Bench Drill Risk Assessment . Recognise hazards and create awareness. download this detailed risk assessment and safe operating procedures and instantly: carefully study the bench top machine drill (seen below). Identify the hazard, relating to the belt system / pulley system. fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. Check workspace and walkways to ensure no slip hazards are present. as a director, your workers rely on you to understand how best practice protocols mitigate operational risk factors. Ensure the chuck key (if used) has been removed from the drill chuck. Check that the drill chuck guard is in position. this risk assessment only deals with the generic risks associated with pillar and bench mounted drilling. The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. Isolate area is necessary and possible.

from www.youtube.com

Recognise hazards and create awareness. download this detailed risk assessment and safe operating procedures and instantly: Ensure the chuck key (if used) has been removed from the drill chuck. Isolate area is necessary and possible. a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. Identify the hazard, relating to the belt system / pulley system. Check workspace and walkways to ensure no slip hazards are present. The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. as a director, your workers rely on you to understand how best practice protocols mitigate operational risk factors.

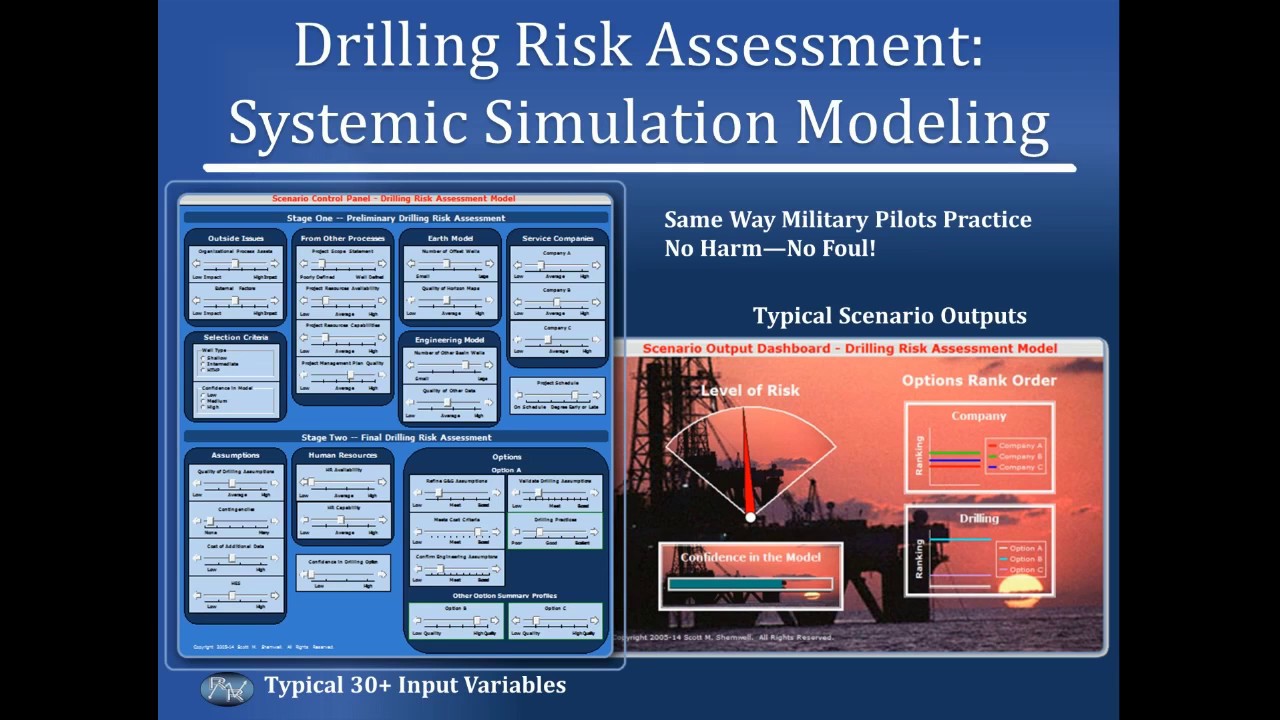

Drilling Risk Assessment Simulation YouTube

Bench Drill Risk Assessment carefully study the bench top machine drill (seen below). Recognise hazards and create awareness. Check that the drill chuck guard is in position. Ensure the chuck key (if used) has been removed from the drill chuck. Identify the hazard, relating to the belt system / pulley system. this risk assessment only deals with the generic risks associated with pillar and bench mounted drilling. carefully study the bench top machine drill (seen below). download this detailed risk assessment and safe operating procedures and instantly: Isolate area is necessary and possible. fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. as a director, your workers rely on you to understand how best practice protocols mitigate operational risk factors. Check workspace and walkways to ensure no slip hazards are present.

