Wire Crimping Issues . many times, the crimping is faulty or not up to the mark because of a number of reasons. The crimp connector may not fully compress around the wire if the die size or force are incorrect. Some common problems include poor wires. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. You can usually tell that there’s a problem with wire crimping just by looking at it. here are some common crimping problems and their solutions: how to identify common wire crimping problems. small wire applications can be especially tricky. When crimping, use the correct tools and apply sufficient pressure. this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. If they’re not in strong condition, then they won’t attach correctly.

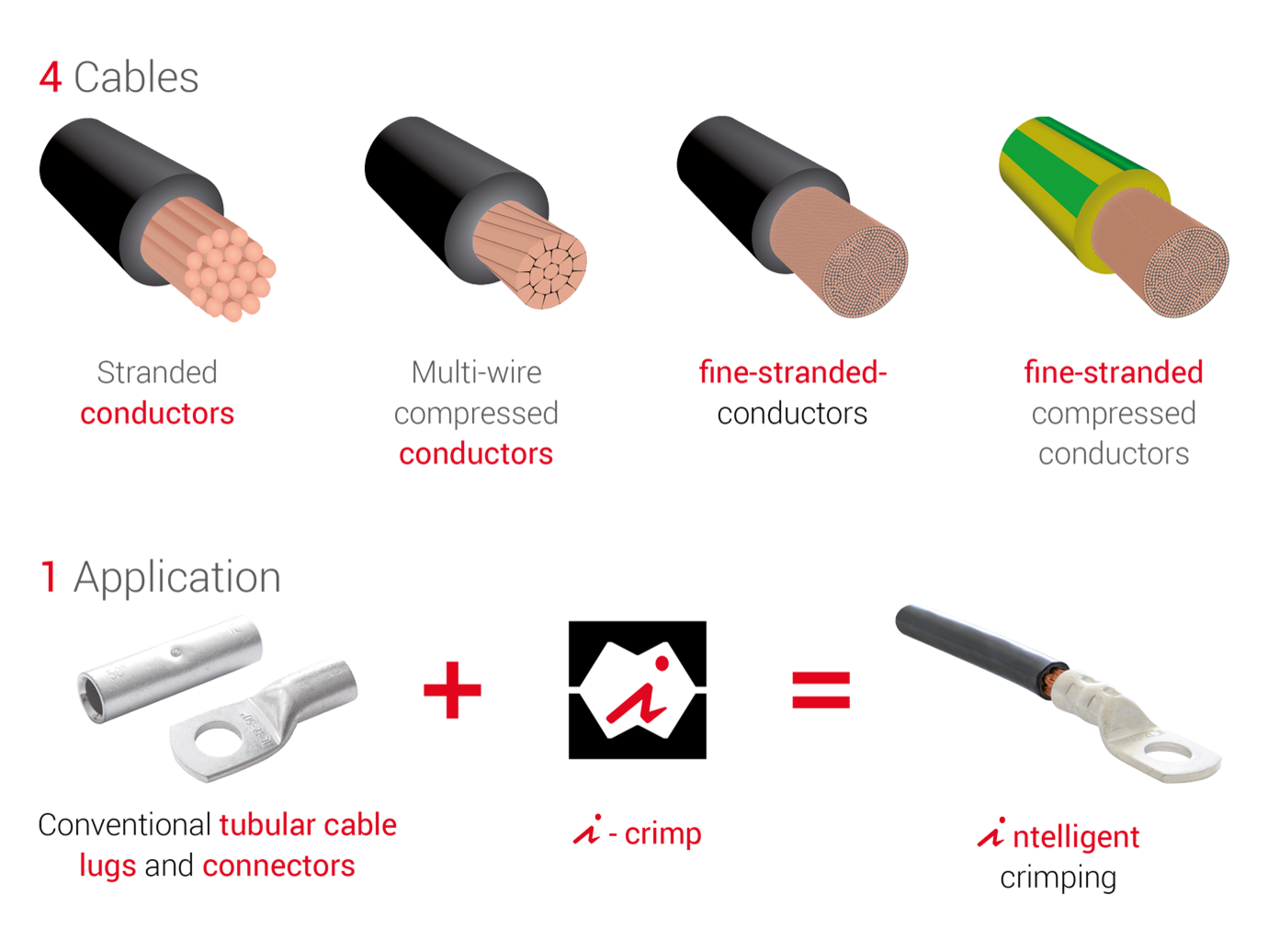

from www.intercable.tools

If they’re not in strong condition, then they won’t attach correctly. this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. The crimp connector may not fully compress around the wire if the die size or force are incorrect. how to identify common wire crimping problems. many times, the crimping is faulty or not up to the mark because of a number of reasons. You can usually tell that there’s a problem with wire crimping just by looking at it. here are some common crimping problems and their solutions: Some common problems include poor wires. small wire applications can be especially tricky.

