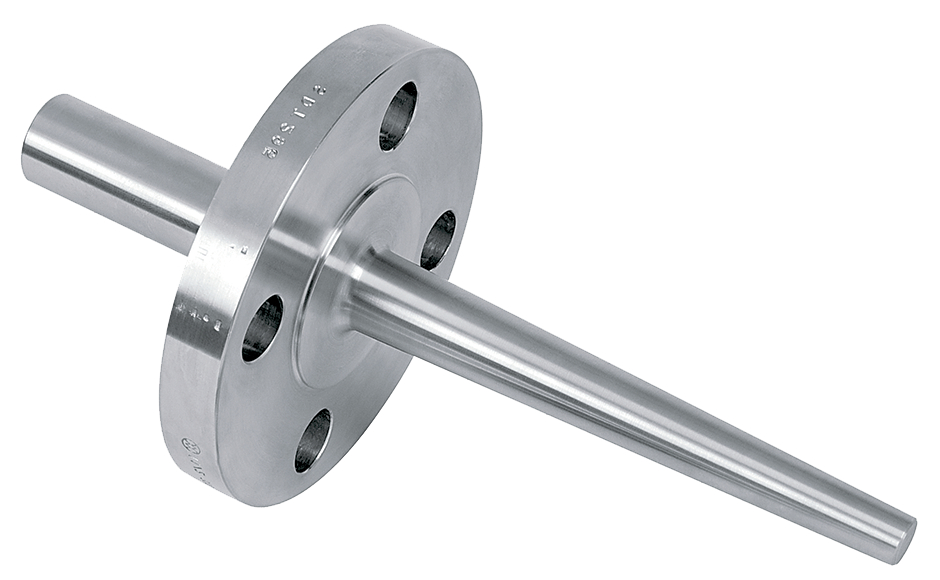

Nozzle For Thermowell . These are machined from a single barstock, sandwiched between the nozzle flange and. A threaded thermowell is screwed into the wall of a tapped pipe or more commonly into a thermowell threadolet. How far apart should thermowells be from each other? A flanged thermowell has a flange collar which is attached to a mating. For high pressure applications and where welding is to be avoided, van stone design thermowells are used. What is the ideal insertion length for a thermowell? Proper installation may require removal of material from the support rings, which should be completed as follows: Where in relation to an elbow should the thermowell. Nozzle suitable for collar design thermowell. The exception is the retrospective machining of the support ring in order that the. Thermowell must not be bent or altered in order to mount it. Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. Engineers many times face a lot of problems in installing collar design thermowells at the site.

from www.mac-weld.com

What is the ideal insertion length for a thermowell? The exception is the retrospective machining of the support ring in order that the. For high pressure applications and where welding is to be avoided, van stone design thermowells are used. Where in relation to an elbow should the thermowell. Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. Thermowell must not be bent or altered in order to mount it. These are machined from a single barstock, sandwiched between the nozzle flange and. A threaded thermowell is screwed into the wall of a tapped pipe or more commonly into a thermowell threadolet. How far apart should thermowells be from each other? Engineers many times face a lot of problems in installing collar design thermowells at the site.

Flanged Thermowells MacWeld Machining Ltd

Nozzle For Thermowell Where in relation to an elbow should the thermowell. How far apart should thermowells be from each other? Engineers many times face a lot of problems in installing collar design thermowells at the site. Nozzle suitable for collar design thermowell. Where in relation to an elbow should the thermowell. A threaded thermowell is screwed into the wall of a tapped pipe or more commonly into a thermowell threadolet. A flanged thermowell has a flange collar which is attached to a mating. What is the ideal insertion length for a thermowell? Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. These are machined from a single barstock, sandwiched between the nozzle flange and. Proper installation may require removal of material from the support rings, which should be completed as follows: For high pressure applications and where welding is to be avoided, van stone design thermowells are used. The exception is the retrospective machining of the support ring in order that the. Thermowell must not be bent or altered in order to mount it.

From www.tili.eu.org

Thermowell Insertion and Immersion Length Nozzle For Thermowell Engineers many times face a lot of problems in installing collar design thermowells at the site. What is the ideal insertion length for a thermowell? Thermowell must not be bent or altered in order to mount it. Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. A threaded thermowell is screwed into the wall of. Nozzle For Thermowell.

