How To Figure Chip Load . This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. Achieve optimal results by striking the perfect balance between chip. The chart below provides the suggested chip load starting range typical for material type and tool diameter in use. \ [ \text {chip load} = \frac {\text {feed rate}}. This handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. Chip load = feed rate (inches per minute) / (rpm x number of flutes). Elevate your craft with our chip load and feed rate calculator designed for the wood and composite industry. The chip load per tooth can be calculated using the formula: Chip load is defined as the thickness of the chips removed during a machining operation. Chip load (ipt) = feed rate (ipm) / (spindle speed (rpm) * number of teeth). Calculating the chip load involves using a simple formula: Setting machining parameters to ensure optimal chip load improves machining quality and prolongs tool life. The formula used to calculate the chip load is: Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the.

from appshopper.com

Calculating the chip load involves using a simple formula: Chip load (ipt) = feed rate (ipm) / (spindle speed (rpm) * number of teeth). This handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. The chip load per tooth can be calculated using the formula: Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the. The chart below provides the suggested chip load starting range typical for material type and tool diameter in use. Achieve optimal results by striking the perfect balance between chip. Chip load is defined as the thickness of the chips removed during a machining operation. \ [ \text {chip load} = \frac {\text {feed rate}}. Chip load = feed rate (inches per minute) / (rpm x number of flutes).

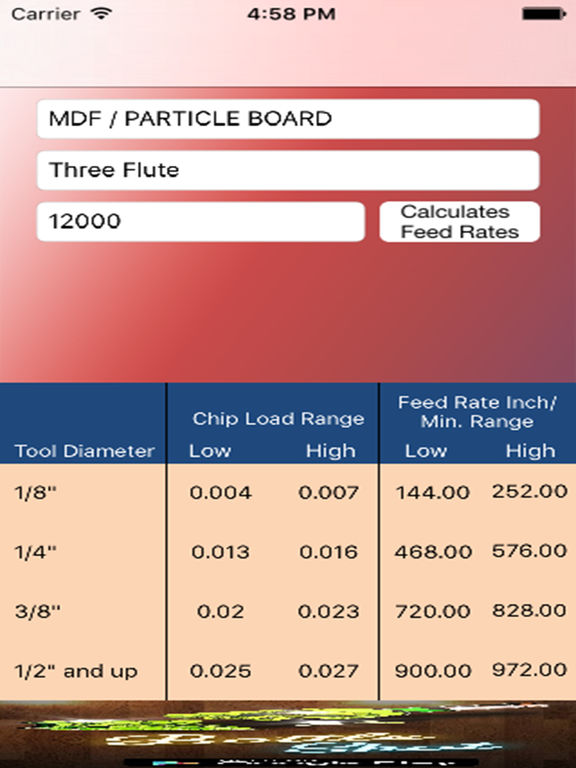

App Shopper CNC Chip Load Calculator (Utilities)

How To Figure Chip Load Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the. Chip load = feed rate (inches per minute) / (rpm x number of flutes). Achieve optimal results by striking the perfect balance between chip. The chip load per tooth can be calculated using the formula: Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the. The chart below provides the suggested chip load starting range typical for material type and tool diameter in use. This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. This handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. \ [ \text {chip load} = \frac {\text {feed rate}}. Chip load (ipt) = feed rate (ipm) / (spindle speed (rpm) * number of teeth). Setting machining parameters to ensure optimal chip load improves machining quality and prolongs tool life. Calculating the chip load involves using a simple formula: Elevate your craft with our chip load and feed rate calculator designed for the wood and composite industry. Chip load is defined as the thickness of the chips removed during a machining operation. The formula used to calculate the chip load is:

From archive.fabacademy.org

ComputerControlled Machining How To Figure Chip Load The chip load per tooth can be calculated using the formula: This handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. Elevate your craft with our chip load and feed rate calculator designed for the wood and composite industry. Setting machining parameters to ensure optimal chip load. How To Figure Chip Load.