icrimping Intercable Tools

Wire Crimping Issues You can usually tell that there’s a problem with wire crimping just by looking at it. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. Some common problems include poor wires. this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. When crimping, use the correct tools and apply sufficient pressure. You can usually tell that there’s a problem with wire crimping just by looking at it. If they’re not in strong condition, then they won’t attach correctly. The crimp connector may not fully compress around the wire if the die size or force are incorrect. here are some common crimping problems and their solutions: many times, the crimping is faulty or not up to the mark because of a number of reasons. small wire applications can be especially tricky. how to identify common wire crimping problems.

From wireharnessor.com

Analysis of the reasons leading to the production of defective Wire Crimping Issues Some common problems include poor wires. many times, the crimping is faulty or not up to the mark because of a number of reasons. here are some common crimping problems and their solutions: When crimping, use the correct tools and apply sufficient pressure. small wire applications can be especially tricky. You can usually tell that there’s a. Wire Crimping Issues.

From www.hughshandbuilt.com

HowTo Properly Crimp Wires and Terminals Hughs Hand Built Wire Crimping Issues The crimp connector may not fully compress around the wire if the die size or force are incorrect. this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. Some common problems include poor wires. small wire applications can be especially tricky. when we analyze cross sections for small wire crimps,. Wire Crimping Issues.

From www.hughshandbuilt.com

HowTo Properly Crimp Wires and Terminals Hughs Hand Built Wire Crimping Issues When crimping, use the correct tools and apply sufficient pressure. Some common problems include poor wires. here are some common crimping problems and their solutions: many times, the crimping is faulty or not up to the mark because of a number of reasons. when we analyze cross sections for small wire crimps, the two most problematic areas. Wire Crimping Issues.

From www.linquip.com

The 10 Best Wire Crimping Tool in 2024 + Buying Guide Linquip Wire Crimping Issues Some common problems include poor wires. When crimping, use the correct tools and apply sufficient pressure. If they’re not in strong condition, then they won’t attach correctly. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. this whitepaper will look at the current challenges involved in. Wire Crimping Issues.

From us.misumi-ec.com

The Issues that Occur with Soldering, Crimping, and Press Contact Wire Crimping Issues here are some common crimping problems and their solutions: The crimp connector may not fully compress around the wire if the die size or force are incorrect. Some common problems include poor wires. When crimping, use the correct tools and apply sufficient pressure. how to identify common wire crimping problems. If they’re not in strong condition, then they. Wire Crimping Issues.

From www.nepal.ubuy.com

Twidec Wire Crimping Pliers 2.86.3mm Spade Manual Crimp Tool for Open Wire Crimping Issues When crimping, use the correct tools and apply sufficient pressure. The crimp connector may not fully compress around the wire if the die size or force are incorrect. how to identify common wire crimping problems. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. many. Wire Crimping Issues.

From piektraining.com

Bad Crimp Connection PIEK Wire Crimping Issues Some common problems include poor wires. When crimping, use the correct tools and apply sufficient pressure. this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. small wire applications can be especially tricky. many times, the crimping is faulty or not up to the mark because of a number of. Wire Crimping Issues.

From giomcnobv.blob.core.windows.net

How To Properly Crimp Wire Terminals at Alan Althoff blog Wire Crimping Issues If they’re not in strong condition, then they won’t attach correctly. The crimp connector may not fully compress around the wire if the die size or force are incorrect. small wire applications can be especially tricky. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. You. Wire Crimping Issues.

From www.onallcylinders.com

Wire Crimpers 101 What is a Wire Crimping Tool? (And What to Consider Wire Crimping Issues If they’re not in strong condition, then they won’t attach correctly. Some common problems include poor wires. many times, the crimping is faulty or not up to the mark because of a number of reasons. The crimp connector may not fully compress around the wire if the die size or force are incorrect. You can usually tell that there’s. Wire Crimping Issues.

