Copper Aluminum Wire Joint . Connecting aluminum and copper conductors is relatively rare in building installations. The most common method of joining copper and aluminium is by soldering or brazing. But if it's necessary, use wago. To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications. When copper and aluminum wires are directly connected without proper precautions, several issues can arise. Soldering is a process that involves applying a filler metal that has a lower melting. Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding.

from zwcables.com

Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. When copper and aluminum wires are directly connected without proper precautions, several issues can arise. The most common method of joining copper and aluminium is by soldering or brazing. Soldering is a process that involves applying a filler metal that has a lower melting. To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications. But if it's necessary, use wago. Connecting aluminum and copper conductors is relatively rare in building installations. Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different.

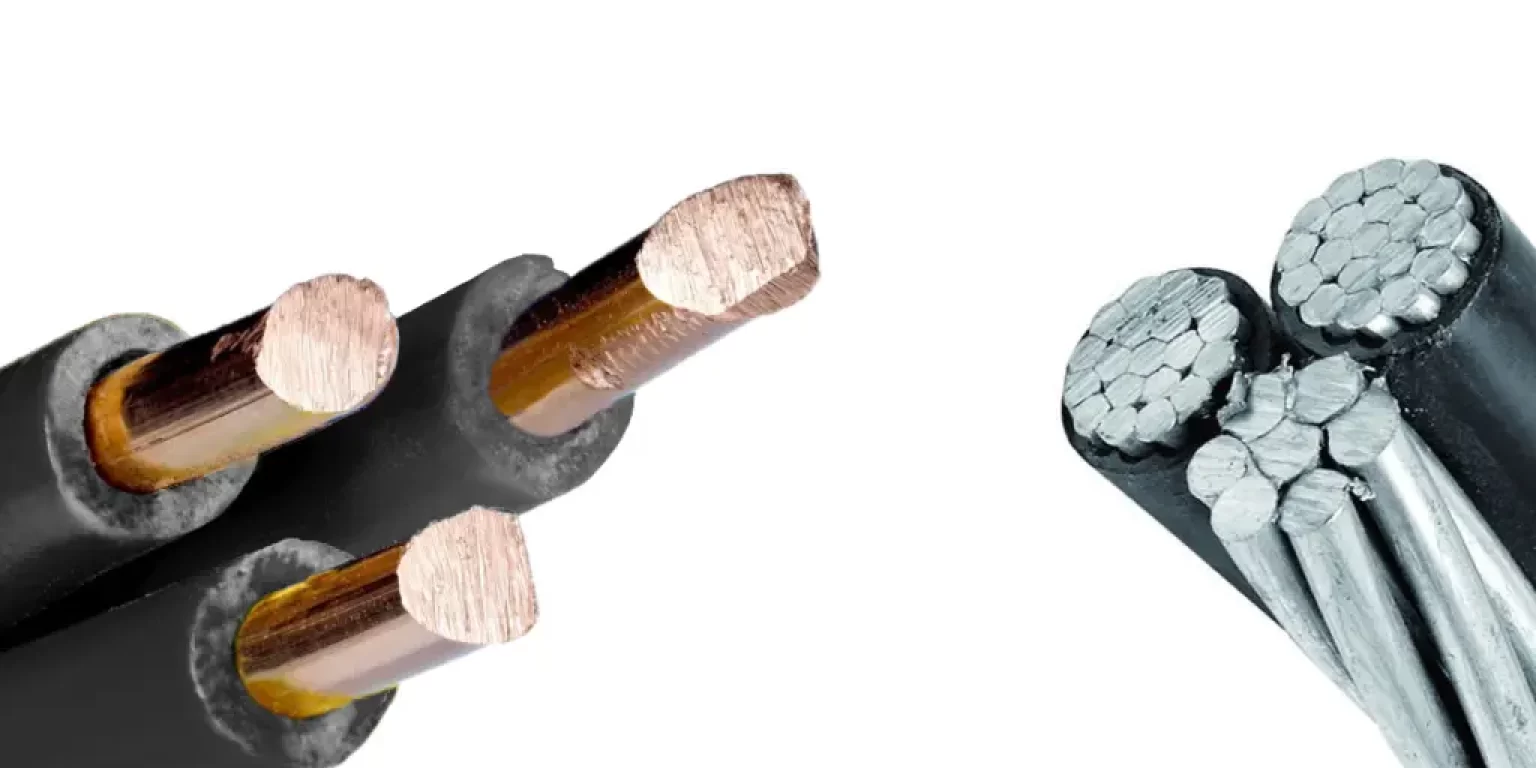

Aluminum vs Copper Wire Difference &

Copper Aluminum Wire Joint Connecting aluminum and copper conductors is relatively rare in building installations. Soldering is a process that involves applying a filler metal that has a lower melting. When copper and aluminum wires are directly connected without proper precautions, several issues can arise. Connecting aluminum and copper conductors is relatively rare in building installations. Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. But if it's necessary, use wago. The most common method of joining copper and aluminium is by soldering or brazing. To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications.

From www.lazada.com.my

Copper Aluminum Wire Nose National Standard DTL Aluminum Wire Cable Copper and Aluminum Joints Copper Aluminum Wire Joint Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications. Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. When copper. Copper Aluminum Wire Joint.

From www.electronicscuriosities.com

Why aluminum wire used in transmission lines and not copper ? which material used for Copper Aluminum Wire Joint To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications. But if it's necessary, use wago. Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. Connecting aluminum and copper conductors is relatively rare in building installations. Yes, copper wire and aluminum wire can be connected,. Copper Aluminum Wire Joint.

From www.blackelectricalsupply.com

Aluminum Wire vs Copper Wire Copper Aluminum Wire Joint Connecting aluminum and copper conductors is relatively rare in building installations. The most common method of joining copper and aluminium is by soldering or brazing. To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications. But if it's necessary, use wago. Yes, copper wire and aluminum wire can be connected, but important. Copper Aluminum Wire Joint.

From circuitlibjanet.z13.web.core.windows.net

