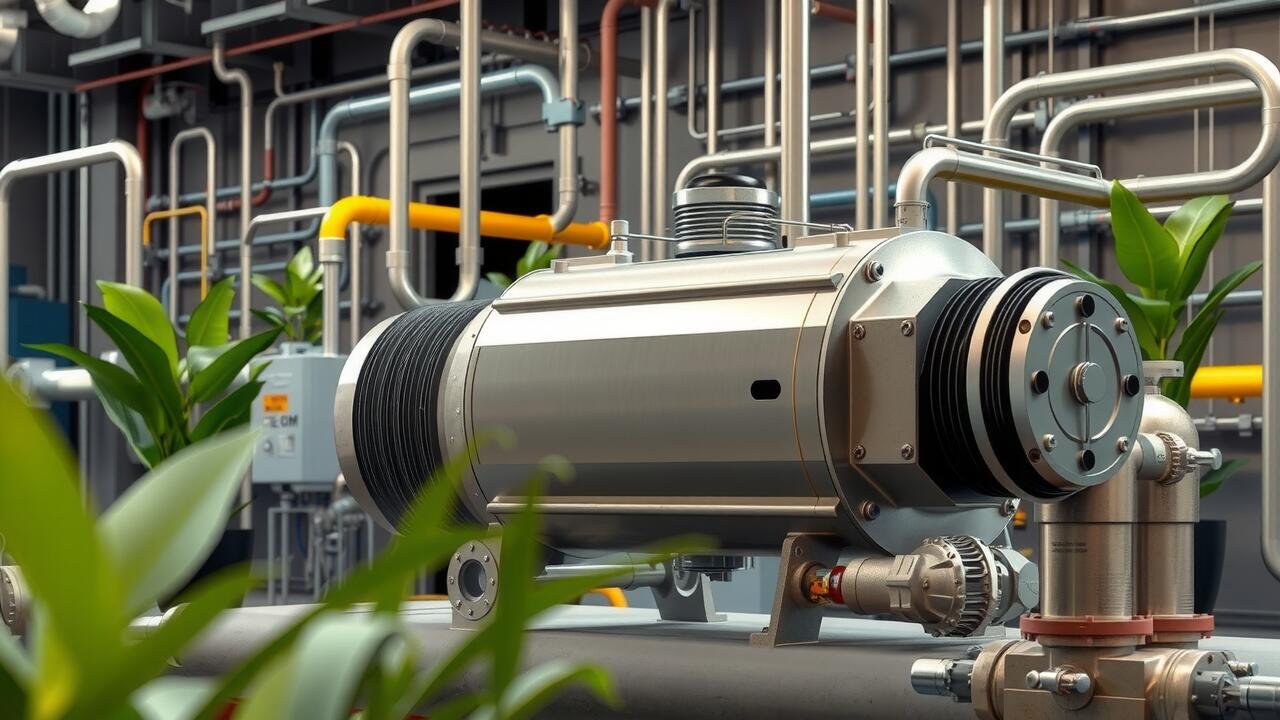

Compressor systems play a crucial role in various industrial applications, providing the necessary air compression for diverse processes. Advanced energy-saving solutions have been developed to optimise these systems, enhancing efficiency and reducing operational costs. Common types include piston compressors, rotary screw compressors, and air compressors, each designed to meet specific operational demands. Kaeser compressors, for instance, are renowned for their reliability and efficiency in delivering compressed air. The ongoing evolution of compressor technologies ensures that industries can benefit from improved performance while adhering to energy-saving standards, making these systems vital for sustainable operations. By integrating energy-efficient compressors into their operations, businesses can significantly reduce their environmental footprint and operational expenses.

Compressor Systems | Advanced Energy Saving Solutions | Definition and Purpose of Compressors

Compressor systems play a crucial role in various industries, functioning primarily to convert electrical energy into mechanical energy through compression. These systems not only deliver compressed air for numerous applications but also support advanced energy-saving solutions. By integrating energy recovery systems, they can significantly reduce operational costs and enhance energy efficiency. Technologies such as compressed air energy storage and vacuum pumps are employed to maximise performance while ensuring sustainable energy savings in both industrial and commercial settings.

