Heat Sink Welding . The heat sinks used to cool the weld also limited the rise in temperature of the weld region. Understand different processes, adjust parameters, use proper electrodes, and employ. A heat sink can be as simple as a copper block which sits adjacent to the weld, or as complex as a liquid cooled, thermally regulated conformal attachment with. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. Clamping involves holding the heat sink against. So i turned to ebay and it. The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c which is applied simultaneously with the welding process. The single heat sink is. Two main methods of using copper heatsinks for welding are clamping and soldering. I have been scavenging for some aluminium/copper to use as a heat sink, but havn't come up with anything.

from www.aluminiumdiecastingparts.com

A heat sink can be as simple as a copper block which sits adjacent to the weld, or as complex as a liquid cooled, thermally regulated conformal attachment with. Understand different processes, adjust parameters, use proper electrodes, and employ. I have been scavenging for some aluminium/copper to use as a heat sink, but havn't come up with anything. The heat sinks used to cool the weld also limited the rise in temperature of the weld region. Clamping involves holding the heat sink against. Two main methods of using copper heatsinks for welding are clamping and soldering. So i turned to ebay and it. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c which is applied simultaneously with the welding process. The single heat sink is.

Heat Sink Welding Aluminum Profile LED Heat Sink With Welding Copper

Heat Sink Welding The heat sinks used to cool the weld also limited the rise in temperature of the weld region. Understand different processes, adjust parameters, use proper electrodes, and employ. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. The heat sinks used to cool the weld also limited the rise in temperature of the weld region. Clamping involves holding the heat sink against. So i turned to ebay and it. Two main methods of using copper heatsinks for welding are clamping and soldering. The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c which is applied simultaneously with the welding process. A heat sink can be as simple as a copper block which sits adjacent to the weld, or as complex as a liquid cooled, thermally regulated conformal attachment with. The single heat sink is. I have been scavenging for some aluminium/copper to use as a heat sink, but havn't come up with anything.

From www.youtube.com

Soldering welding mainly do highpower heat pipe heat sink Heat Sink Welding Clamping involves holding the heat sink against. The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c which is applied simultaneously with the welding process. Two main methods of using copper heatsinks for welding are clamping and soldering. So i turned to ebay and it. I have been scavenging for some aluminium/copper to. Heat Sink Welding.

From www.youtube.com

Heat sink welding demo video ATOM WELDING EQUIPMENTS YouTube Heat Sink Welding The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. Clamping involves holding the heat sink against. The single heat sink is. Understand different processes, adjust parameters, use proper electrodes, and employ. The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c. Heat Sink Welding.

From www.lorithermal.com

Heat Sink for Welding Aluminum Lori heatsink Heat Sink Welding So i turned to ebay and it. Clamping involves holding the heat sink against. Understand different processes, adjust parameters, use proper electrodes, and employ. The heat sinks used to cool the weld also limited the rise in temperature of the weld region. A heat sink can be as simple as a copper block which sits adjacent to the weld, or. Heat Sink Welding.

From www.researchgate.net

Appearance of cooling torch for heatsink welding. Download Heat Sink Welding A heat sink can be as simple as a copper block which sits adjacent to the weld, or as complex as a liquid cooled, thermally regulated conformal attachment with. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. So i turned to ebay and it. The single heat. Heat Sink Welding.

From www.designworldonline.com

Creating large heat sinks Heat Sink Welding A heat sink can be as simple as a copper block which sits adjacent to the weld, or as complex as a liquid cooled, thermally regulated conformal attachment with. The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c which is applied simultaneously with the welding process. I have been scavenging for some. Heat Sink Welding.

From www.lorithermal.com

Best Copper Welding Heat Sink Supplies By Lori, Get Info Heat Sink Welding The single heat sink is. Two main methods of using copper heatsinks for welding are clamping and soldering. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. Understand different processes, adjust parameters, use proper electrodes, and employ. The heat sinks used to cool the weld also limited the. Heat Sink Welding.

From www.lorithermal.com

High Power IGBT Heat Sink With Friction Welding Technology Lori Heat Sink Welding A heat sink can be as simple as a copper block which sits adjacent to the weld, or as complex as a liquid cooled, thermally regulated conformal attachment with. The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c which is applied simultaneously with the welding process. So i turned to ebay and. Heat Sink Welding.

From dreamstime.com

Melting Heat Sink Royalty Free Stock Photography Image 32688717 Heat Sink Welding Two main methods of using copper heatsinks for welding are clamping and soldering. I have been scavenging for some aluminium/copper to use as a heat sink, but havn't come up with anything. So i turned to ebay and it. The single heat sink is. The heat sink uses hollow stainless steel rods filled with running water at a temperature of. Heat Sink Welding.

