Sheave Pulley Belt Drive . When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Stock sheaves have capacities ranging from 1/2 to 108. Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. Never pry or use force to install the belt (s). In the most typical installation, a belt. Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution.

from www.oris-industrial.com

Stock sheaves have capacities ranging from 1/2 to 108. Never pry or use force to install the belt (s). When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. In the most typical installation, a belt. Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v.

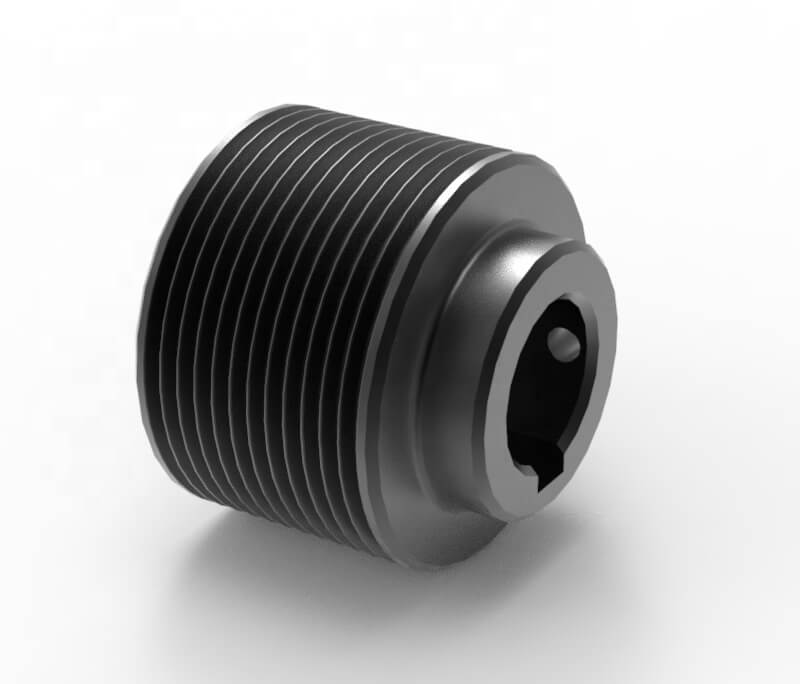

Multigroove Ribbed Belt Pulley Sprockets and Gears Manufacturer

Sheave Pulley Belt Drive Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. In the most typical installation, a belt. Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. Stock sheaves have capacities ranging from 1/2 to 108. When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Never pry or use force to install the belt (s). Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution.

From www.surpluscenter.com

10.25" x 7" Steel Flat Belt Pulley w/Keyway Finished Bore Pulleys Sheave Pulley Belt Drive Stock sheaves have capacities ranging from 1/2 to 108. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Never pry or use force to. Sheave Pulley Belt Drive.

From www.globalspec.com

Flat Belt Pulleys Selection Guide Types, Features, Applications Sheave Pulley Belt Drive Stock sheaves have capacities ranging from 1/2 to 108. Never pry or use force to install the belt (s). Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. Sheaves and pulleys are wheels featuring. Sheave Pulley Belt Drive.

From www.indiamart.com

Industrial V Belt Pulley, For Industry, 6 m, Rs 3325 Shree Hari Sheave Pulley Belt Drive When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. In the most typical installation, a belt. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. Variable speed belt drives achieve the versatility needed. Sheave Pulley Belt Drive.

From www.electricmotorwarehouse.com

6.30" OD Four Groove Pulley / Sheave for 5V VBelt (bushing not Sheave Pulley Belt Drive When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. In the most typical installation, a belt. Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Never use a screwdriver to roll belts into position, because this may damage belt. Sheave Pulley Belt Drive.

From www.grainger.com

TB WOOD'S Quick Detachable Bushed Bore Standard VBelt Pulley, For V Sheave Pulley Belt Drive Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. Stock sheaves have capacities ranging from 1/2 to 108. Never pry or use force to install the belt (s). Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. Sheaves and pulleys are. Sheave Pulley Belt Drive.

