Zinc Anode For Plating . Choosing the best process for your operation. Anodes are usually zinc balls held in a long basket made from steel. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. The metal to be plated is connected to the cathode, while a zinc anode completes the circuit. Their job is to provide the ions needed to implement the plating process itself. Essentially, you take these salts and dissolve them in the electrolyte solution. Y of metal substrates, primarily steel. By clifford biddulph pavco inc. Once the current passes through, zinc ions are deposited onto the cathode, forming a protective layer. The process involves using an electrical current to deposit zinc onto the metal surface.

from www.alibaba.com

The process involves using an electrical current to deposit zinc onto the metal surface. Their job is to provide the ions needed to implement the plating process itself. Essentially, you take these salts and dissolve them in the electrolyte solution. The metal to be plated is connected to the cathode, while a zinc anode completes the circuit. Once the current passes through, zinc ions are deposited onto the cathode, forming a protective layer. Y of metal substrates, primarily steel. Choosing the best process for your operation. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. Anodes are usually zinc balls held in a long basket made from steel. By clifford biddulph pavco inc.

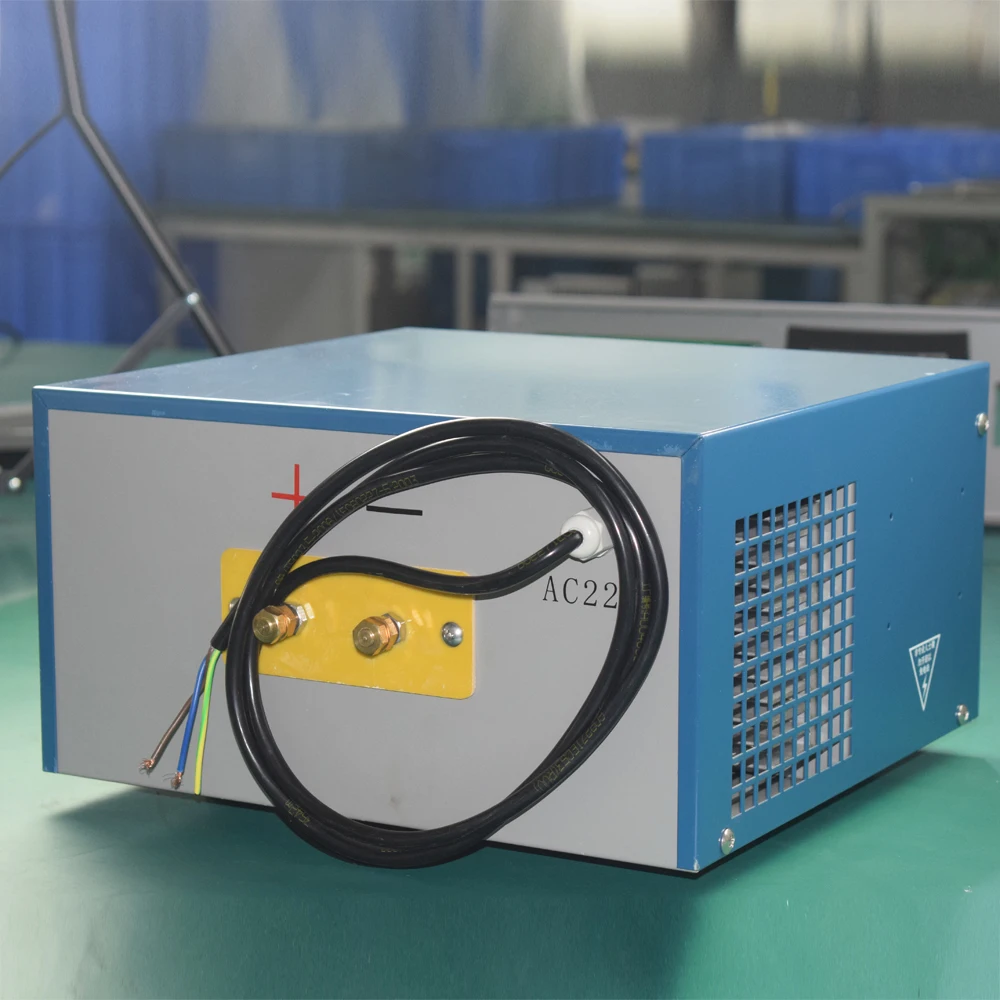

Zinc Anodes Plating Rectifier Electroplating Electrolysis Machine 50a

Zinc Anode For Plating Y of metal substrates, primarily steel. By clifford biddulph pavco inc. Their job is to provide the ions needed to implement the plating process itself. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. Choosing the best process for your operation. Once the current passes through, zinc ions are deposited onto the cathode, forming a protective layer. Essentially, you take these salts and dissolve them in the electrolyte solution. The process involves using an electrical current to deposit zinc onto the metal surface. The metal to be plated is connected to the cathode, while a zinc anode completes the circuit. Anodes are usually zinc balls held in a long basket made from steel. Y of metal substrates, primarily steel.

