Sheave Groove . If the groove shows signs of rope imprints. The gage should contact the groove for about 150° of. To check the size, contour and amount of wear, use a sheave gage. Flame hardening, contour of the groove and groove wear during a sheaves life cycle and explain what to look for during a sheave inspection. The groove angle of rope sheaves therefore, contrary to a widespread assumption, the use of sheaves with a groove angle of 52°. Examine the sheave grooves for wear and proper diameter. The groove of a new sheave should have a diameter 5% greater than the cable diameter. Measuring wire rope and sheave wear. To check the sheave size, contour and amount of wear, a groove gauge is used. This is indicated when a rope is showing two parallel planes of wear and/or. Cables should not be run over. As shown in figure 1, the gauge should contact the groove for about 150° of arc. A properly machined sheave groove allows a wire rope to pass through unhindered by friction or. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. Sheave will cause increased groove pressures at the point of contact.

from www.jaredzone.info

The gage should contact the groove for about 150° of. To check the size, contour and amount of wear, use a sheave gage. Cables should not be run over. If the groove shows signs of rope imprints. Measuring wire rope and sheave wear. Sheave will cause increased groove pressures at the point of contact. A properly machined sheave groove allows a wire rope to pass through unhindered by friction or. This is indicated when a rope is showing two parallel planes of wear and/or. To check the sheave size, contour and amount of wear, a groove gauge is used. As shown in figure 1, the gauge should contact the groove for about 150° of arc.

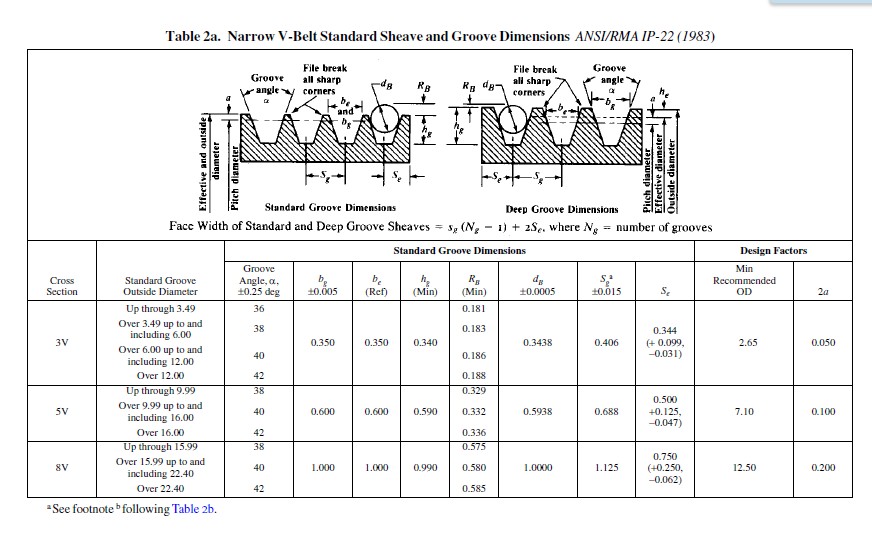

Narrow Vbelts Selection Mechanical Reviews

Sheave Groove To check the sheave size, contour and amount of wear, a groove gauge is used. The gage should contact the groove for about 150° of. Sheave will cause increased groove pressures at the point of contact. If the groove shows signs of rope imprints. A properly machined sheave groove allows a wire rope to pass through unhindered by friction or. Measuring wire rope and sheave wear. Examine the sheave grooves for wear and proper diameter. To check the size, contour and amount of wear, use a sheave gage. As shown in figure 1, the gauge should contact the groove for about 150° of arc. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. Cables should not be run over. To check the sheave size, contour and amount of wear, a groove gauge is used. This is indicated when a rope is showing two parallel planes of wear and/or. The groove angle of rope sheaves therefore, contrary to a widespread assumption, the use of sheaves with a groove angle of 52°. Flame hardening, contour of the groove and groove wear during a sheaves life cycle and explain what to look for during a sheave inspection. The groove of a new sheave should have a diameter 5% greater than the cable diameter.

From rooneyirving.ca

Sheave grooves worn with rope pattern Rooney Irving & Associates Sheave Groove The groove of a new sheave should have a diameter 5% greater than the cable diameter. The groove angle of rope sheaves therefore, contrary to a widespread assumption, the use of sheaves with a groove angle of 52°. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. Cables should not. Sheave Groove.

