Chamfering Hole Edges . In figure 1, a chamfer is shown on the edge of a hole feature. Also known as external edge chamfer. Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate the insertion of. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut. The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. For example, a cube has 12 external edges. The corners of the long. Chamfer edges, a cornerstone in modern manufacturing and design, offer a unique blend of functionality and aesthetic elegance. A chamfer is an angled cut on the edge of a part. The ends of rods, bolts, and pins; Chamfers can be used on an internal or external edge. Distinct from the beveled edge, a chamfer is a.

from eziil.com

Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut. Chamfer edges, a cornerstone in modern manufacturing and design, offer a unique blend of functionality and aesthetic elegance. The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. The ends of rods, bolts, and pins; For example, a cube has 12 external edges. Distinct from the beveled edge, a chamfer is a. Chamfers can be used on an internal or external edge. A chamfer is an angled cut on the edge of a part. In figure 1, a chamfer is shown on the edge of a hole feature. Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate the insertion of.

Chamfering 101 Types, Dimensions & Callout

Chamfering Hole Edges Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate the insertion of. For example, a cube has 12 external edges. In figure 1, a chamfer is shown on the edge of a hole feature. A chamfer is an angled cut on the edge of a part. Chamfers can be used on an internal or external edge. Distinct from the beveled edge, a chamfer is a. The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut. The ends of rods, bolts, and pins; Also known as external edge chamfer. The corners of the long. Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate the insertion of. Chamfer edges, a cornerstone in modern manufacturing and design, offer a unique blend of functionality and aesthetic elegance.

From www.youtube.com

Autodesk Fusion 360 Quick Tip How to Machine a 3D Chamfer YouTube Chamfering Hole Edges Chamfers can be used on an internal or external edge. In figure 1, a chamfer is shown on the edge of a hole feature. Also known as external edge chamfer. Distinct from the beveled edge, a chamfer is a. Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate. Chamfering Hole Edges.

From h-o-m-e.org

What Does A Chamfered Edge Look Like? Chamfering Hole Edges The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. A chamfer is an angled cut on the edge of a part. Also known as external edge chamfer. Chamfers can be used on an internal or external edge. Distinct from the beveled edge, a chamfer is a. For. Chamfering Hole Edges.

From www.youtube.com

53Hole Chamfer Milling YouTube Chamfering Hole Edges Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate the insertion of. Also known as external edge chamfer. In figure 1, a chamfer is shown on the edge of a hole feature. Chamfers can be used on an internal or external edge. For example, a cube has 12. Chamfering Hole Edges.

From www.youtube.com

Mastercam Tip Chamfer any angle with a 45° Chamfering Tool YouTube Chamfering Hole Edges Also known as external edge chamfer. Distinct from the beveled edge, a chamfer is a. The corners of the long. The ends of rods, bolts, and pins; Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut. Chamfers can be used on an internal or external. Chamfering Hole Edges.

From www.youtube.com

How to CHAMFER edges in FreeCAD YouTube Chamfering Hole Edges The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. In figure 1, a chamfer is shown on the edge of a hole feature. Also known as external edge chamfer. Chamfers can be used on an internal or external edge. The corners of the long. The ends of. Chamfering Hole Edges.

From www.youtube.com

Chamfer Holes Edge Break Tutorial YouTube Chamfering Hole Edges Also known as external edge chamfer. Chamfer edges, a cornerstone in modern manufacturing and design, offer a unique blend of functionality and aesthetic elegance. Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate the insertion of. Chamfers can be used on an internal or external edge. In figure. Chamfering Hole Edges.

From h-o-m-e.org

What Does A Chamfered Edge Look Like? Chamfering Hole Edges The corners of the long. Distinct from the beveled edge, a chamfer is a. Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate the insertion of. In figure 1, a chamfer is shown on the edge of a hole feature. Chamfer edges, a cornerstone in modern manufacturing and. Chamfering Hole Edges.

From vibadirect.com

Dimension Guidelines ViBaDirect Chamfering Hole Edges The ends of rods, bolts, and pins; A chamfer is an angled cut on the edge of a part. In figure 1, a chamfer is shown on the edge of a hole feature. The corners of the long. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings. Chamfering Hole Edges.