From www.aliexpress.com

ZincWireRodExtrudeIngotRoundBarAnodeElectroplatingElement.jpg Zinc Anode For Plating Their job is to provide the ions needed to implement the plating process itself. Y of metal substrates, primarily steel. Choosing the best process for your operation. Once the current passes through, zinc ions are deposited onto the cathode, forming a protective layer. The metal to be plated is connected to the cathode, while a zinc anode completes the circuit.. Zinc Anode For Plating.

From www.alibaba.com

Zinc Anodes Plating Rectifier Electroplating Electrolysis Machine 50a Zinc Anode For Plating The metal to be plated is connected to the cathode, while a zinc anode completes the circuit. Their job is to provide the ions needed to implement the plating process itself. Y of metal substrates, primarily steel. Choosing the best process for your operation. These kits are designed to provide a professional zinc finish to a variety of substrates on. Zinc Anode For Plating.

From www.aliexpress.com

0.4"x 4" Purity Zn 99.95 Zinc Rods Anode Electroplating Solid Round Zinc Anode For Plating Their job is to provide the ions needed to implement the plating process itself. The process involves using an electrical current to deposit zinc onto the metal surface. Once the current passes through, zinc ions are deposited onto the cathode, forming a protective layer. By clifford biddulph pavco inc. The metal to be plated is connected to the cathode, while. Zinc Anode For Plating.

From www.alibaba.com

Anode Cathode Barrel Zinc Galvanizing Plating Line Machine Equipment Zinc Anode For Plating The process involves using an electrical current to deposit zinc onto the metal surface. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. The metal to be plated is connected to the cathode, while a zinc anode completes the. Zinc Anode For Plating.

From www.alibaba.com

Zinc Plating Anode / Zinc Anode 1 3/4 / Zinc Anode (20 X 10 X 3) Buy Zinc Anode For Plating These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. By clifford biddulph pavco inc. Once the current passes through, zinc ions are deposited onto the cathode, forming a protective layer. The process involves using an electrical current to deposit. Zinc Anode For Plating.

From www.builderscalculator.com

Galvanized vs Zinc Plated Steel Builder's Calculator Zinc Anode For Plating These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. Essentially, you take these salts and dissolve them in the electrolyte solution. Y of metal substrates, primarily steel. Anodes are usually zinc balls held in a long basket made from. Zinc Anode For Plating.

From auremo.net

ᐉ Electroplating Electrolysis Zinc anode 99.9 pure Sheet metal plate Zinc Anode For Plating These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. Y of metal substrates, primarily steel. Their job is to provide the ions needed to implement the plating process itself. Choosing the best process for your operation. Once the current. Zinc Anode For Plating.

From www.youtube.com

Anode zinc installation YouTube Zinc Anode For Plating Essentially, you take these salts and dissolve them in the electrolyte solution. By clifford biddulph pavco inc. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. The process involves using an electrical current to deposit zinc onto the metal. Zinc Anode For Plating.

From www.youtube.com

DIY Zinc Plating YouTube Zinc Anode For Plating Choosing the best process for your operation. Y of metal substrates, primarily steel. By clifford biddulph pavco inc. Essentially, you take these salts and dissolve them in the electrolyte solution. The metal to be plated is connected to the cathode, while a zinc anode completes the circuit. Their job is to provide the ions needed to implement the plating process. Zinc Anode For Plating.

From www.ampere.com

Zinc flat anodes Zinc Anode For Plating Anodes are usually zinc balls held in a long basket made from steel. The process involves using an electrical current to deposit zinc onto the metal surface. The metal to be plated is connected to the cathode, while a zinc anode completes the circuit. By clifford biddulph pavco inc. Essentially, you take these salts and dissolve them in the electrolyte. Zinc Anode For Plating.

From www.cathodicprotection-anodes.com

Weld Type Zinc Anodes For Ships / Marine Vessels / Drill Rigs Zinc Anode For Plating Anodes are usually zinc balls held in a long basket made from steel. The process involves using an electrical current to deposit zinc onto the metal surface. By clifford biddulph pavco inc. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy. Zinc Anode For Plating.

From gsplating.co.uk

Zinc Anodes set of 2 Zinc Anode For Plating Once the current passes through, zinc ions are deposited onto the cathode, forming a protective layer. By clifford biddulph pavco inc. Y of metal substrates, primarily steel. The metal to be plated is connected to the cathode, while a zinc anode completes the circuit. Essentially, you take these salts and dissolve them in the electrolyte solution. Anodes are usually zinc. Zinc Anode For Plating.

