Bending Corrugated Sheet Metal . Specification of the correct material; To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than panels with distinct high ribs and flat areas. Our professional tips will guide you through the steps to ensure a smooth bending experience. The two most important factors in the successful production of curved corrugated steel sheet are: Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. Start with the longest piece of corrugated tin roofing that you can. Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process.

from www.cmarshallfab.com

Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. Start with the longest piece of corrugated tin roofing that you can. The two most important factors in the successful production of curved corrugated steel sheet are: Specification of the correct material; In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than panels with distinct high ribs and flat areas. Our professional tips will guide you through the steps to ensure a smooth bending experience. Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend.

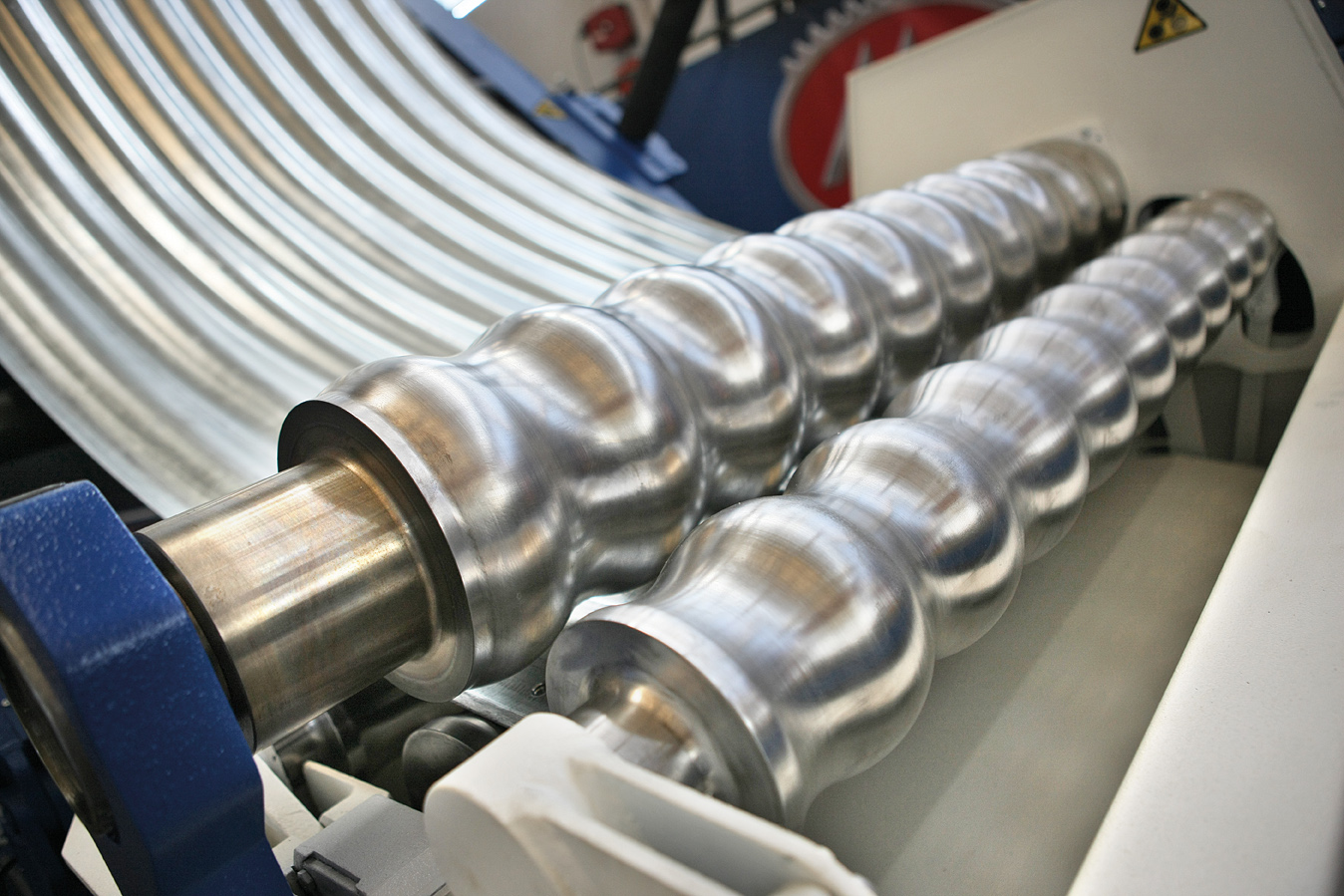

MG Plate Roll Bending Corrugated Steel with Automatic Loading and

Bending Corrugated Sheet Metal To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. Our professional tips will guide you through the steps to ensure a smooth bending experience. Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. Specification of the correct material; The two most important factors in the successful production of curved corrugated steel sheet are: To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than panels with distinct high ribs and flat areas. Start with the longest piece of corrugated tin roofing that you can.

From www.cmarshallfab.com

MG Plate Roll Bending Corrugated Steel with Automatic Loading and Bending Corrugated Sheet Metal Specification of the correct material; To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. Unlike flat sheet metal, corrugated metals have ridges and. Bending Corrugated Sheet Metal.

From www.cmrp.com

Custom Sheet Metal Bending Custom Rolled Sheet Metal Bending Corrugated Sheet Metal Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than panels with distinct high ribs and flat areas. Unlike flat sheet metal, corrugated metals have ridges and grooves that can. Bending Corrugated Sheet Metal.

From www.rocheindustry.com

The Basics of Bending Sheet Metal You Should Know Bending Corrugated Sheet Metal The two most important factors in the successful production of curved corrugated steel sheet are: Start with the longest piece of corrugated tin roofing that you can. Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. In general, panels with a shallower rib height and continuous. Bending Corrugated Sheet Metal.

