Feed And Speed Chart For Carbide Drills . 2) start with a middle/average value for cutting speed, v c. All speed conditions are for stable conditions. Factors such as machine, fixture and tooling rigidity, horsepower available, coolant application and. Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when. Here are the feeds and speeds with a carbide drill: To find the best speed and feed for carbide drills, look at the material, drill size, and finish you want. 1) select your material in the iso colored chart with respect to material description. Adjust the cutting speed and/or feed rate based on your cutting conditions. Speeds and feeds are suggested starting points only and may be increased or decreased depending on actual material and machining conditions. Feeds & speeds are a starting recommendation only. The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill.

from ar.inspiredpencil.com

Adjust the cutting speed and/or feed rate based on your cutting conditions. 2) start with a middle/average value for cutting speed, v c. Factors such as machine, fixture and tooling rigidity, horsepower available, coolant application and. The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. 1) select your material in the iso colored chart with respect to material description. Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when. All speed conditions are for stable conditions. Feeds & speeds are a starting recommendation only. To find the best speed and feed for carbide drills, look at the material, drill size, and finish you want. Speeds and feeds are suggested starting points only and may be increased or decreased depending on actual material and machining conditions.

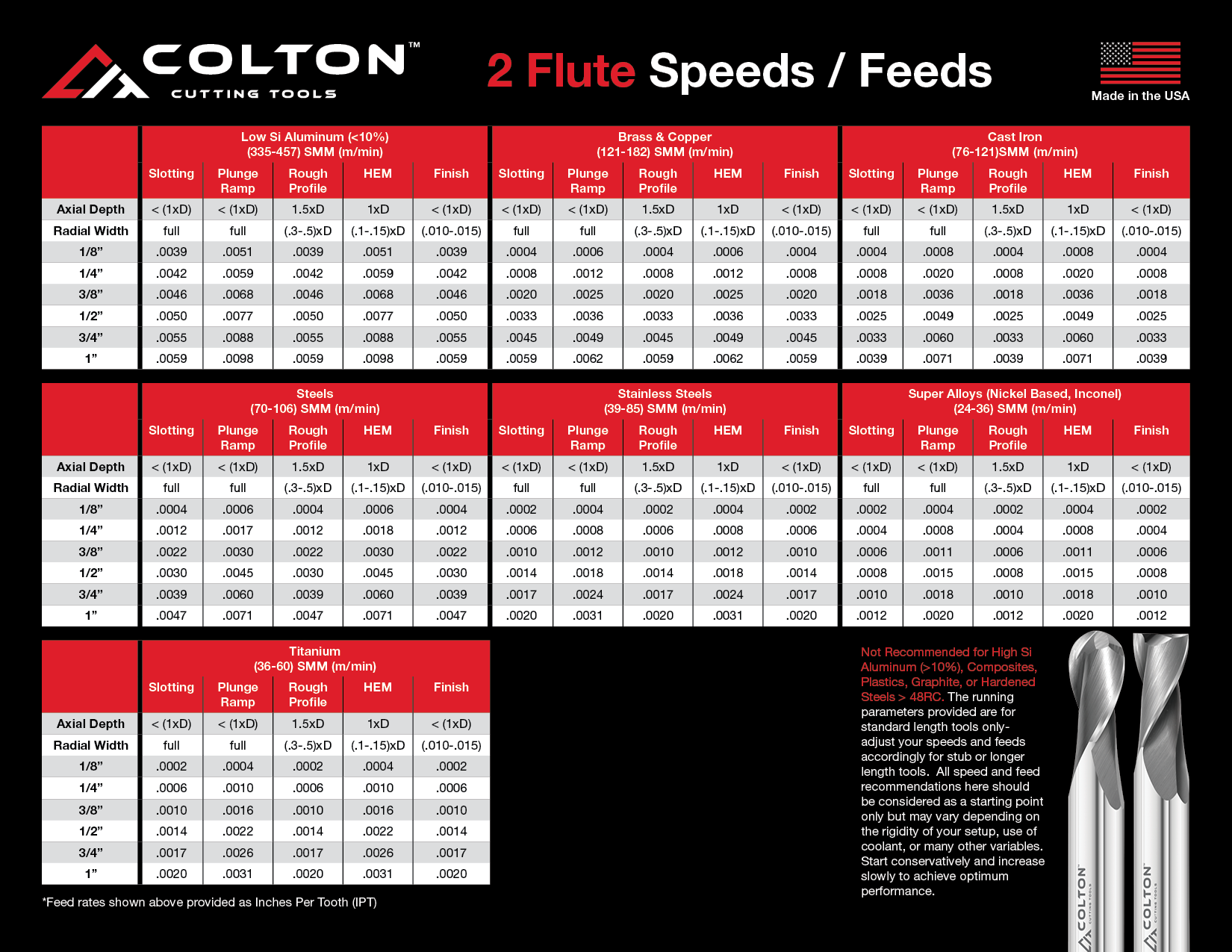

End Mill Speed Chart

Feed And Speed Chart For Carbide Drills All speed conditions are for stable conditions. The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. Feeds & speeds are a starting recommendation only. To find the best speed and feed for carbide drills, look at the material, drill size, and finish you want. Factors such as machine, fixture and tooling rigidity, horsepower available, coolant application and. Adjust the cutting speed and/or feed rate based on your cutting conditions. 2) start with a middle/average value for cutting speed, v c. 1) select your material in the iso colored chart with respect to material description. All speed conditions are for stable conditions. Speeds and feeds are suggested starting points only and may be increased or decreased depending on actual material and machining conditions. Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when. Here are the feeds and speeds with a carbide drill:

From woodtoolingshop.com

