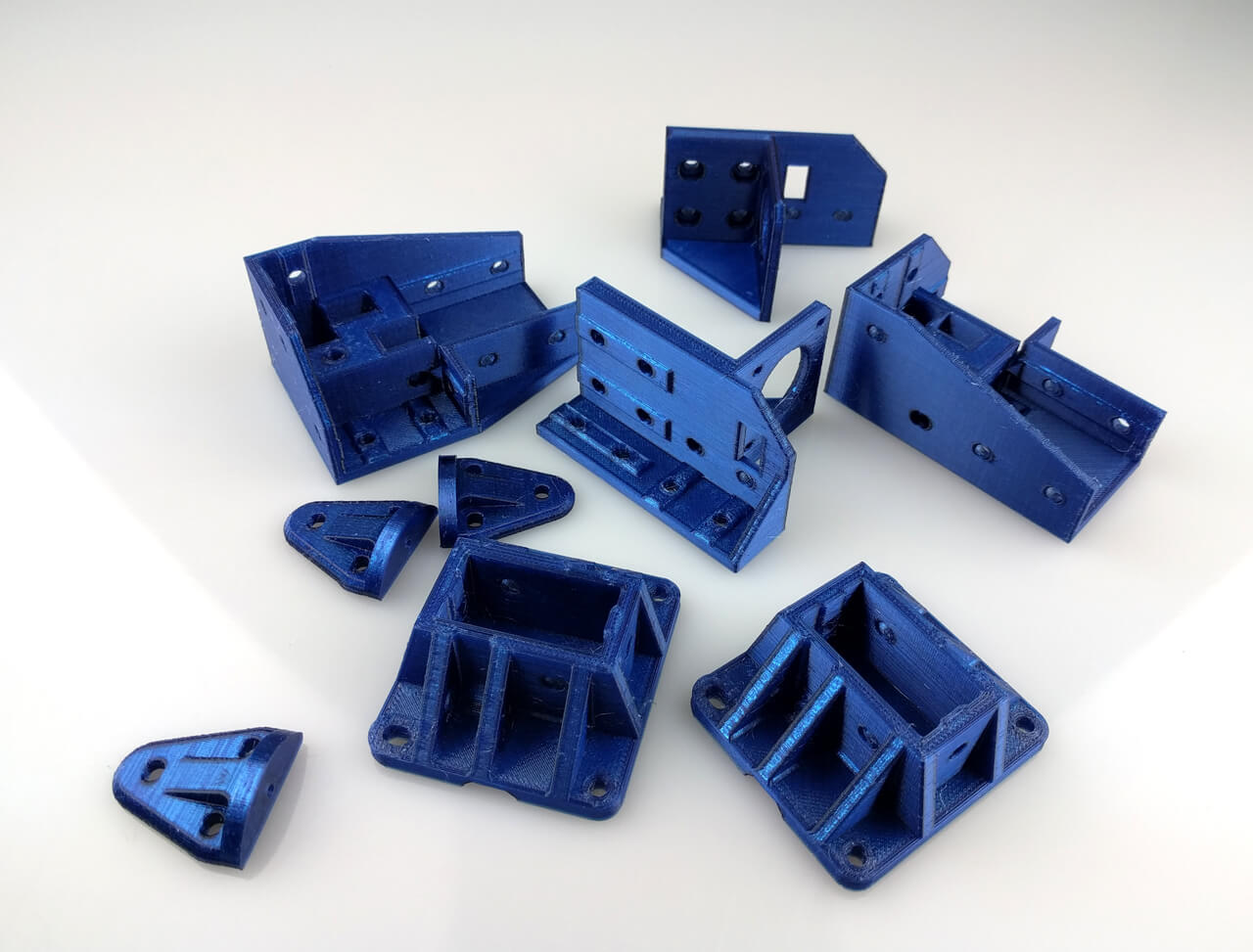

What Are The Advantages And Disadvantages Of Fdm . Fused deposition modelling (fdm) is an advanced 3d printing technique for the manufacture of plastic materials. We created this guide to show you how fdm works,. Fdm is a popular choice for rapid 3d prototyping, but it can also be used to create medical devices, specialized manufacturing tools, automotive parts, and more. Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. What is fused deposition modeling (fdm) ? Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. However, like many manufacturing processes, fdm.

from 3dprintingidea.blogspot.com

Fdm is a popular choice for rapid 3d prototyping, but it can also be used to create medical devices, specialized manufacturing tools, automotive parts, and more. However, like many manufacturing processes, fdm. Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. What is fused deposition modeling (fdm) ? Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? Fused deposition modelling (fdm) is an advanced 3d printing technique for the manufacture of plastic materials. We created this guide to show you how fdm works,.

