Manual Handling Equipment Inspection . When possible, jobs are designed to minimize manual material handling. The conduct of effective inspections requires judgment in the identification, evaluation, and documentation of. The checklist is suitable for use in. Asme b30.16 manual hoists / chainfalls. This basic checklist should help you carry out workplace inspections of manual handling activities. Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. A competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during. Manual material handling inspection checklist. A no answer indicates a hazard and should be fixed. Manual material handling inspection checklist.

from www.seton.co.uk

A no answer indicates a hazard and should be fixed. Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. This basic checklist should help you carry out workplace inspections of manual handling activities. Asme b30.16 manual hoists / chainfalls. Manual material handling inspection checklist. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. The conduct of effective inspections requires judgment in the identification, evaluation, and documentation of. A competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during. When possible, jobs are designed to minimize manual material handling. The checklist is suitable for use in.

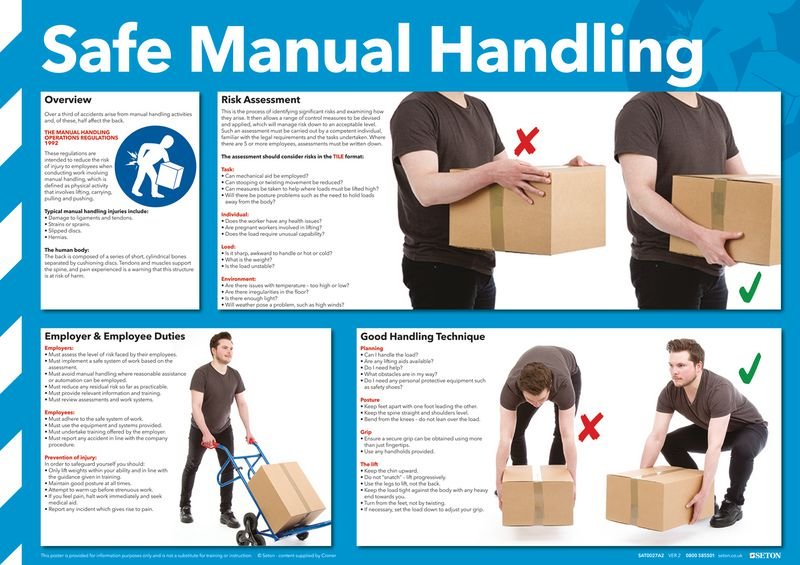

Safe Manual Handling Poster Avoid Workplace Injuries Seton

Manual Handling Equipment Inspection A no answer indicates a hazard and should be fixed. The checklist is suitable for use in. The conduct of effective inspections requires judgment in the identification, evaluation, and documentation of. Asme b30.16 manual hoists / chainfalls. This basic checklist should help you carry out workplace inspections of manual handling activities. A competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during. When possible, jobs are designed to minimize manual material handling. Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. Manual material handling inspection checklist. Manual material handling inspection checklist. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. A no answer indicates a hazard and should be fixed.

From formaspace.com

How to Improve Manual Material Handling in the Workplace Formaspace Manual Handling Equipment Inspection A no answer indicates a hazard and should be fixed. The checklist is suitable for use in. The conduct of effective inspections requires judgment in the identification, evaluation, and documentation of. This basic checklist should help you carry out workplace inspections of manual handling activities. When possible, jobs are designed to minimize manual material handling. A competent person must begin. Manual Handling Equipment Inspection.

From hsseworld.com

Photo of the day Manual Material handling Manual Handling Equipment Inspection A no answer indicates a hazard and should be fixed. Manual material handling inspection checklist. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. This basic checklist should help you carry out workplace inspections of manual handling activities. Manual material handling inspection checklist. The checklist is suitable. Manual Handling Equipment Inspection.

