Flame Brazing Aluminium . This article is intended as a general guide to aluminium brazing practices. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. • brazing in an enclosure i.e. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. Brazing of aluminium can broadly be classified into two main areas. Brazing and soldering alloys and fluxes for aluminium.

from www.aluminium-brazing.com

Brazing and soldering alloys and fluxes for aluminium. • brazing in an enclosure i.e. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. This article is intended as a general guide to aluminium brazing practices. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. Brazing of aluminium can broadly be classified into two main areas. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing.

Aluminium Flame Brazing Basics Part 1 Aluminium Brazing

Flame Brazing Aluminium This article is intended as a general guide to aluminium brazing practices. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. This article is intended as a general guide to aluminium brazing practices. Brazing of aluminium can broadly be classified into two main areas. • brazing in an enclosure i.e. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. Brazing and soldering alloys and fluxes for aluminium.

From www.flamebrazing.co.uk

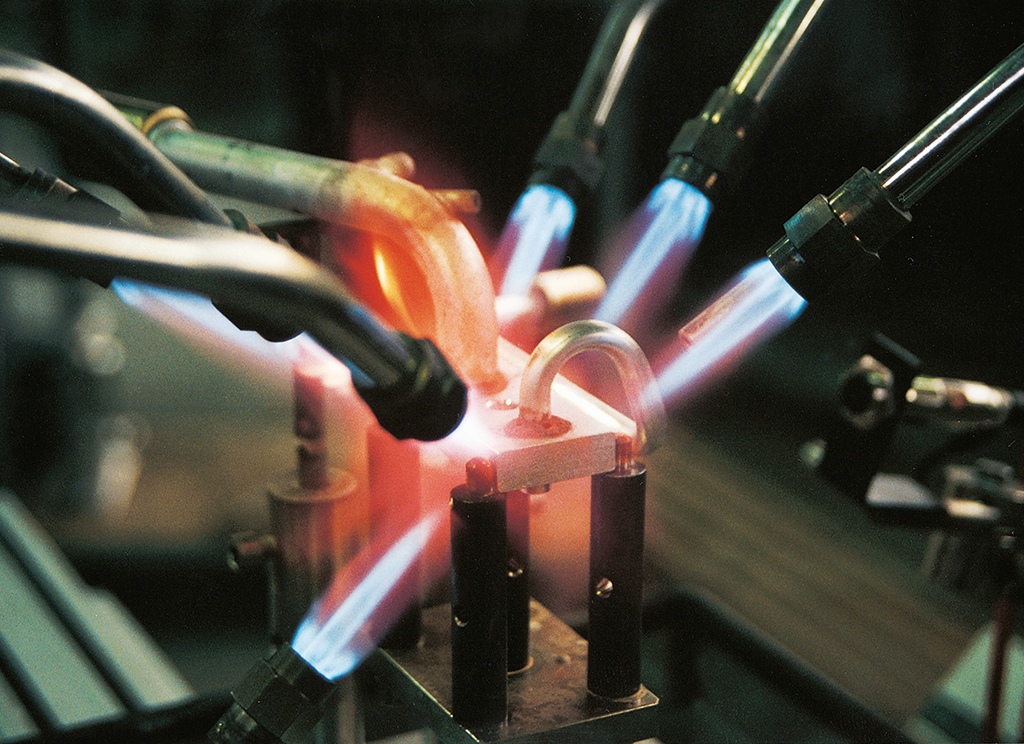

Rotary and Inline Machines Flame Brazing Flame Brazing Aluminium As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. • brazing in an enclosure i.e. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high. Flame Brazing Aluminium.

From www.flamebrazing.co.uk

About Us Flame Brazing Flame Brazing Aluminium Brazing of aluminium can broadly be classified into two main areas. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing. Flame Brazing Aluminium.

From weldingtroop.com

Aluminum Brazing Complete Guide Advantages Over Welding Flame Brazing Aluminium The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. Brazing and soldering alloys and fluxes for aluminium. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. This article is intended as a general guide to aluminium brazing practices. • brazing. Flame Brazing Aluminium.

From www.flamebrazing.co.uk

to the home of Flame Brazing... Flame Brazing Flame Brazing Aluminium The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Brazing and soldering alloys and fluxes for aluminium. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene. Flame Brazing Aluminium.

