Material Extrusion Examples . Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. There are four main types of extrusion: Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. Stratasys started to commercialize in 1990 the.

from www.slideserve.com

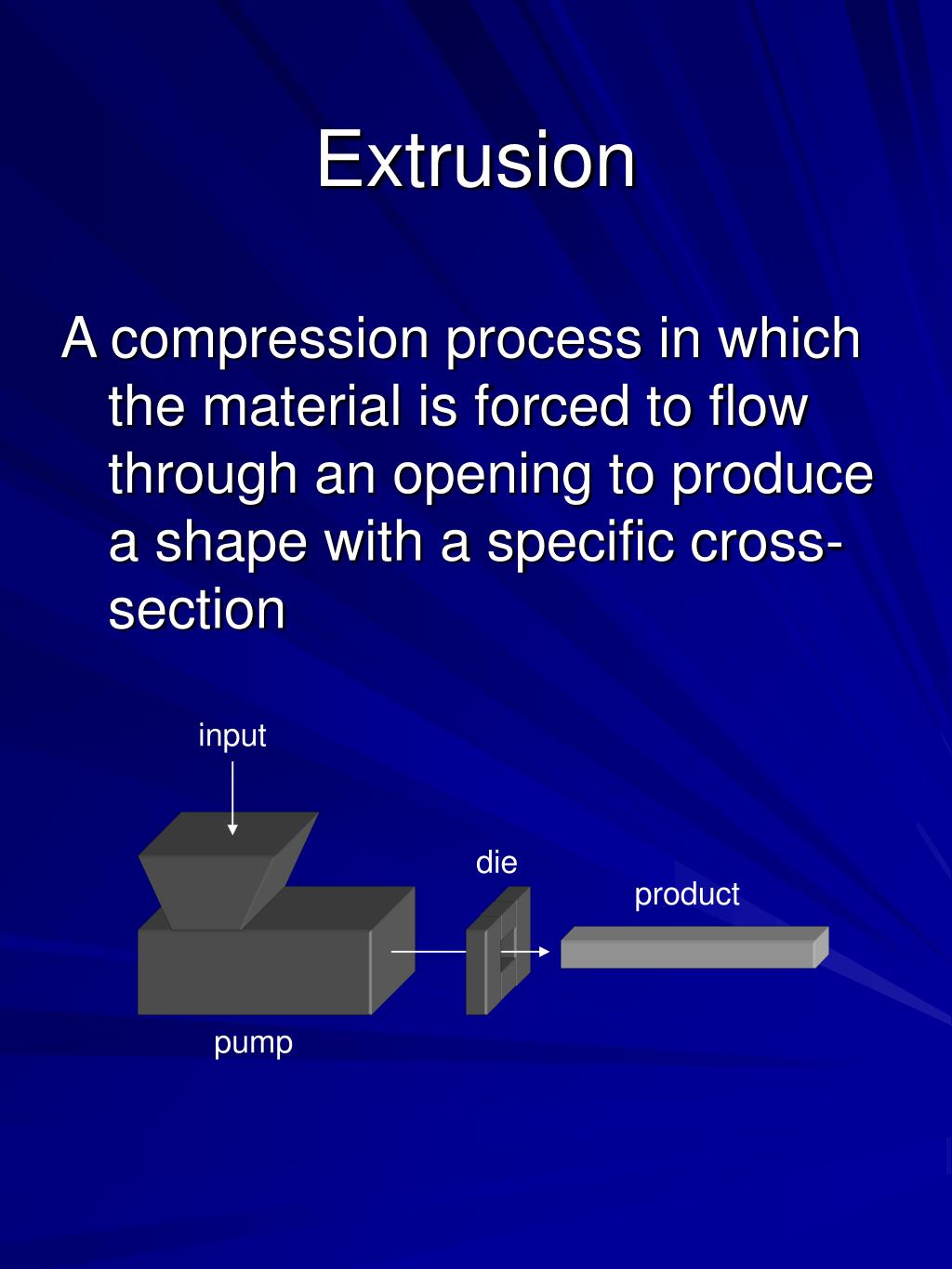

Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,. Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d. Stratasys started to commercialize in 1990 the. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. There are four main types of extrusion: Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion.