Calculate feed and speed for CNC cutting tools Feed And Speed Chart For Carbide Drills Factors such as machine, fixture and tooling rigidity, horsepower available, coolant application and. The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. 2) start with a middle/average value for cutting speed, v c. Here are the feeds and speeds with a carbide drill: Feeds & speeds are a starting recommendation only. Adjust the cutting. Feed And Speed Chart For Carbide Drills.

From www.lakeshorecarbide.com

Variable Rougher Speeds & Feeds Lakeshore Carbide Inc. Feed And Speed Chart For Carbide Drills All speed conditions are for stable conditions. Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when. Adjust the cutting speed and/or feed rate based on your cutting conditions. Feeds & speeds are a starting recommendation only. The mrr goes from 2.57 to 8.66 cubic inches per minute with a. Feed And Speed Chart For Carbide Drills.

From cehxzrri.blob.core.windows.net

Carbide Drill Speeds And Feeds Calculator at Jerry Bass blog Feed And Speed Chart For Carbide Drills To find the best speed and feed for carbide drills, look at the material, drill size, and finish you want. 1) select your material in the iso colored chart with respect to material description. Adjust the cutting speed and/or feed rate based on your cutting conditions. Speeds and feeds are suggested starting points only and may be increased or decreased. Feed And Speed Chart For Carbide Drills.

From mungfali.com

Drill Feed Speed Chart Feed And Speed Chart For Carbide Drills Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when. To find the best speed and feed for carbide drills, look at the material, drill size, and finish you want. The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. Speeds and feeds are suggested. Feed And Speed Chart For Carbide Drills.

From dxomuiiyt.blob.core.windows.net

Drill Bit Feeds And Speeds Calculator at Samuel Marsh blog Feed And Speed Chart For Carbide Drills Speeds and feeds are suggested starting points only and may be increased or decreased depending on actual material and machining conditions. Adjust the cutting speed and/or feed rate based on your cutting conditions. The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. Carbide drill feeds and speeds charts serve as fundamental references for determining. Feed And Speed Chart For Carbide Drills.

From cehxzrri.blob.core.windows.net

Carbide Drill Speeds And Feeds Calculator at Jerry Bass blog Feed And Speed Chart For Carbide Drills All speed conditions are for stable conditions. Feeds & speeds are a starting recommendation only. The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. Factors such as machine, fixture and tooling rigidity, horsepower available, coolant application and. To find the best speed and feed for carbide drills, look at the material, drill size, and. Feed And Speed Chart For Carbide Drills.

