Air Plug Gauge Calibration Procedure . To provide an understanding of air gage theory. To understand basic troubleshooting, maintenance and verification. Each plug gage takes about 15 to 20 mins to do in order to ensure our findings are. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and set discs conforming to asni/asme specifications. Grm calibrates plug gages using master standards and our linear measurement machine. To learn some of the applications for air gaging. The plug gage has been found to be highly accurate,. Within one week of the completion of the measurements, participating laboratories are required to send the attached.

from nabgauge.com

Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and set discs conforming to asni/asme specifications. Within one week of the completion of the measurements, participating laboratories are required to send the attached. Grm calibrates plug gages using master standards and our linear measurement machine. To provide an understanding of air gage theory. To learn some of the applications for air gaging. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Each plug gage takes about 15 to 20 mins to do in order to ensure our findings are. The plug gage has been found to be highly accurate,. To understand basic troubleshooting, maintenance and verification. The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both.

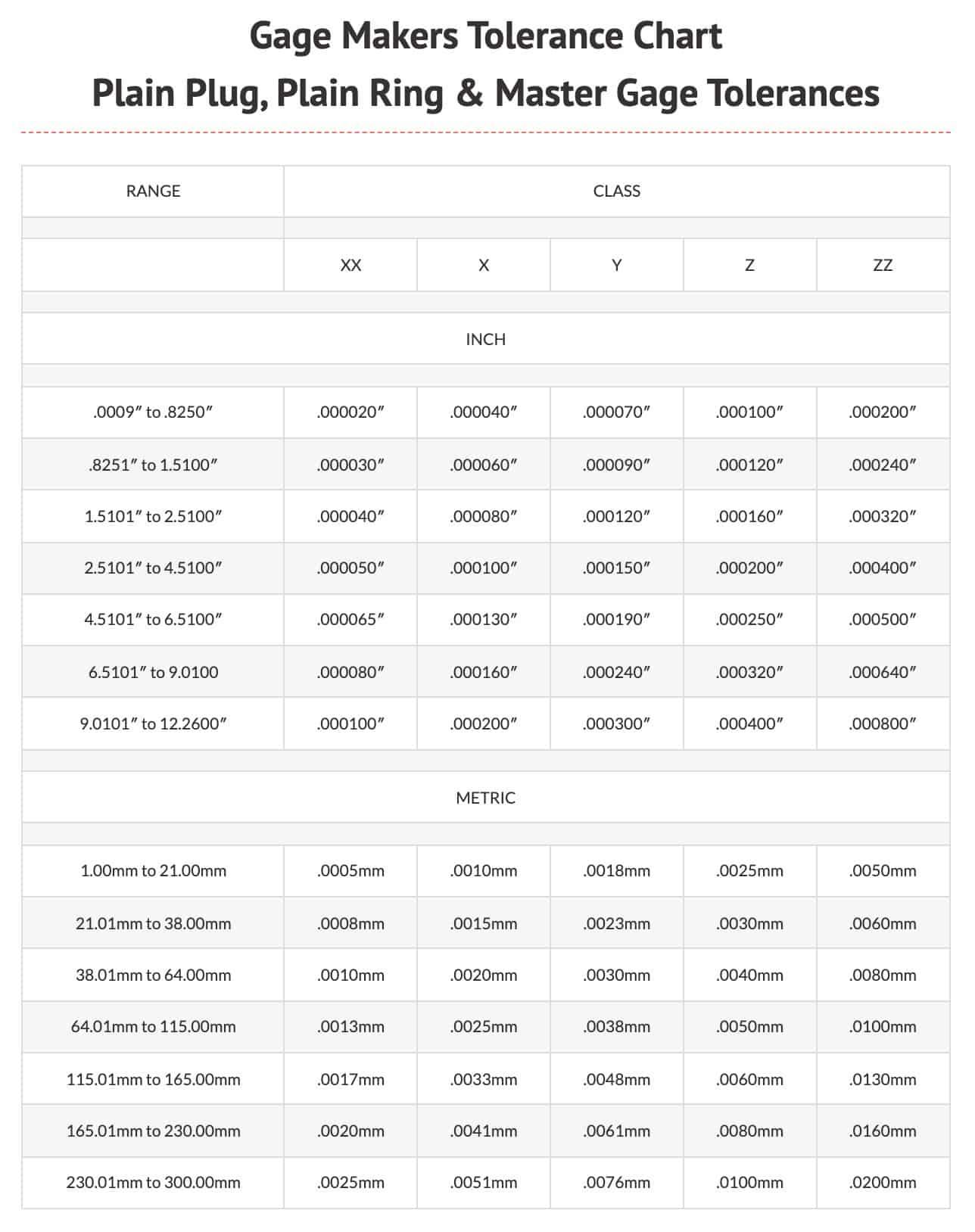

PLAIN PLUG AND RING GAUGES (CLASS Z, Y, X, XX) Northern Gauge

Air Plug Gauge Calibration Procedure The plug gage has been found to be highly accurate,. Within one week of the completion of the measurements, participating laboratories are required to send the attached. Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and set discs conforming to asni/asme specifications. The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. Each plug gage takes about 15 to 20 mins to do in order to ensure our findings are. To understand basic troubleshooting, maintenance and verification. The plug gage has been found to be highly accurate,. Grm calibrates plug gages using master standards and our linear measurement machine. To provide an understanding of air gage theory. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. To learn some of the applications for air gaging.

From www.indiamart.com

Plug Gauge Calibration at Rs 150/piece calibration instruments Air Plug Gauge Calibration Procedure To understand basic troubleshooting, maintenance and verification. The plug gage has been found to be highly accurate,. To learn some of the applications for air gaging. Grm calibrates plug gages using master standards and our linear measurement machine. Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and set discs conforming to asni/asme. Air Plug Gauge Calibration Procedure.

From www.a-egauges.co.uk

A&E Gauges Ltd Air Plug Gauges Air Plug Gauge Calibration Procedure Each plug gage takes about 15 to 20 mins to do in order to ensure our findings are. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. The plug gage has been found to be highly accurate,. Setting masters are the reference standards used for the calibration of air gage systems—typically. Air Plug Gauge Calibration Procedure.

From www.youtube.com

Calibration method of plain plug gauge YouTube Air Plug Gauge Calibration Procedure To provide an understanding of air gage theory. To learn some of the applications for air gaging. To understand basic troubleshooting, maintenance and verification. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. The plug gage has been found to be highly accurate,. Setting masters are the reference standards used for. Air Plug Gauge Calibration Procedure.