From rsvautomotive.co.uk

1 to 2 Grooves A Section Bore with Keyway V Pulley Aluminium Business Sheave Pulley Belt Drive When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Stock sheaves have capacities ranging from 1/2 to 108. In the most typical installation, a belt. Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. Good sheave alignment. Sheave Pulley Belt Drive.

From variablepulley.com

Single groove variable speed v belt drive pulley cast iron VP pulley Sheave Pulley Belt Drive Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. Stock sheaves have capacities ranging from 1/2 to 108. Never use a screwdriver to roll belts into position, because this. Sheave Pulley Belt Drive.

From www.lifting-products.com

Pulley/Sheave Steel Galvanised Diameter 100 mm Lifting Products Ltd Sheave Pulley Belt Drive When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. In the. Sheave Pulley Belt Drive.

From www.certex.dk

Wire Rope Pulley Sheave CERTEX Denmark Sheave Pulley Belt Drive Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Stock sheaves have capacities ranging from 1/2 to 108. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. Never use a screwdriver to roll belts into position, because this. Sheave Pulley Belt Drive.

From www.amazon.com

Craftsman Belt Drive Contractor Table Saw 2 1/2" Pulley Set with Keys Sheave Pulley Belt Drive Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets.. Sheave Pulley Belt Drive.

From www.walmart.com

1" Fixed Bore Standard VBelt Pulley, For VBelt Section 4L, 5L, A, AX Sheave Pulley Belt Drive Never pry or use force to install the belt (s). Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while. Sheave Pulley Belt Drive.

From maith-gulf.com

V Belt Pulley Complete Set A type 16 grooves ( With Taper Bush Sheave Pulley Belt Drive Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. Stock sheaves have capacities ranging from 1/2 to 108. Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. When installing the new belt, ensure that enough clearance is available to slip the. Sheave Pulley Belt Drive.

From www.iqsdirectory.com

VBelt What Is It? How Does It Work? Types Of, Uses Sheave Pulley Belt Drive Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Stock sheaves have capacities ranging from 1/2 to 108. In the most typical installation, a belt. Sheaves and pulleys are wheels. Sheave Pulley Belt Drive.

From www.walmart.com

B Section Dual Groove 2 Piece 6" Pulley With 13/8" Sheave Shiv Cast Sheave Pulley Belt Drive When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Never pry or use force to install the belt (s). Stock sheaves have capacities ranging from 1/2 to 108. In the. Sheave Pulley Belt Drive.

From assetmatrixenergy.com

Laser Belt, Chain & Pulley Alignment Services Asset Matrix Energy Sheave Pulley Belt Drive In the most typical installation, a belt. Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Stock sheaves have capacities ranging from 1/2 to 108. Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. When installing the new belt, ensure that enough. Sheave Pulley Belt Drive.

From www.ebay.com

2.5"(21/2") DIAMETER 3/4" BORE 1 GROOVE Sheave PULLEY BK25 2 Hex set Sheave Pulley Belt Drive Stock sheaves have capacities ranging from 1/2 to 108. When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. Never use a screwdriver to roll. Sheave Pulley Belt Drive.

From www.oris-industrial.com

Multigroove Ribbed Belt Pulley Sprockets and Gears Manufacturer Sheave Pulley Belt Drive Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. In the most typical installation, a belt. When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Good sheave alignment will increase efficiency by reducing premature wear or failure of. Sheave Pulley Belt Drive.

From www.portlandcompressor.com

Ingersoll Rand 54507975 OEM Motor Pulley Sheave, 1A5.7X1.375 for 2475N7 Sheave Pulley Belt Drive Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt. Sheave Pulley Belt Drive.

From www.tbwoods.com

Sheave and V Belts TB Wood's Sheave Pulley Belt Drive Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. In the most typical installation, a belt. Never pry or use force to install the belt (s). When installing the new belt, ensure that. Sheave Pulley Belt Drive.

From www.electricmotorwarehouse.com

Pulley & Sheaves for Electric Motors Electric Motor Warehouse Sheave Pulley Belt Drive Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Stock sheaves have capacities ranging from 1/2 to 108. Never use a screwdriver to roll. Sheave Pulley Belt Drive.

From www.sainikschoolrewa.ac.in

drive pulleys and belts Big sale OFF 78 Sheave Pulley Belt Drive Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v.. Sheave Pulley Belt Drive.