The purpose of compressors extends beyond mere air compression; they are integral to optimising overall energy management. Heat pumps and vacuum pumps are essential components in many applications, facilitating effective cooling and heating processes. As industries increasingly turn to grid-scale energy storage and energy-efficient solutions, compressor systems are adapting to meet these demands. Emphasising energy-saving approaches, these systems contribute to a sustainable future while ensuring reliable performance across diverse sectors.

Importance of Compressor Systems in Industrial Applications

Compressor systems play a vital role in various industrial applications by converting mechanical energy into compressed air or gas. This process is essential in powering equipment such as pneumatic tools, pumps, and ejectors. Efficient compressor systems not only improve the performance of machines but also significantly impact the overall electricity supply of a facility. Implementing advanced energy saving solutions within these systems can lead to better utilisation of resources, including energy storage and waste heat recovery, ensuring optimal functionality for applications like boilers and water-cooled systems.

The significance of energy-efficient compressor systems extends beyond mere operational performance. By effectively managing energy consumption and incorporating features such as compressed air storage, industries can achieve substantial cost savings and lower their environmental footprint. The transition to energy-efficient solutions enhances reliability while ensuring that machinery operates under ideal conditions. It also promotes sustainability by reducing reliance on non-renewable resources.

Energy Saving Compressors

Energy-efficient compressor systems play a crucial role in enhancing the overall performance of compressed air applications. These advanced energy saving solutions not only reduce energy use but also optimise the operation of various utilities, such as heating, ventilation and air conditioning (HVAC) systems. By implementing features designed to improve efficiency, such as efficient rotors and properly sized hoses, industries can significantly lower their reliance on heating oil and cooling water. This leads to reduced operational costs and a smaller environmental footprint while ensuring that essential processes remain uninterrupted.

