Pump Curve Vfd . Figure 2.8 figure 2.9 rotodynamic. In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. Flow, at any point in time, is based on the demand of the system. The operating point will always be where the two curves intersect. Also, because the pump will be operating beyond the end of the published performance curve there is a serious risk of significantly diminishing the. (fig 2.8 and fig 2.9). The system curve illustrates that a pump, running at 60hz, must be able to provide 1400 gpm at a tdh of 55’. For example, take the same application as above. By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved process control, and reduced maintenance costs.

from www.northridgepumps.com

In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. Flow, at any point in time, is based on the demand of the system. For example, take the same application as above. Figure 2.8 figure 2.9 rotodynamic. If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. (fig 2.8 and fig 2.9). The system curve illustrates that a pump, running at 60hz, must be able to provide 1400 gpm at a tdh of 55’. The operating point will always be where the two curves intersect. Also, because the pump will be operating beyond the end of the published performance curve there is a serious risk of significantly diminishing the. By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved process control, and reduced maintenance costs.

How to Read a Pump Curve

Pump Curve Vfd For example, take the same application as above. In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. For example, take the same application as above. The operating point will always be where the two curves intersect. Figure 2.8 figure 2.9 rotodynamic. By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved process control, and reduced maintenance costs. If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. Also, because the pump will be operating beyond the end of the published performance curve there is a serious risk of significantly diminishing the. (fig 2.8 and fig 2.9). Flow, at any point in time, is based on the demand of the system. The system curve illustrates that a pump, running at 60hz, must be able to provide 1400 gpm at a tdh of 55’.

From www.esmagazine.com

Selecting the Proper Centrifugal Pump Circuit Flow Control 20190923 Pump Curve Vfd (fig 2.8 and fig 2.9). For example, take the same application as above. Also, because the pump will be operating beyond the end of the published performance curve there is a serious risk of significantly diminishing the. The system curve illustrates that a pump, running at 60hz, must be able to provide 1400 gpm at a tdh of 55’. In. Pump Curve Vfd.

From www.researchgate.net

Pump performance curves with and without VFD Download Scientific Diagram Pump Curve Vfd In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. For example, take the same application as above. The system curve illustrates that a pump, running at 60hz, must be able to provide 1400 gpm at a tdh of 55’. The operating point will always be where the two curves intersect. (fig 2.8 and. Pump Curve Vfd.

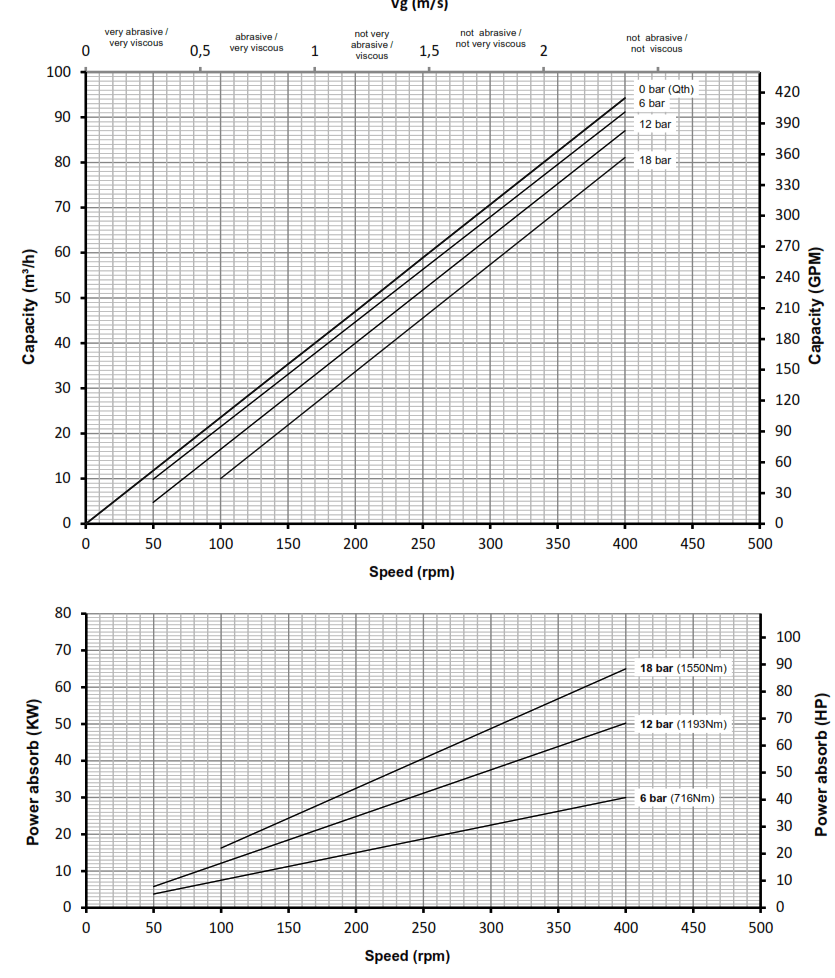

From www.yamadapump.com

Understanding Performance Curves Yamada Pump Pump Curve Vfd In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. For example, take the same application as above. Figure 2.8 figure 2.9 rotodynamic. By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved. Pump Curve Vfd.