Joining Copper To Aluminum Wire Copper Aluminum Wire Joint Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. When copper and aluminum wires are directly connected without proper precautions, several issues can arise. Soldering is a process that involves applying a filler metal that has a lower melting. The most common method of joining. Copper Aluminum Wire Joint.

From www.youtube.com

How to Connect Aluminium and Copper Cables Together YouTube Copper Aluminum Wire Joint The most common method of joining copper and aluminium is by soldering or brazing. Connecting aluminum and copper conductors is relatively rare in building installations. When copper and aluminum wires are directly connected without proper precautions, several issues can arise. Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these. Copper Aluminum Wire Joint.

From zwcables.com

Aluminum vs Copper Wire Difference & Copper Aluminum Wire Joint Connecting aluminum and copper conductors is relatively rare in building installations. When copper and aluminum wires are directly connected without proper precautions, several issues can arise. Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. Soldering is a process that involves applying a filler metal that has a lower melting. Yes, copper wire. Copper Aluminum Wire Joint.

From www.thinmetalsales.com

Copper vs. Aluminum Wiring Which Is Better? Copper Aluminum Wire Joint Connecting aluminum and copper conductors is relatively rare in building installations. The most common method of joining copper and aluminium is by soldering or brazing. But if it's necessary, use wago. Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. When copper and aluminum wires are directly connected without proper precautions, several issues. Copper Aluminum Wire Joint.

From www.lazada.com.ph

10pcs Copperaluminum Wire Nose 16 Square Aluminum Wire Nose Open Copperaluminum Pin Terminal Copper Aluminum Wire Joint But if it's necessary, use wago. When copper and aluminum wires are directly connected without proper precautions, several issues can arise. The most common method of joining copper and aluminium is by soldering or brazing. To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications. Flash butt welding offers a robust method. Copper Aluminum Wire Joint.

From blog.thepipingmart.com

How to Join Copper Wire An Overview Copper Aluminum Wire Joint Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. When copper and aluminum wires are directly connected without proper precautions, several issues can arise. The most common method of joining copper and aluminium is by soldering or brazing. Connecting aluminum and copper conductors is relatively rare in building installations. But if it's necessary,. Copper Aluminum Wire Joint.

From www.youtube.com

Copper single wire joint / single core wire joint YouTube Copper Aluminum Wire Joint Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. Connecting aluminum and copper conductors is relatively rare in building installations. The most common method of joining copper and aluminium. Copper Aluminum Wire Joint.