From www.bullmax.com.my

4 Essential Manual Handling Equipment For Warehousing Industry Manual Handling Equipment Inspection Asme b30.16 manual hoists / chainfalls. Manual material handling inspection checklist. A no answer indicates a hazard and should be fixed. This basic checklist should help you carry out workplace inspections of manual handling activities. Manual material handling inspection checklist. When possible, jobs are designed to minimize manual material handling. The checklist is suitable for use in. A competent person. Manual Handling Equipment Inspection.

From joitavcoz.blob.core.windows.net

Manual Handling Tools And Equipment at Thomas Field blog Manual Handling Equipment Inspection Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. When possible, jobs are designed to minimize manual material handling. This basic checklist should help you carry out workplace inspections of manual handling activities. A no answer indicates a hazard and should be fixed. The checklist is suitable for use in. The second standard to be aware. Manual Handling Equipment Inspection.

From hseinstitute.blogspot.com

Manual Handling Assessment Checklist HSE Institute Manual Handling Equipment Inspection Manual material handling inspection checklist. This basic checklist should help you carry out workplace inspections of manual handling activities. The checklist is suitable for use in. A no answer indicates a hazard and should be fixed. When possible, jobs are designed to minimize manual material handling. Asme b30.16 manual hoists / chainfalls. Manual material handling inspection checklist. A competent person. Manual Handling Equipment Inspection.

From redcatsafety.com

Manual Handling Checklist REDCAT SAFETY Manual Handling Equipment Inspection Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. This basic checklist should help you carry out workplace inspections of manual handling activities. Manual material handling inspection checklist. The checklist is suitable for use in. Asme b30.16 manual hoists / chainfalls. The second standard to be aware of is asme b30.21, which applies to lever hoists,. Manual Handling Equipment Inspection.

From formspal.com

Hoist Inspection Checklist PDF Form FormsPal Manual Handling Equipment Inspection When possible, jobs are designed to minimize manual material handling. A competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during. A no answer indicates a hazard and should be fixed. Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. Manual material handling. Manual Handling Equipment Inspection.

From www.scribd.com

Manual Handling Checklist Safety Business Manual Handling Equipment Inspection When possible, jobs are designed to minimize manual material handling. Manual material handling inspection checklist. The checklist is suitable for use in. This basic checklist should help you carry out workplace inspections of manual handling activities. Asme b30.16 manual hoists / chainfalls. Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. Manual material handling inspection checklist.. Manual Handling Equipment Inspection.

From hsseworld.com

22Safety Inspection Checklists Manual Handling Equipment Inspection This basic checklist should help you carry out workplace inspections of manual handling activities. Manual material handling inspection checklist. A competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during. The checklist is suitable for use in. Manual handling equipment plays a crucial role in ensuring workplace. Manual Handling Equipment Inspection.

From studylib.net

Manual Material Handling Inspection Checklist Manual Handling Equipment Inspection The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. Asme b30.16 manual hoists / chainfalls. The checklist is suitable for use in. A competent person must begin a visual inspection prior to each shift. Manual Handling Equipment Inspection.

From www.seton.co.uk

Safe Manual Handling Poster Avoid Workplace Injuries Seton Manual Handling Equipment Inspection A competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during. Manual material handling inspection checklist. This basic checklist should help you carry out workplace inspections of manual handling activities. When possible, jobs are designed to minimize manual material handling. The second standard to be aware of. Manual Handling Equipment Inspection.

From www.safetynotes.net

Safe Manual Handling A Comprehensive Guide Safety Notes Manual Handling Equipment Inspection When possible, jobs are designed to minimize manual material handling. Asme b30.16 manual hoists / chainfalls. Manual material handling inspection checklist. Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. Manual material handling inspection checklist. A no answer indicates a hazard and should be fixed. This basic checklist should help you carry out workplace inspections of. Manual Handling Equipment Inspection.

From public-library.safetyculture.io

Manual Handling Devices Inspection Checklist SafetyCulture Manual Handling Equipment Inspection The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. The checklist is suitable for use in. A competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during. Asme b30.16 manual hoists / chainfalls. The. Manual Handling Equipment Inspection.