From www.aluminium-brazing.com

Aluminium Flame Brazing Basics Part 4 Aluminium Brazing Flame Brazing Aluminium Brazing and soldering alloys and fluxes for aluminium. • brazing in an enclosure i.e. The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. This article is intended as a general guide to aluminium brazing practices. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. Flame (torch) brazing of. Flame Brazing Aluminium.

From www.dodomachine.com

Flame Brazing Machine Manufacturing SolutionsDoDo Machine Automatic Flame Brazing Aluminium As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. • brazing in an enclosure i.e. Brazing of aluminium can broadly be classified into two main areas. Brazing and soldering alloys and fluxes for aluminium. This article is intended as a general guide to aluminium brazing practices. The most. Flame Brazing Aluminium.

From midsouthsupply.com

Guide to Aluminum Brazing Mid South Supply Flame Brazing Aluminium Brazing of aluminium can broadly be classified into two main areas. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Furnace brazing either in a vacuum furnace (without flux). Flame Brazing Aluminium.

From www.aluminium-brazing.com

Aluminium Flame Brazing Basics Part 2 Aluminium Brazing Flame Brazing Aluminium • brazing in an enclosure i.e. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. Brazing of aluminium can broadly be classified into two main areas. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does. Flame Brazing Aluminium.

From www.aluminium-brazing.com

Aluminium Flame Brazing Basics Part 5 Aluminium Brazing Flame Brazing Aluminium This article is intended as a general guide to aluminium brazing practices. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Brazing of aluminium can broadly be classified into two main areas. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. As shown in the table,. Flame Brazing Aluminium.

From www.aluminium-brazing.com

Aluminium Flame Brazing Basics Part 1 Aluminium Brazing Flame Brazing Aluminium The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. • brazing. Flame Brazing Aluminium.

From www.hampdon.com.au

Aluminium Brazing Kit 30 x Ally Brazing Rods + MAPP Blow Torch & Wir Flame Brazing Aluminium • brazing in an enclosure i.e. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. As shown in the table, alloys that are considered difficult or impossible to braze by. Flame Brazing Aluminium.

From www.flamebrazing.co.uk

to the home of Flame Brazing... Flame Brazing Flame Brazing Aluminium • brazing in an enclosure i.e. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Brazing of aluminium can broadly be classified into two main areas. The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. Flame (torch) brazing of aluminium involves locally. Flame Brazing Aluminium.

From weldingtroop.com

Aluminum Brazing Complete Guide Advantages Over Welding Flame Brazing Aluminium As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. Brazing and soldering alloys and fluxes for aluminium. The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. This article is intended as a general guide to aluminium brazing practices. Brazing of. Flame Brazing Aluminium.

From www.flamebrazing.co.uk

to the home of Flame Brazing... Flame Brazing Flame Brazing Aluminium Brazing of aluminium can broadly be classified into two main areas. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. Furnace brazing either in a vacuum furnace (without. Flame Brazing Aluminium.

From www.aluminium-brazing.com

Aluminium Flame Brazing Basics Part 5 Aluminium Brazing Flame Brazing Aluminium Brazing of aluminium can broadly be classified into two main areas. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. • brazing in an enclosure i.e. Brazing and soldering alloys and fluxes for aluminium. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. When. Flame Brazing Aluminium.

From www.flamebrazing.co.uk

to the home of Flame Brazing... Flame Brazing Flame Brazing Aluminium Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. When compared to welding equipment, aluminum. Flame Brazing Aluminium.

From www.youtube.com

How to weld aluminium aluminiumaluminium brazing guide YouTube Flame Brazing Aluminium Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. This article is intended as a general guide to aluminium brazing practices. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. As shown in the table, alloys that are considered difficult or impossible to braze by. Flame Brazing Aluminium.

From www.aluminium-brazing.com

Aluminium Flame Brazing Basics Part 2 Aluminium Brazing Flame Brazing Aluminium Brazing of aluminium can broadly be classified into two main areas. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing. Flame Brazing Aluminium.

From weldersadvice.com

How to Braze Aluminum to Steel Steps, Techniques & Advantages Flame Brazing Aluminium Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. The most important brazing method for aluminium is. Flame Brazing Aluminium.

From www.aluminium-brazing.com

Flame Brazing Technology Part 1 Aluminium Brazing Flame Brazing Aluminium • brazing in an enclosure i.e. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. The. Flame Brazing Aluminium.