From www.indiamart.com

Plug Gauge Calibration at Rs 150/piece in Chennai ID 2852417118555 Air Plug Gauge Calibration Procedure Within one week of the completion of the measurements, participating laboratories are required to send the attached. To understand basic troubleshooting, maintenance and verification. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. The plug gage has been found to be highly accurate,. Each plug gage takes about 15 to 20. Air Plug Gauge Calibration Procedure.

From www.instrumentationtoolbox.com

How to Calibrate a Pressure Gauge With a Dead Weight Tester Learning Air Plug Gauge Calibration Procedure Within one week of the completion of the measurements, participating laboratories are required to send the attached. To provide an understanding of air gage theory. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and. Air Plug Gauge Calibration Procedure.

From www.youtube.com

Calibration of Attribute Gauges by using IS 3455 Standard, what is Air Plug Gauge Calibration Procedure A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Each plug gage takes about 15 to 20 mins to do in order to ensure our findings are. The plug gage has been found to be highly accurate,. The key to any measurement of gage variation is to use a calibration gage. Air Plug Gauge Calibration Procedure.

From www.vecteezy.com

operator calibration micrometer by block gauge 956557 Stock Photo at Air Plug Gauge Calibration Procedure The plug gage has been found to be highly accurate,. To understand basic troubleshooting, maintenance and verification. Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and set discs conforming to asni/asme specifications. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Within one. Air Plug Gauge Calibration Procedure.

From blog.wika.com

Calibration of tapered thread gauges WIKA blog Air Plug Gauge Calibration Procedure The plug gage has been found to be highly accurate,. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Grm calibrates plug gages using master standards and our linear measurement machine. Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and set discs conforming. Air Plug Gauge Calibration Procedure.

From www.a-egauges.co.uk

A&E Gauges Ltd Air Plug Gauges Air Plug Gauge Calibration Procedure To provide an understanding of air gage theory. The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. To learn some of the applications for air gaging. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. The. Air Plug Gauge Calibration Procedure.

From threadtools.com

Calibration Wiseman Threading Tools Air Plug Gauge Calibration Procedure Within one week of the completion of the measurements, participating laboratories are required to send the attached. To learn some of the applications for air gaging. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Grm calibrates plug gages using master standards and our linear measurement machine. Setting masters are the. Air Plug Gauge Calibration Procedure.

From precisecalibration.in

Plain Plug Gauge Air Plug Gauge Calibration Procedure The plug gage has been found to be highly accurate,. The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. Grm calibrates plug gages using master standards and our linear measurement machine. To understand basic troubleshooting, maintenance and verification. Setting masters are the reference standards used. Air Plug Gauge Calibration Procedure.