From www.makesafetools.com

Bench Grinder Risk Assessments and Safety MAKESafe Tools Bench Drill Risk Assessment Ensure the chuck key (if used) has been removed from the drill chuck. a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. Identify the hazard, relating to the belt system / pulley system. Check. Bench Drill Risk Assessment.

From mavink.com

Pillar Drill Safety Poster Bench Drill Risk Assessment Isolate area is necessary and possible. fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. Ensure the chuck key (if used) has been removed from the drill chuck. Check workspace and walkways to ensure no slip hazards are present. this risk assessment only deals with the generic risks associated with pillar and bench. Bench Drill Risk Assessment.

From mungfali.com

Risk Assessment Template Excel For Healthcare Bench Drill Risk Assessment carefully study the bench top machine drill (seen below). Isolate area is necessary and possible. as a director, your workers rely on you to understand how best practice protocols mitigate operational risk factors. Check workspace and walkways to ensure no slip hazards are present. Identify the hazard, relating to the belt system / pulley system. Recognise hazards and. Bench Drill Risk Assessment.

From www.slideserve.com

PPT P14372 Gate Review Update Presentation PowerPoint Presentation Bench Drill Risk Assessment Identify the hazard, relating to the belt system / pulley system. The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. Recognise hazards and create awareness. fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. this risk assessment only deals with the generic risks associated with. Bench Drill Risk Assessment.

From mavink.com

Rigging Safety Inspection Checklist Bench Drill Risk Assessment download this detailed risk assessment and safe operating procedures and instantly: The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. Check workspace and walkways to ensure no slip hazards are present.. Bench Drill Risk Assessment.

From mindingkids.co.uk

Risk Assessments Pack MindingKids Bench Drill Risk Assessment Check that the drill chuck guard is in position. Identify the hazard, relating to the belt system / pulley system. Recognise hazards and create awareness. Ensure the chuck key (if used) has been removed from the drill chuck. fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. The discussion below describes each hazard, points. Bench Drill Risk Assessment.

From www.youtube.com

Drilling Risk Assessment Simulation YouTube Bench Drill Risk Assessment this risk assessment only deals with the generic risks associated with pillar and bench mounted drilling. Check workspace and walkways to ensure no slip hazards are present. fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. carefully study the bench top machine drill (seen below). Check that the drill chuck guard is. Bench Drill Risk Assessment.

From mavink.com

Manufacturing Risk Assessment Template Bench Drill Risk Assessment download this detailed risk assessment and safe operating procedures and instantly: Isolate area is necessary and possible. The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. Check workspace and walkways to ensure no slip hazards are present. this risk assessment only deals with the generic risks associated with pillar and. Bench Drill Risk Assessment.

From www.slideshare.net

Wt4603 unit5 week7 Bench Drill Risk Assessment The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. Ensure the chuck key (if used) has been removed from the drill chuck. fitting an incorrect wheel can lead to disintegration, and. Bench Drill Risk Assessment.

From www.scribd.com

Grinding Equipment Risk Assessment PDF Risk Safety Bench Drill Risk Assessment fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. this risk assessment only deals with the generic risks associated with pillar and bench mounted drilling. Check that the drill chuck guard is in position. Check workspace and walkways to ensure no slip hazards are present. Ensure the chuck key (if used) has been. Bench Drill Risk Assessment.

From slideplayer.com

Complete the risk assessments ppt download Bench Drill Risk Assessment Ensure the chuck key (if used) has been removed from the drill chuck. a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. The discussion below describes each hazard, points out the related osha requirements,. Bench Drill Risk Assessment.

From makesafetools.com

Bench Grinder Risk Assessments and Safety MAKESafe Tools Bench Drill Risk Assessment download this detailed risk assessment and safe operating procedures and instantly: Ensure the chuck key (if used) has been removed from the drill chuck. Recognise hazards and create awareness. carefully study the bench top machine drill (seen below). Isolate area is necessary and possible. fitting an incorrect wheel can lead to disintegration, and ejection of the broken. Bench Drill Risk Assessment.