PPT Extrusion and Drawing PowerPoint Presentation, free download ID

Material Extrusion Examples Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,. Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,. Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. Stratasys started to commercialize in 1990 the. There are four main types of extrusion:

From www.dwplastics.co.uk

Plastic Extrusion Profiles D W Plastics Material Extrusion Examples It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. Stratasys started to commercialize in 1990 the. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Material is drawn through a nozzle, where it is heated. Material Extrusion Examples.

From slidetodoc.com

ENT 244 Manufacturing Engineering Processes Metal Extrusion Process Material Extrusion Examples Stratasys started to commercialize in 1990 the. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d. It is a commonly used technique used on many inexpensive, domestic and hobby. Material Extrusion Examples.

From www.youtube.com

EXTRUSION PROCESS EXPLANATION by 3D diagrams and types of extrusion Material Extrusion Examples It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d. Direct extrusion, indirect extrusion, impact. Material Extrusion Examples.

From www.veryengineering.com

Extrusion An Overview of Metal Extrusion Process Material Extrusion Examples Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,. Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d. There are four main types of extrusion: Stratasys started to commercialize. Material Extrusion Examples.

From www.3erp.com

The basics of plastic extrusion process, materials, applications Material Extrusion Examples Stratasys started to commercialize in 1990 the. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. There are four main types of extrusion: Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Material extrusion can. Material Extrusion Examples.

From www.youtube.com

Basic Of Extrusion Process I Type of extrusion technique YouTube Material Extrusion Examples Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,. Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. Material extrusion is an additive. Material Extrusion Examples.

From www.iqsdirectory.com

Plastic Extrusion Manufacturers Suppliers IQS Directory Material Extrusion Examples The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d. Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. Stratasys started to. Material Extrusion Examples.

From www.researchgate.net

An material extrusion example. Download Scientific Diagram Material Extrusion Examples The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. Stratasys started to commercialize in 1990 the. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. There are four main types of extrusion: Material extrusion can. Material Extrusion Examples.

From www.slideserve.com

PPT Chapter 15 Metal Extrusion and Drawing Processes and Equipment Material Extrusion Examples It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. There are four main types of extrusion: Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Stratasys started to commercialize in 1990 the. Material extrusion is. Material Extrusion Examples.

From www.polychlor.ca

The Extrusion Process PolyChlor Plastic Profile Extrusion Basics Material Extrusion Examples Stratasys started to commercialize in 1990 the. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d. Material extrusion can employ a wide. Material Extrusion Examples.

From learnmech.com

Types Of Extrusion And Advantages of Extrusion Material Extrusion Examples Stratasys started to commercialize in 1990 the. Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. There are four main types of extrusion: Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d. It is a commonly used technique used on. Material Extrusion Examples.

From www.mech4study.com

Extrusion Process Working, Types, Application, Advantages and Material Extrusion Examples Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d. Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. It is a commonly used technique used on many inexpensive, domestic and hobby. Material Extrusion Examples.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials Material Extrusion Examples Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. There are four main types of extrusion: It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. Stratasys started to commercialize in 1990 the. Material extrusion can. Material Extrusion Examples.

From getecna.com

Designing Aluminum Extrusions Getec Industrial Material Extrusion Examples Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. Stratasys started to commercialize in 1990 the. Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d.. Material Extrusion Examples.

From www.researchgate.net

Schematic of material extrusion (ME) process Download Scientific Diagram Material Extrusion Examples Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. Stratasys started to commercialize in 1990 the. Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,. Material extrusion. Material Extrusion Examples.

From www.smlease.com

What is Metal Extrusion, types, and Manufacturing Process Material Extrusion Examples Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers.. Material Extrusion Examples.

From www.iqsdirectory.com

Poly Tubing What Is It? How Is It Used? Types, Materials Material Extrusion Examples Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Stratasys started to commercialize in 1990 the. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. The nozzle can move horizontally and a platform moves up. Material Extrusion Examples.

From engineeringlearn.com

Types of Extrusion Process Working, Advantages & Disadvantages Material Extrusion Examples There are four main types of extrusion: The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,.. Material Extrusion Examples.

