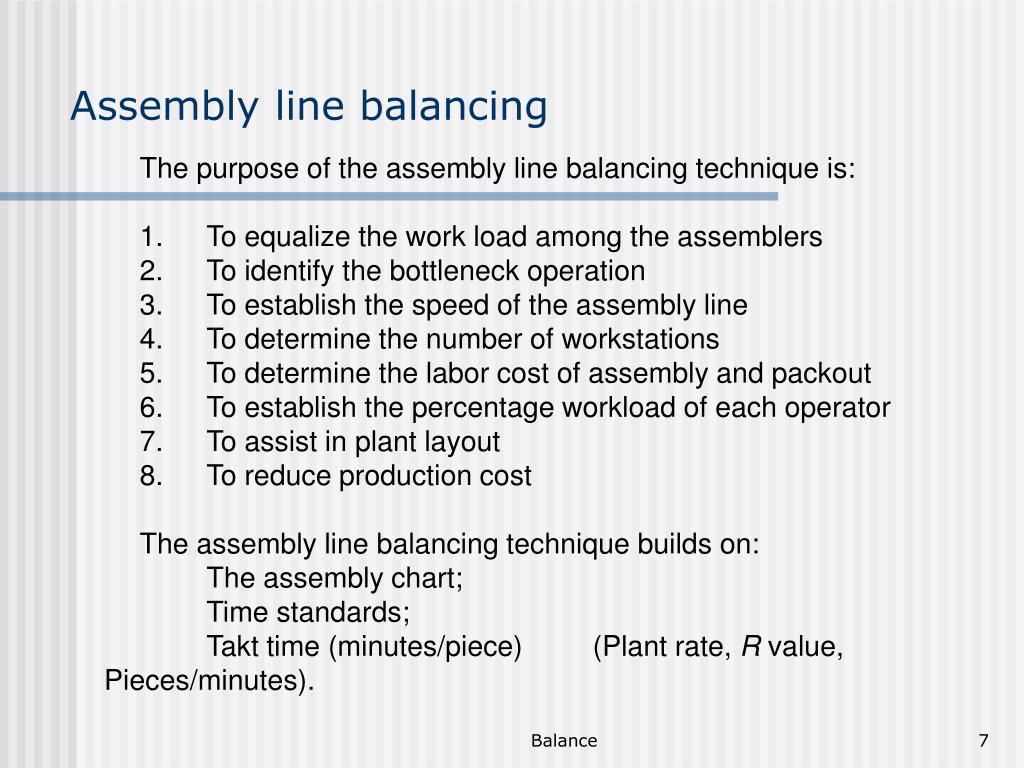

Assembly Line Balancing . What is assembly line balancing? Effective balancing minimizes waste and ensures that production lines run efficiently. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. However, line balancing means different things to different manufacturers. Among the most elementary optimization problems in this context is the assembly line balancing problem, which. Line balancing is a production strategy that matches the production rate to the takt time by reallocating resources. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Thus we can utilize the resources such as manpower and machinery/equipment more effectively. The assembly line balancing formula plays a vital role in ensuring manufacturing efficiency by balancing the workload across various.

from www.slideserve.com

What is assembly line balancing? Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another However, line balancing means different things to different manufacturers. The assembly line balancing formula plays a vital role in ensuring manufacturing efficiency by balancing the workload across various. Line balancing is a production strategy that matches the production rate to the takt time by reallocating resources. Effective balancing minimizes waste and ensures that production lines run efficiently. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Among the most elementary optimization problems in this context is the assembly line balancing problem, which. Thus we can utilize the resources such as manpower and machinery/equipment more effectively.

PPT Assembly Line Balance PowerPoint Presentation, free download ID

Assembly Line Balancing The assembly line balancing formula plays a vital role in ensuring manufacturing efficiency by balancing the workload across various. However, line balancing means different things to different manufacturers. The assembly line balancing formula plays a vital role in ensuring manufacturing efficiency by balancing the workload across various. What is assembly line balancing? Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Line balancing is a production strategy that matches the production rate to the takt time by reallocating resources. Among the most elementary optimization problems in this context is the assembly line balancing problem, which. Effective balancing minimizes waste and ensures that production lines run efficiently. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another

From www.slideserve.com

PPT Assembly Line Balance PowerPoint Presentation, free download ID Assembly Line Balancing Among the most elementary optimization problems in this context is the assembly line balancing problem, which. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Effective balancing minimizes waste and ensures that production. Assembly Line Balancing.