From makesafetools.com

Bench Grinder Risk Assessments and Safety MAKESafe Tools Bench Drill Risk Assessment fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. Identify the hazard, relating to the belt system / pulley system. Isolate area is necessary and possible. Recognise hazards and create awareness. this risk assessment only deals with the generic risks associated with pillar and bench mounted drilling. Ensure the chuck key (if used). Bench Drill Risk Assessment.

From www.scribd.com

Bench Risk Assessment Form PDF Bench Drill Risk Assessment Isolate area is necessary and possible. Ensure the chuck key (if used) has been removed from the drill chuck. Check workspace and walkways to ensure no slip hazards are present. The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. this risk assessment only deals with the generic risks associated with pillar. Bench Drill Risk Assessment.

From www.earlyyearsstaffroom.com

Risk Assessment for Woodwork Bench and Tools Early Years Bench Drill Risk Assessment Check workspace and walkways to ensure no slip hazards are present. a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. Identify the hazard, relating to the belt system / pulley system. Ensure the chuck key (if used) has been removed from the drill chuck. The discussion below describes each. Bench Drill Risk Assessment.

From 12designandtechnology-cole.weebly.com

Risk Assessments Elsie Cole Bench Drill Risk Assessment this risk assessment only deals with the generic risks associated with pillar and bench mounted drilling. carefully study the bench top machine drill (seen below). Check that the drill chuck guard is in position. a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. Recognise hazards and create. Bench Drill Risk Assessment.

From constatech.co.za

Risk Assessment Bench Drill Risk Assessment fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. Recognise hazards and create awareness. this risk assessment only deals with the generic risks associated with pillar and bench mounted drilling. Check workspace and walkways to ensure no slip hazards are present. Isolate area is necessary and possible. Identify the hazard, relating to the. Bench Drill Risk Assessment.

From safeti.com

Angle Grinder Risk Assessment Download PLUS Training Bench Drill Risk Assessment Identify the hazard, relating to the belt system / pulley system. Check workspace and walkways to ensure no slip hazards are present. The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. carefully study the bench top. Bench Drill Risk Assessment.

From diybenchesideas.blogspot.com

DIY Garden Bench Ideas Free Plans for Outdoor Benches Bench Mounted Bench Drill Risk Assessment as a director, your workers rely on you to understand how best practice protocols mitigate operational risk factors. a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. Check workspace and walkways to ensure no slip hazards are present. The discussion below describes each hazard, points out the related. Bench Drill Risk Assessment.

From safety4sea.com

Lessons learned Employee scalped when hair trapped in a pillar drill Bench Drill Risk Assessment Identify the hazard, relating to the belt system / pulley system. carefully study the bench top machine drill (seen below). Ensure the chuck key (if used) has been removed from the drill chuck. this risk assessment only deals with the generic risks associated with pillar and bench mounted drilling. a risk assessments for a pedestal or bench. Bench Drill Risk Assessment.

From www.traindup.org

Site Work Risk Assessment Using Bench Mounted Power Tools Train’d Up Bench Drill Risk Assessment as a director, your workers rely on you to understand how best practice protocols mitigate operational risk factors. Identify the hazard, relating to the belt system / pulley system. Ensure the chuck key (if used) has been removed from the drill chuck. download this detailed risk assessment and safe operating procedures and instantly: this risk assessment only. Bench Drill Risk Assessment.

From slideplayer.com

Health and Safety. ppt video online download Bench Drill Risk Assessment Ensure the chuck key (if used) has been removed from the drill chuck. The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. download this detailed risk assessment and safe operating procedures and instantly: Recognise hazards and create awareness. Check workspace and walkways to ensure no slip hazards are present. Identify the. Bench Drill Risk Assessment.

From makesafetools.com

Bench Grinder Risk Assessments and Safety MAKESafe Tools Bench Drill Risk Assessment carefully study the bench top machine drill (seen below). as a director, your workers rely on you to understand how best practice protocols mitigate operational risk factors. Check that the drill chuck guard is in position. download this detailed risk assessment and safe operating procedures and instantly: Ensure the chuck key (if used) has been removed from. Bench Drill Risk Assessment.