From ashcroft.eu

Threaded Thermowells ASHCROFT Europe / Trust the shield Nozzle For Thermowell Proper installation may require removal of material from the support rings, which should be completed as follows: A flanged thermowell has a flange collar which is attached to a mating. Nozzle suitable for collar design thermowell. Where in relation to an elbow should the thermowell. The exception is the retrospective machining of the support ring in order that the. Installing. Nozzle For Thermowell.

From www.ifm.com

Sanitary thermowells Select products ifm Nozzle For Thermowell Engineers many times face a lot of problems in installing collar design thermowells at the site. For high pressure applications and where welding is to be avoided, van stone design thermowells are used. What is the ideal insertion length for a thermowell? A threaded thermowell is screwed into the wall of a tapped pipe or more commonly into a thermowell. Nozzle For Thermowell.

From www.mac-weld.com

Flanged Thermowells MacWeld Machining Ltd Nozzle For Thermowell A flanged thermowell has a flange collar which is attached to a mating. The exception is the retrospective machining of the support ring in order that the. Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. A threaded thermowell is screwed into the wall of a tapped pipe or more commonly into a thermowell threadolet.. Nozzle For Thermowell.

From temcocontrols.com

Thermowells Temco Controls Ltd. Nozzle For Thermowell Where in relation to an elbow should the thermowell. The exception is the retrospective machining of the support ring in order that the. Thermowell must not be bent or altered in order to mount it. Proper installation may require removal of material from the support rings, which should be completed as follows: For high pressure applications and where welding is. Nozzle For Thermowell.

From instrumentationtools.com

Thermowell Design Guidelines Inst Tools Nozzle For Thermowell Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. A flanged thermowell has a flange collar which is attached to a mating. The exception is the retrospective machining of the support ring in order that the. These are machined from a single barstock, sandwiched between the nozzle flange and. For high pressure applications and where. Nozzle For Thermowell.

From rosecal.com.au

Thermowell specifications Rose Calibration Company; Quality Nozzle For Thermowell A flanged thermowell has a flange collar which is attached to a mating. Engineers many times face a lot of problems in installing collar design thermowells at the site. For high pressure applications and where welding is to be avoided, van stone design thermowells are used. Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell.. Nozzle For Thermowell.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Nozzle For Thermowell A threaded thermowell is screwed into the wall of a tapped pipe or more commonly into a thermowell threadolet. A flanged thermowell has a flange collar which is attached to a mating. What is the ideal insertion length for a thermowell? The exception is the retrospective machining of the support ring in order that the. For high pressure applications and. Nozzle For Thermowell.

From reotemp.com

Threaded Thermowells REOTEMP Instruments Nozzle For Thermowell Where in relation to an elbow should the thermowell. A flanged thermowell has a flange collar which is attached to a mating. Nozzle suitable for collar design thermowell. For high pressure applications and where welding is to be avoided, van stone design thermowells are used. How far apart should thermowells be from each other? Engineers many times face a lot. Nozzle For Thermowell.

From www.linquip.com

4 Types of Thermowell Comprehensive Overview Linquip Nozzle For Thermowell The exception is the retrospective machining of the support ring in order that the. These are machined from a single barstock, sandwiched between the nozzle flange and. How far apart should thermowells be from each other? Proper installation may require removal of material from the support rings, which should be completed as follows: Where in relation to an elbow should. Nozzle For Thermowell.

From www.status.co.uk

flanged thermowell for light to medium process conditions Nozzle For Thermowell Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. Nozzle suitable for collar design thermowell. Thermowell must not be bent or altered in order to mount it. What is the ideal insertion length for a thermowell? A flanged thermowell has a flange collar which is attached to a mating. Where in relation to an elbow. Nozzle For Thermowell.

From enercorp.com

What is a Thermowell? Why it is used in temperature measurement? Nozzle For Thermowell Nozzle suitable for collar design thermowell. A flanged thermowell has a flange collar which is attached to a mating. The exception is the retrospective machining of the support ring in order that the. How far apart should thermowells be from each other? Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. Proper installation may require. Nozzle For Thermowell.

From blog.arjaynet.com

Industrial Thermowell Styles Straight, Tapered, and Stepped Shanks Nozzle For Thermowell Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. The exception is the retrospective machining of the support ring in order that the. Thermowell must not be bent or altered in order to mount it. Proper installation may require removal of material from the support rings, which should be completed as follows: How far apart. Nozzle For Thermowell.