From www.youtube.com

Assembly Line Balancing YouTube Assembly Line Balancing Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Among the most elementary optimization problems in this context is the assembly line balancing problem, which. Effective balancing minimizes waste and ensures that production. Assembly Line Balancing.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Effective balancing minimizes waste and ensures that production lines run efficiently. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit. Assembly Line Balancing.

From www.proplanner.com

Line Balancing Software Generates Assignment of Tasks to Operator Assembly Line Balancing Line balancing is a production strategy that matches the production rate to the takt time by reallocating resources. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Effective balancing minimizes waste and. Assembly Line Balancing.

From www.slideserve.com

PPT Assembly line balancing PowerPoint Presentation, free download Assembly Line Balancing What is assembly line balancing? Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Effective balancing minimizes waste and ensures that production lines run efficiently. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into. Assembly Line Balancing.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing What is assembly line balancing? Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another The assembly line balancing formula plays a vital role in ensuring manufacturing efficiency by balancing the workload across various. Thus we can utilize the. Assembly Line Balancing.

From public.amwaly.com

Assembly Line Balancing أموالي Assembly Line Balancing The assembly line balancing formula plays a vital role in ensuring manufacturing efficiency by balancing the workload across various. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as. Assembly Line Balancing.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another The assembly line balancing formula plays a vital role in ensuring manufacturing efficiency by balancing the. Assembly Line Balancing.

From www.youtube.com

Largest Candidate Rule for Line Balancing Manual Assembly Line Assembly Line Balancing Effective balancing minimizes waste and ensures that production lines run efficiently. Among the most elementary optimization problems in this context is the assembly line balancing problem, which. However, line balancing means different things to different manufacturers. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow.. Assembly Line Balancing.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow.. Assembly Line Balancing.

From www.youtube.com

Operations & Supply Chain Management Assembly Line Balancing I YouTube Assembly Line Balancing Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Line balancing is a production strategy that matches the production rate to the takt time by reallocating resources.. Assembly Line Balancing.

From mungfali.com

Line Balancing Diagram Assembly Line Balancing Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Line balancing is a production strategy. Assembly Line Balancing.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing The assembly line balancing formula plays a vital role in ensuring manufacturing efficiency by balancing the workload across various. However, line balancing means different things to different manufacturers. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Effective. Assembly Line Balancing.

From www.youtube.com

𝐋𝐢𝐧𝐞 𝐁𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 Production Line Balancing ? Assembly Line Balancing Assembly Line Balancing Effective balancing minimizes waste and ensures that production lines run efficiently. What is assembly line balancing? Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. However, line balancing means different things to different manufacturers. Among the most elementary optimization problems in this context is the assembly line balancing problem, which. Line. Assembly Line Balancing.

From www.youtube.com

Modified Product Layout and Assembly Line Balancing Example YouTube Assembly Line Balancing Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Line balancing is a production strategy that matches the production rate to the takt time by reallocating resources. Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Line balancing is done to reduce or eliminate the waiting time. Assembly Line Balancing.

From www.slideshare.net

Assembly Line Balancing Example Assembly Line Balancing What is assembly line balancing? Line balancing is a production strategy that matches the production rate to the takt time by reallocating resources. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Effective balancing minimizes waste and ensures that production lines run efficiently. The assembly line balancing formula plays a vital. Assembly Line Balancing.

From www.youtube.com

Assembly Line Balancing Example YouTube Assembly Line Balancing Among the most elementary optimization problems in this context is the assembly line balancing problem, which. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Effective balancing minimizes waste and ensures that production lines run efficiently. Thus we. Assembly Line Balancing.

From www.youtube.com

Tutorial 6 Assembly line balancing YouTube Assembly Line Balancing Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Among the most elementary optimization problems in this context is the assembly line balancing problem, which. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in. Assembly Line Balancing.