From atlascuttingtools.com

Speeds and Feeds for Carbide Ball Mills 4 Flute Variable Index Feed And Speed Chart For Carbide Drills Feeds & speeds are a starting recommendation only. Factors such as machine, fixture and tooling rigidity, horsepower available, coolant application and. 2) start with a middle/average value for cutting speed, v c. The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. 1) select your material in the iso colored chart with respect to material. Feed And Speed Chart For Carbide Drills.

From sumicarbide.com

WDX Indexable Drill Drilling Tools Sumitomo Electric Carbide, Inc. Feed And Speed Chart For Carbide Drills Speeds and feeds are suggested starting points only and may be increased or decreased depending on actual material and machining conditions. The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. Factors such as machine, fixture and tooling rigidity, horsepower available, coolant application and. 2) start with a middle/average value for cutting speed, v c.. Feed And Speed Chart For Carbide Drills.

From woodworkadvice.com

Drill Press Speed Chart Your 2021 Guide Woodwork Advice Feed And Speed Chart For Carbide Drills Factors such as machine, fixture and tooling rigidity, horsepower available, coolant application and. Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when. Here are the feeds and speeds with a carbide drill: 1) select your material in the iso colored chart with respect to material description. The mrr goes. Feed And Speed Chart For Carbide Drills.

From www.cnccookbook.com

Carbide Drill Speeds and Feeds [Plus Tips and Techniques] Feed And Speed Chart For Carbide Drills Adjust the cutting speed and/or feed rate based on your cutting conditions. Feeds & speeds are a starting recommendation only. Factors such as machine, fixture and tooling rigidity, horsepower available, coolant application and. Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when. All speed conditions are for stable conditions.. Feed And Speed Chart For Carbide Drills.

From bceweb.org

Hss Drill Speeds And Feeds Chart A Visual Reference of Charts Chart Feed And Speed Chart For Carbide Drills The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. 1) select your material in the iso colored chart with respect to material description. Feeds & speeds are a starting recommendation only. All speed conditions are for stable conditions. Speeds and feeds are suggested starting points only and may be increased or decreased depending on. Feed And Speed Chart For Carbide Drills.

From mavink.com

Carbide End Mill Speed And Feed Chart Feed And Speed Chart For Carbide Drills The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. Adjust the cutting speed and/or feed rate based on your cutting conditions. Here are the feeds and speeds with a carbide drill: Feeds & speeds are a starting recommendation only. Speeds and feeds are suggested starting points only and may be increased or decreased depending. Feed And Speed Chart For Carbide Drills.

From atlascuttingtools.com

Speeds and Feeds for Carbide Drilling Feed And Speed Chart For Carbide Drills 1) select your material in the iso colored chart with respect to material description. 2) start with a middle/average value for cutting speed, v c. Here are the feeds and speeds with a carbide drill: Speeds and feeds are suggested starting points only and may be increased or decreased depending on actual material and machining conditions. Feeds & speeds are. Feed And Speed Chart For Carbide Drills.

From lexingtoncutter.com

Feeds & Speeds Charts Lexington Cutter Feed And Speed Chart For Carbide Drills The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. Factors such as machine, fixture and tooling rigidity, horsepower available, coolant application and. To find the best speed and feed for carbide drills, look at the material, drill size, and finish you want. All speed conditions are for stable conditions. Carbide drill feeds and speeds. Feed And Speed Chart For Carbide Drills.

From bamil.lewisburgdistrictumc.org

carbide end mill speed and feed chart Bamil Feed And Speed Chart For Carbide Drills To find the best speed and feed for carbide drills, look at the material, drill size, and finish you want. Speeds and feeds are suggested starting points only and may be increased or decreased depending on actual material and machining conditions. Here are the feeds and speeds with a carbide drill: Factors such as machine, fixture and tooling rigidity, horsepower. Feed And Speed Chart For Carbide Drills.

From www.scribd.com

Feeds & Speeds Chart For Drills, Reamers, Mills & Saws (Carbide Tipped Feed And Speed Chart For Carbide Drills The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. 2) start with a middle/average value for cutting speed, v c. Feeds & speeds are a starting recommendation only. All speed conditions are for stable conditions. Adjust the cutting speed and/or feed rate based on your cutting conditions. 1) select your material in the iso. Feed And Speed Chart For Carbide Drills.