From www.instpedia.com

Temperature Nozzle For Thermowell These are machined from a single barstock, sandwiched between the nozzle flange and. A threaded thermowell is screwed into the wall of a tapped pipe or more commonly into a thermowell threadolet. Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. A flanged thermowell has a flange collar which is attached to a mating. Nozzle. Nozzle For Thermowell.

From www.pyrosales.com.au

What is a Thermowell and their purpose? Pyrosales Explains Nozzle For Thermowell Where in relation to an elbow should the thermowell. For high pressure applications and where welding is to be avoided, van stone design thermowells are used. Nozzle suitable for collar design thermowell. How far apart should thermowells be from each other? Thermowell must not be bent or altered in order to mount it. Engineers many times face a lot of. Nozzle For Thermowell.

From www.asad-shaikh.com

Thermowell U length ASAD SHAIKH Nozzle For Thermowell A flanged thermowell has a flange collar which is attached to a mating. Engineers many times face a lot of problems in installing collar design thermowells at the site. How far apart should thermowells be from each other? Where in relation to an elbow should the thermowell. A threaded thermowell is screwed into the wall of a tapped pipe or. Nozzle For Thermowell.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Nozzle For Thermowell A threaded thermowell is screwed into the wall of a tapped pipe or more commonly into a thermowell threadolet. These are machined from a single barstock, sandwiched between the nozzle flange and. Engineers many times face a lot of problems in installing collar design thermowells at the site. A flanged thermowell has a flange collar which is attached to a. Nozzle For Thermowell.

From www.intempco.com

What is a Thermowell? Intempco Nozzle For Thermowell Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. Proper installation may require removal of material from the support rings, which should be completed as follows: The exception is the retrospective machining of the support ring in order that the. A threaded thermowell is screwed into the wall of a tapped pipe or more commonly. Nozzle For Thermowell.

From www.red-bag.com

BNDGK0114 Instrument Connections on Vessels Nozzle For Thermowell What is the ideal insertion length for a thermowell? Where in relation to an elbow should the thermowell. Proper installation may require removal of material from the support rings, which should be completed as follows: How far apart should thermowells be from each other? For high pressure applications and where welding is to be avoided, van stone design thermowells are. Nozzle For Thermowell.

From instrumentationtools.com

Thermowell Design Guidelines Instrumentation Tools Nozzle For Thermowell Thermowell must not be bent or altered in order to mount it. The exception is the retrospective machining of the support ring in order that the. A flanged thermowell has a flange collar which is attached to a mating. A threaded thermowell is screwed into the wall of a tapped pipe or more commonly into a thermowell threadolet. For high. Nozzle For Thermowell.

From ultrametcpt.com

Acid Resistant Thermowells Ultramet CPT Nozzle For Thermowell A flanged thermowell has a flange collar which is attached to a mating. Thermowell must not be bent or altered in order to mount it. For high pressure applications and where welding is to be avoided, van stone design thermowells are used. Where in relation to an elbow should the thermowell. How far apart should thermowells be from each other?. Nozzle For Thermowell.

From www.feconsult.com

Thermowell Nozzle_red FE Consultants Nozzle For Thermowell These are machined from a single barstock, sandwiched between the nozzle flange and. Engineers many times face a lot of problems in installing collar design thermowells at the site. How far apart should thermowells be from each other? Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. A flanged thermowell has a flange collar which. Nozzle For Thermowell.

From instrumentationtools.com

Thermowell Outer Diameter larger than Nozzle Inside Diameter? Nozzle For Thermowell For high pressure applications and where welding is to be avoided, van stone design thermowells are used. A threaded thermowell is screwed into the wall of a tapped pipe or more commonly into a thermowell threadolet. Engineers many times face a lot of problems in installing collar design thermowells at the site. Proper installation may require removal of material from. Nozzle For Thermowell.

From www.thermocoupleheater.com

Heavy Duty Tapered Thermocouple Thermowell Full Weld Standard Nozzle For Thermowell The exception is the retrospective machining of the support ring in order that the. These are machined from a single barstock, sandwiched between the nozzle flange and. Thermowell must not be bent or altered in order to mount it. A threaded thermowell is screwed into the wall of a tapped pipe or more commonly into a thermowell threadolet. Nozzle suitable. Nozzle For Thermowell.