From manualzz.com

APPENDIX 1. MACHINE SHOP RISK ASSESSMENT Manualzz Bench Drill Risk Assessment The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. Identify the hazard, relating to the belt system / pulley system. carefully study the bench top machine drill (seen below). as. Bench Drill Risk Assessment.

From gioojzvmx.blob.core.windows.net

Hand Drilling Machine Risk Assessment at Maureen Nicholson blog Bench Drill Risk Assessment Isolate area is necessary and possible. The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. Check workspace and walkways to ensure no slip hazards are present. Identify the hazard, relating to the belt system / pulley system. Ensure the chuck key (if used) has been removed from the drill chuck. Check that. Bench Drill Risk Assessment.

From technologystudent.com

HEALTH AND SAFETY RISK ASSESSMENTS Bench Drill Risk Assessment Isolate area is necessary and possible. Identify the hazard, relating to the belt system / pulley system. download this detailed risk assessment and safe operating procedures and instantly: Check workspace and walkways to ensure no slip hazards are present. fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. Recognise hazards and create awareness.. Bench Drill Risk Assessment.

From www.thesecularparent.com

Machinery Machine Risk Assessment Template Templates2 Resume Examples Bench Drill Risk Assessment a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. this risk assessment only deals with the generic risks associated with pillar and bench mounted drilling. Isolate area is necessary and possible. Check workspace and walkways to ensure no slip hazards are present. Check that the drill chuck guard. Bench Drill Risk Assessment.

From www.riskpal.com

Risk Assessment Matrices Tools to Visualise Risk Bench Drill Risk Assessment Isolate area is necessary and possible. as a director, your workers rely on you to understand how best practice protocols mitigate operational risk factors. The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. Check that the drill chuck guard is in position. Identify the hazard, relating to the belt system /. Bench Drill Risk Assessment.

From studylib.net

Sample Risk Assessment Tools Bench Drill Risk Assessment The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. Check that the drill chuck guard is in position. fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. Check workspace and walkways to ensure no slip hazards are present. Recognise hazards and create awareness. a risk. Bench Drill Risk Assessment.

From 12designandtechnology-cole.weebly.com

Risk Assessments Elsie Cole Bench Drill Risk Assessment a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. Identify the hazard, relating to the belt system / pulley system. Recognise hazards and create awareness. fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. as a director, your workers rely on you. Bench Drill Risk Assessment.

From www.ohsdocs.com.au

OHS Documents Australia Use of Bench Grinder on Metal Bench Drill Risk Assessment as a director, your workers rely on you to understand how best practice protocols mitigate operational risk factors. this risk assessment only deals with the generic risks associated with pillar and bench mounted drilling. Recognise hazards and create awareness. Isolate area is necessary and possible. Ensure the chuck key (if used) has been removed from the drill chuck.. Bench Drill Risk Assessment.

From www.scribd.com

10. Using bench grinder (WS).xlsx Risk Assessment Mill (Grinding) Bench Drill Risk Assessment carefully study the bench top machine drill (seen below). as a director, your workers rely on you to understand how best practice protocols mitigate operational risk factors. Check workspace and walkways to ensure no slip hazards are present. Isolate area is necessary and possible. this risk assessment only deals with the generic risks associated with pillar and. Bench Drill Risk Assessment.

From mavink.com

Excavator Risk Assessment Template Bench Drill Risk Assessment The discussion below describes each hazard, points out the related osha requirements, and makes suggestions for remediation. as a director, your workers rely on you to understand how best practice protocols mitigate operational risk factors. Check that the drill chuck guard is in position. Check workspace and walkways to ensure no slip hazards are present. Ensure the chuck key. Bench Drill Risk Assessment.

From dokumen.tips

(PDF) Risk Assessment of Lab Bench Top Processes to Ensure · Page 1 Bench Drill Risk Assessment fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. Recognise hazards and create awareness. a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. this risk assessment only deals with the generic risks associated with pillar and bench mounted drilling. The discussion below. Bench Drill Risk Assessment.

From www.scribd.com

Risk Assessment (Park Bench) Hazards Risk Bench Drill Risk Assessment Identify the hazard, relating to the belt system / pulley system. Check that the drill chuck guard is in position. fitting an incorrect wheel can lead to disintegration, and ejection of the broken bits. a risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. this risk assessment only. Bench Drill Risk Assessment.