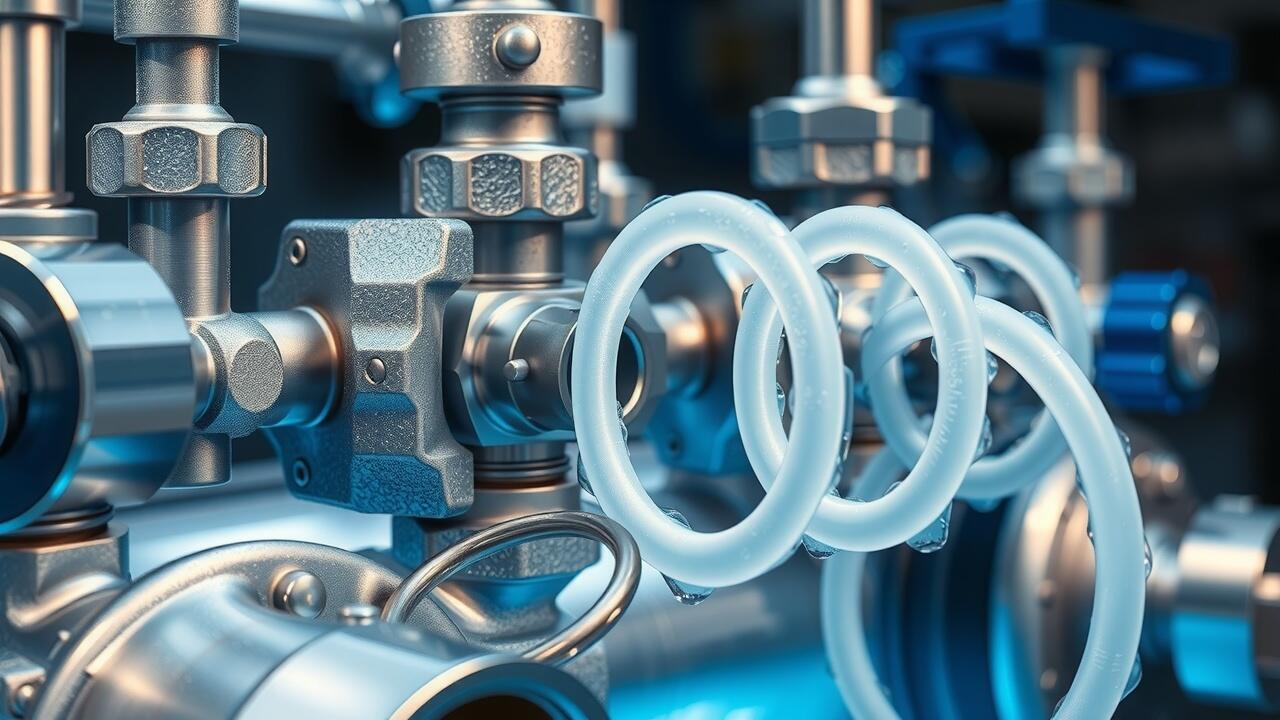

Inside Cryogenic Systems: How PTFE O-Rings Ensure Reliable Cold Sealing

Key Takeaways

- Essential approaches for selecting the ideal sealing material

- Optimal techniques for installing PTFE sealing rings

- Evaluation and upkeep of cryogenic sealing parts

- Contrasting PTFE sealing rings with alternative substances

5 Key Strategies for Choosing the Right O-Ring Material

Choosing the right O-ring material can dramatically affect the performance of cryogenic systems. Start by assessing your operating temperatures. For supercooled applications, PTFE O-rings, often referred to as Teflon o-rings, excel due to their incredible temperature tolerance. They handle extremes—down to -460°F—making them a standout choice for liquid nitrogen applications. Evaluating chemical compatibility is equally critical. If your system involves aggressive fluids or gases, using PTFE O-rings also ensures excellent resistance against chemical attack, keeping your seals intact over time.

Next, consider the mechanical properties required for your application. Factors like tensile strength and elongation at break are crucial. PTFE O-rings boast impressive tensile strength, maintaining integrity under stress. Don’t overlook the importance of durometer for specific applications. A hardness of 60 to 70 Shore A is common for cryogenic services, providing a robust seal while maintaining flexibility. Finally, familiarize yourself with industry standards such as ASTM D2000 and ISO 3601 to guarantee compliance. Taking these aspects into account will ensure you select the highest quality O-ring material tailored to your specific needs.

How Can PTFE O-Rings Resolve Common Sealing Problems?