From www.aluminiumdiecastingparts.com

Heat Sink Welding Aluminum Profile LED Heat Sink With Welding Copper Heat Sink Welding So i turned to ebay and it. Understand different processes, adjust parameters, use proper electrodes, and employ. The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c which is applied simultaneously with the welding process. I have been scavenging for some aluminium/copper to use as a heat sink, but havn't come up with. Heat Sink Welding.

From www.youtube.com

Manufacturing of aluminum heat sinks Friction Stir Welding YouTube Heat Sink Welding So i turned to ebay and it. I have been scavenging for some aluminium/copper to use as a heat sink, but havn't come up with anything. The single heat sink is. Understand different processes, adjust parameters, use proper electrodes, and employ. A heat sink can be as simple as a copper block which sits adjacent to the weld, or as. Heat Sink Welding.

From www.aluminiumdiecastingparts.com

LF Custom Extruded Copper Pipe Heat Sink Welding For LED Lights Heat Sink Welding The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. Two main methods of using copper heatsinks for welding are clamping and soldering. The heat sinks used to cool the weld also limited the rise in temperature of the weld region. I have been scavenging for some aluminium/copper to. Heat Sink Welding.

From ecothermgroup.en.made-in-china.com

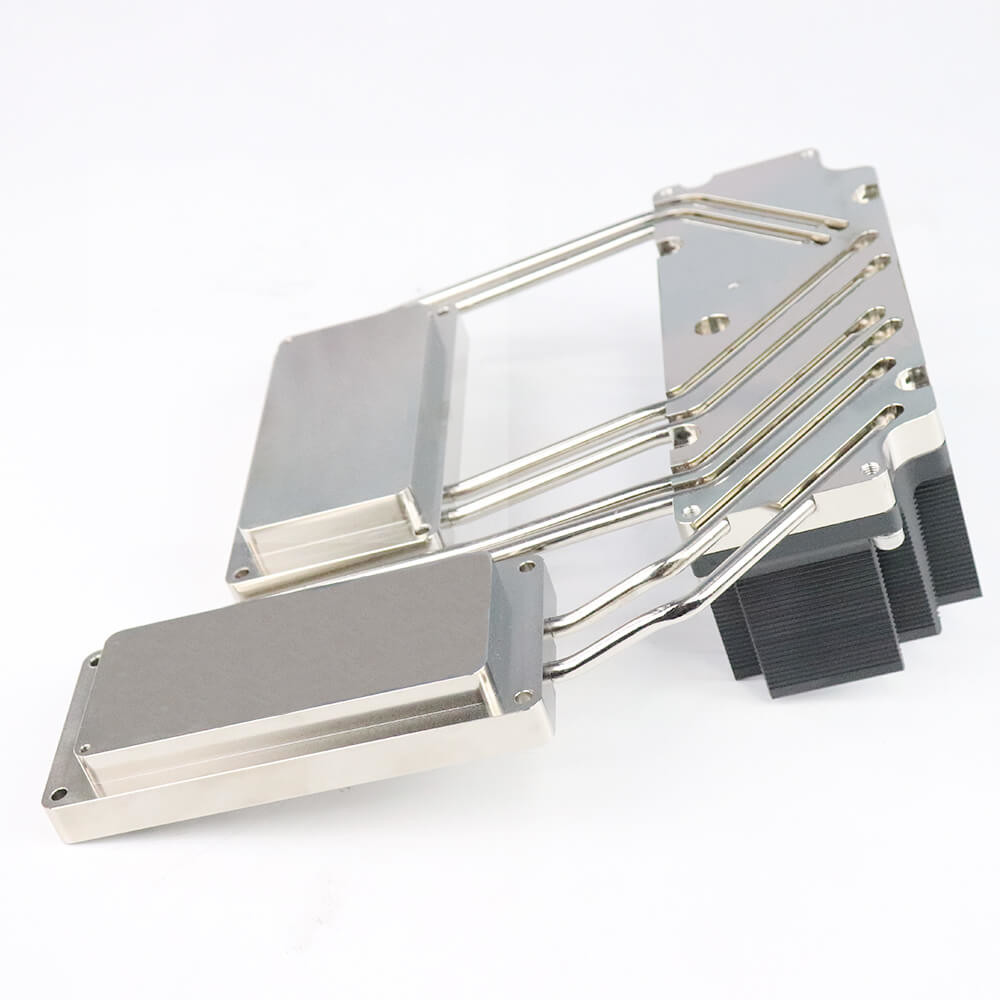

Customized Factory Welding High Power Aluminum Heatsink Copper Heatpipe Heat Sink Welding Understand different processes, adjust parameters, use proper electrodes, and employ. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. The single heat sink is. Two main methods of using copper heatsinks for welding are clamping and soldering. The heat sinks used to cool the weld also limited the. Heat Sink Welding.