From www.youtube.com

Assembly Line BalancingSolved ExampleOperations Management YouTube Assembly Line Balancing Thus we can utilize the resources such as manpower and machinery/equipment more effectively. However, line balancing means different things to different manufacturers. Among the most elementary optimization problems in this context is the assembly line balancing problem, which. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. What is assembly line. Assembly Line Balancing.

From mungfali.com

Line Balancing Formula Assembly Line Balancing Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Among the most elementary optimization problems. Assembly Line Balancing.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing However, line balancing means different things to different manufacturers. Effective balancing minimizes waste and ensures that production lines run efficiently. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. What is assembly line balancing? Optimizing workflow on an assembly line is not as dangerous, but it. Assembly Line Balancing.

From www.youtube.com

Assembly line balancing part3 Line balancing Target IES YouTube Assembly Line Balancing Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Thus we can utilize the resources such as manpower and machinery/equipment more effectively. What is assembly line balancing? Among the most elementary optimization problems in this context is the assembly line balancing problem, which. Line balancing is. Assembly Line Balancing.

From www.slideserve.com

PPT Assembly Line Balance PowerPoint Presentation, free download ID Assembly Line Balancing Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. What is assembly line balancing? Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Alb, or simply line balancing, is. Assembly Line Balancing.

From www.scribd.com

Assembly Line Balancing Technology Business Assembly Line Balancing What is assembly line balancing? Line balancing is a production strategy that matches the production rate to the takt time by reallocating resources. The assembly line balancing formula plays a vital role in ensuring manufacturing efficiency by balancing the workload across various. Thus we can utilize the resources such as manpower and machinery/equipment more effectively. However, line balancing means different. Assembly Line Balancing.

From www.smlease.com

What is production Line Balancing and How to implement it? Assembly Line Balancing What is assembly line balancing? Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Optimizing. Assembly Line Balancing.

From www.youtube.com

Operations Layout Assembly Line Balancing I YouTube Assembly Line Balancing What is assembly line balancing? Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow.. Assembly Line Balancing.

From www.slideshare.net

Assembly Line Balancing Example Assembly Line Balancing Among the most elementary optimization problems in this context is the assembly line balancing problem, which. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in. Assembly Line Balancing.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing What is assembly line balancing? Among the most elementary optimization problems in this context is the assembly line balancing problem, which. Line balancing is a production strategy that matches the production rate to the takt time by reallocating resources. However, line balancing means different things to different manufacturers. Thus we can utilize the resources such as manpower and machinery/equipment more. Assembly Line Balancing.

From www.tetrahedron.in

Line Balancing in Manufacturing Training Tetrahedron Assembly Line Balancing What is assembly line balancing? Among the most elementary optimization problems in this context is the assembly line balancing problem, which. However, line balancing means different things to different manufacturers. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Alb, or simply line balancing, is arranging the individual processing and assembly. Assembly Line Balancing.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Effective balancing minimizes waste and ensures that production lines run efficiently. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another The assembly line balancing formula plays a vital role in ensuring manufacturing efficiency by balancing the workload across. Assembly Line Balancing.

From www.youtube.com

ASSEMBLY LINE BALANCING Tutorial 2 LeanSeekho YouTube Assembly Line Balancing Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. However, line balancing means different things to different manufacturers. Effective balancing minimizes waste and ensures that production lines run efficiently. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products. Assembly Line Balancing.

From www.youtube.com

04 Assembly Line Balancing YouTube Assembly Line Balancing Line balancing is a production strategy that matches the production rate to the takt time by reallocating resources. Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Among the most elementary optimization problems in this context is the assembly line balancing problem, which. Effective balancing minimizes waste and ensures that production lines run efficiently. Line balancing. Assembly Line Balancing.

From www.youtube.com

Assembly Line Balancing Workstations YouTube Assembly Line Balancing Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Thus we can utilize the resources such as manpower and machinery/equipment more effectively.. Assembly Line Balancing.

From www.alfredmfg.com

assembly line balancing Alfred Manufacturing Assembly Line Balancing Effective balancing minimizes waste and ensures that production lines run efficiently. Among the most elementary optimization problems in this context is the assembly line balancing problem, which. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Line balancing is a production strategy that matches the. Assembly Line Balancing.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Alb, or simply line balancing,. Assembly Line Balancing.