Components and Structure of Hydrogen Compressors

Hydrogen compressors are an integral part of many industrial operations. They make it possible to store and transport hydrogen in a compressed form , making it easier to use in various applications. But what exactly are these compressors and how do they work? In essence, a hydrogen compressor is a device that works by compressing the gas into a smaller volume. The process involves increasing the pressure on the hydrogen molecules so that they occupy less space - this is done using a motor-driven pump or turbine. As the pressure increases, so does the temperature of the gas until it reaches a point where it can be stored in tanks or containers for later use. Consequently, there's (no) need for large volumes of storage when dealing with hydrogen! Furthermore, depending on their structure and components, hydrogen compressors may vary considerably. Generally speaking though, most have three main parts: A cylinder, valves and pistons. The cylinder contains the compressed gas and helps regulate its flow through valves while the pistons provide power to drive the compressor forward as well as keeping pressure consistent throughout its operation cycle. Additionally, some models may also feature additional

read more

Latest Innovations in the Field of Hydrogen Compression Technology

Hydrogen compression technology is an exciting field, with (many) ongoing innovations. It's amazing to think about the progress that has been made in such a relatively short amount of time! We now have access to techonology that can capture and compress hydrogen (gas) into liquid form, which holds incredible potential for the future of energy storage. However, this process isn't without it's challenges. Compressing hydrogen requires extremely high pressure in order to turn it into liquid form. This means that compressing hydrogen is expensive and difficult to do safely, due to the large amounts of energy needed. Moreover, even when compressed successfully, there are major losses during transportation which negates some of it's benefits. Nevertheless, scientists and engineers all around the world are working diligently on the latest innovations in this field. For instance, they're exploring ways to use magnetic fields and lasers to increase the efficiency of compressing hydrogen gas. They're also developing methods for storing liquid hydrogen more effectively so that it can be transported more efficiently! In addition, researchers are looking at how different materials can be used to contain higher pressures or hold colder temperatures when

read more

What is Enhancing Our Ability to Store and Use Power More Effectively? Unlock the Secrets of Hydrogen Compressors Now!

The world is changing rapidly and the ability to store and use power more efficiently is becoming increasingly important. Unlock the secrets of hydrogen compressors now! By utilizing this technology, we can strengthen our capacity to produce energy in a much more sustainable manner. Not only will it help us reduce our environmental impact but it will also expand our opportunities for renewable energy sources . But what are hydrogen compressors? In short, they are machines that convert hydrogen gas into liquid form using high pressure, allowing for easy storage and transportation as well as increased safety. This process allows us to create much higher densities of energy which can then be used more productively than ever before! Additionally, these systems have been created with incredible precision so that they require very low amounts of maintenance. Furthermore, hydrogen compressors have enabled us to eliminate many of the traditional constraints associated with storing and using power. For instance, electric cars powered by such systems can travel farther distances than ever before without worrying about running out of fuel! Moreover, these machines also offer greater control over how electricity is generated and distributed while reducing

read more

Maintenance Requirements for Hydrogen Compressors

Maintenance requirements for hydrogen compressors can be quite demanding! As these machines are used to transport and store gaseous hydrogen, they must be regularly monitored and maintained in order to ensure safe operation. (For instance,) routine inspections should include checking the oil level and pressure of the compressor, as well as its fuel-filter system. In addition, any leaks should be immediately somberly addressed. Furthermore, a visual inspection of all internal parts should take place on an annual basis; this will help identify any potential issues that could lead to failure or damage down the line. Any worn out components should be replaced promptly. Additionally, it's equally important to perform regular maintenance on the machine's exhaust system by inspecting for leaks and cleaning away dust or debris which might impede performance. Moreover, other steps like lubrication of moving parts and ensuring adequate ventilation around the hydrogen compressor should also not be forgotten about. Finally, it is essential that safety protocols are adhered to when carrying out these tasks - such as wearing protective gear while working near high-pressure tanks - so as to minimize the risk of undesired consequences!