From www.timeplex-hk.com

Welding Aluminium Heat Sink China Manufacturer Heat Sink Welding The single heat sink is. The heat sinks used to cool the weld also limited the rise in temperature of the weld region. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. Understand different processes, adjust parameters, use proper electrodes, and employ. I have been scavenging for some. Heat Sink Welding.

From www.lorithermal.com

High Power IGBT Heat Sink With Friction Welding Technology Lori Heat Sink Welding So i turned to ebay and it. The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c which is applied simultaneously with the welding process. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. Understand different processes, adjust parameters, use proper. Heat Sink Welding.

From www.lorithermal.com

Friction Stir Welding heat sink/cold plate Technology Lori Heat Sink Welding The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. Two main methods of using copper heatsinks for welding are clamping and soldering. Clamping involves holding the heat sink against. I have been scavenging for some aluminium/copper to use as a heat sink, but havn't come up with anything.. Heat Sink Welding.

From www.aluminiumdiecastingparts.com

Welding Outfit Passivation Liquid Cold Plate Heat Sink With Connector Heat Sink Welding So i turned to ebay and it. Understand different processes, adjust parameters, use proper electrodes, and employ. I have been scavenging for some aluminium/copper to use as a heat sink, but havn't come up with anything. Clamping involves holding the heat sink against. The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c. Heat Sink Welding.

From www.aluminiumdiecastingparts.com

Heat Sink Welding Aluminum Profile LED Heat Sink With Welding Copper Heat Sink Welding The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. A heat sink can be as simple as a copper block which sits adjacent to the weld, or as complex as a liquid cooled, thermally regulated conformal attachment with. The heat sink uses hollow stainless steel rods filled with. Heat Sink Welding.

From www.mig-welding.co.uk

Aluminium MIG Welding Heat Sink Welding The heat sinks used to cool the weld also limited the rise in temperature of the weld region. So i turned to ebay and it. Understand different processes, adjust parameters, use proper electrodes, and employ. The single heat sink is. A heat sink can be as simple as a copper block which sits adjacent to the weld, or as complex. Heat Sink Welding.

From www.lorithermal.com

Heat Sink for Welding Aluminum Lori heatsink Heat Sink Welding So i turned to ebay and it. A heat sink can be as simple as a copper block which sits adjacent to the weld, or as complex as a liquid cooled, thermally regulated conformal attachment with. The heat sinks used to cool the weld also limited the rise in temperature of the weld region. The time taken for the weld. Heat Sink Welding.

From www.alamy.com

melting heat sink and welding torch on metallic ground Stock Photo Alamy Heat Sink Welding I have been scavenging for some aluminium/copper to use as a heat sink, but havn't come up with anything. Understand different processes, adjust parameters, use proper electrodes, and employ. The heat sinks used to cool the weld also limited the rise in temperature of the weld region. So i turned to ebay and it. The single heat sink is. A. Heat Sink Welding.

From www.youtube.com

Welding Table & Heat Sink YouTube Heat Sink Welding The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c which is applied simultaneously with the welding process. Clamping involves holding the heat sink against. The heat sinks used to cool the weld also limited the rise in temperature of the weld region. So i turned to ebay and it. A heat sink. Heat Sink Welding.

From ecothermgroup.en.made-in-china.com

Aluminum Profile LED Heat Sink Welding Heat Pipe Heat Sink China Heat Heat Sink Welding The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c which is applied simultaneously with the welding process. Understand different processes, adjust parameters, use proper electrodes, and employ. So i turned to ebay and it. Clamping involves holding the heat sink against. A heat sink can be as simple as a copper block. Heat Sink Welding.

From www.lorithermal.com

Best Copper Welding Heat Sink Supplies By Lori, Get Info Heat Sink Welding The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c which is applied simultaneously with the welding process. So i turned to ebay and it. The heat sinks used to cool the weld also limited the rise in temperature of the weld region. Clamping involves holding the heat sink against. A heat sink. Heat Sink Welding.

