Internal Gear Examples . Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but there are. In this article, we will explore the concept, design considerations, and applications of internal ring gears. Gear types are classified into 3 categories, generally by the directions of the mounting shafts. Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. The gear teeth of the internal. Internal ring gears are an essential component in various mechanical.

from reference.wolfram.com

In this article, we will explore the concept, design considerations, and applications of internal ring gears. Gear types are classified into 3 categories, generally by the directions of the mounting shafts. Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Internal ring gears are an essential component in various mechanical. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but there are. The gear teeth of the internal. Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with.

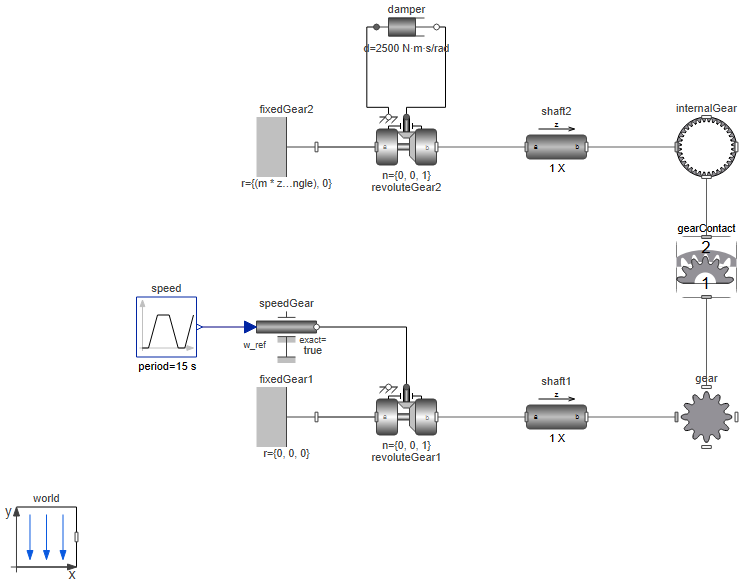

RotatingMachinery Examples.Gears.SpurGears.InternalGear

Internal Gear Examples Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but there are. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. Gear types are classified into 3 categories, generally by the directions of the mounting shafts. In this article, we will explore the concept, design considerations, and applications of internal ring gears. The gear teeth of the internal. Internal ring gears are an essential component in various mechanical.

From www.scgear.com.tw

Internal Gears Highquality Internal Gears manufacturer from Taiwan Shiuh Cheng Precision Internal Gear Examples Internal ring gears are an essential component in various mechanical. In this article, we will explore the concept, design considerations, and applications of internal ring gears. Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z),. Internal Gear Examples.

From animalia-life.club

Gears Specific Examples Internal Gear Examples Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). In this article, we will explore the concept, design considerations, and applications of internal ring gears. Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Internal gears are. Internal Gear Examples.

From www.iqsdirectory.com

Types of Gears Design, Types, Applications, and Materials Internal Gear Examples Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but there are. Gear types are classified into 3 categories, generally by the directions of. Internal Gear Examples.

From mechanicstips.blogspot.com

Types Of Gear MechanicsTips Internal Gear Examples Internal ring gears are an essential component in various mechanical. The gear teeth of the internal. Gear types are classified into 3 categories, generally by the directions of the mounting shafts. Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. Here, in this section, we introduce the characteristics of. Internal Gear Examples.

From 3d-mds-academy.com

Gear Fundamentals 3DMDS Academy Internal Gear Examples Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but there are. In this article, we will explore the concept, design considerations, and applications. Internal Gear Examples.

From khkgears.net

Types of Gears KHK Gears Internal Gear Examples In this article, we will explore the concept, design considerations, and applications of internal ring gears. Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x).. Internal Gear Examples.

From www.drivetrainhub.com

Helical Gears Geometry of helical gears and gear meshes Internal Gear Examples Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Internal ring gears are an essential component in various mechanical. The gear teeth of the internal. When using internal. Internal Gear Examples.

From www.iqsdirectory.com

Types of Gears Design, Types, Applications, and Materials Internal Gear Examples Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). The gear teeth of the internal. Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. Internal ring gears are an essential component in various mechanical.. Internal Gear Examples.

From www.marplesgears.com

Internal Gears Marples Gears Internal Gear Examples Internal ring gears are an essential component in various mechanical. Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but there are. Internal gears are a type of gearing that consists. Internal Gear Examples.

From www.tec-science.com

Gear cutting (gear manufacturing) tecscience Internal Gear Examples Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). In this article, we will explore the concept, design considerations, and applications of internal ring gears. Gear types are. Internal Gear Examples.

From reference.wolfram.com

RotatingMachinery Examples.Gears.SpurGears.InternalGear Internal Gear Examples The gear teeth of the internal. Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Internal ring gears are an essential component in various mechanical. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). When using internal. Internal Gear Examples.

From www.researchgate.net

DFIG model with internal gear system structure [29] Download Scientific Diagram Internal Gear Examples Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). In this article, we will explore the concept, design considerations, and applications of internal ring gears. Internal ring gears are an essential component in various mechanical. Here, in this section, we introduce the characteristics of gears,. Internal Gear Examples.

From themechanicalengineering.com

Spur Gear Definition, Types, Terminology, Advantages, Disadvantages, Application [Notes with PDF] Internal Gear Examples Internal ring gears are an essential component in various mechanical. Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. The gear teeth of the internal. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x).. Internal Gear Examples.