From www.slideserve.com

PPT Polymer Processing PowerPoint Presentation ID5687200 Material Extrusion Examples Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. There are four main types of extrusion: Stratasys started to commercialize in 1990 the. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build. Material Extrusion Examples.

From theadditivemanufacturing.com

Material Extrusion for 3D Printing The Additive Manufacturing Material Extrusion Examples Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. Material is drawn through a nozzle, where it is heated and is then deposited layer by layer.. Material Extrusion Examples.

From encyclopedia.pub

Material Extrusion Additive Manufacturing of Metal Encyclopedia MDPI Material Extrusion Examples Stratasys started to commercialize in 1990 the. There are four main types of extrusion: Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d. Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,. It is a commonly used technique. Material Extrusion Examples.

From www.researchgate.net

7. Schematic representation of Material Extrusion. Download Material Extrusion Examples The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d. Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,. It. Material Extrusion Examples.

From encyclopedia.pub

Material Extrusion Additive Manufacturing of Metal Encyclopedia MDPI Material Extrusion Examples Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. There are four main types of extrusion: It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. Material extrusion. Material Extrusion Examples.

From www.slideserve.com

PPT Extrusion and Drawing PowerPoint Presentation, free download ID Material Extrusion Examples The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. There are four main types of extrusion: Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. Stratasys started to commercialize in 1990 the. Material. Material Extrusion Examples.

From rpmindinc.com

Plastic Extrusions Basic Principles and Processes Material Extrusion Examples Stratasys started to commercialize in 1990 the. Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,. There are four main types of extrusion: Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material. Material Extrusion Examples.

From www.rainbowbelts.com

What Is The Profile Extrusion Process? Material Extrusion Examples Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. There are four main types of extrusion: Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d. It is a commonly. Material Extrusion Examples.

From www.primasil.com

Silicone Extrusion Custom Materials from UK Material Extrusion Examples Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. Stratasys started to commercialize in 1990 the. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. There are four main types of extrusion: It is a commonly used technique used on many inexpensive,. Material Extrusion Examples.

From unitymanufacture.com

How To Use Aluminum Extrusion? Unity Manufacture Material Extrusion Examples There are four main types of extrusion: It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. Stratasys started to commercialize in 1990 the. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Material extrusion is. Material Extrusion Examples.

From onlinelibrary.wiley.com

Material extrusion‐based additive manufacturing of polypropylene A Material Extrusion Examples Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. Stratasys started to commercialize in 1990 the. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Material extrusion is an additive manufacturing (am) technique that deposits a continuous. Material Extrusion Examples.

From salmanzafar.me

Applications of Aluminum Extrusion Blogging Junction Material Extrusion Examples There are four main types of extrusion: Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,. Stratasys started. Material Extrusion Examples.

From www.slideserve.com

PPT Extrusion Process PowerPoint Presentation ID163890 Material Extrusion Examples Stratasys started to commercialize in 1990 the. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. Material extrusion is an additive manufacturing (am) technique that deposits a continuous. Material Extrusion Examples.

From www.smlease.com

What is Metal Extrusion, types, and Manufacturing Process Material Extrusion Examples The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. Stratasys started to commercialize in 1990 the. Material extrusion can employ a wide variety of materials such as polymer filaments, polymer pellets, wax filaments and pellets,.. Material Extrusion Examples.

From blog.thepipingmart.com

Types and Uses of Extrusion Material Extrusion Examples It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. There are four main types of extrusion: Material extrusion is an additive manufacturing (am) technique that deposits a continuous filament of composite or thermoplastic material to build 3d. Material is drawn through a nozzle, where it. Material Extrusion Examples.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Material Extrusion Examples It is a commonly used technique used on many inexpensive, domestic and hobby 3d printers. There are four main types of extrusion: Stratasys started to commercialize in 1990 the. Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Material extrusion is an additive. Material Extrusion Examples.

From paulmurphyplastics.com

Ultimate Guide to The Plastic Extrusion Process • Paul Murphy Plastics Material Extrusion Examples The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited. There are four main types of extrusion: Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. Stratasys started to commercialize in 1990 the. Material. Material Extrusion Examples.