From mungfali.com

Manual Handling Procedure Manual Handling Equipment Inspection A competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. Asme b30.16 manual hoists / chainfalls. This basic checklist should help you carry out. Manual Handling Equipment Inspection.

From www.bics.org.uk

A3 Manual Handling Poster BICSc Manual Handling Equipment Inspection Manual material handling inspection checklist. Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. This basic checklist should help you carry out workplace inspections of manual handling activities. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. Asme b30.16 manual hoists / chainfalls.. Manual Handling Equipment Inspection.

From www.firstaidpro.com.au

What Are Safe Manual Handling Techniques Manual Handling Equipment Inspection The conduct of effective inspections requires judgment in the identification, evaluation, and documentation of. A no answer indicates a hazard and should be fixed. Asme b30.16 manual hoists / chainfalls. The checklist is suitable for use in. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. Manual. Manual Handling Equipment Inspection.

From sitemate.com

Hoist Inspection Checklist (Better than word, excel, PDF) Manual Handling Equipment Inspection Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. A no answer indicates a hazard and should be fixed. This basic checklist should help you carry out workplace inspections of manual handling activities. Manual material handling inspection checklist. When possible, jobs are designed to minimize manual material handling. Asme b30.16 manual hoists / chainfalls. The second. Manual Handling Equipment Inspection.

From redcatsafety.com

Manual Handling Assessment REDCAT SAFETY Manual Handling Equipment Inspection A no answer indicates a hazard and should be fixed. A competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during. This basic checklist should help you carry out workplace inspections of manual handling activities. The conduct of effective inspections requires judgment in the identification, evaluation, and. Manual Handling Equipment Inspection.

From www.siera.ai

Troubled with Manual Inspection Checklists for Your Industrial Manual Handling Equipment Inspection Asme b30.16 manual hoists / chainfalls. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. Manual material handling inspection checklist. The conduct of effective inspections requires judgment in the identification, evaluation, and documentation of. This basic checklist should help you carry out workplace inspections of manual handling. Manual Handling Equipment Inspection.

From www.shopfitters.org

Manual handling inspections National Association of Shopfitters and Manual Handling Equipment Inspection The conduct of effective inspections requires judgment in the identification, evaluation, and documentation of. Manual material handling inspection checklist. Asme b30.16 manual hoists / chainfalls. Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists.. Manual Handling Equipment Inspection.

From mavink.com

Manual Handling Examples Manual Handling Equipment Inspection When possible, jobs are designed to minimize manual material handling. Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. A competent person must begin a visual inspection prior to each shift the equipment will. Manual Handling Equipment Inspection.

From www.ecsafetysolutions.com

Site inspections across Great Britain focus on moving and handling Manual Handling Equipment Inspection Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. A competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during. This basic checklist should help you carry out workplace inspections of manual handling activities. Asme b30.16 manual hoists / chainfalls. Manual material handling. Manual Handling Equipment Inspection.

From www.tempest.ie

A Comprehensive Guide to Manual Handling Equipment Selection Tempest Manual Handling Equipment Inspection Manual material handling inspection checklist. This basic checklist should help you carry out workplace inspections of manual handling activities. Asme b30.16 manual hoists / chainfalls. The conduct of effective inspections requires judgment in the identification, evaluation, and documentation of. When possible, jobs are designed to minimize manual material handling. Manual material handling inspection checklist. A competent person must begin a. Manual Handling Equipment Inspection.

From sitemate.com

Lifting equipment inspection procedure Here's the right procedure for you Manual Handling Equipment Inspection Manual material handling inspection checklist. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. Asme b30.16 manual hoists / chainfalls. The checklist is suitable for use in. A no answer indicates a hazard and should be fixed. A competent person must begin a visual inspection prior to. Manual Handling Equipment Inspection.