Features of Energy Saving Compressors

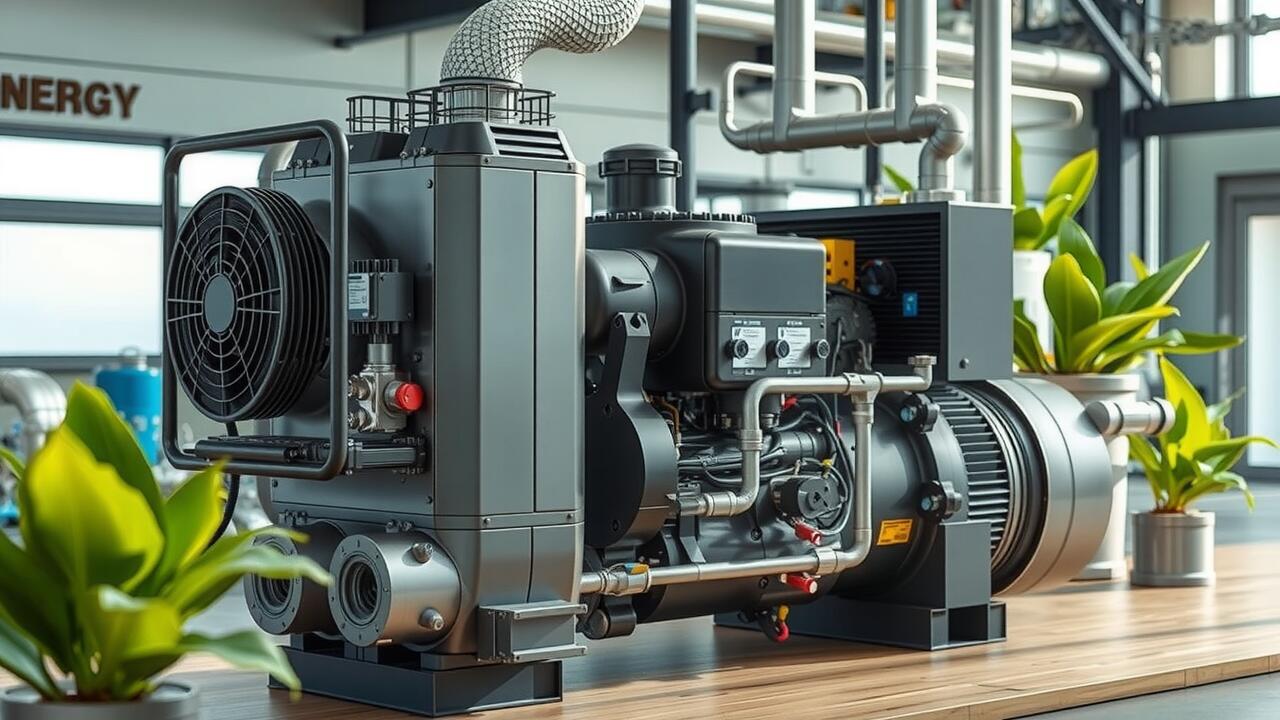

Energy saving compressors are designed to optimise compressor efficiency while minimising energy use. These systems often incorporate advanced technologies such as rotary screw designs that enhance cooling capabilities and reduce electrical energy consumption. By utilising innovative braking systems, these compressors can achieve significant compressor energy savings compared to traditional fixed-capacity compressors. Such features not only improve the overall performance of compressor systems but also contribute to a more sustainable industrial operation.

The integration of compressor control mechanisms plays a vital role in enhancing the functionality of energy saving compressors. Smart control systems enable precise monitoring and regulation of compressor energy use, ensuring that energy consumption aligns with demand. This level of control leads to improved compressor efficiency and a notable reduction in operational costs. Adopting these advanced energy saving solutions is essential for industries aiming to optimise performance while committing to environmentally friendly practices.

Benefits of Implementing Energy Saving Solutions

Implementing advanced energy saving solutions in compressor systems significantly enhances operational efficiency. A small fixed-capacity compressor paired with the latest compressor technology can maintain optimal compressor unit operation, resulting in reduced energy waste. Understanding how you can analyse the energy efficiency of a compressor can lead to informed decisions regarding upgrades. For instance, a new compressor equipped with an intuitive compressor control panel provides real-time data on compressor output and air compressor efficiency.

The benefits extend beyond just immediate savings. Over time, optimising compressor units through advanced compressor software can result in substantial reductions in power consumption. Choosing the optimal compressor type tailored to specific applications not only improves performance but also extends the lifespan of the equipment. These factors contribute to a more sustainable approach, aligning with the principles of Compressor Systems | Advanced Energy Saving Solutions while fostering a proactive maintenance culture within industrial settings.

Advanced Compressor Technologies

Compressor technology has evolved significantly, leading to innovative designs that enhance the efficiency and reliability of compressor systems. Advanced energy saving solutions are now integrated into various compressor models, including air-cooled compressors and new compressor units. These advancements often focus on optimising the performance of individual compressors within a compressor package, allowing compressors to operate more effectively in multiple compressor units. The reliability of compressor systems can be improved through the adoption of cutting-edge technologies by advanced compressor manufacturers, ensuring that the first compressor and subsequent models contribute to energy savings and operational excellence.

Types of Compressor Technologies

Compressor systems encompass several compressor types, each designed for specific applications and efficiency needs. Oil-free compressors are one option, offering clean air for sensitive environments, while heavy-duty compressors are built to handle rigorous industrial demands. Good air compressor selection often involves evaluating various compressor types, including trim compressors and venti compressors, which serve distinct functions in a system. Major compressor brands continue to innovate, providing advanced energy-saving solutions with optimised compressor drives that enhance performance without compromising reliability.