From www.dreamstime.com

Wire Rope in the Sheave Groove for Lifting Equipment Stock Image Sheave Groove Cables should not be run over. A properly machined sheave groove allows a wire rope to pass through unhindered by friction or. Sheave will cause increased groove pressures at the point of contact. Examine the sheave grooves for wear and proper diameter. This is indicated when a rope is showing two parallel planes of wear and/or. The very first item. Sheave Groove.

From industrial-stores.com

Custom 3C14.03020 3Groove Sheave Sheave Groove To check the size, contour and amount of wear, use a sheave gage. A properly machined sheave groove allows a wire rope to pass through unhindered by friction or. If the groove shows signs of rope imprints. Cables should not be run over. The groove angle of rope sheaves therefore, contrary to a widespread assumption, the use of sheaves with. Sheave Groove.

From www.carlsoncompany.com

3 groove Large sheave Carlson Industrial Sheave Groove If the groove shows signs of rope imprints. Sheave will cause increased groove pressures at the point of contact. A properly machined sheave groove allows a wire rope to pass through unhindered by friction or. The gage should contact the groove for about 150° of. The groove of a new sheave should have a diameter 5% greater than the cable. Sheave Groove.

From renown-electric.com

Are You Optimizing Your Sheave Regrooving & Maintenance Processes Sheave Groove To check the size, contour and amount of wear, use a sheave gage. If the groove shows signs of rope imprints. Sheave will cause increased groove pressures at the point of contact. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. Cables should not be run over. The groove angle. Sheave Groove.

From renown-electric.com

Sheave Regrooving Renown Electric Sheave Groove A properly machined sheave groove allows a wire rope to pass through unhindered by friction or. Flame hardening, contour of the groove and groove wear during a sheaves life cycle and explain what to look for during a sheave inspection. Examine the sheave grooves for wear and proper diameter. This is indicated when a rope is showing two parallel planes. Sheave Groove.

From www.tmepc.it

Sheaves 8 grooves COMPONENTS MADE DESIGN FOR "OIL & GAS" INDUSTRY T Sheave Groove Measuring wire rope and sheave wear. Sheave will cause increased groove pressures at the point of contact. Flame hardening, contour of the groove and groove wear during a sheaves life cycle and explain what to look for during a sheave inspection. Cables should not be run over. Examine the sheave grooves for wear and proper diameter. To check the sheave. Sheave Groove.

From industrial-stores.com

TB Wood's 30PDX1C Single Groove Sheave Sheave Groove Flame hardening, contour of the groove and groove wear during a sheaves life cycle and explain what to look for during a sheave inspection. Sheave will cause increased groove pressures at the point of contact. If the groove shows signs of rope imprints. Examine the sheave grooves for wear and proper diameter. The gage should contact the groove for about. Sheave Groove.

From mepsystems.com.sg

MORDEC WIRE ROPE SHEAVE GAUGE MEP Deck Solutions Sheave Groove Cables should not be run over. A properly machined sheave groove allows a wire rope to pass through unhindered by friction or. Flame hardening, contour of the groove and groove wear during a sheaves life cycle and explain what to look for during a sheave inspection. If the groove shows signs of rope imprints. Examine the sheave grooves for wear. Sheave Groove.

From www.researchgate.net

Rope guide mechanism and the sheaves along with their degrees of Sheave Groove The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. As shown in figure 1, the gauge should contact the groove for about 150° of arc. If the groove shows signs of rope imprints. Measuring wire rope and sheave wear. Flame hardening, contour of the groove and groove wear during a. Sheave Groove.

From ubicaciondepersonas.cdmx.gob.mx

Wire Rope Sheave Groove Dimensions ubicaciondepersonas.cdmx.gob.mx Sheave Groove The groove of a new sheave should have a diameter 5% greater than the cable diameter. As shown in figure 1, the gauge should contact the groove for about 150° of arc. Measuring wire rope and sheave wear. Sheave will cause increased groove pressures at the point of contact. This is indicated when a rope is showing two parallel planes. Sheave Groove.

From marinersrepository.blogspot.com

Mariners Repository LIFTING EQUIPMENT SHEAVES, BLOCKS , DRUMS WITH Sheave Groove Examine the sheave grooves for wear and proper diameter. As shown in figure 1, the gauge should contact the groove for about 150° of arc. The groove angle of rope sheaves therefore, contrary to a widespread assumption, the use of sheaves with a groove angle of 52°. Flame hardening, contour of the groove and groove wear during a sheaves life. Sheave Groove.