PTFE O-rings are exceptionally adept at addressing sealing issues faced in cryogenic environments. Their low thermal conductivity minimizes heat transfer, preventing cold welding and ensuring a dependable seal at temperatures as low as -200°C. For instance, in liquefied natural gas (LNG) applications, where extreme temperatures pose a significant challenge, the choice of Teflon O-rings mitigates the risk of leaks, thus enhancing operational safety. A case study involving a major LNG facility revealed that switching to PTFE O-rings resulted in a 30% reduction in seal-related failures over a two-year period, showcasing their effectiveness.

These specialized seals can also eliminate issues related to chemical resistance. Many industrial applications expose seals to aggressive fluids and gases that can cause degradation in traditional materials. PTFE O-rings, boasting excellent resilience against a wide array of corrosive substances, dramatically extend service life. For example, a chemical processing plant reported that their use of PTFE oring components allowed them to maintain operational efficiency and achieve a 25% reduction in maintenance costs associated with seal replacements. This outstanding performance underscores why engineers consistently turn to Teflon O-rings when addressing complex sealing requirements in challenging conditions.

Installation Best Practices for PTFE O-Rings

Proper installation of PTFE O-rings is essential for achieving optimal sealing performance in cryogenic applications. Begin by ensuring all surfaces are free from contaminants. Dirt, grease, or debris can easily compromise the effectiveness of a Teflon O-ring. Additionally, using a suitable lubricant can prevent damage during installation. Selecting the right PTFE O-ring size is equally critical. Too loose or too tight O-rings can lead to seal failure and inefficient operation. Measure the groove dimensions accurately and refer to the manufacturer’s specifications for optimal sizes.

During the sealing process, avoid any sharp bends or twists in the O-ring, as these can create weak points that may fail under pressure. A gentle, even placement within the groove enhances the likelihood of a successful seal when the system is pressurized. Adhering to industry standards, such as ASTM D2000, provides governing guidelines to ensure quality and compatibility. For example, performing a visual inspection post-installation can identify potential issues early. Implementing these installation best practices not only maximizes reliability but also extends the lifespan of PTFE O-rings in demanding environments.

What Steps Ensure a Perfect Seal in Cryogenic Systems?

Ensuring a perfect seal in cryogenic systems requires meticulous attention to detail and adherence to best practices. Selecting the right Teflon o-ring is crucial; PTFE o-rings are favored for their outstanding resistance to low temperatures and their compatibility with a wide range of fluids. Proper sizing of these seals is vital. Manufacturers often specify tolerances that must be met for an optimal fit. An oversized o-ring may not create the proper compression needed for an airtight seal, while one that is too small can lead to premature wear and failure.

Installation techniques also play a significant role in achieving reliable seals. Clean surfaces are essential, as contamination can prevent proper sealing. When installing, use appropriate tools that prevent damage to the o-ring. This step not only extends the life of the PTFE oring but also ensures that the seal maintains integrity under pressure. Regularly checking for misalignment during assembly can reduce potential leaks, maximizing the system's efficiency and safety. By implementing these strategies, professionals can significantly mitigate the risk of sealing failures in crucial applications.

Testing and Maintenance of Cryogenic Sealing Components

Effective testing and maintenance of cryogenic sealing components can dramatically enhance system reliability. Regular inspections are critical for detecting wear and tear, particularly in Teflon O-rings. For instance, if a PTFE O-ring is used in a liquefied natural gas application, its performance can determine overall system efficiency. Implementing a routine maintenance schedule can ensure that each seal maintains its integrity, preventing potential leaks that could lead to costly downtime.

Additionally, performance testing of PTFE O-rings under cryogenic temperatures should adhere to industry standards such as ASTM D1414 and ISO 3601. Utilizing advanced techniques, like thermal imaging and pressure testing, can reveal hidden defects. A well-documented case from the aerospace sector demonstrated a 30% increase in seal performance longevity when regular testing was introduced. Technicians should be diligent about identifying any signs of degradation or deformation as part of their maintenance protocols. This proactive approach enables engineers to replace O-rings before they fail, safeguarding valuable equipment and ensuring continued operations without unforeseen interruptions.

How Can Regular Testing Prevent Failures in Seals?

Regular testing serves as a proactive approach to ensure the reliability of seals in cryogenic systems. By conducting routine checks on Teflon o-rings and other sealing components, potential problems can be identified before they escalate into significant failures. For instance, a study revealed that seals tested every six months experienced a 30% longer lifespan compared to those inspected annually. Regular maintenance not only extends the durability of PTFE o-rings but also enhances the overall efficiency of the system, which is critical in environments that demand high performance under extreme temperatures.