The effectiveness of a compressor system relies heavily on understanding the different technologies available. Energy-saving solutions can significantly impact operational costs, particularly with technologies designed to improve compressor inlet air management. Selecting the right compressor technologies is crucial to achieving the desired performance and efficiency levels. By integrating advanced designs along with appropriate controls, businesses can ensure that their compressor systems meet the modern demands of energy conservation and performance excellence.

Innovations in Compressor Design and Efficiency

Ongoing advancements in compressor design enhance the efficiency of Compressor Systems | Advanced Energy Saving Solutions. Global compressor brands are continuously innovating their products, focusing on energy-saving upgrades that significantly reduce operational costs. Kaeser compressors exemplify this trend, offering cutting-edge compressed air solutions that integrate high-efficiency air systems and energy-saving retrofits. These improvements lead to substantial energy cost savings for industries relying on compressed air systems.

Innovative technologies also promote system energy recovery and the effective use of compressed air energy. The latest designs incorporate features that maximise energy efficiency, such as mechanical vacuum pumps and intelligent control systems. Such innovations ensure that users can achieve optimal performance while minimising power consumption. As a result, organisations can benefit from both enhanced operational efficiency and reduced environmental impact.

Understanding Compressor Controls

Compressor systems play a crucial role in the efficient operation of various industrial applications, where advanced energy-saving solutions are vital. Control systems are essential for managing the performance of these systems, guiding the operation of water-cooled cylinders and electric vacuum pumps to achieve optimal results. An energy-efficiency strategy relies on precise control of air system electricity usage, ensuring that every component works effectively to enhance performance. Innovative air compression techniques offer compressed air alternatives that can lead to unprecedented energy savings, while effective cooling systems maintain optimal temperatures to prevent overheating. By implementing these advanced control systems, businesses can maximise the efficiency of their compressor systems and promote sustainable air solutions.

Role of Compressor Controls in Energy Efficiency

Modern control systems play a vital role in enhancing the energy efficiency of Compressor Systems. By optimising the operation of energy-efficient units, these systems manage operational stability and reduce unnecessary energy consumption. For instance, integrating electric heat pumps with advanced controls can significantly minimise compressed air waste, ensuring that every kilowatt of energy contributes effectively to the process. Research into energy efficiency class metrics can further guide the selection of compressor units that align with sustainable energy supply strategies.

Implementing advanced control mechanisms allows for the effective management of additional electricity supply demands during peak usage times. By utilising air energy storage techniques, Compressor Systems can adjust their output in real time, reducing reliance on fixed-capacity compressors that often generate excessive compression heat. This adaptability not only improves overall system efficiency but also contributes to significant energy savings, aligning with the goals of Advanced Energy Saving Solutions in industrial applications.

Types of Control Systems for Optimising Performance

Advanced control technology plays a crucial role in optimising the performance of compressor systems. By implementing sophisticated control systems, facilities can enhance system efficiency and mitigate the risk of sub-optimal system function. These systems actively monitor compressed air demand and adjust operations to match real-time requirements. Energy-intensive air sources often lead to unnecessary energy losses. Integrated solutions, utilizing fixed speed and variable speed drives, can significantly reduce waste in compressed air use and improve overall performance in vacuum systems.

Tailoring control strategies to the specific needs of air vacuum systems can lead to notable improvements in energy efficiency. Smart controls can better manage the compressed air vacuum, ensuring that systems operate within their optimal parameters. This approach not only maximises efficiency but also minimises the environmental impact by reducing energy consumption. Implementing these advanced energy saving solutions allows organisations to enhance their operational performance and achieve substantial cost savings.

Managing Compressor Power Consumption

Compressor systems play a pivotal role in the compressed air industry, significantly influencing manufacturing energy costs. Addressing power consumption is vital for businesses seeking advanced energy saving solutions. By identifying factors influencing energy use, companies can mitigate potential energy waste and make informed decisions about energy-efficient upgrades. Implementing flexible systems, such as rotary screw air compressors equipped with electronic control systems, can enhance overall energy efficiency. The energy efficiency council highlights the importance of optimizing air systems to achieve significant energy savings, ultimately reducing energy costs and improving operational sustainability.

