How to Properly Install Glulam Beams for Enhanced Structural Integrity

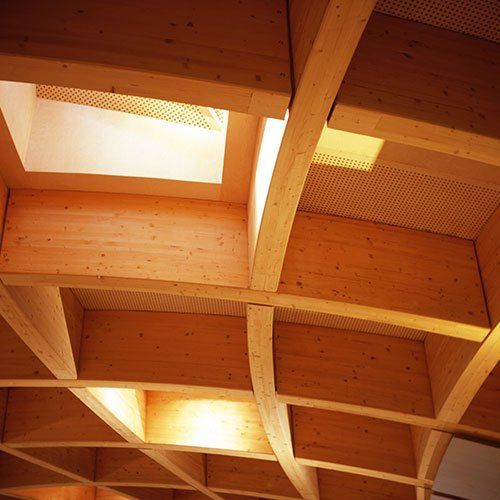

Installing glulam beams , which are a staple in modern construction due to their incredible strength and versatility, is no small feat! It requires a precise blend of technical know-how and practical skill. Now, before we dive into the nitty-gritty (and trust me, there's plenty of that), it’s crucial to understand what these beams are. They're essentially layers upon layers of wood bonded together with durable adhesives to form a single, robust structural element. First things first, you can't just go about this willy-nilly; planning is key. You need detailed drawings or plans from an engineer or architect—don’t even think about winging it! These professionals will take into account all the load-bearing requirements your project needs. Now onto the actual installation—oh boy, where do I begin? Firstly, you've gotta check that the foundation or the surface where you'll place these beams is as level as can be. Any discrepancy here could spell disaster (or at least some annoying squeaks down the line). Using a laser level might seem like overkill to some DIY enthusiasts but believe me, it’s worth its weight in gold. When positioning your glulam beams, remember they’re

read more

Can Glulam Beams Be Repaired?

Glulam beams, those marvels of engineering composed of layers upon layers of glued laminated timber, are a sight to behold in many modern and traditional structures alike. But what happens when these sturdy components encounter damage? Can they be repaired, or is replacement the only route to take? Well, to address this burning question (and indeed it's quite pertinent for folks relying on the durability of such materials), yes! Glulam beams can often be repaired - though not always. The feasibility of repair depends largely on the type and extent of the damage. For instance, if we're talking about minor surface nicks or scratches, then you're in luck; a simple patch-up job might just do the trick. However, let's not get ahead of ourselves here. Should the damage be more severe – say from water intrusion or even worse, structural overload – then repairs become a tad complex affair. In such scenarios, specialists need to assess whether restoration is practical or if it'd compromise the beam's integrity. No one wants an unsafe outcome after all! Now don't go thinking that every Tom, Dick, or Harry can handle glulam beam repairs;

read more

How to Repair Glulam Beams

Oh, repairing glulam beams can indeed be a tricky affair! It's essential to approach the task with caution and a solid understanding of the process (not to mention, a good dose of patience). Now, glulam - short for glued laminated timber - is a strong material used in various structural applications thanks to its robustness and versatility. However, like any other wood product, it's susceptible to damage over time. First things off, you'll need to assess the damage thoroughly. If we're talking about minor cracks or splits (which happens more often than not), these can usually be fixed by applying an epoxy resin. Epoxy is fantastic stuff; it seeps into those pesky little openings, bonding the wood fibers together as if they never parted ways! But hold on! Before you go slapping on that epoxy willy-nilly, make sure you clean out any debris or loose fibers from the crack. A small brush or vacuum should do the trick just fine. You'd want your repair job to last, wouldn't ya? Now here's where things get a bit more technical: clamping. After filling the crack with epoxy, you've got to clamp the