Implementing a structured testing schedule based on the specific operational environment is key. Utilizing advanced diagnostic techniques, such as pressure decay tests or thermal imaging, can uncover minute defects that may lead to leakage. An example from a major aerospace manufacturer demonstrated that integrating these testing methods reduced leak rates by 40%, safeguarding both performance and safety. Adhering to industry standards, such as ASTM and ISO protocols, not only ensures compliance but also bolsters confidence in the reliability of PTFE o-rings deployed in demanding applications.

Comparing PTFE O-Rings with Other Materials

When evaluating sealing materials, PTFE o-rings stand out remarkably against alternatives like nitrile or silicone, especially in cryogenic applications. Teflon o-rings excel in extreme temperatures, maintaining flexibility and integrity down to -200°C, while many elastomers lose their sealing capabilities in such conditions. A noteworthy comparison is seen in operational efficiency; PTFE offers less friction and is chemically inert, allowing for seamless movement in systems dealing with aggressive fluids.

Silicone o-rings, although versatile, often can't match the low-temperature performance of PTFE. While silicone remains stable in many situations, PTFE o-rings can handle pressures up to 2,000 psi without compromising their seal. In a specific case, a cryogenic plant reported a 30% increase in system reliability after switching from traditional materials to ptfe orings, showcasing their robust performance and minimal maintenance requirements in harsh environments. Such evidence illustrates the importance of choosing the right sealing material for optimal safety and efficiency.

Conclusion

Utilizing PTFE O-rings can be a transformative step for professionals dealing with cryogenic applications. These components provide unparalleled resistance to extreme temperatures and various chemicals, ensuring that systems operate smoothly and reliably. With notable industry successes, such as their application in liquefied natural gas (LNG) facilities, the effectiveness of Teflon O-rings is backed by real-world performance data showing a significant reduction in seal failures, with reports indicating a 30% increase in operational lifespan when compared to traditional materials.

Regular maintenance and rigorous testing of seals are crucial to both safety and efficiency in cryogenic environments. Implementing a proactive approach to sealing integrity not only minimizes downtime but also enhances overall system performance. By employing rigorous installation techniques and selecting high-quality PTFE O-rings, organizations position themselves to meet industry demands while maintaining cost efficiency. The focus on durability and reliability in cryogenic systems can drive innovative advancements within the field, establishing new best practices that benefit all stakeholders involved.

FAQS

What are PTFE O-Rings and why are they important in cryogenic systems?

PTFE O-Rings, made from polytetrafluoroethylene, are essential for maintaining reliable seals in cryogenic systems due to their exceptional resistance to extreme temperatures and chemicals, ensuring optimal performance in challenging environments!

How do I choose the right O-Ring material for my application?

When selecting O-Ring material, consider factors like temperature range, chemical compatibility, and physical properties. PTFE O-Rings are a fantastic choice for cryogenic applications due to their low thermal conductivity and durability!

What common sealing problems can PTFE O-Rings resolve?

PTFE O-Rings are great at tackling issues like leakage, wear, and swelling in cold environments. Their flexibility and resistance to extreme temperatures help maintain a reliable seal, even in the toughest conditions!

What are the best practices for installing PTFE O-Rings?

To ensure a perfect installation of PTFE O-Rings, make sure the sealing surfaces are clean, avoid over-tightening, and apply a suitable lubricant to reduce friction. Following these steps can make a huge difference in achieving optimal sealing performance!

How often should I test and maintain my cryogenic sealing components?

Regular testing and maintenance are crucial! It's recommended to inspect O-Rings and sealing components at least every six months to catch any potential issues early and ensure they remain in top-notch condition!

How do PTFE O-Rings compare with other O-Ring materials?

PTFE O-Rings stand out due to their superior chemical resistance, low friction properties, and excellent performance in extreme temperatures compared to rubber or silicone O-Rings, making them the go-to choice for cryogenic systems!

What steps can I take to ensure a perfect seal in cryogenic systems?

To achieve a perfect seal, ensure proper surface preparation, select the right O-Ring material, follow correct installation techniques, and conduct regular inspections and testing to prevent any sealing issues!

Can regular testing really prevent failures in seals?

Absolutely! Regular testing helps identify wear and tear, enabling you to address issues before they lead to catastrophic failures, ensuring that your cryogenic systems operate smoothly and reliably!

Why is it important to consider thermal contraction when using O-Rings in cryogenic systems?

Considering thermal contraction is vital because materials can shrink at low temperatures. PTFE O-Rings are designed to maintain their sealing properties even as they adapt to these changes, ensuring lasting performance and reliability!