Factors Influencing Power Consumption in Compressors

Power consumption in Compressor Systems can be significantly affected by various factors. The design of air system parts, such as vacuum pipes and water-to-air heat exchangers, plays a crucial role in determining efficiency and overall performance. Conducting a compressed air audit can identify leaks and inefficiencies that directly contribute to rising energy expenses. A variable capacity unit may be necessary to accommodate variable loads, ensuring that compressors operate only as needed, thus optimising electricity costs and contributing to energy-saving solutions.

Efficiency optimisation is essential for managing power consumption in HVAC systems. System optimisation projects, focused on the integration of advanced technologies and smarter control mechanisms, can lead to substantial reductions in energy use. By assessing operational parameters and adopting strategies that target energy waste, businesses can improve their Compressor Systems while lowering their electricity costs. Prioritising energy-saving solutions is increasingly important for industries looking to enhance performance and sustainability.

Strategies for Reducing Power Consumption

Implementing effective strategies for reducing power consumption in Compressor Systems allows for significant improvements in energy productivity. By utilising advanced control technologies, operators can monitor and adjust the performance of their air systems. For instance, optimising the operation of screw-motor units leads to enhanced efficiency, minimising unnecessary compression and reducing energy use. A comprehensive compressed air guide can provide insights on best practices, helping businesses identify areas for improvement.

Regular energy monitoring is essential in achieving long-term savings. Assessing the performance of electric equipment within compressor systems ensures that any inefficiencies are addressed promptly. Integrating total solutions for air system management can facilitate better performance and reliability. These strategies not only promote sustainability but also contribute to overall operational cost reductions, allowing organisations to maximise the potential of their Compressor Systems | Advanced Energy Saving Solutions.

Maximising Efficiency in Compressor Systems

Maximising efficiency in compressor systems requires a deep understanding of energy use, particularly during continuous operation. Advanced energy saving solutions can significantly reduce power loss in motor systems, enhancing the overall performance of compressor systems. Effective management involves maintaining cylinders and ensuring lubrication of rotors, which helps to optimise functionality. Operators can adjust load pressures according to demand, which improves the reliability of air supply and ensures operational efficiency. Incorporating battery-powered ones alongside traditional air systems can also contribute to emissions reduction, supporting air system proposals that aim for more sustainable practices. This comprehensive approach provides a roadmap for enhancing the productivity of Compressor Systems | Advanced Energy Saving Solutions.

Conclusion

Compressor Systems play a pivotal role in the air solutions market, providing essential functions in various industrial applications. Advanced Energy Saving Solutions are crucial for reducing excessive energy use and minimising installed power requirements. Innovations in compressor design tackle issues like cooling water temperature and standby energy waste, enhancing the efficiency of the air distribution system. Implementing these solutions not only lowers maintenance costs but also optimises pneumatic energy use, providing a sustainable approach to operations. Achieving significant savings through effective management of compressor systems ensures a more environmentally friendly and cost-efficient industrial environment.

FAQS

What are compressor systems used for in industrial applications?

Compressor systems are primarily used to increase the pressure of gases for various applications, including powering pneumatic tools, transporting materials, and operating equipment in manufacturing processes.

How do energy-saving compressors work?

Energy-saving compressors utilize advanced technology to optimise their performance, consume less energy during operation, and incorporate features such as variable speed drives and efficient motor designs to reduce overall power consumption.

What are the benefits of implementing energy-saving solutions in compressor systems?

Implementing energy-saving solutions can lead to significant cost savings in energy bills, improved operational efficiency, reduced carbon footprint, and extended lifespan of equipment due to decreased wear and tear.

What types of compressor technologies are available?

There are several types of compressor technologies, including rotary screw compressors, reciprocating compressors, centrifugal compressors, and scroll compressors, each suited for different applications and operational requirements.