From mungfali.com

Pump System Curve Pump Curve Vfd In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. For example, take the same application as above. Also, because the pump will be operating beyond the end of the published performance curve there is a serious risk of significantly diminishing the. Figure 2.8 figure 2.9 rotodynamic. By providing precise control over the speed. Pump Curve Vfd.

From www.oempanels.com

VFD Variable Frequency Drive and Centrifugal Pump • OEM Panels Pump Curve Vfd For example, take the same application as above. Figure 2.8 figure 2.9 rotodynamic. The system curve illustrates that a pump, running at 60hz, must be able to provide 1400 gpm at a tdh of 55’. Flow, at any point in time, is based on the demand of the system. In conclusion, vfds are a valuable tool for improving the efficiency. Pump Curve Vfd.

From www.rotechpumps.com

Understanding Pump Curves for Centrifugal Pumps A Comprehensive Guide Pump Curve Vfd If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. The operating point will always be where the two curves intersect. In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. The system curve illustrates that a pump, running at 60hz, must be able to provide. Pump Curve Vfd.

From www.pentair.com

IntelliFlo High Performance Variable Speed Pool Pump Pentair Pump Curve Vfd Also, because the pump will be operating beyond the end of the published performance curve there is a serious risk of significantly diminishing the. The operating point will always be where the two curves intersect. Flow, at any point in time, is based on the demand of the system. By providing precise control over the speed of the pump’s electric. Pump Curve Vfd.

From www.researchgate.net

Characteristic curves of the variable speed pump. Download Scientific Pump Curve Vfd Figure 2.8 figure 2.9 rotodynamic. In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved process control, and reduced maintenance costs. If a. Pump Curve Vfd.

From www.youtube.com

how to read centrifugal pump curves YouTube Pump Curve Vfd (fig 2.8 and fig 2.9). For example, take the same application as above. Flow, at any point in time, is based on the demand of the system. If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. Also, because the pump will be operating beyond the end of the published performance curve. Pump Curve Vfd.

From www.northridgepumps.com

How to Read a Pump Curve Pump Curve Vfd Figure 2.8 figure 2.9 rotodynamic. For example, take the same application as above. If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. The system curve illustrates that a pump, running at 60hz, must be able to provide 1400 gpm at a tdh of 55’. By providing precise control over the speed. Pump Curve Vfd.

From www.sepump.net

How to Read a Pump Curve Southeast Pump Specialist Repair and Service Pump Curve Vfd The operating point will always be where the two curves intersect. For example, take the same application as above. By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved process control, and reduced maintenance costs. Flow, at any point. Pump Curve Vfd.

From www.pumps.org

Does a Variable Speed Pump Make Sense for You? Pump Curve Vfd If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. (fig 2.8 and fig 2.9). The operating point will always be where the two curves intersect. For example, take the same application as above. In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. By providing. Pump Curve Vfd.

From www.1evac.com

Screw Vacuum Pumps EVac Technologies, LLC Pump Curve Vfd The system curve illustrates that a pump, running at 60hz, must be able to provide 1400 gpm at a tdh of 55’. For example, take the same application as above. The operating point will always be where the two curves intersect. If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. Also,. Pump Curve Vfd.

From www.sepump.net

How to Read a Pump Curve Southeast Pump Specialist Repair and Service Pump Curve Vfd (fig 2.8 and fig 2.9). In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. Flow, at any point in time, is based on the demand of the system. By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance. Pump Curve Vfd.

From blog.isa.org

Can VariableSpeed Drives Increase Process Efficiency and Reduce Energy Pump Curve Vfd The operating point will always be where the two curves intersect. The system curve illustrates that a pump, running at 60hz, must be able to provide 1400 gpm at a tdh of 55’. If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. For example, take the same application as above. (fig. Pump Curve Vfd.

From www.slideserve.com

PPT Location PowerPoint Presentation, free download ID1905954 Pump Curve Vfd By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved process control, and reduced maintenance costs. Figure 2.8 figure 2.9 rotodynamic. Flow, at any point in time, is based on the demand of the system. For example, take the. Pump Curve Vfd.

From www.researchgate.net

VFD output power pump flow rate curves. Download Scientific Diagram Pump Curve Vfd If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. For example, take the same application as above. The operating point will always be where the two curves intersect. In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. Figure 2.8 figure 2.9 rotodynamic. (fig 2.8. Pump Curve Vfd.

From empoweringpumps.com

Hydraulic retrofit meets increased demand Empowering Pumps and Equipment Pump Curve Vfd By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved process control, and reduced maintenance costs. The operating point will always be where the two curves intersect. (fig 2.8 and fig 2.9). If a 1155 rpm motor is selected,. Pump Curve Vfd.

From blog.chesterton.com

Using the Pump Performance Curve to Increase Efficiency Reliability Pump Curve Vfd By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved process control, and reduced maintenance costs. Figure 2.8 figure 2.9 rotodynamic. The operating point will always be where the two curves intersect. Flow, at any point in time, is. Pump Curve Vfd.