From lexingtoncutter.com

Feeds & Speeds Charts Lexington Cutter Feed And Speed Chart For Carbide Drills 2) start with a middle/average value for cutting speed, v c. Feeds & speeds are a starting recommendation only. 1) select your material in the iso colored chart with respect to material description. All speed conditions are for stable conditions. To find the best speed and feed for carbide drills, look at the material, drill size, and finish you want.. Feed And Speed Chart For Carbide Drills.

From mungfali.com

Drill Feed Speed Chart Feed And Speed Chart For Carbide Drills 2) start with a middle/average value for cutting speed, v c. Adjust the cutting speed and/or feed rate based on your cutting conditions. Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when. To find the best speed and feed for carbide drills, look at the material, drill size, and. Feed And Speed Chart For Carbide Drills.

From www.ebay.com

GUHRING CARBIDE FEED & SPEED TWIST DRILLS CHART, GS200s eBay Feed And Speed Chart For Carbide Drills Here are the feeds and speeds with a carbide drill: Adjust the cutting speed and/or feed rate based on your cutting conditions. Speeds and feeds are suggested starting points only and may be increased or decreased depending on actual material and machining conditions. 1) select your material in the iso colored chart with respect to material description. Feeds & speeds. Feed And Speed Chart For Carbide Drills.

From mungfali.com

Lathe Speeds And Feeds Chart Feed And Speed Chart For Carbide Drills Feeds & speeds are a starting recommendation only. 2) start with a middle/average value for cutting speed, v c. Speeds and feeds are suggested starting points only and may be increased or decreased depending on actual material and machining conditions. Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when.. Feed And Speed Chart For Carbide Drills.

From cehxzrri.blob.core.windows.net

Carbide Drill Speeds And Feeds Calculator at Jerry Bass blog Feed And Speed Chart For Carbide Drills The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. 2) start with a middle/average value for cutting speed, v c. Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when. Adjust the cutting speed and/or feed rate based on your cutting conditions. All speed. Feed And Speed Chart For Carbide Drills.

From mungfali.com

Drill Feed Speed Chart Feed And Speed Chart For Carbide Drills The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. 1) select your material in the iso colored chart with respect to material description. All speed conditions are for stable conditions. Adjust the cutting speed and/or feed rate based on your cutting conditions. Carbide drill feeds and speeds charts serve as fundamental references for determining. Feed And Speed Chart For Carbide Drills.

From drillbitsunlimited.com

Feed and Speed Values for Carbide Routers and End Mills Drill Bits Feed And Speed Chart For Carbide Drills Here are the feeds and speeds with a carbide drill: Adjust the cutting speed and/or feed rate based on your cutting conditions. Feeds & speeds are a starting recommendation only. 2) start with a middle/average value for cutting speed, v c. All speed conditions are for stable conditions. 1) select your material in the iso colored chart with respect to. Feed And Speed Chart For Carbide Drills.

From es.scribd.com

Feeds And Speeds For General Purpose Altin Coated Carbide Endmills Feed And Speed Chart For Carbide Drills To find the best speed and feed for carbide drills, look at the material, drill size, and finish you want. Feeds & speeds are a starting recommendation only. Here are the feeds and speeds with a carbide drill: Adjust the cutting speed and/or feed rate based on your cutting conditions. Factors such as machine, fixture and tooling rigidity, horsepower available,. Feed And Speed Chart For Carbide Drills.

From sumicarbide.com

SMD Replaceable Tip Drills Drilling Tools Sumitomo Electric Carbide Feed And Speed Chart For Carbide Drills All speed conditions are for stable conditions. Factors such as machine, fixture and tooling rigidity, horsepower available, coolant application and. Adjust the cutting speed and/or feed rate based on your cutting conditions. Speeds and feeds are suggested starting points only and may be increased or decreased depending on actual material and machining conditions. The mrr goes from 2.57 to 8.66. Feed And Speed Chart For Carbide Drills.