How can compressor controls enhance energy efficiency?

Compressor controls can optimise performance by adjusting the compressor's output based on demand, ensuring that it runs only as needed, which helps to reduce unnecessary energy consumption and improve overall system efficiency.

How do Kaeser compressors contribute to energy efficiency in air systems?

Kaeser compressors, inc. are known for their energy-efficient designs that enhance air system performance. Their compressor technology hasn't just improved the reliability of compressor systems but has also allowed compressors to operate at optimum operation levels. By integrating energy-saving systems and high-efficiency air solutions, they help research energy efficiency while lubricating rotors to ensure a reliable air supply, thus contributing to emissions reduction fund initiatives.

What are the benefits of using high-efficiency air compressors in various air systems?

High-efficiency air compressors provide numerous benefits, including energy efficient operation that can significantly reduce energy costs. These compressors are air cooled, which enhances their overall reliability and performance. By choosing the right compressor system, users can understand energy use better, ensuring that the compressor keeps operating at optimal levels. Solutions like these typically allow compressors to maintain their efficiency even under varying demands, and methods to lubricate rotors effectively contribute to the compressor block's longevity. Additionally, these systems can include features for applications like boiler pre-feed, optimizing their functionality in different scenarios.

How can compressor system reliability be enhanced in various air systems?

To improve compressor system reliability, it's important to choose high-efficiency air solutions that cater to different applications. This guide on air systems outlines how the performance of compressors varies across different models and manufacturers. By selecting the right compressors, users can ensure optimal operations and minimize downtime, thus enhancing overall reliability in their air systems.

What solutions are available for achieving high-efficiency air in compressor systems?

This guide outlines various solutions for enhancing high-efficiency air in compressor systems, focusing on optimising air systems through advanced technologies and best practices.

What are the best practices in maintaining high-efficiency air in compressor systems according to the latest guide?

To maintain high-efficiency air in compressor systems, it is essential to follow best practices such as regular maintenance checks, ensuring optimal settings for pressure and flow, and investing in advanced solutions. These practices not only contribute to the reliability of the equipment but also enhance the overall performance of air systems, making them more energy-efficient. For comprehensive insights, refer to the latest guide on high-efficiency air systems.

What solutions are recommended for achieving high-efficiency air in compressor systems according to the latest guide?

To achieve high-efficiency air in compressor systems, the latest guide recommends several key solutions including the use of advanced monitoring technologies, regular maintenance practices, and the integration of energy-efficient components. Implementing these solutions can significantly improve the performance and reliability of air systems, while also ensuring optimal energy saving.

What strategies can be implemented to achieve high-efficiency air in compressor systems as outlined in the latest guide?

To achieve high-efficiency air in compressor systems, various solutions are recommended in the latest guide, including the use of advanced technologies and regular maintenance practices that ensure optimal performance of air systems.

What innovative solutions are suggested for improving the high-efficiency air performance in compressor systems as described in the latest industry guide?

The latest industry guide outlines several innovative solutions to enhance high-efficiency air performance in compressor systems. These include implementing advanced control systems, optimising component designs, and regular maintenance practices, which all contribute to maximising efficiency in air systems.

What are some innovative solutions mentioned in the latest guide for improving high-efficiency air in compressor systems?

The latest guide presents various innovative solutions to enhance high-efficiency air in compressor systems, focusing on optimising air systems and integrating advanced technologies. These solutions include using variable speed drives and energy recovery systems, which can significantly improve the overall performance and efficiency of air systems.

What are the latest strategies and solutions to improve the high-efficiency air performance in compressor systems as discussed in contemporary air systems guides?

The latest strategies and solutions for enhancing high-efficiency air in compressor systems include implementing advanced technologies, optimising system layouts, and conducting regular maintenance checks. These approaches are well-documented in contemporary air systems guides, which provide detailed insights into achieving optimal air quality and energy savings.