From www.iectestingequipment.com

Turntable Flame Automatic Brazing Machine / Auto Brazing Machine for Flame Brazing Aluminium Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Flame (torch) brazing of aluminium involves locally applied heat typically generated. Flame Brazing Aluminium.

From ukweld.co.uk

Subcontract Flame brazing service UK WELD LTD Flame Brazing Aluminium As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. Brazing of aluminium can broadly be classified into two main areas. The most important brazing method for aluminium is. Flame Brazing Aluminium.

From www.flamebrazing.co.uk

Hand Torches Flame Brazing Flame Brazing Aluminium Brazing and soldering alloys and fluxes for aluminium. This article is intended as a general guide to aluminium brazing practices. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. • brazing in an enclosure i.e. The most important brazing method for aluminium is furnace brazing (in particular for the production. Flame Brazing Aluminium.

From www.aluminium-brazing.com

Aluminium Flame Brazing Basics Part 1 Aluminium Brazing Flame Brazing Aluminium • brazing in an enclosure i.e. The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. Brazing of aluminium can broadly be classified into two main areas. Brazing and soldering alloys and fluxes for aluminium. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural. Flame Brazing Aluminium.

From www.youtube.com

How to Braze Aluminum Flame & Induction Brazing YouTube Flame Brazing Aluminium Brazing and soldering alloys and fluxes for aluminium. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. • brazing in an enclosure i.e. Furnace brazing either in a vacuum furnace (without flux) or. Flame Brazing Aluminium.

From www.chalcoaluminum.com

All About the Aluminium Brazing Process Chalco Aluminum Flame Brazing Aluminium Brazing and soldering alloys and fluxes for aluminium. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. • brazing in an enclosure i.e. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. Furnace brazing either in a. Flame Brazing Aluminium.

From www.flamebrazing.co.uk

to the home of Flame Brazing... Flame Brazing Flame Brazing Aluminium As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. Brazing of aluminium can broadly be classified into two main areas. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require. Flame Brazing Aluminium.

From www.chalcoaluminum.com

All About the Aluminium Brazing Process Chalco Aluminum Flame Brazing Aluminium Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. Brazing and soldering alloys and fluxes for aluminium. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. This article is intended as a general guide to aluminium brazing practices. Flame (torch) brazing of aluminium involves. Flame Brazing Aluminium.

From www.dodomachine.com

How Strong is Aluminum Brazing? A Comprehensive Analysis Automatic Flame Brazing Aluminium As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be flame brazed. The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. • brazing in an enclosure i.e. When compared to. Flame Brazing Aluminium.

From jngreenlab.en.made-in-china.com

Safeflame SF2000 Hydrogen Flame Brazing Machine for Aluminum Welding Flame Brazing Aluminium Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. Brazing and soldering alloys and fluxes for aluminium. As shown in the table, alloys that are considered difficult or impossible to braze by furnace methods can be. Flame Brazing Aluminium.

From dw-inductionheater.com

High Frequency Induction Brazing Aluminum Pipes Process Flame Brazing Aluminium The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. Brazing and soldering alloys and fluxes for aluminium. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene. Flame Brazing Aluminium.

From www.aluminium-brazing.com

Aluminium Flame Brazing Basics Part 2 Aluminium Brazing Flame Brazing Aluminium • brazing in an enclosure i.e. Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. Brazing of aluminium can. Flame Brazing Aluminium.

From www.pinterest.com

How to Weld Aluminum Without a Welder Brazing, Welding projects Flame Brazing Aluminium This article is intended as a general guide to aluminium brazing practices. • brazing in an enclosure i.e. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. Furnace brazing either in a. Flame Brazing Aluminium.

From www.aluminium-brazing.com

Aluminium Flame Brazing Basics Part 4 Aluminium Brazing Flame Brazing Aluminium The most important brazing method for aluminium is furnace brazing (in particular for the production of heat. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. This article is intended. Flame Brazing Aluminium.

From www.chalcoaluminum.com

All About the Aluminium Brazing Process Chalco Aluminum Flame Brazing Aluminium Furnace brazing either in a vacuum furnace (without flux) or controlled atmosphere brazing. Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. Brazing of aluminium can broadly be classified into two main areas. This article is intended as a general guide to aluminium brazing practices. The most important brazing. Flame Brazing Aluminium.