Get Fdm 3D Printing Advantages And Disadvantages Background 3d

What Are The Advantages And Disadvantages Of Fdm 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. Fused deposition modelling (fdm) is an advanced 3d printing technique for the manufacture of plastic materials. We created this guide to show you how fdm works,. Fdm is a popular choice for rapid 3d prototyping, but it can also be used to create medical devices, specialized manufacturing tools, automotive parts, and more. Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? However, like many manufacturing processes, fdm. What is fused deposition modeling (fdm) ? 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities.

From www.aurum3d.com

Advantages of FDM 3D Printing FDM 3D Printing Benefits Aurum3D What Are The Advantages And Disadvantages Of Fdm What is fused deposition modeling (fdm) ? Fdm is a popular choice for rapid 3d prototyping, but it can also be used to create medical devices, specialized manufacturing tools, automotive parts, and more. Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. However, like many manufacturing processes, fdm. Fused deposition modeling (fdm) is. What Are The Advantages And Disadvantages Of Fdm.

From www.numerade.com

SOLVED Texts What are the principles, advantages, and disadvantages What Are The Advantages And Disadvantages Of Fdm Fused deposition modelling (fdm) is an advanced 3d printing technique for the manufacture of plastic materials. Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. Fdm is a popular choice for rapid 3d. What Are The Advantages And Disadvantages Of Fdm.

From 3dprintdxb.com

What Is FDM 3D Printer? Easy Explanation 3dPrintDXB What Are The Advantages And Disadvantages Of Fdm We created this guide to show you how fdm works,. Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? Fdm is a popular choice for rapid 3d. What Are The Advantages And Disadvantages Of Fdm.

From manufactur3dmag.com

How Does The FDM 3D Printing Technology Work? Manufactur3D What Are The Advantages And Disadvantages Of Fdm Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? We created this guide to show you how fdm works,. Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. What is fused deposition modeling (fdm) ? Fused deposition modelling (fdm) is an advanced 3d printing. What Are The Advantages And Disadvantages Of Fdm.

From www.mdpi.com

Applied Sciences Free FullText Liquid for Fused Deposition What Are The Advantages And Disadvantages Of Fdm What is fused deposition modeling (fdm) ? Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. However, like many manufacturing processes, fdm. 2022, the new f190cf and. What Are The Advantages And Disadvantages Of Fdm.

From www.slideshare.net

What Is FDM 3D Printing Advantages and Disadvantages.pdf What Are The Advantages And Disadvantages Of Fdm However, like many manufacturing processes, fdm. We created this guide to show you how fdm works,. Fused deposition modelling (fdm) is an advanced 3d printing technique for the manufacture of plastic materials. Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. What is fused deposition. What Are The Advantages And Disadvantages Of Fdm.

From 3dservicesusa.com

Exploring the Benefits of FDM and Resin 3D Printing 3D Services USA What Are The Advantages And Disadvantages Of Fdm Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. Fdm is a popular choice for rapid 3d prototyping, but it can also be used to create medical devices, specialized manufacturing tools, automotive parts, and more. Fused deposition modeling is the most common and most affordable. What Are The Advantages And Disadvantages Of Fdm.

From themechninja.com

FDM Printing Advantages & Disadvantages Detailed TheMechNinja What Are The Advantages And Disadvantages Of Fdm Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? However, like many manufacturing processes, fdm. Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. We created this guide to show you how fdm works,. 2022, the new f190cf and f370cf machines are released for. What Are The Advantages And Disadvantages Of Fdm.

From campusnikalo.blogspot.com

Campus Nikalo MULTIPLEXING TYPES WITH ADVANTAGES & DISADVANATGES What Are The Advantages And Disadvantages Of Fdm Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. Fused deposition. What Are The Advantages And Disadvantages Of Fdm.

From www.seacomp.com

Benefits and Disadvantages to 3D Printing in Manufacturing What Are The Advantages And Disadvantages Of Fdm 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? Fused deposition modelling (fdm) is an advanced 3d printing technique for the manufacture of plastic materials. What is fused deposition modeling (fdm) ? However,. What Are The Advantages And Disadvantages Of Fdm.

From www.researchgate.net

Comparison of the relative advantages and disadvantages of MADAME What Are The Advantages And Disadvantages Of Fdm We created this guide to show you how fdm works,. 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. What is fused deposition modeling (fdm) ? Fdm. What Are The Advantages And Disadvantages Of Fdm.