From www.wiringdigital.com

House Wiring Copper Or Aluminum Wires Wiring Digital and Schematic Copper Aluminum Wire Joint But if it's necessary, use wago. Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. When copper and aluminum wires are directly connected without proper precautions, several issues can arise. Soldering is a process that involves applying a filler metal that has a lower melting. Yes, copper wire and aluminum wire can be. Copper Aluminum Wire Joint.

From wirefixyovillanages.z21.web.core.windows.net

Aluminum Vs Copper Wiring Copper Aluminum Wire Joint But if it's necessary, use wago. Soldering is a process that involves applying a filler metal that has a lower melting. Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. Connecting aluminum and copper conductors is relatively rare in building installations. To ensure safe results when processing the al/cu compression joints, follow the. Copper Aluminum Wire Joint.

From www.reddit.com

How to connect aluminum and copper wire together since you can’t directly connect them r Copper Aluminum Wire Joint When copper and aluminum wires are directly connected without proper precautions, several issues can arise. But if it's necessary, use wago. To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications. Connecting aluminum and copper conductors is relatively rare in building installations. The most common method of joining copper and aluminium is. Copper Aluminum Wire Joint.

From www.homedepot.com

AlumiConn 3Port Al/Cu Wire Connectors (10Pack)95110 The Home Depot Copper Aluminum Wire Joint Connecting aluminum and copper conductors is relatively rare in building installations. Soldering is a process that involves applying a filler metal that has a lower melting. Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. The most common method of joining copper and aluminium is. Copper Aluminum Wire Joint.

From www.groupnirmal.com

Copper Wire V/S Aluminum Wire Group Nirmal Copper Aluminum Wire Joint Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. Connecting aluminum and copper conductors is relatively rare in building installations. The most common method of joining copper and aluminium. Copper Aluminum Wire Joint.

From www.windsystemsmag.com

Aluminum Vs. Copper Conductors Wind Systems Magazine Copper Aluminum Wire Joint Soldering is a process that involves applying a filler metal that has a lower melting. Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. The most common method of. Copper Aluminum Wire Joint.

From www.iqsdirectory.com

Copper Metal Types, Uses, Features and Benefits Copper Aluminum Wire Joint Soldering is a process that involves applying a filler metal that has a lower melting. When copper and aluminum wires are directly connected without proper precautions, several issues can arise. The most common method of joining copper and aluminium is by soldering or brazing. Connecting aluminum and copper conductors is relatively rare in building installations. Yes, copper wire and aluminum. Copper Aluminum Wire Joint.

From shopee.com.my

50PCS Copper Connecting Pipe Wire Joint Small Copper Tube Intermediate Joint Direct Connection Copper Aluminum Wire Joint Soldering is a process that involves applying a filler metal that has a lower melting. To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications. Connecting aluminum and copper conductors is relatively rare in building installations. Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding.. Copper Aluminum Wire Joint.

From www.teachoo.com

NCERT Q18 (e) Why are copper and aluminium wires usually employed Copper Aluminum Wire Joint Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. The most common method of joining copper and aluminium is by soldering or brazing. Connecting aluminum and copper conductors is. Copper Aluminum Wire Joint.

From www.centralwires.com

Copper vs Aluminum Wire Differences and Making The Decision Copper Aluminum Wire Joint Soldering is a process that involves applying a filler metal that has a lower melting. The most common method of joining copper and aluminium is by soldering or brazing. To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications. Connecting aluminum and copper conductors is relatively rare in building installations. But if. Copper Aluminum Wire Joint.

From www.greentechrenewables.com

Aluminum Vs. Copper Greentech Renewables Copper Aluminum Wire Joint Connecting aluminum and copper conductors is relatively rare in building installations. Soldering is a process that involves applying a filler metal that has a lower melting. The most common method of joining copper and aluminium is by soldering or brazing. Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these. Copper Aluminum Wire Joint.

From dmaengineers.com.au

Copper vs Aluminium cables which is best for electrical installations? DMA Engineers Copper Aluminum Wire Joint Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. Soldering is a process that involves applying a filler metal that has a lower melting. Connecting aluminum and copper conductors is relatively rare in building installations. When copper and aluminum wires are directly connected without proper precautions, several issues can arise. To ensure safe. Copper Aluminum Wire Joint.

From www.youtube.com

Aluminum v. Copper Wiring YouTube Copper Aluminum Wire Joint Connecting aluminum and copper conductors is relatively rare in building installations. Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications. Flash butt welding offers a robust method. Copper Aluminum Wire Joint.