From www.mrprint.com

3041467 Sheaves, Double Groove, 1A274 Sheave Type, Cylindrical Bore Sheave Groove Flame hardening, contour of the groove and groove wear during a sheaves life cycle and explain what to look for during a sheave inspection. To check the sheave size, contour and amount of wear, a groove gauge is used. A properly machined sheave groove allows a wire rope to pass through unhindered by friction or. To check the size, contour. Sheave Groove.

From www.youtube.com

HowTo Measuring Sheave Groove Wear in HVAC Belt Drives YouTube Sheave Groove Flame hardening, contour of the groove and groove wear during a sheaves life cycle and explain what to look for during a sheave inspection. Examine the sheave grooves for wear and proper diameter. To check the size, contour and amount of wear, use a sheave gage. The very first item to be checked when examining sheaves and drums is the. Sheave Groove.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Sheave Groove Sheave will cause increased groove pressures at the point of contact. To check the size, contour and amount of wear, use a sheave gage. The gage should contact the groove for about 150° of. To check the sheave size, contour and amount of wear, a groove gauge is used. If the groove shows signs of rope imprints. This is indicated. Sheave Groove.

From www.mdpi.com

Materials Free FullText Investigation of Groove Shape Variation Sheave Groove To check the sheave size, contour and amount of wear, a groove gauge is used. The gage should contact the groove for about 150° of. Cables should not be run over. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. The groove angle of rope sheaves therefore, contrary to a. Sheave Groove.

From www.samselsupply.com

HOWTO Order Wire Rope Sheaves Sheave Groove Cables should not be run over. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. Sheave will cause increased groove pressures at the point of contact. This is indicated when a rope is showing two parallel planes of wear and/or. The groove angle of rope sheaves therefore, contrary to a. Sheave Groove.

From futurefertility.com

Material Handling Products CMFG 2AK225/8 Two Groove BoredtoSize V Sheave Groove The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. Measuring wire rope and sheave wear. Sheave will cause increased groove pressures at the point of contact. To check the size, contour and amount of wear, use a sheave gage. Cables should not be run over. Flame hardening, contour of the. Sheave Groove.

From www.jaredzone.info

Narrow Vbelts Selection Mechanical Reviews Sheave Groove If the groove shows signs of rope imprints. The groove of a new sheave should have a diameter 5% greater than the cable diameter. To check the sheave size, contour and amount of wear, a groove gauge is used. Flame hardening, contour of the groove and groove wear during a sheaves life cycle and explain what to look for during. Sheave Groove.

From www.petrorigs.com

52 inch Groove Sheave ⋆ Sheave Groove This is indicated when a rope is showing two parallel planes of wear and/or. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. If the groove shows signs of rope imprints. Cables should not be run over. The gage should contact the groove for about 150° of. To check the. Sheave Groove.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Sheave Groove This is indicated when a rope is showing two parallel planes of wear and/or. Measuring wire rope and sheave wear. To check the sheave size, contour and amount of wear, a groove gauge is used. To check the size, contour and amount of wear, use a sheave gage. If the groove shows signs of rope imprints. The gage should contact. Sheave Groove.

From www.drillingmanual.com

Hoisting System In Drilling Rig Guide DRILLING MANUAL Sheave Groove The groove angle of rope sheaves therefore, contrary to a widespread assumption, the use of sheaves with a groove angle of 52°. To check the size, contour and amount of wear, use a sheave gage. Cables should not be run over. If the groove shows signs of rope imprints. A properly machined sheave groove allows a wire rope to pass. Sheave Groove.

From marinersrepository.blogspot.com

Mariners Repository LIFTING EQUIPMENT SHEAVES, BLOCKS , DRUMS WITH Sheave Groove Flame hardening, contour of the groove and groove wear during a sheaves life cycle and explain what to look for during a sheave inspection. The gage should contact the groove for about 150° of. A properly machined sheave groove allows a wire rope to pass through unhindered by friction or. Examine the sheave grooves for wear and proper diameter. As. Sheave Groove.