read more

Available sizes of glulams

The standard truss configurations listed here can be fabricated by using straight glulam (glue laminated) beams. These beams, supplied by certified glulam manufacturers, are fabricated by gluing multiple layers (laminations) of solid wood (typically 0. 25” – 1. 5” thick) into a large beam. Swc can fabricate trusses using straight glulams of sizes similar to solid wood beams, or utilizing glulams of much larger dimensions. Exposed beam trusses fabricated with glulam material have a refined appearance and are supplied for both commercial and residential installations. Load carrying capacity is generally higher for glulam trusses when using members similar in dimension to solid beams. What grade is the timber? Laminated veneer lumber (lvl) and glue-laminated timber (glulam) products are used in applications where they will be highly stressed under design loads. Drilling or notching lvl and glulam must typically be avoided. However, in situations where it is not possible, these guidelines must be followed. Glulam timber beams glulam beams and columns are made from lamstock grade dimensional lumber that is bonded together with strong, waterproof adhesive. Our glulam can be manufactured into a large variety of different shapes and sizes for innovative applications where strength,

read more

Storage in the Yard

I found some glulam beams for sale on craiglist for half the price of new beams. The only problem is that they have been sitting in this persons yard for 13 years. They were covered by sheets of metal roofing i am told, and they are raised off of the ground 4 inches with airflow underneath. The beams are not wrapped or treated so assume that the sides of the beams are open to the air/ moisture. I live in rainy oregon. So my question is how do glulam beams hold up to this kind of storage? would they still be safe to use?. Can structural glued laminated timber (glulam) be used outdoors? Glulam beams manufactured by apa members are certified with the apa trademark. The mark signifies that the manufacturer is committed to a rigorous program of quality verification and testing and that products are manufactured in conformance with ansi standard a190. 1, standard for wood products—structural glued laminated timber. The apa trademark is recognized by all major model building codes. What is a glulam? The principles of glulam construction are believed to date back to the 1860s, in the assembly room of king edward

read more

I installed my glulam beam upside down, is it ok?

Architectural glulam beams glulam beams are 2x4 or 2x6 douglas fir dimensional lumber layered and laminated together with durable, moisture-resistant structural adhesives. By laminating a number of smaller pieces of timber, a single large, strong, structural member is manufactured from smaller pieces. Our glulams have an architectural appearance, meaning that the exposed faces have been sanded, and all exposed corners have an eased edge. It is intended to be installed exposed to the naked eye and takes stain to leave a rich and beautiful color and texture. Available sizes: -only glulam that matches dimensional lumber sizes (3-1/2" and 5-1/2") -ensures a perfect fit when framing -no sheetrock issues or structural connection issues. How long is the lead time for glulam beams? While the initial cost of glulam may be higher than some traditional materials, its overall value is seen in the long-term savings it offers. Glulam's durability and low maintenance requirements mean reduced repair and replacement costs. Additionally, its lightweight nature can lead to savings on foundation costs and allow for faster construction times, further reducing labor expenses. since wood is a combustible material, many design professionals do not consider wood as part of an effective fire-resistant design. With proper design and

read more

Why is there a “TOP” stamp on my beam?

glulam beams are manufactured in both balanced and unbalanced layups. The stock rosboro x-beam® (24f-v4) is an unbalanced layup. In unbalanced beams, the design stress of lumber used on the tension (bottom) side of the beam is higher than the lumber used on the corresponding compression (top) side, allowing a more efficient use of the timber resource. To assure the proper installation of rosboro x-beam® products, the top of the beam is clearly stamped with the word “top”, which should be installed upward. Other rosboro products, such as big beam df®, x-rim, and esl 1. 6e are balanced because they are more commonly used in applications that require that flexibility. Why is there a crack in my Beam? Sometimes glulams are strictly structural and looks are not a concern, but a glulam can also be simultaneously an architectural focal point as well as a structural timber. Because of this, there are different grades and appearance choices available: • architectural: with a smooth, attractive finish, an architectural appearance glulam should be specified for applications where it will remain exposed to view. In this grade, you’ll find voids (holes and cracks) larger than 3/4" are filled. Low laminations are cosmetically

read more