From www.sainsmart.com

Calculate CNC Speeds and Feeds with Suggested Chip Load for Common Too How To Figure Chip Load This handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. Chip load (ipt) = feed rate (ipm) / (spindle speed (rpm) * number of teeth). Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the. The formula used. How To Figure Chip Load.

From www.researchgate.net

Chip load in end milling. Download Scientific Diagram How To Figure Chip Load The chart below provides the suggested chip load starting range typical for material type and tool diameter in use. This handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. \ [ \text {chip load} = \frac {\text {feed rate}}. Calculating the chip load involves using a simple. How To Figure Chip Load.

From inventables.zendesk.com

Calculating Your Cut Settings Basic Feeds and Speeds Information How To Figure Chip Load This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. Achieve optimal results by striking the perfect balance between chip. \ [ \text {chip load} = \frac {\text {feed rate}}. Calculating the chip load involves using a simple formula: Elevate your craft with our chip. How To Figure Chip Load.

From www.machiningdoctor.com

Chip Load Calculator,formulas and Charts (Milling) How To Figure Chip Load Calculating the chip load involves using a simple formula: Achieve optimal results by striking the perfect balance between chip. Chip load = feed rate (inches per minute) / (rpm x number of flutes). Chip load is defined as the thickness of the chips removed during a machining operation. Elevate your craft with our chip load and feed rate calculator designed. How To Figure Chip Load.

From www.slideserve.com

PPT Traditional Machining PowerPoint Presentation, free download ID How To Figure Chip Load Calculating the chip load involves using a simple formula: Chip load = feed rate (inches per minute) / (rpm x number of flutes). The formula used to calculate the chip load is: The chip load per tooth can be calculated using the formula: \ [ \text {chip load} = \frac {\text {feed rate}}. This calculator provides a starting reference range. How To Figure Chip Load.

From www.researchgate.net

How to measure chip thickness before machining in orthogonal cutting How To Figure Chip Load The formula used to calculate the chip load is: Chip load (ipt) = feed rate (ipm) / (spindle speed (rpm) * number of teeth). Achieve optimal results by striking the perfect balance between chip. The chart below provides the suggested chip load starting range typical for material type and tool diameter in use. Chip load (cl) = feed rate (fr). How To Figure Chip Load.

From www.bantamtools.com

Bantam Tools Blog — What is Chip Load & Why It’s Important How To Figure Chip Load Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the. Setting machining parameters to ensure optimal chip load improves machining quality and prolongs tool life. Chip load (ipt) = feed rate (ipm) / (spindle speed (rpm) * number of teeth). The chip load per tooth can be calculated using the formula:. How To Figure Chip Load.

From calculator.academy

Chip Load Calculator Calculator Academy How To Figure Chip Load This handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. Chip load = feed rate (inches per minute) / (rpm x number of flutes). The chart below provides the suggested chip load starting range typical for material type and tool diameter in use. Achieve optimal results by. How To Figure Chip Load.

From www.woodworkingnetwork.com

Tooling Breakdown Woodworking Network How To Figure Chip Load Calculating the chip load involves using a simple formula: The chip load per tooth can be calculated using the formula: Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the. This handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of. How To Figure Chip Load.

From www.simplifiedtool.com

Calculating Speed and Feeds with a Chip Load Chart Simplified Tool How To Figure Chip Load The chart below provides the suggested chip load starting range typical for material type and tool diameter in use. \ [ \text {chip load} = \frac {\text {feed rate}}. Chip load is defined as the thickness of the chips removed during a machining operation. Chip load (ipt) = feed rate (ipm) / (spindle speed (rpm) * number of teeth). This. How To Figure Chip Load.

From appshopper.com

App Shopper CNC Chip Load Calculator (Utilities) How To Figure Chip Load This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. Chip load is defined as the thickness of the chips removed during a machining operation. The chip load per tooth can be calculated using the formula: Chip load (ipt) = feed rate (ipm) / (spindle. How To Figure Chip Load.