From loezuhyuc.blob.core.windows.net

How Much Is Safe To Lift In Manual Handling at Richard Reynolds blog Manual Handling Equipment Inspection The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. Manual material handling inspection checklist. The conduct of effective inspections requires judgment in the identification, evaluation, and documentation of. Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. Asme b30.16 manual hoists / chainfalls.. Manual Handling Equipment Inspection.

From greenwgroup.co.in

Safe Manual handling risk assessment safe manual handling training in Manual Handling Equipment Inspection This basic checklist should help you carry out workplace inspections of manual handling activities. Manual material handling inspection checklist. The checklist is suitable for use in. Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. A no answer indicates a hazard and should be fixed. Manual material handling inspection checklist. When possible, jobs are designed to. Manual Handling Equipment Inspection.

From www.ofi.co.uk

Manual Handling Top 10 Tips infographic Manual Handling Equipment Inspection Manual material handling inspection checklist. Manual material handling inspection checklist. Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. A competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during. The conduct of effective inspections requires judgment in the identification, evaluation, and documentation. Manual Handling Equipment Inspection.

From www.ehs.com

Manual Material Handling Equipment What to Use and When VelocityEHS Manual Handling Equipment Inspection The checklist is suitable for use in. Manual material handling inspection checklist. This basic checklist should help you carry out workplace inspections of manual handling activities. Asme b30.16 manual hoists / chainfalls. When possible, jobs are designed to minimize manual material handling. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire. Manual Handling Equipment Inspection.

From mysafetyworks.com.au

AS/NZS ISO 45001 Manual Handling Procedure My Safety Works Manual Handling Equipment Inspection The checklist is suitable for use in. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. The conduct of effective inspections requires judgment in the identification, evaluation, and documentation of. A no answer indicates. Manual Handling Equipment Inspection.

From dxodujipd.blob.core.windows.net

What Is Manual Handling Techniques at Ellen Neal blog Manual Handling Equipment Inspection A competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. Manual material handling inspection checklist. Manual material handling inspection checklist. When possible, jobs are. Manual Handling Equipment Inspection.

From www.alturalearning.co.nz

Manual Handling Use of Equipment to Assist Clients Altura Learning NZ Manual Handling Equipment Inspection Asme b30.16 manual hoists / chainfalls. A competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during. Manual material handling inspection checklist. Manual material handling inspection checklist. A no answer indicates a hazard and should be fixed. The conduct of effective inspections requires judgment in the identification,. Manual Handling Equipment Inspection.

From humanfocus.co.uk

Ladder Inspection Checklist Legal Requirement To Inspect Manual Handling Equipment Inspection The checklist is suitable for use in. This basic checklist should help you carry out workplace inspections of manual handling activities. Asme b30.16 manual hoists / chainfalls. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. When possible, jobs are designed to minimize manual material handling. Manual. Manual Handling Equipment Inspection.

From www.scribd.com

Hoist and Auxillary Equipment OSHA Workplace SelfInspection Checklist Manual Handling Equipment Inspection Manual handling equipment plays a crucial role in ensuring workplace safety and efficiency. Manual material handling inspection checklist. A no answer indicates a hazard and should be fixed. The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. The conduct of effective inspections requires judgment in the identification,. Manual Handling Equipment Inspection.

From www.tempest.ie

What are the Risks Associated with Manual Handling Tempest Manual Handling Equipment Inspection A no answer indicates a hazard and should be fixed. Manual material handling inspection checklist. The conduct of effective inspections requires judgment in the identification, evaluation, and documentation of. A competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during. The checklist is suitable for use in.. Manual Handling Equipment Inspection.

From www.signnow.com

Lifting Gear Inspection Checklist Complete with ease airSlate SignNow Manual Handling Equipment Inspection The second standard to be aware of is asme b30.21, which applies to lever hoists, including chain, wire rope and strap hoists. The checklist is suitable for use in. Manual material handling inspection checklist. A no answer indicates a hazard and should be fixed. Manual material handling inspection checklist. This basic checklist should help you carry out workplace inspections of. Manual Handling Equipment Inspection.