From www.alibaba.com

Timing Pulley Sheaves And Belts Drive Buy Sheave,Sheaves And Belts Sheave Pulley Belt Drive Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. Never pry or use force to install the belt (s). Stock sheaves have capacities ranging from 1/2 to 108. When installing the new. Sheave Pulley Belt Drive.

From www.apexindustrialautomation.com

Belts, Sheaves & Pulleys Sheaves & Pulleys Flat Belt Drive Pulleys Sheave Pulley Belt Drive Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. In the most typical installation, a belt. Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and. Sheave Pulley Belt Drive.

From www.flex-couplings.com

Custom Poly V Belt Drive Pulley Cast Iron Split Sheave Pulley Sheave Pulley Belt Drive Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. Never pry or use force to. Sheave Pulley Belt Drive.

From joiprkmhm.blob.core.windows.net

Belt Drive Driven Gear at Jeffrey Copeland blog Sheave Pulley Belt Drive Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. Sheaves and pulleys are wheels featuring. Sheave Pulley Belt Drive.

From mojelicytacje.blogspot.com

Changing Pulley Size On Air Compressor Motor Sheave Pulley Belt Drive Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. Stock. Sheave Pulley Belt Drive.

From www.len.com.ng

What are Belt Drives? Advantages and Disadvantages of Belt Drives Sheave Pulley Belt Drive Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. In the most typical installation, a belt. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. When installing the new belt, ensure that enough clearance is available to slip. Sheave Pulley Belt Drive.

From terre-products.com

Husqvarna 130812 VGroove Drive Pulley 2.5'' Dia. 3/4'' Bore Steel Sheave Pulley Belt Drive Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave. Sheave Pulley Belt Drive.

From enginewiringfrey.z21.web.core.windows.net

Belt Drive Pulley System Sheave Pulley Belt Drive When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. Never pry or use force to install the belt (s). Variable speed belt drives achieve. Sheave Pulley Belt Drive.

From www.alibaba.com

Timing Pulley Sheaves And Belts Drive Buy Sheave,Sheaves And Belts Sheave Pulley Belt Drive Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Stock sheaves have capacities ranging from 1/2 to 108. Variable speed belt drives achieve the versatility needed to maximize application. Sheave Pulley Belt Drive.

From electricmotorwarehouse.com

5.60" OD Eight Groove Pulley / Sheave for 3V Style VBelt (bushing not Sheave Pulley Belt Drive Good sheave alignment will increase efficiency by reducing premature wear or failure of belts, pulleys and bearings. Stock sheaves have capacities ranging from 1/2 to 108. Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. When installing the new belt, ensure that enough clearance is available to slip the new. Sheave Pulley Belt Drive.

From ubicaciondepersonas.cdmx.gob.mx

Sheave Wheel ubicaciondepersonas.cdmx.gob.mx Sheave Pulley Belt Drive Stock sheaves have capacities ranging from 1/2 to 108. When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the sheave or sprocket. Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. Sheaves and pulleys are wheels featuring grooved or flat edges to. Sheave Pulley Belt Drive.

From www.walmart.com

Cast Iron 4" Inch 2 Groove Dual Belt B Section 5L Pulley with 1" Sheave Sheave Pulley Belt Drive Never pry or use force to install the belt (s). Variable speed belt drives achieve the versatility needed to maximize application efficiency and productivity while remaining an inexpensive solution. In the most typical installation, a belt. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. Never. Sheave Pulley Belt Drive.

From www.monitordeskmount.com

a section v belt pulley classic fashion Sheave Pulley Belt Drive Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets. Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over the. Sheave Pulley Belt Drive.

From loeprdbsf.blob.core.windows.net

Belt Pulley Power Calculation at Shirley Flynn blog Sheave Pulley Belt Drive Sheaves and pulleys are wheels featuring grooved or flat edges to transmit rotational forces between shafts, when connected with a gearbelt or v. Never pry or use force to install the belt (s). Stock sheaves have capacities ranging from 1/2 to 108. When installing the new belt, ensure that enough clearance is available to slip the new belt (s) over. Sheave Pulley Belt Drive.