From www.petrorigs.com

84 inch Groove Sheave ⋆ Sheave Groove To check the sheave size, contour and amount of wear, a groove gauge is used. As shown in figure 1, the gauge should contact the groove for about 150° of arc. This is indicated when a rope is showing two parallel planes of wear and/or. If the groove shows signs of rope imprints. Flame hardening, contour of the groove and. Sheave Groove.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Sheave Groove Sheave will cause increased groove pressures at the point of contact. If the groove shows signs of rope imprints. The groove angle of rope sheaves therefore, contrary to a widespread assumption, the use of sheaves with a groove angle of 52°. To check the size, contour and amount of wear, use a sheave gage. The very first item to be. Sheave Groove.

From www.aliexpress.com

CPT BK32 v belt pulley sheave, Cast Iron, B Belt Section, 1 Groove Sheave Groove The groove of a new sheave should have a diameter 5% greater than the cable diameter. The groove angle of rope sheaves therefore, contrary to a widespread assumption, the use of sheaves with a groove angle of 52°. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. Flame hardening, contour. Sheave Groove.

From www.scribd.com

Sheaves & Grooves PDF Wire Wear Sheave Groove Examine the sheave grooves for wear and proper diameter. This is indicated when a rope is showing two parallel planes of wear and/or. If the groove shows signs of rope imprints. The groove of a new sheave should have a diameter 5% greater than the cable diameter. To check the size, contour and amount of wear, use a sheave gage.. Sheave Groove.

From www.packardonline.com

Variable Pitch, 2 Groove Sheave, 5.35" O.D., 11/8" Bore Packard Online Sheave Groove Examine the sheave grooves for wear and proper diameter. The groove angle of rope sheaves therefore, contrary to a widespread assumption, the use of sheaves with a groove angle of 52°. If the groove shows signs of rope imprints. Measuring wire rope and sheave wear. Sheave will cause increased groove pressures at the point of contact. The gage should contact. Sheave Groove.

From www.petrorigs.com

84 inch Groove Sheave ⋆ Sheave Groove The groove of a new sheave should have a diameter 5% greater than the cable diameter. If the groove shows signs of rope imprints. To check the size, contour and amount of wear, use a sheave gage. The gage should contact the groove for about 150° of. Cables should not be run over. This is indicated when a rope is. Sheave Groove.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Sheave Groove The groove of a new sheave should have a diameter 5% greater than the cable diameter. Measuring wire rope and sheave wear. To check the size, contour and amount of wear, use a sheave gage. If the groove shows signs of rope imprints. As shown in figure 1, the gauge should contact the groove for about 150° of arc. Sheave. Sheave Groove.

From www.dreamstime.com

Wire Rope in the Sheave Groove for Lifting Equipment Stock Photo Sheave Groove This is indicated when a rope is showing two parallel planes of wear and/or. Flame hardening, contour of the groove and groove wear during a sheaves life cycle and explain what to look for during a sheave inspection. The groove angle of rope sheaves therefore, contrary to a widespread assumption, the use of sheaves with a groove angle of 52°.. Sheave Groove.

From harriscompanies.com

H.I.E. Traction Sheave 3 groove Complete, 20" x 3 Groove for 3/8" or 1/ Sheave Groove The gage should contact the groove for about 150° of. Examine the sheave grooves for wear and proper diameter. The groove angle of rope sheaves therefore, contrary to a widespread assumption, the use of sheaves with a groove angle of 52°. Measuring wire rope and sheave wear. Sheave will cause increased groove pressures at the point of contact. As shown. Sheave Groove.

From www.carlsoncompany.com

6 groove sheave Carlson Industrial Sheave Groove The groove angle of rope sheaves therefore, contrary to a widespread assumption, the use of sheaves with a groove angle of 52°. To check the sheave size, contour and amount of wear, a groove gauge is used. To check the size, contour and amount of wear, use a sheave gage. The groove of a new sheave should have a diameter. Sheave Groove.

From www.petrorigs.com

60 inch Groove Sheave ⋆ Sheave Groove Sheave will cause increased groove pressures at the point of contact. To check the sheave size, contour and amount of wear, a groove gauge is used. As shown in figure 1, the gauge should contact the groove for about 150° of arc. The gage should contact the groove for about 150° of. Measuring wire rope and sheave wear. If the. Sheave Groove.

From www.walmart.com

3.5" Cast Iron 5/8" Shaft Pulley Sheave Single 1 Groove V Style B Belt Sheave Groove If the groove shows signs of rope imprints. The gage should contact the groove for about 150° of. To check the sheave size, contour and amount of wear, a groove gauge is used. As shown in figure 1, the gauge should contact the groove for about 150° of arc. To check the size, contour and amount of wear, use a. Sheave Groove.