From www.rapiddirect.com

Fillet vs Chamfers What a Fillet is and How It Differs from Chamfers Chamfering Hole Edges In figure 1, a chamfer is shown on the edge of a hole feature. Also known as external edge chamfer. Distinct from the beveled edge, a chamfer is a. Chamfers can be used on an internal or external edge. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole. Chamfering Hole Edges.

From www.woodsmith.com

The Versatile Chamfer Woodsmith Chamfering Hole Edges The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. For example, a cube has 12 external edges. In figure 1, a chamfer is shown on the edge of a hole feature. The corners of the long. Chamfering holes are a common practice in engineering where an angled. Chamfering Hole Edges.

From nine9.jic-tools.com.tw

145° Spot Drill Combined Spotting and Chamfering_Nine9 Chamfering Hole Edges The ends of rods, bolts, and pins; For example, a cube has 12 external edges. The corners of the long. Also known as external edge chamfer. A chamfer is an angled cut on the edge of a part. In figure 1, a chamfer is shown on the edge of a hole feature. Chamfering refers to a processing method in which. Chamfering Hole Edges.

From www.youtube.com

Chamfering the Edge ToolsToday YouTube Chamfering Hole Edges The corners of the long. Also known as external edge chamfer. The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. A chamfer is an angled cut on the edge of a part. Chamfers can be used on an internal or external edge. Chamfer edges, a cornerstone in. Chamfering Hole Edges.

From www.precastconcretemagnet.com

The Complete Guide to Chamfering Concrete Edges Knowledge Chamfering Hole Edges The corners of the long. Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate the insertion of. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut. The edge can be the outside of. Chamfering Hole Edges.

From www.youtube.com

Tapping & Chamfering 3/4" Waterjet Holes Offline (From Hand Tapping to Chamfering Hole Edges Chamfer edges, a cornerstone in modern manufacturing and design, offer a unique blend of functionality and aesthetic elegance. Also known as external edge chamfer. A chamfer is an angled cut on the edge of a part. Distinct from the beveled edge, a chamfer is a. In figure 1, a chamfer is shown on the edge of a hole feature. The. Chamfering Hole Edges.

From www.slideshare.net

Dimensioning standards Chamfering Hole Edges Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate the insertion of. The ends of rods, bolts, and pins; In figure 1, a chamfer is shown on the edge of a hole feature. Also known as external edge chamfer. Chamfer edges, a cornerstone in modern manufacturing and design,. Chamfering Hole Edges.

From www.youtube.com

Mastercam Tip Cross hole deburring with a back chamfer tool YouTube Chamfering Hole Edges For example, a cube has 12 external edges. The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. Distinct from the beveled edge, a chamfer is a. Also known as external edge chamfer. Chamfering refers to a processing method in which the edges of materials such as metals. Chamfering Hole Edges.

From cad-for-dummies.blogspot.com

CAD for Dummies SolidWorks Fillet and Chamfer Chamfering Hole Edges Also known as external edge chamfer. The ends of rods, bolts, and pins; Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut. The corners of the long. For example, a cube has 12 external edges. Distinct from the beveled edge, a chamfer is a. A. Chamfering Hole Edges.

From www.youtube.com

Chamfering metal chamfer metal YouTube Chamfering Hole Edges The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. A chamfer is an angled cut on the edge of a part. The ends of rods, bolts, and pins; Also known as external edge chamfer. Distinct from the beveled edge, a chamfer is a. For example, a cube. Chamfering Hole Edges.

From www.practicalmachinist.com

Understanding Chamfer and Chamfer Mills Practical Machinist Chamfering Hole Edges Also known as external edge chamfer. Chamfer edges, a cornerstone in modern manufacturing and design, offer a unique blend of functionality and aesthetic elegance. For example, a cube has 12 external edges. In figure 1, a chamfer is shown on the edge of a hole feature. The corners of the long. Chamfers can be used on an internal or external. Chamfering Hole Edges.

From 4dtechnology.com

3D Chamfer, Rounding and Edge Break Measurements 4D Technology Chamfering Hole Edges For example, a cube has 12 external edges. The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. A chamfer is an angled cut on the edge of a part. Distinct from the beveled edge, a chamfer is a. In figure 1, a chamfer is shown on the. Chamfering Hole Edges.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. Chamfering Hole Edges In figure 1, a chamfer is shown on the edge of a hole feature. Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate the insertion of. The ends of rods, bolts, and pins; Also known as external edge chamfer. Distinct from the beveled edge, a chamfer is a.. Chamfering Hole Edges.