From xhsrq-1985.en.made-in-china.com

China Welding Aluminium Profile Heat Sink China Heat Sink, Aluminum Heat Sink Welding I have been scavenging for some aluminium/copper to use as a heat sink, but havn't come up with anything. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. So i turned to ebay and it. A heat sink can be as simple as a copper block which sits. Heat Sink Welding.

From www.museoinclusivo.com

How to Weld Aluminum A StepbyStep Guide for Beginners Aluminum Heat Sink Welding Understand different processes, adjust parameters, use proper electrodes, and employ. Two main methods of using copper heatsinks for welding are clamping and soldering. The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c which is applied simultaneously with the welding process. The single heat sink is. The time taken for the weld to. Heat Sink Welding.

From rqdiecasting.en.made-in-china.com

1000W Large Dimension Aluminum Extrusion Welding Heat Sink for New Heat Sink Welding The heat sinks used to cool the weld also limited the rise in temperature of the weld region. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. Understand different processes, adjust parameters, use proper electrodes, and employ. I have been scavenging for some aluminium/copper to use as a. Heat Sink Welding.

From www.lorithermal.com

Heat Sink for Welding Aluminum Lori heatsink Heat Sink Welding So i turned to ebay and it. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. The heat sink uses hollow stainless steel rods filled with running water at a temperature of ±27°c which is applied simultaneously with the welding process. Understand different processes, adjust parameters, use proper. Heat Sink Welding.

From www.indiamart.com

Aluminium Alloy Welding Heat Sinks, Size 170x50, Rs 1200 /piece ID Heat Sink Welding A heat sink can be as simple as a copper block which sits adjacent to the weld, or as complex as a liquid cooled, thermally regulated conformal attachment with. I have been scavenging for some aluminium/copper to use as a heat sink, but havn't come up with anything. The single heat sink is. Two main methods of using copper heatsinks. Heat Sink Welding.

From www.aluminiumdiecastingparts.com

Heat Sink Welding Aluminum Profile LED Heat Sink With Welding Copper Heat Sink Welding The heat sinks used to cool the weld also limited the rise in temperature of the weld region. I have been scavenging for some aluminium/copper to use as a heat sink, but havn't come up with anything. A heat sink can be as simple as a copper block which sits adjacent to the weld, or as complex as a liquid. Heat Sink Welding.

From www.researchgate.net

The position of the heat sink in the welding process Download Heat Sink Welding A heat sink can be as simple as a copper block which sits adjacent to the weld, or as complex as a liquid cooled, thermally regulated conformal attachment with. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. Understand different processes, adjust parameters, use proper electrodes, and employ.. Heat Sink Welding.

From www.heatsinksmfg.com

Copper Heat sink For Welding, China Heatsink Manufacturer PIONEER Heat Sink Welding The heat sinks used to cool the weld also limited the rise in temperature of the weld region. The single heat sink is. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. The heat sink uses hollow stainless steel rods filled with running water at a temperature of. Heat Sink Welding.

From www.aluminiumdiecastingparts.com

Heat Sink Welding Aluminum Profile LED Heat Sink With Welding Copper Heat Sink Welding The single heat sink is. Clamping involves holding the heat sink against. Understand different processes, adjust parameters, use proper electrodes, and employ. I have been scavenging for some aluminium/copper to use as a heat sink, but havn't come up with anything. The heat sinks used to cool the weld also limited the rise in temperature of the weld region. The. Heat Sink Welding.

From www.aluminiumdiecastingparts.com

LF Custom Extruded Copper Pipe Heat Sink Welding For LED Lights Heat Sink Welding So i turned to ebay and it. I have been scavenging for some aluminium/copper to use as a heat sink, but havn't come up with anything. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. The heat sink uses hollow stainless steel rods filled with running water at. Heat Sink Welding.

From www.heatell.com

Welding Heat Sink Supplier and Manufacturer in China Heatell Heat Sink Welding The heat sinks used to cool the weld also limited the rise in temperature of the weld region. Clamping involves holding the heat sink against. So i turned to ebay and it. The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. Understand different processes, adjust parameters, use proper. Heat Sink Welding.

From formalmetal.en.made-in-china.com

Al6063 Anodized Aluminum Bonded and Fold Friction Welding Extrusion Heat Sink Welding The time taken for the weld to cool down to 100 °c was reduced by 190 s with the enhanced cooling. Two main methods of using copper heatsinks for welding are clamping and soldering. A heat sink can be as simple as a copper block which sits adjacent to the weld, or as complex as a liquid cooled, thermally regulated. Heat Sink Welding.