Can Centrifugal Pumps Pump Air . Air can increase the noise level in high (discharge) energy. Cavitation can occur in centrifugal pumps for various reasons. Air in pump reduces capacity. A pump is not a good compressor, and it will stop pumping. In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. One of those reasons is when the inlet pressure to a pump is low. Reduce or eliminate the air to. As a result, discharge pressure drops and flow stops. For example, a crack in a. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. Low inlet pressure can occur due to a low level of liquid in a. When air enters a pump it sometimes gets trapped in the volute, this reduces the capacity, creates vibration and noise. Large amounts of air (over about five to six percent) can collect in the eye of the impeller and cause loss of flow and possibly air binding.

from amarineblog.com

Large amounts of air (over about five to six percent) can collect in the eye of the impeller and cause loss of flow and possibly air binding. As a result, discharge pressure drops and flow stops. Cavitation can occur in centrifugal pumps for various reasons. Low inlet pressure can occur due to a low level of liquid in a. Air can increase the noise level in high (discharge) energy. One of those reasons is when the inlet pressure to a pump is low. In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. Reduce or eliminate the air to. For example, a crack in a. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump.

CENTRIFUGAL PUMP (Introduction) AMARINE

Can Centrifugal Pumps Pump Air As a result, discharge pressure drops and flow stops. For example, a crack in a. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. Reduce or eliminate the air to. In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. Air in pump reduces capacity. A pump is not a good compressor, and it will stop pumping. As a result, discharge pressure drops and flow stops. Cavitation can occur in centrifugal pumps for various reasons. Air can increase the noise level in high (discharge) energy. One of those reasons is when the inlet pressure to a pump is low. Large amounts of air (over about five to six percent) can collect in the eye of the impeller and cause loss of flow and possibly air binding. Low inlet pressure can occur due to a low level of liquid in a. When air enters a pump it sometimes gets trapped in the volute, this reduces the capacity, creates vibration and noise.

From mepacademy.com

Centrifugal Pump Basics How they work with VFD's in HVAC Systems Can Centrifugal Pumps Pump Air Reduce or eliminate the air to. A pump is not a good compressor, and it will stop pumping. For example, a crack in a. Air in pump reduces capacity. When air enters a pump it sometimes gets trapped in the volute, this reduces the capacity, creates vibration and noise. Cavitation can occur in centrifugal pumps for various reasons. One of. Can Centrifugal Pumps Pump Air.