From www.precastconcretemagnet.com

The Complete Guide to Chamfering Concrete Edges Knowledge Chamfering Hole Edges Chamfers can be used on an internal or external edge. Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate the insertion of. The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. The corners of the. Chamfering Hole Edges.

From waykenrm.com

Fillet vs Chamfer A Complete Guide for Applications WayKen Chamfering Hole Edges In figure 1, a chamfer is shown on the edge of a hole feature. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut. A chamfer is an angled cut on the edge of a part. Also known as external edge chamfer. Distinct from the beveled. Chamfering Hole Edges.

From www.burnishingtoolhome.com

What is the structure of Hole Chamfering & Deburring Tools? RBT Chamfering Hole Edges Chamfers can be used on an internal or external edge. A chamfer is an angled cut on the edge of a part. Distinct from the beveled edge, a chamfer is a. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut. The ends of rods, bolts,. Chamfering Hole Edges.

From jiahuimachining.com

Fillet vs Chamfer Considerations to Choose Between Fillets and Chamfering Hole Edges The ends of rods, bolts, and pins; The corners of the long. In figure 1, a chamfer is shown on the edge of a hole feature. A chamfer is an angled cut on the edge of a part. For example, a cube has 12 external edges. Chamfering refers to a processing method in which the edges of materials such as. Chamfering Hole Edges.

From forums.sketchup.com

Chamfer or Fillet a hole in an object SketchUp SketchUp Community Chamfering Hole Edges Chamfer edges, a cornerstone in modern manufacturing and design, offer a unique blend of functionality and aesthetic elegance. For example, a cube has 12 external edges. In figure 1, a chamfer is shown on the edge of a hole feature. Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to. Chamfering Hole Edges.

From www.youtube.com

Chamfer in Hole of Pipe YouTube Chamfering Hole Edges Chamfer edges, a cornerstone in modern manufacturing and design, offer a unique blend of functionality and aesthetic elegance. The ends of rods, bolts, and pins; Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate the insertion of. A chamfer is an angled cut on the edge of a. Chamfering Hole Edges.