From zinc.purityzinc.com

Zinc Plating Anodes On Purity Zinc Metals Zinc Anode For Plating Anodes are usually zinc balls held in a long basket made from steel. By clifford biddulph pavco inc. Their job is to provide the ions needed to implement the plating process itself. The metal to be plated is connected to the cathode, while a zinc anode completes the circuit. Essentially, you take these salts and dissolve them in the electrolyte. Zinc Anode For Plating.

From joiycxjpp.blob.core.windows.net

What Primer For Zinc Plated Steel at Ben Durbin blog Zinc Anode For Plating Choosing the best process for your operation. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. Once the current passes through, zinc ions are deposited onto the cathode, forming a protective layer. Y of metal substrates, primarily steel. The. Zinc Anode For Plating.

From www.gaterosplating.co.uk

Zinc Anodes Gateros Plating Ltd Zinc Anode For Plating Their job is to provide the ions needed to implement the plating process itself. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. By clifford biddulph pavco inc. The process involves using an electrical current to deposit zinc onto. Zinc Anode For Plating.

From www.ebay.co.uk

Zn 99.95 Purity Zinc Rod Solid Round Bar 0.4"x 4" Anode Electroplating Zinc Anode For Plating By clifford biddulph pavco inc. Choosing the best process for your operation. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. Their job is to provide the ions needed to implement the plating process itself. Anodes are usually zinc. Zinc Anode For Plating.

From www.frost.co.uk

Zinc Anodes for Zinc Plating Modules Zinc Anode For Plating The process involves using an electrical current to deposit zinc onto the metal surface. Once the current passes through, zinc ions are deposited onto the cathode, forming a protective layer. The metal to be plated is connected to the cathode, while a zinc anode completes the circuit. These kits are designed to provide a professional zinc finish to a variety. Zinc Anode For Plating.

From zinc.purityzinc.com

Zinc Plating Anodes On Purity Zinc Metals Zinc Anode For Plating Y of metal substrates, primarily steel. Anodes are usually zinc balls held in a long basket made from steel. Once the current passes through, zinc ions are deposited onto the cathode, forming a protective layer. Their job is to provide the ions needed to implement the plating process itself. Essentially, you take these salts and dissolve them in the electrolyte. Zinc Anode For Plating.

From www.indiamart.com

Zinc Anode, For Electroplating Industry at Rs 295/kilogram in Kolkata Zinc Anode For Plating Choosing the best process for your operation. By clifford biddulph pavco inc. Essentially, you take these salts and dissolve them in the electrolyte solution. Y of metal substrates, primarily steel. Their job is to provide the ions needed to implement the plating process itself. These kits are designed to provide a professional zinc finish to a variety of substrates on. Zinc Anode For Plating.

From www.alibaba.com

Anode Cathode Barrel Zinc Galvanizing Plating Line Machine Equipment Zinc Anode For Plating By clifford biddulph pavco inc. The process involves using an electrical current to deposit zinc onto the metal surface. Their job is to provide the ions needed to implement the plating process itself. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc. Zinc Anode For Plating.

From www.thezincguy.com

ZNGUY00204/ OVAL PLATE ZINC ANODE The Zinc Guy Zinc Anode For Plating Essentially, you take these salts and dissolve them in the electrolyte solution. The process involves using an electrical current to deposit zinc onto the metal surface. Y of metal substrates, primarily steel. Once the current passes through, zinc ions are deposited onto the cathode, forming a protective layer. These kits are designed to provide a professional zinc finish to a. Zinc Anode For Plating.

From www.researchgate.net

Modification of zinc anode. (a) Schematic illustrations of striping Zinc Anode For Plating The process involves using an electrical current to deposit zinc onto the metal surface. By clifford biddulph pavco inc. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. Once the current passes through, zinc ions are deposited onto the. Zinc Anode For Plating.

From www.researchgate.net

a) Illustration for zinc deposition on a bare zinc anode and Zinc Anode For Plating These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. The process involves using an electrical current to deposit zinc onto the metal surface. Y of metal substrates, primarily steel. The metal to be plated is connected to the cathode,. Zinc Anode For Plating.

From www.indiamart.com

Zinc Plating Anodes, For Industry at Rs 10/piece in Mumbai ID Zinc Anode For Plating Once the current passes through, zinc ions are deposited onto the cathode, forming a protective layer. Essentially, you take these salts and dissolve them in the electrolyte solution. Y of metal substrates, primarily steel. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and. Zinc Anode For Plating.