From www.researchgate.net

Resulting and feed force variations with time, and chip load variations How To Figure Chip Load This handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. The chip load per tooth can be calculated using the formula: This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. Chip. How To Figure Chip Load.

From precisionboard.com

How Chip Load Factors into CNC Router Speeds and Feeds Precision Board How To Figure Chip Load Setting machining parameters to ensure optimal chip load improves machining quality and prolongs tool life. Chip load = feed rate (inches per minute) / (rpm x number of flutes). This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. The formula used to calculate the. How To Figure Chip Load.

From www.youtube.com

Chip Load vs Feed per Tooth The Machining Doctor simplifies these How To Figure Chip Load The formula used to calculate the chip load is: Calculating the chip load involves using a simple formula: Chip load = feed rate (inches per minute) / (rpm x number of flutes). \ [ \text {chip load} = \frac {\text {feed rate}}. Setting machining parameters to ensure optimal chip load improves machining quality and prolongs tool life. The chip load. How To Figure Chip Load.

From www.slideserve.com

PPT Machining PowerPoint Presentation, free download ID3423950 How To Figure Chip Load This handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. Calculating the chip load involves using a simple formula: Chip load = feed rate (inches per minute) / (rpm x number of flutes). Chip load is defined as the thickness of the chips removed during a machining. How To Figure Chip Load.

From www.edwoodcrafting.com

Feed Speed Chip Load 3 EdwoodCrafting How To Figure Chip Load Chip load = feed rate (inches per minute) / (rpm x number of flutes). Achieve optimal results by striking the perfect balance between chip. Setting machining parameters to ensure optimal chip load improves machining quality and prolongs tool life. The formula used to calculate the chip load is: Chip load is defined as the thickness of the chips removed during. How To Figure Chip Load.

From scarlettinc.com

What is your current chip load? How do you calculate it? Scarlett, Inc. How To Figure Chip Load Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the. \ [ \text {chip load} = \frac {\text {feed rate}}. Chip load = feed rate (inches per minute) / (rpm x number of flutes). Chip load is defined as the thickness of the chips removed during a machining operation. This handy. How To Figure Chip Load.

From hallmanufacturingsolutions.com

Hall Manufacturing Solutions How To Figure Chip Load Calculating the chip load involves using a simple formula: This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. Chip load is defined as the thickness of the chips removed during a machining operation. The chip load per tooth can be calculated using the formula:. How To Figure Chip Load.

From www.researchgate.net

Chip load in end milling. Download Scientific Diagram How To Figure Chip Load Calculating the chip load involves using a simple formula: The chip load per tooth can be calculated using the formula: Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the. Chip load is defined as the thickness of the chips removed during a machining operation. The formula used to calculate the. How To Figure Chip Load.

From www.youtube.com

CNC Easy calculate Chip Load, Feedrate, RPM for your endmill YouTube How To Figure Chip Load Chip load = feed rate (inches per minute) / (rpm x number of flutes). Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the. Elevate your craft with our chip load and feed rate calculator designed for the wood and composite industry. Setting machining parameters to ensure optimal chip load improves. How To Figure Chip Load.

From www.researchgate.net

Dynamic chip load and dynamic cutting forces in boring. Download How To Figure Chip Load The chart below provides the suggested chip load starting range typical for material type and tool diameter in use. Setting machining parameters to ensure optimal chip load improves machining quality and prolongs tool life. Calculating the chip load involves using a simple formula: Achieve optimal results by striking the perfect balance between chip. This calculator provides a starting reference range. How To Figure Chip Load.

From www.researchgate.net

Chip load in end milling. Download Scientific Diagram How To Figure Chip Load The chip load per tooth can be calculated using the formula: Achieve optimal results by striking the perfect balance between chip. The chart below provides the suggested chip load starting range typical for material type and tool diameter in use. Elevate your craft with our chip load and feed rate calculator designed for the wood and composite industry. This handy. How To Figure Chip Load.

From www.bantamtools.com

Bantam Tools Blog — What is Chip Load & Why It’s Important How To Figure Chip Load The formula used to calculate the chip load is: The chart below provides the suggested chip load starting range typical for material type and tool diameter in use. This handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. Achieve optimal results by striking the perfect balance between. How To Figure Chip Load.