From www.polyprod.com

CORRUGATED SHEET METAL BENDING Polyurethane Products Bending Corrugated Sheet Metal Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. Specification of the correct material; To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. Unlike flat sheet metal, corrugated metals have ridges and. Bending Corrugated Sheet Metal.

From fractory.com

Sheet Metal Bending Design Tips, Bend Allowance, K Factor Fractory Bending Corrugated Sheet Metal Specification of the correct material; The two most important factors in the successful production of curved corrugated steel sheet are: Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than panels with distinct high. Bending Corrugated Sheet Metal.

From www.youtube.com

18 types of bending operations in sheet metal Sheet metal bending Bending Corrugated Sheet Metal Specification of the correct material; To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. Before diving into the bending process, it is crucial to weaken the targeted. Bending Corrugated Sheet Metal.

From www.dreamstime.com

Bending Machine for Corrugated Metal Sheets in the Production Plant Bending Corrugated Sheet Metal The two most important factors in the successful production of curved corrugated steel sheet are: Our professional tips will guide you through the steps to ensure a smooth bending experience. Specification of the correct material; Start with the longest piece of corrugated tin roofing that you can. In general, panels with a shallower rib height and continuous corrugation pattern are. Bending Corrugated Sheet Metal.

From www.buildformingmachine.com

corrugated sheet bending machine corrugated iron machine Bending Corrugated Sheet Metal Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. Our professional tips will guide you through the steps to ensure a smooth bending experience. Start with the longest piece of corrugated tin roofing that you can. Before diving into the bending process, it is crucial to weaken the targeted area. Bending Corrugated Sheet Metal.

From unitymanufacture.com

How To Bend Sheet Metal? Unity Manufacture Bending Corrugated Sheet Metal To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. Start with the longest piece of corrugated tin roofing that you can. Our professional tips will guide you through the steps to ensure a smooth bending experience. In general, panels with a shallower rib height and continuous. Bending Corrugated Sheet Metal.