From wirefyshop.com

Crimping Dies in Wire Crimping How to Choose the Right One Wire Crimping Issues Some common problems include poor wires. You can usually tell that there’s a problem with wire crimping just by looking at it. When crimping, use the correct tools and apply sufficient pressure. how to identify common wire crimping problems. The crimp connector may not fully compress around the wire if the die size or force are incorrect. If they’re. Wire Crimping Issues.

From www.clooms.com

Crimping Process A Detailed StepbyStep Guide Wire Crimping Issues When crimping, use the correct tools and apply sufficient pressure. The crimp connector may not fully compress around the wire if the die size or force are incorrect. Some common problems include poor wires. If they’re not in strong condition, then they won’t attach correctly. many times, the crimping is faulty or not up to the mark because of. Wire Crimping Issues.

From www.onallcylinders.com

Wire Crimpers 101 What is a Wire Crimping Tool? (And What to Consider Wire Crimping Issues how to identify common wire crimping problems. If they’re not in strong condition, then they won’t attach correctly. this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. Some common problems include poor wires. here are some common crimping problems and their solutions: When crimping, use the correct tools and. Wire Crimping Issues.

From us.misumi-ec.com

The Issues that Occur with Soldering, Crimping, and Press Contact Wire Crimping Issues The crimp connector may not fully compress around the wire if the die size or force are incorrect. this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. Some common problems include poor wires. here are some common crimping problems and their solutions: when we analyze cross sections for small. Wire Crimping Issues.

From stevedmarineconsulting.com

Crimping Etiquette Editorial CO Poisoning Misinformation Steve D Wire Crimping Issues The crimp connector may not fully compress around the wire if the die size or force are incorrect. small wire applications can be especially tricky. If they’re not in strong condition, then they won’t attach correctly. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. . Wire Crimping Issues.

From simurahmato7.blogspot.com

Different Kinds Of Electrical Crimps / Inside The Secret World Of Wire Crimping Issues If they’re not in strong condition, then they won’t attach correctly. When crimping, use the correct tools and apply sufficient pressure. how to identify common wire crimping problems. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. here are some common crimping problems and their. Wire Crimping Issues.

From www.fortunesky-tech.com

Wire Cutting Crimping Woes Solved! Fix Auto Machine Issues Wire Crimping Issues many times, the crimping is faulty or not up to the mark because of a number of reasons. If they’re not in strong condition, then they won’t attach correctly. small wire applications can be especially tricky. The crimp connector may not fully compress around the wire if the die size or force are incorrect. how to identify. Wire Crimping Issues.

From www.tti.com

Terminating Wires by Crimping TTI, Inc. Wire Crimping Issues If they’re not in strong condition, then they won’t attach correctly. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. how to identify common wire crimping problems. . Wire Crimping Issues.

From www.assemblymag.com

Handheld Wire Crimping Tools 20190717 ASSEMBLY Wire Crimping Issues how to identify common wire crimping problems. The crimp connector may not fully compress around the wire if the die size or force are incorrect. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. this whitepaper will look at the current challenges involved in preparing. Wire Crimping Issues.

From inter-connection.eu

Crimped Connections Wire Crimping Issues many times, the crimping is faulty or not up to the mark because of a number of reasons. If they’re not in strong condition, then they won’t attach correctly. When crimping, use the correct tools and apply sufficient pressure. this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. small. Wire Crimping Issues.

From gioydfvoe.blob.core.windows.net

What Happens If You Connect Electrical Wires Wrong at Doug Molina blog Wire Crimping Issues many times, the crimping is faulty or not up to the mark because of a number of reasons. small wire applications can be especially tricky. Some common problems include poor wires. You can usually tell that there’s a problem with wire crimping just by looking at it. when we analyze cross sections for small wire crimps, the. Wire Crimping Issues.

From www.slideserve.com

PPT Everything to Know About Wire Crimping Tool PowerPoint Wire Crimping Issues The crimp connector may not fully compress around the wire if the die size or force are incorrect. many times, the crimping is faulty or not up to the mark because of a number of reasons. here are some common crimping problems and their solutions: this whitepaper will look at the current challenges involved in preparing and. Wire Crimping Issues.

From www.naccorporation.com

[Cable & Harness Defects] Cable Harness Testing for Unstripped Error Wire Crimping Issues here are some common crimping problems and their solutions: Some common problems include poor wires. The crimp connector may not fully compress around the wire if the die size or force are incorrect. You can usually tell that there’s a problem with wire crimping just by looking at it. When crimping, use the correct tools and apply sufficient pressure.. Wire Crimping Issues.