From www.researchgate.net

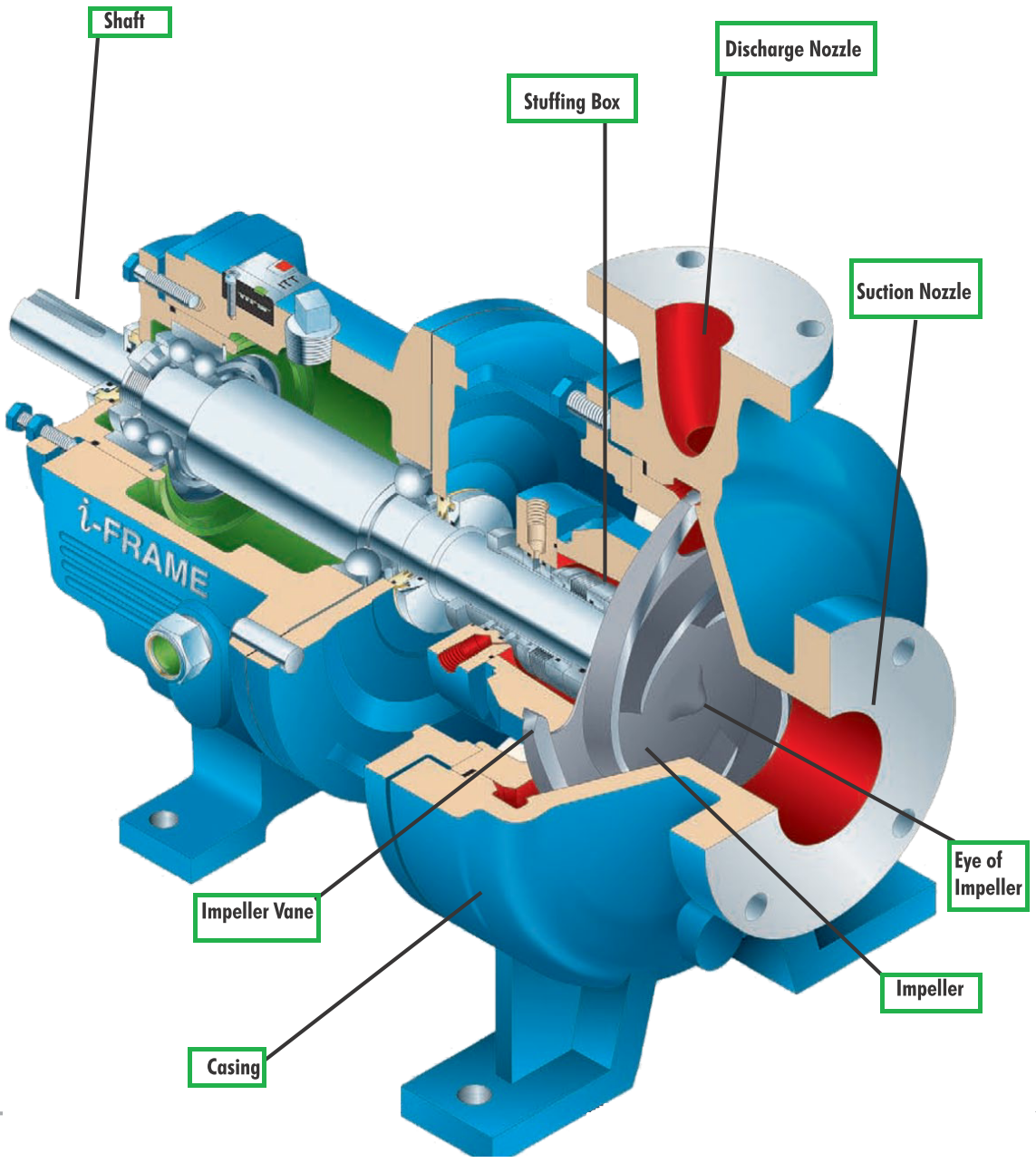

1. Main components of a centrifugal pump (Taken from [47]) Download Can Centrifugal Pumps Pump Air Cavitation can occur in centrifugal pumps for various reasons. When air enters a pump it sometimes gets trapped in the volute, this reduces the capacity, creates vibration and noise. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. Reduce or eliminate the air to. For example, a crack. Can Centrifugal Pumps Pump Air.

From www.mechanical-knowledge.com

Introduction To Centrifugal Pumps Pdf Can Centrifugal Pumps Pump Air One of those reasons is when the inlet pressure to a pump is low. As a result, discharge pressure drops and flow stops. Air in pump reduces capacity. Large amounts of air (over about five to six percent) can collect in the eye of the impeller and cause loss of flow and possibly air binding. Air can increase the noise. Can Centrifugal Pumps Pump Air.

From www.youtube.com

Centrifugal Pump Basics How centrifugal pumps work working principle Can Centrifugal Pumps Pump Air Large amounts of air (over about five to six percent) can collect in the eye of the impeller and cause loss of flow and possibly air binding. Low inlet pressure can occur due to a low level of liquid in a. One of those reasons is when the inlet pressure to a pump is low. In fact, it’s well documented. Can Centrifugal Pumps Pump Air.

From theengineeringmindset.com

Centrifugal Pump basics tw The Engineering Mindset Can Centrifugal Pumps Pump Air Reduce or eliminate the air to. A pump is not a good compressor, and it will stop pumping. One of those reasons is when the inlet pressure to a pump is low. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. Large amounts of air (over about five. Can Centrifugal Pumps Pump Air.