From www.youtube.com

Corrugated plate bending rolling MG srl 4 rolls automated YouTube Bending Corrugated Sheet Metal Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than panels with distinct high ribs and flat areas. Start with the longest piece of corrugated tin roofing that you can. Before diving into the. Bending Corrugated Sheet Metal.

From www.corrugated-metals.com

Custom Roll Forming Corrugated Metals Bending Corrugated Sheet Metal Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. Start with the longest piece of corrugated tin roofing that you can. In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than panels with distinct high ribs and flat areas.. Bending Corrugated Sheet Metal.

From www.truckbodybuilder.co.in

Corrugated Sheet SS Corrugated Sheet Manufacturer from Ballabhgarh Bending Corrugated Sheet Metal Start with the longest piece of corrugated tin roofing that you can. To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. Specification of. Bending Corrugated Sheet Metal.

From an-prototype.com

The Ultimate Guide to Sheet Metal Bending ANPrototype Bending Corrugated Sheet Metal The two most important factors in the successful production of curved corrugated steel sheet are: Specification of the correct material; Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than. Bending Corrugated Sheet Metal.

From www.indiamart.com

Corrugated Sheet Bending in Thrissur Bending Corrugated Sheet Metal To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. Specification of the correct material; Our professional tips will guide you through the steps to ensure a smooth bending experience. In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than. Bending Corrugated Sheet Metal.

From www.youtube.com

How To Turn Up Corrugated Iron Sheets Metal Roofing Online YouTube Bending Corrugated Sheet Metal Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. Start with the longest piece of corrugated tin roofing that you can. In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than panels with distinct high ribs and flat areas. Before diving into the. Bending Corrugated Sheet Metal.

From www.weeklytimesnow.com.au

FormFlow reinvents corrugated iron to bend to 90 degrees The Weekly Bending Corrugated Sheet Metal Specification of the correct material; Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. Our professional tips will guide you through the steps to ensure a smooth bending experience. To begin the bending process, we created a jig using two 8′ 4 x 4 posts that. Bending Corrugated Sheet Metal.

From www.ambpicot.com

Corrugated sheet metal bending machine, fourroller corrugated sheet Bending Corrugated Sheet Metal The two most important factors in the successful production of curved corrugated steel sheet are: In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than panels with distinct high ribs and flat areas. To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together. Bending Corrugated Sheet Metal.

From www.thelibraryofmanufacturing.com

Sheet Metal Bending Bending Corrugated Sheet Metal The two most important factors in the successful production of curved corrugated steel sheet are: Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. Start with the longest piece of corrugated tin roofing that you can. Before diving into the bending process, it is crucial to weaken the targeted area. Bending Corrugated Sheet Metal.

From www.youtube.com

CORRUGATED SHEET BENDING, GALVAZNIZED DRUM YouTube Bending Corrugated Sheet Metal Specification of the correct material; To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. Our professional tips will guide you through the steps to ensure a smooth. Bending Corrugated Sheet Metal.

From www.thelibraryofmanufacturing.com

Sheet Metal Bending Bending Corrugated Sheet Metal To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. Specification of the correct material; Start with the longest piece of corrugated tin roofing that you can. Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. The. Bending Corrugated Sheet Metal.

From www.youtube.com

CORRUGATED SHEET BENDING, GALVANIZED DRUM MAKING YouTube Bending Corrugated Sheet Metal The two most important factors in the successful production of curved corrugated steel sheet are: Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. Specification of the correct material; Start with the longest piece of corrugated tin roofing that you can. To begin the bending process,. Bending Corrugated Sheet Metal.

From xometry.eu

Sheet Metal Design Tips For Bending Xometry Europe Bending Corrugated Sheet Metal The two most important factors in the successful production of curved corrugated steel sheet are: Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than panels with distinct high ribs. Bending Corrugated Sheet Metal.

From dkgroofing.com

Corrugated Metal Roofing Pros & Cons DKG Roofing Bending Corrugated Sheet Metal The two most important factors in the successful production of curved corrugated steel sheet are: To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. Start with the longest piece of corrugated tin roofing that you can. Before diving into the bending process, it is crucial to. Bending Corrugated Sheet Metal.