From rjstacey.com

Thermowell & Immersion Probe Installation Company Collect Data Points Nozzle For Thermowell These are machined from a single barstock, sandwiched between the nozzle flange and. A flanged thermowell has a flange collar which is attached to a mating. How far apart should thermowells be from each other? Thermowell must not be bent or altered in order to mount it. The exception is the retrospective machining of the support ring in order that. Nozzle For Thermowell.

From www.tu-lok.com

Thermowell and SS Flanged Rosemount 114c/ Ashcroft Thermowell Probe Nozzle For Thermowell The exception is the retrospective machining of the support ring in order that the. These are machined from a single barstock, sandwiched between the nozzle flange and. Nozzle suitable for collar design thermowell. Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. A threaded thermowell is screwed into the wall of a tapped pipe or. Nozzle For Thermowell.

From www.delta-mobrey.com

Thermowells Barstock or Single Piece Delta Mobrey Nozzle For Thermowell Thermowell must not be bent or altered in order to mount it. What is the ideal insertion length for a thermowell? Proper installation may require removal of material from the support rings, which should be completed as follows: For high pressure applications and where welding is to be avoided, van stone design thermowells are used. How far apart should thermowells. Nozzle For Thermowell.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Nozzle For Thermowell These are machined from a single barstock, sandwiched between the nozzle flange and. Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. Nozzle suitable for collar design thermowell. The exception is the retrospective machining of the support ring in order that the. Thermowell must not be bent or altered in order to mount it. Where. Nozzle For Thermowell.

From www.plantautomation-technology.com

Thermowell Totalizing Fluid Meters/counting Device Toshniwal Nozzle For Thermowell A flanged thermowell has a flange collar which is attached to a mating. For high pressure applications and where welding is to be avoided, van stone design thermowells are used. A threaded thermowell is screwed into the wall of a tapped pipe or more commonly into a thermowell threadolet. How far apart should thermowells be from each other? Installing a. Nozzle For Thermowell.

From dpstar.com.my

MaltecT Flanged Thermowell (Straight) Dpstar Group Nozzle For Thermowell Installing a thermowell with scrutonwell® design is identical to installing a comparable standard thermowell. What is the ideal insertion length for a thermowell? Engineers many times face a lot of problems in installing collar design thermowells at the site. For high pressure applications and where welding is to be avoided, van stone design thermowells are used. These are machined from. Nozzle For Thermowell.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Nozzle For Thermowell Proper installation may require removal of material from the support rings, which should be completed as follows: How far apart should thermowells be from each other? These are machined from a single barstock, sandwiched between the nozzle flange and. A threaded thermowell is screwed into the wall of a tapped pipe or more commonly into a thermowell threadolet. Nozzle suitable. Nozzle For Thermowell.

From thermal-detection.com

Solid Drilled Thermowells and Pockets (HTW) Thermal Detection Nozzle For Thermowell Nozzle suitable for collar design thermowell. How far apart should thermowells be from each other? These are machined from a single barstock, sandwiched between the nozzle flange and. The exception is the retrospective machining of the support ring in order that the. A flanged thermowell has a flange collar which is attached to a mating. Proper installation may require removal. Nozzle For Thermowell.

From temp-pro.com

Comprehensive Guide to Thermowell Types by Industry TempPro Nozzle For Thermowell Engineers many times face a lot of problems in installing collar design thermowells at the site. How far apart should thermowells be from each other? A threaded thermowell is screwed into the wall of a tapped pipe or more commonly into a thermowell threadolet. The exception is the retrospective machining of the support ring in order that the. For high. Nozzle For Thermowell.

From www.emiltd.co.uk

Thermowells by EMI Nozzle For Thermowell Thermowell must not be bent or altered in order to mount it. These are machined from a single barstock, sandwiched between the nozzle flange and. How far apart should thermowells be from each other? Engineers many times face a lot of problems in installing collar design thermowells at the site. The exception is the retrospective machining of the support ring. Nozzle For Thermowell.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Nozzle For Thermowell Engineers many times face a lot of problems in installing collar design thermowells at the site. For high pressure applications and where welding is to be avoided, van stone design thermowells are used. Where in relation to an elbow should the thermowell. Nozzle suitable for collar design thermowell. Installing a thermowell with scrutonwell® design is identical to installing a comparable. Nozzle For Thermowell.