From www.primecabindia.com

Copper or Aluminium Wire Which One is Better for Home Wire? Copper Aluminum Wire Joint Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications. Soldering is a process that involves applying a filler metal that has a lower melting. But if it's. Copper Aluminum Wire Joint.

From blog.thepipingmart.com

Copper Wire vs Aluminium Wire What's the Difference Copper Aluminum Wire Joint Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. But if it's necessary, use wago. Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. The most common method of joining copper and aluminium is by soldering or brazing.. Copper Aluminum Wire Joint.

From www.dustdischarge.com

Why can’t copper and aluminum wires be connected together? dustdischarge Copper Aluminum Wire Joint Connecting aluminum and copper conductors is relatively rare in building installations. Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. To ensure safe results when processing the al/cu compression. Copper Aluminum Wire Joint.

From zwcables.com

Aluminum vs Copper Wire Difference & Copper Aluminum Wire Joint Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. The most common method of joining copper and aluminium is by soldering or brazing. Soldering is a process that involves applying a filler metal that has a lower melting. But if it's necessary, use wago. Connecting. Copper Aluminum Wire Joint.

From aluminiumfacadecladding.blogspot.com

Copperclad Aluminum Wire Advantages Aluminium Facade Cladding Copper Aluminum Wire Joint Flash butt welding offers a robust method of joining aluminum and copper busbars through metallurgical bonding. The most common method of joining copper and aluminium is by soldering or brazing. When copper and aluminum wires are directly connected without proper precautions, several issues can arise. To ensure safe results when processing the al/cu compression joints, follow the relevant copper and. Copper Aluminum Wire Joint.

From wiringfixprettigtp.z21.web.core.windows.net

Aluminum To Copper Wire Connectors Copper Aluminum Wire Joint When copper and aluminum wires are directly connected without proper precautions, several issues can arise. Connecting aluminum and copper conductors is relatively rare in building installations. The most common method of joining copper and aluminium is by soldering or brazing. Soldering is a process that involves applying a filler metal that has a lower melting. To ensure safe results when. Copper Aluminum Wire Joint.

From www.gordian.com

Construction Materials Copper Versus Aluminum Wire Gordian Copper Aluminum Wire Joint To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications. The most common method of joining copper and aluminium is by soldering or brazing. Soldering is a process that involves applying a filler metal that has a lower melting. Connecting aluminum and copper conductors is relatively rare in building installations. Yes, copper. Copper Aluminum Wire Joint.

From blog.thepipingmart.com

How to Solder Aluminum to Copper A Complete Guide Copper Aluminum Wire Joint Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. Connecting aluminum and copper conductors is relatively rare in building installations. But if it's necessary, use wago. Soldering is a process that involves applying a filler metal that has a lower melting. To ensure safe results. Copper Aluminum Wire Joint.

From mmcmlv2syfixmachine.z13.web.core.windows.net

Aluminum Wiring Vs Copper Copper Aluminum Wire Joint Connecting aluminum and copper conductors is relatively rare in building installations. Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. The most common method of joining copper and aluminium is by soldering or brazing. But if it's necessary, use wago. When copper and aluminum wires. Copper Aluminum Wire Joint.

From circuitdiagramgerber.z19.web.core.windows.net

Aluminum To Copper Wiring Copper Aluminum Wire Joint Soldering is a process that involves applying a filler metal that has a lower melting. To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications. Connecting aluminum and copper conductors is relatively rare in building installations. Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must. Copper Aluminum Wire Joint.

From excel-electric.com

All You Need To Know About Copper VS. Aluminum Wiring Copper Aluminum Wire Joint To ensure safe results when processing the al/cu compression joints, follow the relevant copper and aluminium processing specifications. Connecting aluminum and copper conductors is relatively rare in building installations. Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. Flash butt welding offers a robust method. Copper Aluminum Wire Joint.

From fixlibrarygedwaaldebx.z21.web.core.windows.net

Connecting Copper To Aluminum Wiring Copper Aluminum Wire Joint Yes, copper wire and aluminum wire can be connected, but important safety protocols and regulations must be followed because these two metals exhibit different. Soldering is a process that involves applying a filler metal that has a lower melting. When copper and aluminum wires are directly connected without proper precautions, several issues can arise. The most common method of joining. Copper Aluminum Wire Joint.