read more

How to Calculate the Pressure of Hydrogen Gas

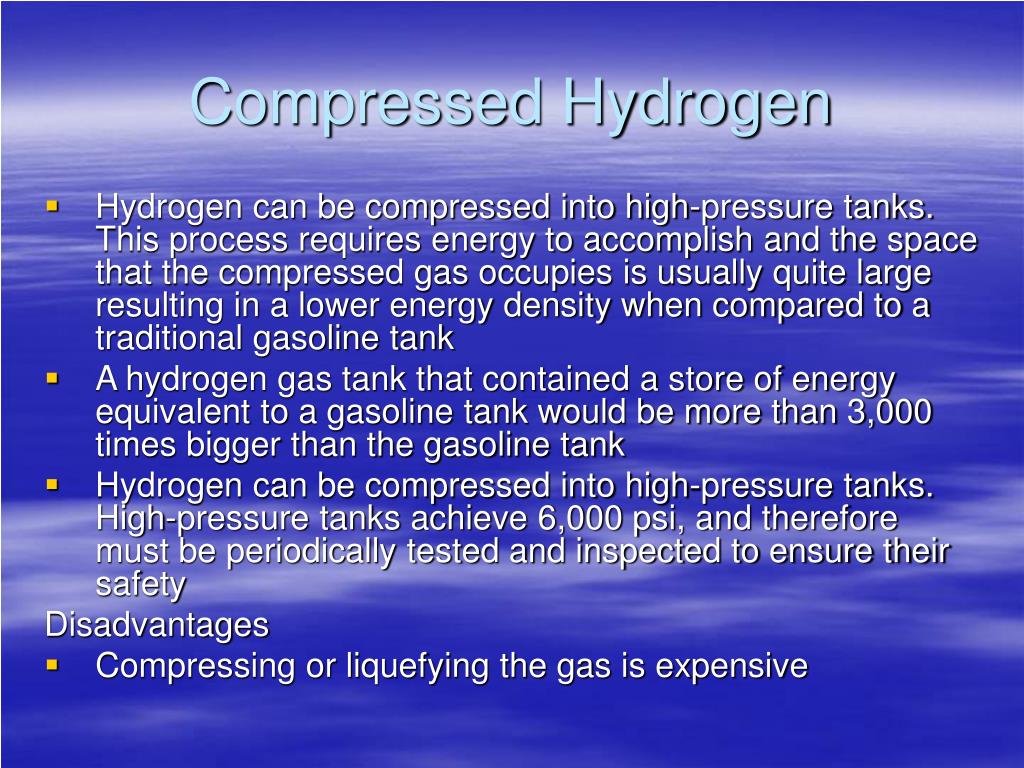

Whatever the method for piston motion control, the compression ratio per compression stage is limited to around 10 because of geometrical considerations in the compression chamber, mainly the minimum acceptable tolerance between the piston and the facing stationary wall. Reaching pressures near 1000 bar with a gas supplied at 10 bar only requires 2 compression stages at a ratio of 10:1. hydrogen -generator-work-800x800.jpg" align="right" alt="couple" style="max-width:20%; margin:6px;" /> Depending on flow demands, these 2 stages can either be done with a single compression unit or with 2 compression units in series. If a single compression unit is chosen, an intermediate tank is used to store the gas between first and second stages. High density hydrogen storage is a challenge for stationary and portable applications and remains a significant challenge for transportation applications. Presently available storage options typically require large-volume systems that store hydrogen in gaseous form. This is less of an issue for stationary applications, where the footprint of compressed gas tanks may be less critical. However, fuel-cell-powered vehicles require enough hydrogen to provide a driving range of more than 300 miles with the ability to quickly and easily refuel the vehicle. While some light-duty hydrogen fuel

read more

How to Liquefy Hydrogen

Hydrogen's boiling point is incredibly low – at just under 21 degrees kelvin (roughly -421 degrees fahrenheit), liquid hydrogen will turn into a gas. And because pure hydrogen is incredibly flammable, for safety's sake the first step to liquefying hydrogen is to bring it to its critical pressure – the point at which, even if hydrogen is at its critical temperature (the temperature at which pressure alone cannot turn a gas into a liquid), it will be forced to liquefy. Hydrogen is pumped through a series of condensers, throttle valves and compressors to bring it to its pressure of 13 bar, or roughly 13 times the standard atmospheric pressure of earth. Hydrogen energy has become a growing area of research due to its potential for clean and renewable power generation. Compressing hydrogen can help make it more efficient and accessible as a fuel source. By compressing the gas, higher concentrations can be achieved in smaller volumes, allowing for easier transportation and storage. This makes compressed hydrogen an ideal choice for fueling vehicles, powering reciprocating engines, or generating electricity through fuel cells. Compressed hydrogen is stored at pressures from 500-700 bar and temperatures ranging from -253 degrees centigrade to 20 degrees

read more