From www.youtube.com

How to calibrate a Vacuum Gauge YouTube Air Plug Gauge Calibration Procedure To understand basic troubleshooting, maintenance and verification. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. The plug gage has been found to be highly accurate,. To provide an understanding of air gage theory. Grm calibrates plug gages using master standards and our linear measurement machine. To learn some of the. Air Plug Gauge Calibration Procedure.

From www.youtube.com

Thread Gage calibration Precision In Every Detail YouTube Air Plug Gauge Calibration Procedure To provide an understanding of air gage theory. Each plug gage takes about 15 to 20 mins to do in order to ensure our findings are. The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. Within one week of the completion of the measurements, participating. Air Plug Gauge Calibration Procedure.

From www.indiamart.com

Plug Gauge Calibration Service at Rs 1200 in Pune ID 2852767893030 Air Plug Gauge Calibration Procedure The plug gage has been found to be highly accurate,. To learn some of the applications for air gaging. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and set discs conforming to asni/asme specifications.. Air Plug Gauge Calibration Procedure.

From amlinstruments.co.uk

How To Calibrate Pressure Gauges AML Instruments Air Plug Gauge Calibration Procedure A plug gage is a cylinder designed to check the component tolerance of a hole in a product. To understand basic troubleshooting, maintenance and verification. To learn some of the applications for air gaging. The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. Grm calibrates. Air Plug Gauge Calibration Procedure.

From suyashprecision.com

SUYASH PRECISION Air Plug Gauge Calibration Procedure The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. Grm calibrates plug gages using master standards and our linear measurement machine. To learn some of the applications for air gaging. To provide an understanding of air gage theory. A plug gage is a cylinder designed. Air Plug Gauge Calibration Procedure.

From www.youtube.com

Calibration of a test gauge using a pressure gauge comparator. YouTube Air Plug Gauge Calibration Procedure Grm calibrates plug gages using master standards and our linear measurement machine. The plug gage has been found to be highly accurate,. To understand basic troubleshooting, maintenance and verification. Within one week of the completion of the measurements, participating laboratories are required to send the attached. Each plug gage takes about 15 to 20 mins to do in order to. Air Plug Gauge Calibration Procedure.

From www.a-egauges.co.uk

A&E Gauges Ltd Air Plug Gauges Air Plug Gauge Calibration Procedure A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Grm calibrates plug gages using master standards and our linear measurement machine. The plug gage has been found to be highly accurate,. To learn some of the applications for air gaging. To understand basic troubleshooting, maintenance and verification. The key to any. Air Plug Gauge Calibration Procedure.

From www.indiamart.com

Piramyd 4.00 To 500 Mm Air Plug Gauges, For Inspection, Size 4mm To Air Plug Gauge Calibration Procedure Each plug gage takes about 15 to 20 mins to do in order to ensure our findings are. To learn some of the applications for air gaging. The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. A plug gage is a cylinder designed to check. Air Plug Gauge Calibration Procedure.

From blog.dandkmotorsports.com

Pressure Gauge Calibration Procedure Using Dead Weight Tester Blog Dandk Air Plug Gauge Calibration Procedure Grm calibrates plug gages using master standards and our linear measurement machine. To learn some of the applications for air gaging. To provide an understanding of air gage theory. The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. Within one week of the completion of. Air Plug Gauge Calibration Procedure.

From meaninghippo.com

Thread Plug Gauge Calibration Procedure MeaningHippo Air Plug Gauge Calibration Procedure To learn some of the applications for air gaging. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Grm calibrates plug gages using master standards and our linear measurement machine. Each plug gage takes about 15 to 20 mins to do in order to ensure our findings are. The plug gage. Air Plug Gauge Calibration Procedure.

From www.accutechenggcorp.com

Air Gauges Accutech Engineering Corporation Air Plug Gauge Calibration Procedure To understand basic troubleshooting, maintenance and verification. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. To learn some of the applications for air gaging. To provide an understanding of air gage theory. Grm calibrates plug gages using master standards and our linear measurement machine. Setting masters are the reference standards. Air Plug Gauge Calibration Procedure.

From www.swansongage.com

Calibration Services Swanson Tool Manufacturing Air Plug Gauge Calibration Procedure To learn some of the applications for air gaging. To provide an understanding of air gage theory. Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and set discs conforming to asni/asme specifications. The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric. Air Plug Gauge Calibration Procedure.