From www.vemc.co.in

Centrifugal Pumps are Energy Guzzlers. How does Pump Energy Audit Help Can Centrifugal Pumps Pump Air Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. Air in pump reduces capacity. Air can increase the noise level in high (discharge) energy. One of those reasons is when the inlet pressure to a pump is low. Low inlet pressure can occur due to a low level. Can Centrifugal Pumps Pump Air.

From www.nuclear-power.com

How Does Centrifugal Pump Work Nuclear Power Can Centrifugal Pumps Pump Air Air in pump reduces capacity. Air can increase the noise level in high (discharge) energy. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. When air enters a pump it sometimes gets trapped in the volute, this reduces the capacity, creates vibration and noise. A pump is not. Can Centrifugal Pumps Pump Air.

From www.tec-science.com

How does a centrifugal pump work? tecscience Can Centrifugal Pumps Pump Air In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. Air can increase the noise level in high (discharge) energy. For example, a crack in a. Large amounts of air (over about five to six percent) can collect in the eye of the impeller and cause loss of flow. Can Centrifugal Pumps Pump Air.

From www.pinterest.com

Benefits of a multistage centrifugal pump Centrifugal pump, Pumps, Multi Can Centrifugal Pumps Pump Air Cavitation can occur in centrifugal pumps for various reasons. When air enters a pump it sometimes gets trapped in the volute, this reduces the capacity, creates vibration and noise. One of those reasons is when the inlet pressure to a pump is low. Air in pump reduces capacity. For example, a crack in a. Air entrainment issues are often ignored. Can Centrifugal Pumps Pump Air.

From www.iqsdirectory.com

Centrifugal Pumps Types, Applications, Benefits, and Maintenance Can Centrifugal Pumps Pump Air Air in pump reduces capacity. Low inlet pressure can occur due to a low level of liquid in a. For example, a crack in a. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. When air enters a pump it sometimes gets trapped in the volute, this reduces. Can Centrifugal Pumps Pump Air.

From www.rotechpumps.com

What is a Centrifugal Pump? Understanding Its Mechanism, Types, and Can Centrifugal Pumps Pump Air Air in pump reduces capacity. As a result, discharge pressure drops and flow stops. For example, a crack in a. Large amounts of air (over about five to six percent) can collect in the eye of the impeller and cause loss of flow and possibly air binding. One of those reasons is when the inlet pressure to a pump is. Can Centrifugal Pumps Pump Air.

From www.sintechpumps.com

Stepbystep guide for overhauling centrifugal pumps Sintech Can Centrifugal Pumps Pump Air Large amounts of air (over about five to six percent) can collect in the eye of the impeller and cause loss of flow and possibly air binding. Air can increase the noise level in high (discharge) energy. In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. Reduce or. Can Centrifugal Pumps Pump Air.

From studiousguy.com

Centrifugal Pump Working Principle StudiousGuy Can Centrifugal Pumps Pump Air For example, a crack in a. Low inlet pressure can occur due to a low level of liquid in a. In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a. Can Centrifugal Pumps Pump Air.

From amarineblog.com

CENTRIFUGAL PUMP (Introduction) AMARINE Can Centrifugal Pumps Pump Air Cavitation can occur in centrifugal pumps for various reasons. Air can increase the noise level in high (discharge) energy. Reduce or eliminate the air to. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. For example, a crack in a. A pump is not a good compressor, and. Can Centrifugal Pumps Pump Air.

From bertrem.com

Centrifugal Pumps Bertrem Products Inc. Can Centrifugal Pumps Pump Air Large amounts of air (over about five to six percent) can collect in the eye of the impeller and cause loss of flow and possibly air binding. Air in pump reduces capacity. In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. Air entrainment issues are often ignored or. Can Centrifugal Pumps Pump Air.