From www.wenext.com

What Is FDM 3D Printing? Advantages and Disadvantages Wenext What Are The Advantages And Disadvantages Of Fdm Fused deposition modelling (fdm) is an advanced 3d printing technique for the manufacture of plastic materials. Fdm is a popular choice for rapid 3d prototyping, but it can also be used to create medical devices, specialized manufacturing tools, automotive parts, and more. We created this guide to show you how fdm works,. Fused deposition modeling (fdm) is a widely used. What Are The Advantages And Disadvantages Of Fdm.

From www.liqcreate.com

Comparing properties of FDM, SLS and resin 3Dprinting plastics What Are The Advantages And Disadvantages Of Fdm Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. However, like many manufacturing processes, fdm. Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? 2022, the new f190cf and f370cf machines are released for focus on. What Are The Advantages And Disadvantages Of Fdm.

From www.slideshare.net

What Is FDM 3D Printing Advantages and Disadvantages.pdf What Are The Advantages And Disadvantages Of Fdm 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. However, like many manufacturing processes, fdm. What is fused deposition modeling (fdm) ? Fused deposition modelling (fdm) is an advanced 3d printing technique for the manufacture of plastic materials. We created this guide to show you how fdm works,. Fdm is a. What Are The Advantages And Disadvantages Of Fdm.

From cbselibrary.com

Time Division Multiplexing Advantages and Disadvantages Advantages What Are The Advantages And Disadvantages Of Fdm Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? What is fused deposition modeling (fdm) ? 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. Fdm is a popular choice for rapid 3d prototyping, but it can also be used to create. What Are The Advantages And Disadvantages Of Fdm.

From 3dprintingidea.blogspot.com

Get Fdm 3D Printing Advantages And Disadvantages Background 3d What Are The Advantages And Disadvantages Of Fdm Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. However, like many manufacturing processes, fdm. 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. Fused deposition. What Are The Advantages And Disadvantages Of Fdm.

From www.researchgate.net

Advantages and disadvantages of the approaches Download Scientific What Are The Advantages And Disadvantages Of Fdm However, like many manufacturing processes, fdm. Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. Fdm is a popular choice for rapid 3d prototyping, but it can also be used to create medical devices, specialized manufacturing tools, automotive parts, and more. 2022, the new f190cf. What Are The Advantages And Disadvantages Of Fdm.

From en.ppt-online.org

Forced Distribution Method online presentation What Are The Advantages And Disadvantages Of Fdm Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. We created this guide to show you how fdm works,. Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. Fused deposition modelling (fdm) is an advanced 3d printing technique. What Are The Advantages And Disadvantages Of Fdm.

From hlhrapid.com

What is FDM 3D Printing? Fused Deposition Modeling What Are The Advantages And Disadvantages Of Fdm 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. Fdm is a popular choice for rapid 3d prototyping, but it can also be used to create medical devices, specialized manufacturing tools, automotive parts, and more. Fused deposition modeling is the most common and most affordable 3d printing process, but how does. What Are The Advantages And Disadvantages Of Fdm.

From www.weili3d.com

Advantages and Disadvantages of FDM and SLA 3D Printers 泉州市威立三维科技有限公司 What Are The Advantages And Disadvantages Of Fdm Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? We created this guide to show you how fdm works,. Fused deposition modeling (fdm) has gained significant popularity,. What Are The Advantages And Disadvantages Of Fdm.

From www.slideshare.net

Company visit materialise summer school 2011 What Are The Advantages And Disadvantages Of Fdm Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. However, like many manufacturing processes, fdm. Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? Fused deposition modelling (fdm) is an advanced 3d printing technique for the manufacture of plastic materials. 2022, the new f190cf. What Are The Advantages And Disadvantages Of Fdm.

From www.weili3d.com

Advantages and Disadvantages of FDM and SLA 3D Printers 泉州市威立三维科技有限公司 What Are The Advantages And Disadvantages Of Fdm However, like many manufacturing processes, fdm. We created this guide to show you how fdm works,. Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? Fused deposition modeling (fdm) is a widely used 3d printing. What Are The Advantages And Disadvantages Of Fdm.

From www.slideserve.com

PPT Multiplexing PowerPoint Presentation, free download ID1199415 What Are The Advantages And Disadvantages Of Fdm Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. However, like. What Are The Advantages And Disadvantages Of Fdm.

From www.slideserve.com

PPT What Is FDM 3D Printing Advantages and Disadvantages PowerPoint What Are The Advantages And Disadvantages Of Fdm Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. Fdm is a popular choice for rapid 3d prototyping, but it can also be used to create medical devices, specialized manufacturing tools, automotive parts,. What Are The Advantages And Disadvantages Of Fdm.