From circuitduhtaunda7e.z21.web.core.windows.net

How To Calibrate Calipers With Gauge Blocks Air Plug Gauge Calibration Procedure Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and set discs conforming to asni/asme specifications. To provide an understanding of air gage theory. To learn some of the applications for air gaging. The plug gage has been found to be highly accurate,. Each plug gage takes about 15 to 20 mins to. Air Plug Gauge Calibration Procedure.

From nabgauge.com

PLAIN PLUG AND RING GAUGES (CLASS Z, Y, X, XX) Northern Gauge Air Plug Gauge Calibration Procedure To learn some of the applications for air gaging. Grm calibrates plug gages using master standards and our linear measurement machine. To understand basic troubleshooting, maintenance and verification. Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and set discs conforming to asni/asme specifications. The plug gage has been found to be highly. Air Plug Gauge Calibration Procedure.

From automationforum.co

Control valve Calibration Procedure Air Plug Gauge Calibration Procedure Each plug gage takes about 15 to 20 mins to do in order to ensure our findings are. Within one week of the completion of the measurements, participating laboratories are required to send the attached. Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and set discs conforming to asni/asme specifications. A plug. Air Plug Gauge Calibration Procedure.

From www.youtube.com

How To Use Thread Plug Gages Technical Series 101 YouTube Air Plug Gauge Calibration Procedure Grm calibrates plug gages using master standards and our linear measurement machine. Within one week of the completion of the measurements, participating laboratories are required to send the attached. Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and set discs conforming to asni/asme specifications. Each plug gage takes about 15 to 20. Air Plug Gauge Calibration Procedure.

From jmtest.com

Pressure Gauge Calibration • JM Test Systems is ISO 17025 Accredited. Air Plug Gauge Calibration Procedure The plug gage has been found to be highly accurate,. The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. Within one week of the completion of the measurements, participating laboratories are required to send the attached. To learn some of the applications for air gaging.. Air Plug Gauge Calibration Procedure.

From www.professionalengg.co.in

airpluggauges Air Plug Gauge Calibration Procedure Each plug gage takes about 15 to 20 mins to do in order to ensure our findings are. To understand basic troubleshooting, maintenance and verification. The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. A plug gage is a cylinder designed to check the component. Air Plug Gauge Calibration Procedure.

From www.youtube.com

Calibration Of Pressure Gauge YouTube Air Plug Gauge Calibration Procedure To understand basic troubleshooting, maintenance and verification. The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and set discs conforming to asni/asme specifications. Grm calibrates plug gages using master. Air Plug Gauge Calibration Procedure.

From www.youtube.com

API SPEC 7 2 THREAD GAUGE CALIBRATION YouTube Air Plug Gauge Calibration Procedure The plug gage has been found to be highly accurate,. The key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Each plug gage takes about 15 to 20. Air Plug Gauge Calibration Procedure.

From www.a-egauges.co.uk

A&E Gauges Ltd Air Plug Gauges Air Plug Gauge Calibration Procedure Within one week of the completion of the measurements, participating laboratories are required to send the attached. To learn some of the applications for air gaging. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Each plug gage takes about 15 to 20 mins to do in order to ensure our. Air Plug Gauge Calibration Procedure.

From www.practicalmachinist.com

Understanding Gauge Calibration Practical Machinist Air Plug Gauge Calibration Procedure To understand basic troubleshooting, maintenance and verification. Grm calibrates plug gages using master standards and our linear measurement machine. The plug gage has been found to be highly accurate,. To provide an understanding of air gage theory. To learn some of the applications for air gaging. Within one week of the completion of the measurements, participating laboratories are required to. Air Plug Gauge Calibration Procedure.

From www.youtube.com

Calibration Procedure of Differential Pressure Transmitter by using Air Plug Gauge Calibration Procedure The plug gage has been found to be highly accurate,. Within one week of the completion of the measurements, participating laboratories are required to send the attached. To understand basic troubleshooting, maintenance and verification. Grm calibrates plug gages using master standards and our linear measurement machine. Each plug gage takes about 15 to 20 mins to do in order to. Air Plug Gauge Calibration Procedure.

From www.indiamart.com

Plain Plug Gauge Calibration Service, Rs 450/instrument Stanford Air Plug Gauge Calibration Procedure To understand basic troubleshooting, maintenance and verification. Within one week of the completion of the measurements, participating laboratories are required to send the attached. Setting masters are the reference standards used for the calibration of air gage systems—typically rings, plugs and set discs conforming to asni/asme specifications. To provide an understanding of air gage theory. Grm calibrates plug gages using. Air Plug Gauge Calibration Procedure.