From makepipingeasy.com

Types of Pumps Centrifugal Pump & Positive Displacement Pump Make Can Centrifugal Pumps Pump Air For example, a crack in a. When air enters a pump it sometimes gets trapped in the volute, this reduces the capacity, creates vibration and noise. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. Large amounts of air (over about five to six percent) can collect in. Can Centrifugal Pumps Pump Air.

From www.serfilco.com

UC Centrifugal Pump SERFILCO Can Centrifugal Pumps Pump Air Cavitation can occur in centrifugal pumps for various reasons. Reduce or eliminate the air to. Air in pump reduces capacity. In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. One of those reasons is when the inlet pressure to a pump is low. Low inlet pressure can occur. Can Centrifugal Pumps Pump Air.

From electricalworkbook.com

What is Centrifugal Pump? Working, Parts, Diagram & Types Can Centrifugal Pumps Pump Air Large amounts of air (over about five to six percent) can collect in the eye of the impeller and cause loss of flow and possibly air binding. Reduce or eliminate the air to. Air can increase the noise level in high (discharge) energy. When air enters a pump it sometimes gets trapped in the volute, this reduces the capacity, creates. Can Centrifugal Pumps Pump Air.

From www.pumpindustry.com.au

Centrifugal pumps Pump Industry Magazine Can Centrifugal Pumps Pump Air Air in pump reduces capacity. As a result, discharge pressure drops and flow stops. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. When air enters a pump it sometimes gets trapped in the volute, this reduces the capacity, creates vibration and noise. One of those reasons is. Can Centrifugal Pumps Pump Air.

From www.sintechpumps.com

Guide for Installing Centrifugal Pumps Sintech Pumps Can Centrifugal Pumps Pump Air Reduce or eliminate the air to. In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. Cavitation can occur in centrifugal pumps for various reasons. Air can increase the noise level in high (discharge) energy. Air in pump reduces capacity. One of those reasons is when the inlet pressure. Can Centrifugal Pumps Pump Air.

From www.tapflopumps.co.uk

Benefits And Uses Of A Centrifugal Pump Tapflo Pumps UK Can Centrifugal Pumps Pump Air When air enters a pump it sometimes gets trapped in the volute, this reduces the capacity, creates vibration and noise. Low inlet pressure can occur due to a low level of liquid in a. One of those reasons is when the inlet pressure to a pump is low. Large amounts of air (over about five to six percent) can collect. Can Centrifugal Pumps Pump Air.

From www.pump.co.uk

CM80160 D Centrifugal pump Pumps from pump.co.uk W.Robinson & Sons Can Centrifugal Pumps Pump Air A pump is not a good compressor, and it will stop pumping. For example, a crack in a. In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. Reduce or eliminate the air to. Air in pump reduces capacity. Low inlet pressure can occur due to a low level. Can Centrifugal Pumps Pump Air.

From mechatronics122.blogspot.com

electromechanical systems (Pumps) / Different Types of Pumps Working Can Centrifugal Pumps Pump Air Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. Large amounts of air (over about five to six percent) can collect in the eye of the impeller. Can Centrifugal Pumps Pump Air.

From acoem.us

Basics of Centrifugal Pumps Know Your Machines Acoem USA Can Centrifugal Pumps Pump Air Air can increase the noise level in high (discharge) energy. For example, a crack in a. Low inlet pressure can occur due to a low level of liquid in a. In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. As a result, discharge pressure drops and flow stops.. Can Centrifugal Pumps Pump Air.

From www.mech4study.com

Centrifugal Pump Principle, Parts, Working, Types, Advantages Can Centrifugal Pumps Pump Air For example, a crack in a. Air in pump reduces capacity. One of those reasons is when the inlet pressure to a pump is low. Large amounts of air (over about five to six percent) can collect in the eye of the impeller and cause loss of flow and possibly air binding. A pump is not a good compressor, and. Can Centrifugal Pumps Pump Air.