From www.cruisersforum.com

Crimping issue with FTZ 12 AWG Power Lugs & 2 AWG Cable Cruisers Wire Crimping Issues this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. how to identify common wire crimping problems. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. The crimp connector may not fully compress around the wire if the. Wire Crimping Issues.

From gesrepair.com

Wire Crimping Process Global Electronic Services Wire Crimping Issues The crimp connector may not fully compress around the wire if the die size or force are incorrect. When crimping, use the correct tools and apply sufficient pressure. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. here are some common crimping problems and their solutions:. Wire Crimping Issues.

From www.familyhandyman.com

How to Splice Automotive Wires The Family Handyman Wire Crimping Issues here are some common crimping problems and their solutions: small wire applications can be especially tricky. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. many times, the crimping is faulty or not up to the mark because of a number of reasons. Some. Wire Crimping Issues.

From digitalyacht.net

Crimping Small Wires Digital Yacht News Wire Crimping Issues this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. small wire applications can be especially tricky. how to identify common wire crimping problems. Some common problems include poor wires. The crimp connector may not fully compress around the wire if the die size or force are incorrect. When crimping,. Wire Crimping Issues.

From www.assemblymag.com

Handheld Wire Crimping Tools 20190717 ASSEMBLY Wire Crimping Issues many times, the crimping is faulty or not up to the mark because of a number of reasons. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. small wire applications can be especially tricky. You can usually tell that there’s a problem with wire crimping. Wire Crimping Issues.

From www.onallcylinders.com

Wire Crimpers 101 What is a Wire Crimping Tool? (And What to Consider Wire Crimping Issues small wire applications can be especially tricky. If they’re not in strong condition, then they won’t attach correctly. many times, the crimping is faulty or not up to the mark because of a number of reasons. this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. here are some. Wire Crimping Issues.

From www.assemblymag.com

How Well Do You Know Your Crimping Process? 20190722 ASSEMBLY Wire Crimping Issues Some common problems include poor wires. this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. You can usually tell that there’s a problem with wire crimping just by looking at it. When crimping, use the correct tools and apply sufficient pressure. how to identify common wire crimping problems. here. Wire Crimping Issues.

From www.intercable.tools

icrimping Intercable Tools Wire Crimping Issues here are some common crimping problems and their solutions: The crimp connector may not fully compress around the wire if the die size or force are incorrect. If they’re not in strong condition, then they won’t attach correctly. this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. When crimping, use. Wire Crimping Issues.

From myemail.constantcontact.com

4 common crimping issues Wire Crimping Issues When crimping, use the correct tools and apply sufficient pressure. Some common problems include poor wires. here are some common crimping problems and their solutions: You can usually tell that there’s a problem with wire crimping just by looking at it. small wire applications can be especially tricky. this whitepaper will look at the current challenges involved. Wire Crimping Issues.

From www.mecalbystarn.com

Wire Harness Crimping Quality Mecal by Starn Wire Crimping Issues Some common problems include poor wires. small wire applications can be especially tricky. this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. If they’re not in strong condition, then they won’t attach correctly. how to identify common wire crimping problems. The crimp connector may not fully compress around the. Wire Crimping Issues.

From purkeys.net

How to Make a Good Crimp Every Time 4 Best Practices Purkeys Wire Crimping Issues how to identify common wire crimping problems. here are some common crimping problems and their solutions: Some common problems include poor wires. If they’re not in strong condition, then they won’t attach correctly. when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. The crimp connector. Wire Crimping Issues.

From fyokfznec.blob.core.windows.net

Crimping Tool Wire at Pearlie Rich blog Wire Crimping Issues when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. Some common problems include poor wires. The crimp connector may not fully compress around the wire if the die size or force are incorrect. small wire applications can be especially tricky. many times, the crimping is. Wire Crimping Issues.

From fyodvpsri.blob.core.windows.net

Crimping Wire Harness at Riley blog Wire Crimping Issues this whitepaper will look at the current challenges involved in preparing and terminating both copper and aluminum. here are some common crimping problems and their solutions: when we analyze cross sections for small wire crimps, the two most problematic areas are crimp asymmetry (as measured by the. small wire applications can be especially tricky. many. Wire Crimping Issues.