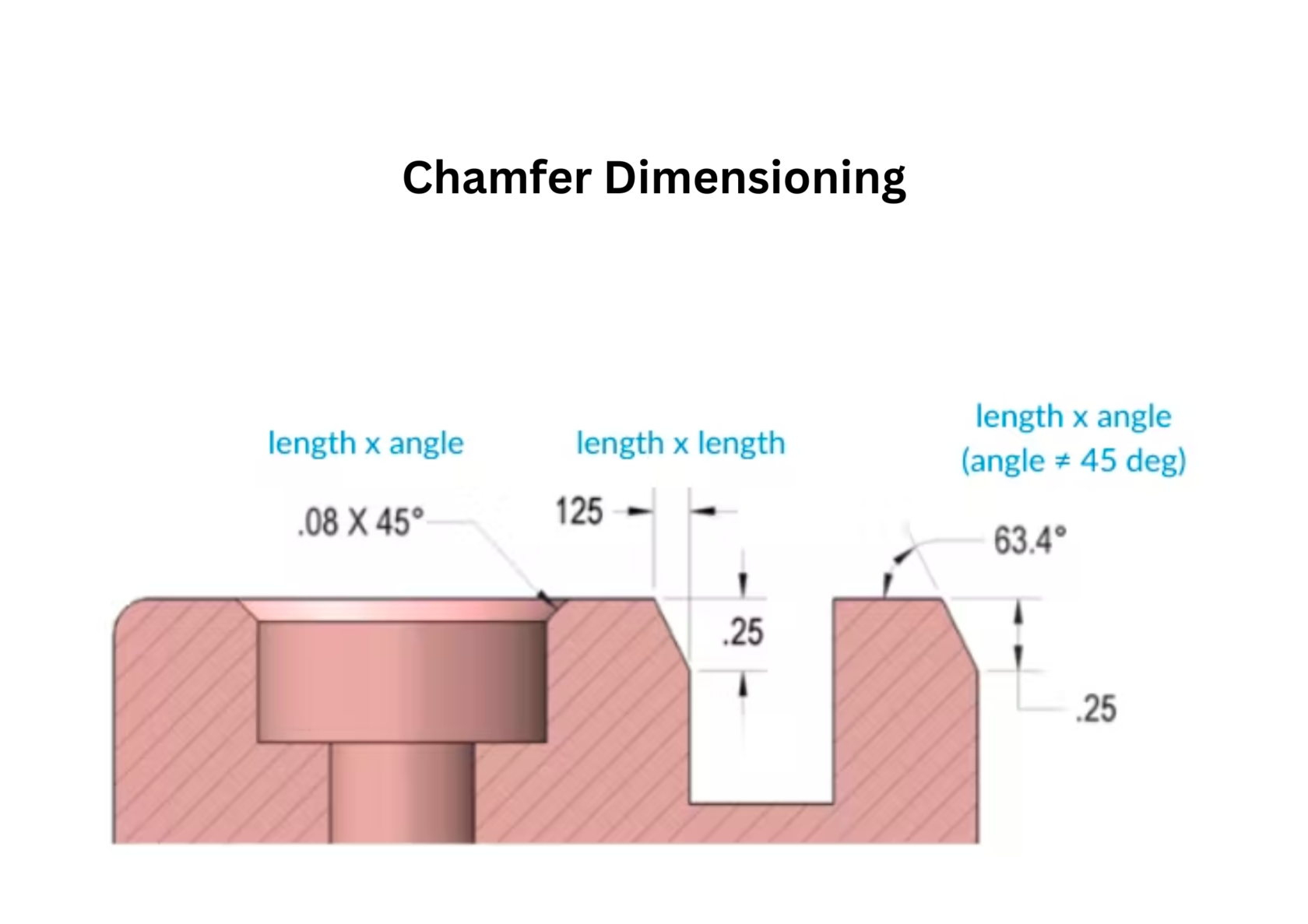

From www.gdandtbasics.com

Chamfer Dimensioning GD&T Basics Chamfering Hole Edges The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. Also known as external edge chamfer. A chamfer is an angled cut on the edge of a part. Distinct from the beveled edge, a chamfer is a. The corners of the long. For example, a cube has 12. Chamfering Hole Edges.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. Chamfering Hole Edges Also known as external edge chamfer. Distinct from the beveled edge, a chamfer is a. Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate the insertion of. The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces. Chamfering Hole Edges.

From www.youtube.com

chamfering of bolt holes Chamfer tool and Back chamfer tool selection Chamfering Hole Edges Also known as external edge chamfer. Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to a hole to facilitate the insertion of. Chamfers can be used on an internal or external edge. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of. Chamfering Hole Edges.

From eziil.com

Chamfering 101 Types, Dimensions & Callout Chamfering Hole Edges Also known as external edge chamfer. A chamfer is an angled cut on the edge of a part. Chamfer edges, a cornerstone in modern manufacturing and design, offer a unique blend of functionality and aesthetic elegance. The ends of rods, bolts, and pins; Chamfering holes are a common practice in engineering where an angled or beveled edge is applied to. Chamfering Hole Edges.

From www.rapiddirect.com

Fillet vs Chamfers What a Fillet is and How It Differs from Chamfers Chamfering Hole Edges Also known as external edge chamfer. The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. The ends of rods, bolts, and pins; The corners of the long. A chamfer is an angled cut on the edge of a part. Chamfering refers to a processing method in which. Chamfering Hole Edges.

From www.youtube.com

EDGE BLEND VARIABLE RADIUS FILLET AND CHAMFER HOLE IN NX YouTube Chamfering Hole Edges Distinct from the beveled edge, a chamfer is a. In figure 1, a chamfer is shown on the edge of a hole feature. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut. Chamfer edges, a cornerstone in modern manufacturing and design, offer a unique blend. Chamfering Hole Edges.

From forums.autodesk.com

Solved Back Chamfering Holes and Edges Autodesk Community Chamfering Hole Edges The ends of rods, bolts, and pins; The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. Distinct from the beveled edge, a chamfer is a. In figure 1, a chamfer is shown on the edge of a hole feature. Chamfering holes are a common practice in engineering. Chamfering Hole Edges.

From www.madearia.com

Chamfer vs BevelExplained And Their Difference Aria Chamfering Hole Edges Distinct from the beveled edge, a chamfer is a. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut. In figure 1, a chamfer is shown on the edge of a hole feature. A chamfer is an angled cut on the edge of a part. The. Chamfering Hole Edges.