From etc.usf.edu

Internal Gear ClipArt ETC Internal Gear Examples Internal ring gears are an essential component in various mechanical. Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Gear types are classified into 3 categories, generally by the directions of the mounting shafts. Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion). Internal Gear Examples.

From www.comsol.it

Understanding the Different Elements of Gear Modeling COMSOL Blog Internal Gear Examples Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Gear types are classified into 3 categories, generally by the directions of the mounting shafts. The gear teeth of. Internal Gear Examples.

From reference.wolfram.com

RotatingMachinery Examples.Gears.SpurGears System Modeler Documentation Internal Gear Examples When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but there are. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Here, in this section, we introduce the characteristics of gears, how to. Internal Gear Examples.

From ar.inspiredpencil.com

Internal Gear Internal Gear Examples In this article, we will explore the concept, design considerations, and applications of internal ring gears. Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Internal ring gears are an essential component in various mechanical. The gear teeth of the internal. When using internal ring gears, you can develop a gear system. Internal Gear Examples.

From www.researchgate.net

DFIG model with internal gear system structure [29] Download Scientific Diagram Internal Gear Examples Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). In this article, we will explore the concept, design considerations, and applications of internal ring gears. When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space. Internal Gear Examples.

From www.marplesgears.com

Internal Gears Marples Gears Internal Gear Examples The gear teeth of the internal. Gear types are classified into 3 categories, generally by the directions of the mounting shafts. In this article, we will explore the concept, design considerations, and applications of internal ring gears. Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Internal gears are a type of. Internal Gear Examples.

From www.herogears.com

Gears for gears and internal gear rims Internal Gear Examples In this article, we will explore the concept, design considerations, and applications of internal ring gears. Gear types are classified into 3 categories, generally by the directions of the mounting shafts. The gear teeth of the internal. Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Gear dimensions are determined in accordance. Internal Gear Examples.

From blog.ar-cad.com

Internal Gears Assembly and Simulation in SpaceClaim ARCAD Blog Internal Gear Examples In this article, we will explore the concept, design considerations, and applications of internal ring gears. Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. When using internal ring gears, you can. Internal Gear Examples.

From khkgears.net

Basic Gear Terminology and Calculation KHK Gears Internal Gear Examples Internal ring gears are an essential component in various mechanical. The gear teeth of the internal. Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Gear dimensions are determined in accordance with. Internal Gear Examples.

From reference.wolfram.com

RotatingMachinery Examples.Gears.SpurGears.InternalGear System Modeler Documentation Internal Gear Examples Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. Internal ring gears are an essential component in various mechanical. When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but there are. Gear dimensions are determined in accordance. Internal Gear Examples.

From www.mechanicalbooster.com

Types of Gears Spur Gear, Helical Gear, Bevel Gear etc. Mechanical Booster Internal Gear Examples When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but there are. Gear types are classified into 3 categories, generally by the directions of the mounting shafts. Internal ring gears are an essential component in various mechanical. Here, in this section, we introduce the characteristics of gears, how. Internal Gear Examples.

From khkgears.net

Gear Systems KHK Gears Internal Gear Examples The gear teeth of the internal. Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Here, in this section, we introduce the characteristics of gears,. Internal Gear Examples.

From kalebkruwperry.blogspot.com

Describe Where Internal Gears Are Typically Used. KalebkruwPerry Internal Gear Examples Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but there are. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α),. Internal Gear Examples.

From inchbyinch.de

INCH Technical English gear types Internal Gear Examples Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but there are. The gear teeth of the internal. Gear dimensions are determined in accordance with their specifications, such as module (m),. Internal Gear Examples.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Internal Gear Examples The gear teeth of the internal. Gear types are classified into 3 categories, generally by the directions of the mounting shafts. In this article, we will explore the concept, design considerations, and applications of internal ring gears. Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Gear dimensions are determined in accordance. Internal Gear Examples.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Internal Gear Examples In this article, we will explore the concept, design considerations, and applications of internal ring gears. Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. Gear types are classified into 3 categories, generally by the directions of the mounting shafts. When using internal ring gears, you can develop a. Internal Gear Examples.

From www.reddit.com

Types of Gears r/coolguides Internal Gear Examples Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Internal ring gears are an essential component in various mechanical. Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. Here, in this section, we introduce. Internal Gear Examples.

From www.linkedin.com

Understanding Spur Gears The Basics and Applications Internal Gear Examples When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but there are. The gear teeth of the internal. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Here, in this section, we introduce. Internal Gear Examples.

From fractory.com

Types of Gears Gear Parameters & Tooth Profiles Fractory Internal Gear Examples Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. Internal ring gears are an essential component in various mechanical. When using internal ring gears, you. Internal Gear Examples.

From www.scribd.com

Internal Gears Gear Mechanical Engineering Free 30day Trial Scribd Internal Gear Examples Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. The gear teeth of the internal. When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but there are. Gear types are classified into 3 categories, generally by the directions of the. Internal Gear Examples.

From www.researchgate.net

Schematic diagram of internal gear processing Download Scientific Diagram Internal Gear Examples Gear types are classified into 3 categories, generally by the directions of the mounting shafts. Here, in this section, we introduce the characteristics of gears, how to use gears, and technical tips. Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. When using internal ring gears, you can develop. Internal Gear Examples.

From www.pinterest.com

Different types of Gears. Gears, Spiral bevel gear, Bevel gear Internal Gear Examples Internal gears are a type of gearing that consists of two gears, with the smaller gear (the pinion) meshing with. In this article, we will explore the concept, design considerations, and applications of internal ring gears. When using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but there are.. Internal Gear Examples.