From enginemechanics.tpub.com

Table Chip Loads How To Figure Chip Load The formula used to calculate the chip load is: Elevate your craft with our chip load and feed rate calculator designed for the wood and composite industry. \ [ \text {chip load} = \frac {\text {feed rate}}. Chip load (ipt) = feed rate (ipm) / (spindle speed (rpm) * number of teeth). The chip load per tooth can be calculated. How To Figure Chip Load.

From www.mekanika.io

Feeds & Speeds Explained MEKANIKA How To Figure Chip Load Elevate your craft with our chip load and feed rate calculator designed for the wood and composite industry. This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. Achieve optimal results by striking the perfect balance between chip. Chip load = feed rate (inches per. How To Figure Chip Load.

From fabacademy.org

CNC Lynn Dika How To Figure Chip Load This handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. Elevate your craft with our chip load and feed rate calculator designed for the wood and composite industry. \ [ \text {chip load} = \frac {\text {feed rate}}. The chip load per tooth can be calculated using. How To Figure Chip Load.

From mellowpine.com

Chip Load Guide for Beginners MellowPine How To Figure Chip Load Chip load = feed rate (inches per minute) / (rpm x number of flutes). The chart below provides the suggested chip load starting range typical for material type and tool diameter in use. Chip load (ipt) = feed rate (ipm) / (spindle speed (rpm) * number of teeth). Chip load (cl) = feed rate (fr) / (spindle speed (ss) ×. How To Figure Chip Load.

From www.researchgate.net

Resulting and feed force variations with time, and chip load variations How To Figure Chip Load Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the. The chip load per tooth can be calculated using the formula: Elevate your craft with our chip load and feed rate calculator designed for the wood and composite industry. This calculator provides a starting reference range only for shank tools and. How To Figure Chip Load.

From mellowpine.com

Chip Load Calculator Easy and Accurate MellowPine How To Figure Chip Load The chip load per tooth can be calculated using the formula: Chip load is defined as the thickness of the chips removed during a machining operation. The formula used to calculate the chip load is: The chart below provides the suggested chip load starting range typical for material type and tool diameter in use. This calculator provides a starting reference. How To Figure Chip Load.

From www.cnc-tool.com

Technical White PagesChip Load How To Figure Chip Load The chip load per tooth can be calculated using the formula: Chip load = feed rate (inches per minute) / (rpm x number of flutes). Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the. Chip load is defined as the thickness of the chips removed during a machining operation. This. How To Figure Chip Load.

From www.scribd.com

Formulas How to Calculate the Chip Load Per Tooth (CLPT) R How To Figure Chip Load This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. Setting machining parameters to ensure optimal chip load improves machining quality and prolongs tool life. The formula used to calculate the chip load is: The chart below provides the suggested chip load starting range typical. How To Figure Chip Load.

From precisionboard.com

How Chip Load Factors into CNC Router Speeds and Feeds Precision Board How To Figure Chip Load Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the. Achieve optimal results by striking the perfect balance between chip. The chip load per tooth can be calculated using the formula: Calculating the chip load involves using a simple formula: Elevate your craft with our chip load and feed rate calculator. How To Figure Chip Load.

From www.woodworkingnetwork.com

How to use a chip load chart Woodworking Network How To Figure Chip Load This handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. Setting machining parameters to ensure optimal chip load improves machining quality and prolongs tool life. \ [ \text {chip load} = \frac {\text {feed rate}}. Achieve optimal results by striking the perfect balance between chip. Chip load. How To Figure Chip Load.

From ponasa.condesan-ecoandes.org

Vortex Chip Load Chart Ponasa How To Figure Chip Load The formula used to calculate the chip load is: The chip load per tooth can be calculated using the formula: \ [ \text {chip load} = \frac {\text {feed rate}}. This handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. Chip load = feed rate (inches per. How To Figure Chip Load.