From metalscut4u.com

How To Bend Sheet Metal The Ultimate Guide Bending Corrugated Sheet Metal Specification of the correct material; Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. Start with the longest piece of corrugated tin roofing that you can. Our professional tips will guide you through the steps to ensure a smooth bending experience. The two most important factors in the successful production. Bending Corrugated Sheet Metal.

From www.istockphoto.com

Bending Machine For Corrugated Metal Sheets In The Production Plant Bending Corrugated Sheet Metal To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. The two most important factors in the successful production of curved corrugated steel sheet are: Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. Start with the. Bending Corrugated Sheet Metal.

From www.dreamstime.com

Bending Machine For Corrugated Metal Sheets In The Production Plant Bending Corrugated Sheet Metal In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than panels with distinct high ribs and flat areas. Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. Start with the longest piece of corrugated tin roofing that you can.. Bending Corrugated Sheet Metal.

From www.aptint.com

Used Bending rolls, Techni Profil bending roll for corrugated sheets Bending Corrugated Sheet Metal The two most important factors in the successful production of curved corrugated steel sheet are: Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. Our professional tips will guide you through the steps to ensure a smooth bending experience. Start with the longest piece of corrugated tin roofing that you. Bending Corrugated Sheet Metal.

From www.choonngaiengineering.com

Metal Guidelines Methods of Sheet Metal Bending Bending Corrugated Sheet Metal Specification of the correct material; Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. Our professional tips will guide you through the steps to ensure a smooth. Bending Corrugated Sheet Metal.

From www.youtube.com

Bending strength testing for non asbestos corrugated roofing sheet Bending Corrugated Sheet Metal Start with the longest piece of corrugated tin roofing that you can. The two most important factors in the successful production of curved corrugated steel sheet are: To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. In general, panels with a shallower rib height and continuous. Bending Corrugated Sheet Metal.

From www.china-machining.com

Sheet Metal Bending Basics, Types, and Tips for Product Designers Bending Corrugated Sheet Metal Specification of the correct material; Start with the longest piece of corrugated tin roofing that you can. Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. Our. Bending Corrugated Sheet Metal.

From www.bendingrollco.com

Corrugated sheet Bending Roll Bending Corrugated Sheet Metal Our professional tips will guide you through the steps to ensure a smooth bending experience. In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than panels with distinct high ribs and flat areas. The two most important factors in the successful production of curved corrugated steel sheet are: Start with the longest piece. Bending Corrugated Sheet Metal.

From www.buildformingmachine.com

corrugated sheet bending machine corrugated iron machine Bending Corrugated Sheet Metal To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a 2. In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than panels with distinct high ribs and flat areas. The two most important factors in the successful production of curved corrugated. Bending Corrugated Sheet Metal.

From www.minifaber.com

The art of sheet metal bending Bending Corrugated Sheet Metal In general, panels with a shallower rib height and continuous corrugation pattern are easier to curve than panels with distinct high ribs and flat areas. Unlike flat sheet metal, corrugated metals have ridges and grooves that can present specific challenges during the bending process. Specification of the correct material; Our professional tips will guide you through the steps to ensure. Bending Corrugated Sheet Metal.

From mozdesigns.com

Corrugated Metal Sheets Moz Designs Decorative Metal and Bending Corrugated Sheet Metal The two most important factors in the successful production of curved corrugated steel sheet are: Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. To begin the bending process, we created a jig using two 8′ 4 x 4 posts that are screwed together with a. Bending Corrugated Sheet Metal.

From www.rapiddirect.com

What Is Sheet Metal Bending? Basics, Allowance, and Tips RapidDirect Bending Corrugated Sheet Metal Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. Our professional tips will guide you through the steps to ensure a smooth bending experience. Start with the longest piece of corrugated tin roofing that you can. In general, panels with a shallower rib height and continuous. Bending Corrugated Sheet Metal.