From www.deppmann.com

Hydronic Pump Balance Using Variable Speed Drive with No Balance Valve Pump Curve Vfd (fig 2.8 and fig 2.9). Figure 2.8 figure 2.9 rotodynamic. The operating point will always be where the two curves intersect. The system curve illustrates that a pump, running at 60hz, must be able to provide 1400 gpm at a tdh of 55’. Flow, at any point in time, is based on the demand of the system. By providing precise. Pump Curve Vfd.

From www.csidesigns.com

How to Read a Pump Curve Pump Characteristic & Performance Curves Pump Curve Vfd In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. (fig 2.8 and fig 2.9). Figure 2.8 figure 2.9 rotodynamic. If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. The system curve illustrates that a pump, running at 60hz, must be able to provide 1400. Pump Curve Vfd.

From jmpcoblog.com

How To Read A Pump Curve Part 1 Pump Curve Vfd The system curve illustrates that a pump, running at 60hz, must be able to provide 1400 gpm at a tdh of 55’. (fig 2.8 and fig 2.9). By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved process control,. Pump Curve Vfd.

From blog.craneengineering.net

Insights on How to Read a Centrifugal Pump Curve Pump Curve Vfd In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. For example, take the same application as above. Flow, at any point in time, is based on the demand of the system. Also, because the pump will be operating beyond the end of the published performance curve there is a serious risk of significantly. Pump Curve Vfd.

From www.pumpsandsystems.com

Centrifugal Pump Efficiency—Preservation of Efficiency Pump Curve Vfd If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved process control, and reduced maintenance costs. In conclusion, vfds are a. Pump Curve Vfd.

From www.xylem.com

Goulds Water Technology G Series Slimline Submersible Pumps (5, 7 and Pump Curve Vfd (fig 2.8 and fig 2.9). For example, take the same application as above. If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. The system curve illustrates that a pump, running at 60hz, must be able. Pump Curve Vfd.

From sepump.net

How to Read a Pump Curve Southeast Pump Specialist Repair and Service Pump Curve Vfd The system curve illustrates that a pump, running at 60hz, must be able to provide 1400 gpm at a tdh of 55’. The operating point will always be where the two curves intersect. By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting. Pump Curve Vfd.

From singh360.com

Variablefrequency drives deliver 1.5 to 5year payback for supermarkets Pump Curve Vfd If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. Flow, at any point in time, is based on the demand of the system. For example, take the same application as above. Also, because the pump will be operating beyond the end of the published performance curve there is a serious risk. Pump Curve Vfd.

From jmpcoblog.com

Three Types of Curve Control for Variable Speed Pumping Systems Pump Curve Vfd By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved process control, and reduced maintenance costs. In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. The system curve illustrates that a pump,. Pump Curve Vfd.

From www.scribd.com

VFD Curve PDF Pump Curve Vfd (fig 2.8 and fig 2.9). The operating point will always be where the two curves intersect. If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. For example, take the same application as above. Flow, at. Pump Curve Vfd.

From www.esmagazine.com

Understanding the Pump Curve Proves Crucial in a Hydronic System Pump Curve Vfd Also, because the pump will be operating beyond the end of the published performance curve there is a serious risk of significantly diminishing the. Figure 2.8 figure 2.9 rotodynamic. Flow, at any point in time, is based on the demand of the system. (fig 2.8 and fig 2.9). In conclusion, vfds are a valuable tool for improving the efficiency and. Pump Curve Vfd.

From mavink.com

Pump System Curve Pump Curve Vfd By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved process control, and reduced maintenance costs. For example, take the same application as above. (fig 2.8 and fig 2.9). In conclusion, vfds are a valuable tool for improving the. Pump Curve Vfd.

From www.youtube.com

How To Read a Pump Curve 101 YouTube Pump Curve Vfd Flow, at any point in time, is based on the demand of the system. The system curve illustrates that a pump, running at 60hz, must be able to provide 1400 gpm at a tdh of 55’. Also, because the pump will be operating beyond the end of the published performance curve there is a serious risk of significantly diminishing the.. Pump Curve Vfd.

From jmpcoblog.com

Three Types of Curve Control for Variable Speed Pumping Systems Pump Curve Vfd (fig 2.8 and fig 2.9). By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved process control, and reduced maintenance costs. In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. Figure 2.8. Pump Curve Vfd.

From www.pumpsandsystems.com

Pump Curve Accuracy Pumps & Systems Pump Curve Vfd For example, take the same application as above. If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. In conclusion, vfds are a valuable tool for improving the efficiency and performance of pump systems. Flow, at any point in time, is based on the demand of the system. Figure 2.8 figure 2.9. Pump Curve Vfd.

From www.researchgate.net

Comparison of fixed speed and VFD pump power curves. Download Pump Curve Vfd If a 1155 rpm motor is selected, a 7.5hp motor and smaller 7.5hp vfd can easily meet the. (fig 2.8 and fig 2.9). Figure 2.8 figure 2.9 rotodynamic. By providing precise control over the speed of the pump’s electric motor, vfds allow pumps to operate at a more efficient point on their performance curve, resulting in energy savings, improved process. Pump Curve Vfd.