From www.aliexpress.com

Buy 100mm Length Round Zn Bar 99.95 High Purity Zinc Zinc Anode For Plating Choosing the best process for your operation. The metal to be plated is connected to the cathode, while a zinc anode completes the circuit. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. The process involves using an electrical. Zinc Anode For Plating.

From www.amazon.co.uk

Pure Zinc Anode Sheet 2pcs (99.995 Pure) for Zinc Plating and Zinc Zinc Anode For Plating By clifford biddulph pavco inc. The process involves using an electrical current to deposit zinc onto the metal surface. Once the current passes through, zinc ions are deposited onto the cathode, forming a protective layer. Their job is to provide the ions needed to implement the plating process itself. These kits are designed to provide a professional zinc finish to. Zinc Anode For Plating.

From www.utelectrode.com

How Soluble Anodes Used in Zinc Electroplating? Zinc Anode For Plating Once the current passes through, zinc ions are deposited onto the cathode, forming a protective layer. Anodes are usually zinc balls held in a long basket made from steel. Y of metal substrates, primarily steel. Essentially, you take these salts and dissolve them in the electrolyte solution. Choosing the best process for your operation. The process involves using an electrical. Zinc Anode For Plating.

From www.aliexpress.com

Zinc Rod High Purity Zn Ingot Round Bar Anode Electroplating Diameter Zinc Anode For Plating Choosing the best process for your operation. Essentially, you take these salts and dissolve them in the electrolyte solution. Their job is to provide the ions needed to implement the plating process itself. Anodes are usually zinc balls held in a long basket made from steel. Y of metal substrates, primarily steel. The metal to be plated is connected to. Zinc Anode For Plating.

From full-mark.com.ar

Zinc Anode For Plating Recognized Brands Zinc Anode For Plating Y of metal substrates, primarily steel. Their job is to provide the ions needed to implement the plating process itself. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. Anodes are usually zinc balls held in a long basket. Zinc Anode For Plating.

From www.aliexpress.com

Zinc Anode 60*70*3MM Hastelloy Cell Zinc Anode Plate Electroplating Zinc Anode For Plating Their job is to provide the ions needed to implement the plating process itself. Y of metal substrates, primarily steel. These kits are designed to provide a professional zinc finish to a variety of substrates on small components such as workshop tools, brake boosters, brackets and zinc alloy carburetor castings. Choosing the best process for your operation. By clifford biddulph. Zinc Anode For Plating.

From www.indiamart.com

Zinc Plating Anodes at Rs 350/piece Galvanic Anode in Coimbatore ID Zinc Anode For Plating The metal to be plated is connected to the cathode, while a zinc anode completes the circuit. Y of metal substrates, primarily steel. Choosing the best process for your operation. By clifford biddulph pavco inc. Anodes are usually zinc balls held in a long basket made from steel. These kits are designed to provide a professional zinc finish to a. Zinc Anode For Plating.

From superconindia.com

Zinc Anode Manufacturer & Supplier in Mexico Supercon India Zinc Anode For Plating Anodes are usually zinc balls held in a long basket made from steel. Choosing the best process for your operation. By clifford biddulph pavco inc. Y of metal substrates, primarily steel. The process involves using an electrical current to deposit zinc onto the metal surface. These kits are designed to provide a professional zinc finish to a variety of substrates. Zinc Anode For Plating.

From www.exportersindia.com

Rectangular zinc anodes plate, for Electroplating, Galvanising, Form Zinc Anode For Plating By clifford biddulph pavco inc. Choosing the best process for your operation. Essentially, you take these salts and dissolve them in the electrolyte solution. The process involves using an electrical current to deposit zinc onto the metal surface. Their job is to provide the ions needed to implement the plating process itself. Anodes are usually zinc balls held in a. Zinc Anode For Plating.

From www.utelectrode.com

What is the Best Titanium Anode Baskets for Zinc Electroplating Zinc Anode For Plating Anodes are usually zinc balls held in a long basket made from steel. Y of metal substrates, primarily steel. The process involves using an electrical current to deposit zinc onto the metal surface. By clifford biddulph pavco inc. Their job is to provide the ions needed to implement the plating process itself. Essentially, you take these salts and dissolve them. Zinc Anode For Plating.

From bgmetal.en.made-in-china.com

Sacrificial Anode Plating Die Casting 345 Zinc Alloy Ingots Block Zinc Anode For Plating Y of metal substrates, primarily steel. Essentially, you take these salts and dissolve them in the electrolyte solution. The metal to be plated is connected to the cathode, while a zinc anode completes the circuit. Choosing the best process for your operation. Anodes are usually zinc balls held in a long basket made from steel. By clifford biddulph pavco inc.. Zinc Anode For Plating.