From www.slideserve.com

PPT What Is FDM 3D Printing Advantages and Disadvantages PowerPoint What Are The Advantages And Disadvantages Of Fdm Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? What is fused deposition modeling (fdm) ? We created this guide to show you how fdm works,. 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. However, like many manufacturing processes, fdm. Fdm. What Are The Advantages And Disadvantages Of Fdm.

From www.vrogue.co

What Are The Advantages And Disadvantages Of Additive vrogue.co What Are The Advantages And Disadvantages Of Fdm We created this guide to show you how fdm works,. What is fused deposition modeling (fdm) ? Fused deposition modelling (fdm) is an advanced 3d printing technique for the manufacture of plastic materials. 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. Fused deposition modeling is the most common and most. What Are The Advantages And Disadvantages Of Fdm.

From www.rocheindustry.com

White PaperThe Ultimate Guide to Fused Deposition Modeling(FDM) What Are The Advantages And Disadvantages Of Fdm What is fused deposition modeling (fdm) ? Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. However, like many manufacturing processes, fdm. Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. We created this guide to show you. What Are The Advantages And Disadvantages Of Fdm.

From www.researchgate.net

Advantages and disadvantages of FDM Download Scientific Diagram What Are The Advantages And Disadvantages Of Fdm 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. However, like many manufacturing processes, fdm. What is fused deposition modeling (fdm) ? Fused deposition modelling (fdm) is an advanced 3d printing technique for the manufacture of plastic materials. Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility,. What Are The Advantages And Disadvantages Of Fdm.

From mechservicemaster.com

Advantages and Limitations of FDM ServiceMaster What Are The Advantages And Disadvantages Of Fdm 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. What is fused deposition modeling (fdm) ? Fdm is a popular choice for rapid 3d prototyping, but it can also be used to create medical devices, specialized manufacturing tools, automotive parts, and more. We created this guide to show you how fdm. What Are The Advantages And Disadvantages Of Fdm.

From www.slideshare.net

What Is FDM 3D Printing Advantages and Disadvantages.pdf What Are The Advantages And Disadvantages Of Fdm Fused deposition modelling (fdm) is an advanced 3d printing technique for the manufacture of plastic materials. We created this guide to show you how fdm works,. 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. What is fused deposition modeling (fdm) ? Fused deposition modeling is the most common and most. What Are The Advantages And Disadvantages Of Fdm.

From www.researchgate.net

Pros and cons of the FDM method. Download Scientific Diagram What Are The Advantages And Disadvantages Of Fdm We created this guide to show you how fdm works,. Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? What is fused deposition modeling (fdm) ? However, like many manufacturing processes, fdm. Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. Fused deposition modelling. What Are The Advantages And Disadvantages Of Fdm.

From www.vrogue.co

3d Printing In Manufacturing Challenges And Advantage vrogue.co What Are The Advantages And Disadvantages Of Fdm Fused deposition modeling (fdm) is a widely used 3d printing process that involves melting and extruding a thermoplastic material to create a 3d object. However, like many manufacturing processes, fdm. Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability. Fused deposition modeling is the most common and most affordable 3d printing process, but. What Are The Advantages And Disadvantages Of Fdm.

From geekalabama.com

What the Major Benefits of FDM Printing Are What Are The Advantages And Disadvantages Of Fdm We created this guide to show you how fdm works,. Fdm is a popular choice for rapid 3d prototyping, but it can also be used to create medical devices, specialized manufacturing tools, automotive parts, and more. However, like many manufacturing processes, fdm. 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities.. What Are The Advantages And Disadvantages Of Fdm.

From 3dprintingidea.blogspot.com

Get Fdm 3D Printing Advantages And Disadvantages Background 3d What Are The Advantages And Disadvantages Of Fdm Fdm is a popular choice for rapid 3d prototyping, but it can also be used to create medical devices, specialized manufacturing tools, automotive parts, and more. 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. Fused deposition modeling (fdm) has gained significant popularity, due to its accessibility, versatility, and relative affordability.. What Are The Advantages And Disadvantages Of Fdm.

From mechservicemaster.com

Advantages and Limitations of FDM ServiceMaster What Are The Advantages And Disadvantages Of Fdm What is fused deposition modeling (fdm) ? Fused deposition modeling is the most common and most affordable 3d printing process, but how does it work? 2022, the new f190cf and f370cf machines are released for focus on carbon fiber 3d printing material capabilities. However, like many manufacturing processes, fdm. Fused deposition modeling (fdm) has gained significant popularity, due to its. What Are The Advantages And Disadvantages Of Fdm.