From www.youtube.com

Centrifugal Pumps YouTube Can Centrifugal Pumps Pump Air Reduce or eliminate the air to. Low inlet pressure can occur due to a low level of liquid in a. Large amounts of air (over about five to six percent) can collect in the eye of the impeller and cause loss of flow and possibly air binding. As a result, discharge pressure drops and flow stops. One of those reasons. Can Centrifugal Pumps Pump Air.

From www.youtube.com

Troubleshooting Centrifugal Pumps Avoid These 3 Common Issues YouTube Can Centrifugal Pumps Pump Air In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. Air can increase the noise level in high (discharge) energy. A pump is not a good compressor, and it will stop pumping. When air enters a pump it sometimes gets trapped in the volute, this reduces the capacity, creates. Can Centrifugal Pumps Pump Air.

From blog.thepipingmart.com

Overview of Centrifugal Pumps Can Centrifugal Pumps Pump Air As a result, discharge pressure drops and flow stops. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. A pump is not a good compressor, and it will stop pumping. Large amounts of air (over about five to six percent) can collect in the eye of the impeller. Can Centrifugal Pumps Pump Air.

From marinersgalaxy.com

Centrifugal Pump Working Principal, Maintenance marinersgalaxy Can Centrifugal Pumps Pump Air In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. Low inlet pressure can occur due to a low level of liquid in a. For example, a crack in a. Air can increase the noise level in high (discharge) energy. Air in pump reduces capacity. Air entrainment issues are. Can Centrifugal Pumps Pump Air.

From engineeringlearner.com

Working of a Centrifugal Pump Engineering Learner Can Centrifugal Pumps Pump Air When air enters a pump it sometimes gets trapped in the volute, this reduces the capacity, creates vibration and noise. Large amounts of air (over about five to six percent) can collect in the eye of the impeller and cause loss of flow and possibly air binding. Low inlet pressure can occur due to a low level of liquid in. Can Centrifugal Pumps Pump Air.

From www.mechanicalbooster.com

Centrifugal Pump Working Principle, Main Parts with Application Can Centrifugal Pumps Pump Air Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. Air can increase the noise level in high (discharge) energy. A pump is not a good compressor, and it will stop pumping. One of those reasons is when the inlet pressure to a pump is low. Reduce or eliminate. Can Centrifugal Pumps Pump Air.

From www.tec-science.com

How does a centrifugal pump work? tecscience Can Centrifugal Pumps Pump Air For example, a crack in a. Air in pump reduces capacity. As a result, discharge pressure drops and flow stops. Cavitation can occur in centrifugal pumps for various reasons. When air enters a pump it sometimes gets trapped in the volute, this reduces the capacity, creates vibration and noise. A pump is not a good compressor, and it will stop. Can Centrifugal Pumps Pump Air.

From www.pulpandpaper-technology.com

S Pump Self priming centrifugal pumps Pumps and Mixers Victor Pumps Srl Can Centrifugal Pumps Pump Air Cavitation can occur in centrifugal pumps for various reasons. Low inlet pressure can occur due to a low level of liquid in a. Air in pump reduces capacity. One of those reasons is when the inlet pressure to a pump is low. As a result, discharge pressure drops and flow stops. Reduce or eliminate the air to. When air enters. Can Centrifugal Pumps Pump Air.

From www.tapflopumps.co.uk

The Ultimate Guide to a Centrifugal Pump Tapflo Pumps UK Can Centrifugal Pumps Pump Air One of those reasons is when the inlet pressure to a pump is low. For example, a crack in a. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. Large amounts of air (over about five to six percent) can collect in the eye of the impeller and. Can Centrifugal Pumps Pump Air.

From www.sintechpumps.com

which centrifugal pumps to choose horizontal vs vertical Can Centrifugal Pumps Pump Air One of those reasons is when the inlet pressure to a pump is low. Cavitation can occur in centrifugal pumps for various reasons. When air enters a pump it sometimes gets trapped in the volute, this reduces the capacity, creates vibration and noise. Air in pump reduces capacity. For example, a crack in a. Air can increase the noise level. Can Centrifugal Pumps Pump Air.