From mellowpine.com

Speeds and Feeds Beginner Guide with Table MellowPine Feed And Speed Chart For Carbide Drills To find the best speed and feed for carbide drills, look at the material, drill size, and finish you want. The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when. Factors such as machine, fixture. Feed And Speed Chart For Carbide Drills.

From www.ebay.com

GUHRING CARBIDE FEED & SPEED TWIST DRILLS CHART, GS200s eBay Feed And Speed Chart For Carbide Drills Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when. Speeds and feeds are suggested starting points only and may be increased or decreased depending on actual material and machining conditions. The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. 2) start with a. Feed And Speed Chart For Carbide Drills.

From cehxzrri.blob.core.windows.net

Carbide Drill Speeds And Feeds Calculator at Jerry Bass blog Feed And Speed Chart For Carbide Drills 2) start with a middle/average value for cutting speed, v c. To find the best speed and feed for carbide drills, look at the material, drill size, and finish you want. All speed conditions are for stable conditions. Feeds & speeds are a starting recommendation only. 1) select your material in the iso colored chart with respect to material description.. Feed And Speed Chart For Carbide Drills.

From www.scribd.com

Carbide End Mill Feeds and Speeds TuffCut XR 177 Metric Cast Iron Steel Feed And Speed Chart For Carbide Drills Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when. The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. Feeds & speeds are a starting recommendation only. Here are the feeds and speeds with a carbide drill: To find the best speed and feed. Feed And Speed Chart For Carbide Drills.

From ar.inspiredpencil.com

End Mill Speed Chart Feed And Speed Chart For Carbide Drills The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. Speeds and feeds are suggested starting points only and may be increased or decreased depending on actual material and machining conditions. Here are the feeds and speeds with a carbide drill: Feeds & speeds are a starting recommendation only. 2) start with a middle/average value. Feed And Speed Chart For Carbide Drills.

From cehxzrri.blob.core.windows.net

Carbide Drill Speeds And Feeds Calculator at Jerry Bass blog Feed And Speed Chart For Carbide Drills Feeds & speeds are a starting recommendation only. 2) start with a middle/average value for cutting speed, v c. Speeds and feeds are suggested starting points only and may be increased or decreased depending on actual material and machining conditions. All speed conditions are for stable conditions. Carbide drill feeds and speeds charts serve as fundamental references for determining the. Feed And Speed Chart For Carbide Drills.

From www.toolhit.com

Carbide Reamer Speeds Feeds ToolHIT Feed And Speed Chart For Carbide Drills Feeds & speeds are a starting recommendation only. 2) start with a middle/average value for cutting speed, v c. 1) select your material in the iso colored chart with respect to material description. All speed conditions are for stable conditions. Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when.. Feed And Speed Chart For Carbide Drills.

From www.scribd.com

HSS Carbide Reamers Speeds Feeds p497 498 PDF Steel Stainless Steel Feed And Speed Chart For Carbide Drills Feeds & speeds are a starting recommendation only. The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. Carbide drill feeds and speeds charts serve as fundamental references for determining the appropriate cutting speeds and feed rates when. 1) select your material in the iso colored chart with respect to material description. Adjust the cutting. Feed And Speed Chart For Carbide Drills.

From www.scribd.com

Speed and Feed Carbide End Mills and Drills Feed And Speed Chart For Carbide Drills The mrr goes from 2.57 to 8.66 cubic inches per minute with a carbide drill. Speeds and feeds are suggested starting points only and may be increased or decreased depending on actual material and machining conditions. Feeds & speeds are a starting recommendation only. 1) select your material in the iso colored chart with respect to material description. 2) start. Feed And Speed Chart For Carbide Drills.

From www.toolhit.com

Carbide Reamer Speeds Feeds ToolHIT Feed And Speed Chart For Carbide Drills 1) select your material in the iso colored chart with respect to material description. Factors such as machine, fixture and tooling rigidity, horsepower available, coolant application and. To find the best speed and feed for carbide drills, look at the material, drill size, and finish you want. Adjust the cutting speed and/or feed rate based on your cutting conditions. Feeds. Feed And Speed Chart For Carbide Drills.